change time Seat Altea 2015 Owner's Guide

[x] Cancel search | Manufacturer: SEAT, Model Year: 2015, Model line: Altea, Model: Seat Altea 2015Pages: 236, PDF Size: 4.23 MB

Page 174 of 236

Advice

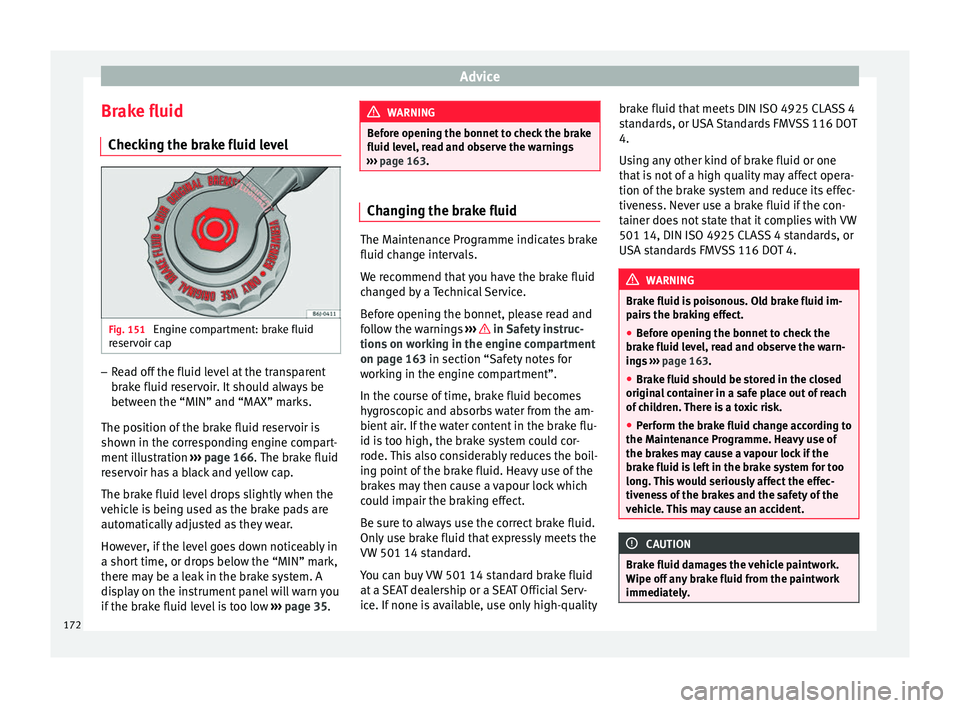

Brake fluid Checking the brake fluid level Fig. 151

Engine compartment: brake fluid

reservoir cap –

Read off the fluid level at the transparent

brake fluid reservoir. It should always be

between the “MIN” and “MAX” marks.

The position of the brake fluid reservoir is

shown in the corresponding engine compart-

ment illustration ››› page 166. The brake fluid

reservoir has a black and yellow cap.

The brake fluid level drops slightly when the

vehicle is being used as the brake pads are

automatically adjusted as they wear.

However, if the level goes down noticeably in

a short time, or drops below the “MIN” mark,

there may be a leak in the brake system. A

display on the instrument panel will warn you

if the brake fluid level is too low ››› page 35. WARNING

Before opening the bonnet to check the brake

fluid level, read and observe the warnings

››› page 163. Changing the brake fluid

The Maintenance Programme indicates brake

fluid change intervals.

We recommend that you have the brake fluid

changed by a Technical Service.

Before opening the bonnet, please read and

follow the warnings

››› in Safety instruc-

tions on working in the engine compartment

on page 163 in section “Safety notes for

w ork

ing in the engine compartment”.

In the course of time, brake fluid becomes

hygroscopic and absorbs water from the am-

bient air. If the water content in the brake flu-

id is too high, the brake system could cor-

rode. This also considerably reduces the boil-

ing point of the brake fluid. Heavy use of the

brakes may then cause a vapour lock which

could impair the braking effect.

Be sure to always use the correct brake fluid.

Only use brake fluid that expressly meets the

VW 501 14 standard.

You can buy VW 501 14 standard brake fluid

at a SEAT dealership or a SEAT Official Serv-

ice. If none is available, use only high-quality brake fluid that meets DIN ISO 4925 CLASS 4

standards, or USA Standards FMVSS 116 DOT

4.

Using any other kind of brake fluid or one

that is not of a high quality may affect opera-

tion of the brake system and reduce its effec-

tiveness. Never use a brake fluid if the con-

tainer does not state that it complies with VW

501 14, DIN ISO 4925 CLASS 4 standards, or

USA standards FMVSS 116 DOT 4.

WARNING

Brake fluid is poisonous. Old brake fluid im-

pairs the braking effect.

● Before opening the bonnet to check the

brake fluid level, read and observe the warn-

ings ››› page 163.

● Br ak

e fluid should be stored in the closed

original container in a safe place out of reach

of children. There is a toxic risk.

● Perform the brake fluid change according to

the Maintenance Programme. Heavy use of

the brakes may cause a vapour lock if the

brake fluid is left in the brake system for too

long. This would seriously affect the effec-

tiveness of the brakes and the safety of the

vehicle. This may cause an accident. CAUTION

Brake fluid damages the vehicle paintwork.

Wipe off any brake fluid from the paintwork

immediately. 172

Page 175 of 236

Checking and refilling levels

For the sake of the environment

The brake pads and brake fluid must be col-

lected and disposed of according the applica-

ble regulations. The SEAT Technical Service

network has the necessary equipment and

qualified personnel for collecting and dispos-

ing of this waste material. Vehicle battery

Warnings on handling the battery Wear eye protection

Battery acid is extremely corrosive. Wear pro-

tective gloves and eye protection!

Fires, sparks, open flames and smoking are

prohibited!

A highly explosive mixture of gases is released

when the battery is under charge.

Keep children away from acid and batteries!

WARNING

Always be aware of the danger of injury and

chemical burns as well as the risk of accident

or fire when working on the battery and the

electrical system:

● Wear eye protection. Protect your eyes,

skin and clothing from acid and particles con-

taining lead. ●

Battery acid is extremely corrosive. Wear

protective gloves and eye protection. Do not

tilt the batteries. This could spill acid through

the vents. Rinse battery acid from eyes imme-

diately for several minutes with clear water.

Then seek medical care immediately. Neutral-

ise any acid splashes on the skin or clothing

with a soapy solution, and rinse off with plen-

ty of water. If acid is swallowed by mistake,

consult a doctor immediately.

● Fires, sparks, open flames and smoking are

prohibited. When handling cables and electri-

cal equipment, avoid causing sparks and

electrostatic charge. Never short the battery

terminals. High-energy sparks can cause in-

jury.

● A highly explosive mixture of gases is re-

leased when the battery is under charge. The

batteries should be charged in a well-ventila-

ted room only.

● Keep children away from acid and batteries.

● Before working on the electrical system,

you must switch off the engine, the ignition

and all electrical devices. The negative cable

on the battery must be disconnected. When a

light bulb is changed, you need only switch

off the light.

● Deactivate the anti-theft alarm by unlock-

ing the vehicle before you disconnect the bat-

tery! The alarm will otherwise be triggered.

● When disconnecting the battery from the

vehicle on-board network, disconnect first

the negative cable and then the positive ca-

ble. ●

Switch off all electrical devices before re-

connecting the battery. Reconnect first the

positive cable and then the negative cable.

Never reverse the polarity of the connections.

This could cause an electrical fire.

● Never charge a frozen battery, or one which

has thawed. This could result in explosions

and chemical burns. Always replace a battery

which has frozen. A flat battery can also

freeze at temperatures close to 0 °C (+32 °F).

● Ensure that the vent hose is always connec-

ted to the battery.

● Never use a defective battery. This could

cause an explosion. Replace a damaged bat-

tery immediately. CAUTION

● Never disconnect the battery if the ignition

is switched on or if the engine is running.

This could damage the electrical system or

electronic components.

● Do not expose the battery to direct sunlight

over a long period of time, as the intense ul-

traviolet radiation can damage the battery

housing.

● If the vehicle is left standing in cold condi-

tions for a long period, protect the battery

from “freezing”. If it freezes it will be dam-

aged. 173

Technical specifications

Advice

Operation

Safety

Page 179 of 236

Wheels

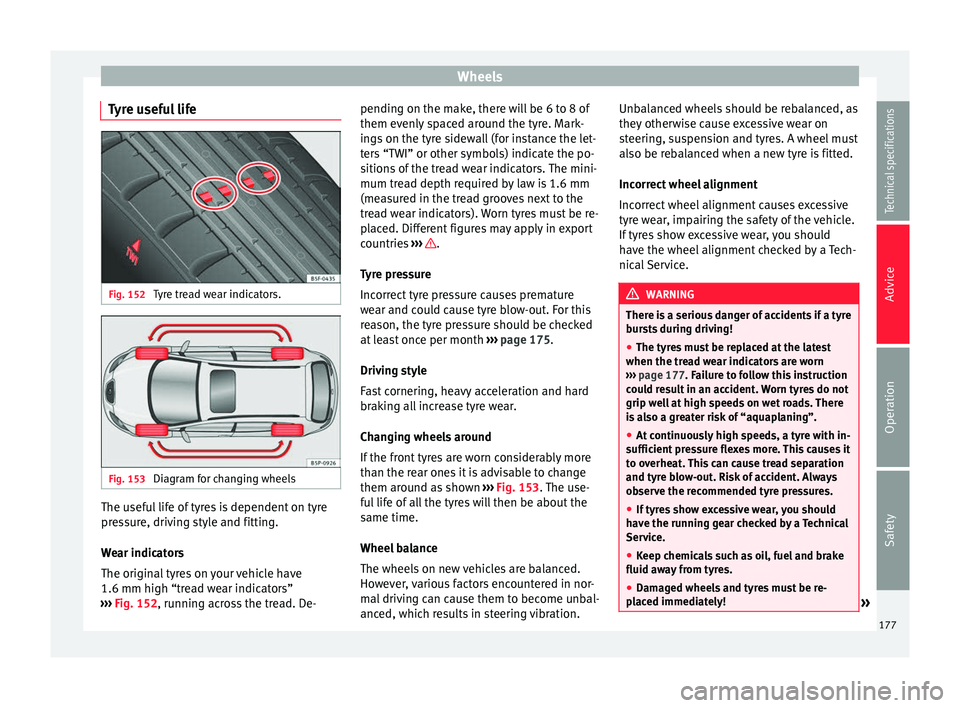

Tyre useful life Fig. 152

Tyre tread wear indicators. Fig. 153

Diagram for changing wheels The useful life of tyres is dependent on tyre

pressure, driving style and fitting.

Wear indicators

The original tyres on your vehicle have

1.6 mm high “tread wear indicators”

››› Fig. 152 , running across the tread. De- pendin

g on the m ake, there will be 6 to 8 of

them evenly spaced around the tyre. Mark-

ings on the tyre sidewall (for instance the let-

ters “TWI” or other symbols) indicate the po-

sitions of the tread wear indicators. The mini-

mum tread depth required by law is 1.6 mm

(measured in the tread grooves next to the

tread wear indicators). Worn tyres must be re-

placed. Different figures may apply in export

countries ››› .

Tyre pressure

Incorrect tyre pressure causes premature

wear and could cause tyre blow-out. For this

reason, the tyre pressure should be checked

at least once per month ››› page 175.

Driving style

Fast cornering, heavy acceleration and hard

braking all increase tyre wear.

Changing wheels around

If the front tyres are worn considerably more

than the rear ones it is advisable to change

them around as shown ››› Fig. 153 . The use-

f u

l life of all the tyres will then be about the

same time.

Wheel balance

The wheels on new vehicles are balanced.

However, various factors encountered in nor-

mal driving can cause them to become unbal-

anced, which results in steering vibration. Unbalanced wheels should be rebalanced, as

they otherwise cause excessive wear on

steering, suspension and tyres. A wheel must

also be rebalanced when a new tyre is fitted.

Incorrect wheel alignment

Incorrect wheel alignment causes excessive

tyre wear, impairing the safety of the vehicle.

If tyres show excessive wear, you should

have the wheel alignment checked by a Tech-

nical Service.

WARNING

There is a serious danger of accidents if a tyre

bursts during driving!

● The tyres must be replaced at the latest

when the tread wear indicators are worn

››› page 177. Failure to follow this instruction

could result in an accident. Worn tyres do not

grip well at high speeds on wet roads. There

is also a greater risk of “aquaplaning”.

● At continuously high speeds, a tyre with in-

sufficient pressure flexes more. This causes it

to overheat. This can cause tread separation

and tyre blow-out. Risk of accident. Always

observe the recommended tyre pressures.

● If tyres show excessive wear, you should

have the running gear checked by a Technical

Service.

● Keep chemicals such as oil, fuel and brake

fluid away from tyres.

● Damaged wheels and tyres must be re-

placed immediately! » 177

Technical specifications

Advice

Operation

Safety

Page 182 of 236

Advice

For the sake of the environment

Old tyres must be disposed of according to

the laws in the country concerned. Note

● For technical reasons, it is not generally

possible to use the wheels from other vehi-

cles. This can also apply to wheels of the

same model. The use of wheels or tyres

which have not been approved by SEAT for

use with your model may invalidate the vehi-

cle's type approval for use on public roads.

● If the spare tyre is not the same as the

tyres that are mounted on the vehicle (e.g.

winter tyres) you should only use the spare

tyre for a short period of time and drive with

extra care. Refit the normal road wheel as

soon as possible. Wheel bolts

The design of wheel bolts is matched to the

rims. If different wheel rims are fitted, the

correct wheel bolts with the right length and

correctly shaped bolt heads must be used.

This ensures that wheels are fitted securely

and that the brake system functions correctly.

In certain circumstances, you should not use

wheel bolts from a different vehicle, even if it

is the same model

›››

page 147. After the wheels have been changed, the

tightening torque of the wheel bolts should

be checked as soon as possible with a torque

wrench

››› . The tightening torque for steel

and alloy wheels is 120 Nm. WARNING

If the wheel bolts are not tightened correctly,

the wheel could become loose while driving.

Risk of accident.

● The wheel bolts must be clean and turn

easily. Never apply grease or oil to them.

● Use only wheel bolts which belong to the

wheel.

● If the tightening torque of the wheel bolts

is too low, they could loosen whilst the vehi-

cle is in motion. Risk of accident! If the tight-

ening torque is too high, the wheel bolts and

threads can be damaged. CAUTION

The prescribed tightening torque for wheel

bolts for steel and alloy wheels is 120 Nm. Winter service

Winter tyres In winter conditions winter tyres will consid-

erably improve the vehicle's handling. Sum-mer tyres (width, rubber compound, tread

pattern) provide less grip on ice and snow.

Winter tyres must be inflated to a

pressure of

0.2 bar (2.9 psi/20 kPa) higher than the pres-

sures specified for summer tyres (see sticker

on fuel tank flap).

Winter tyres must be fitted on all four wheels.

Information on permitted winter tyre sizes

can be found in the vehicle's registration

documentation. Use only radial winter tyres.

All tyre sizes listed in the vehicle documenta-

tion also apply to winter tyres.

Winter tyres lose their effectiveness when the

tread is worn down to a depth of 4 mm.

The speed rating code ››› page 179, New

tyres and wheels determines the following

speed limits for winter tyres:

›

› › max. 160 km/h

max. 180 km/h

max. 190 km/h

max. 210 km/h

In some countries, vehicles which can exceed

the speed rating of the fitted tyre must have

an appropriate sticker in the driver's field of

view. These stickers are available from your

technical service. The legal requirements of

each country must be followed.

Do not have winter tyres fitted for unnecessa-

rily long periods. Vehicles with summer tyres Q

S

T

H

180

Page 184 of 236

Advice

●

Never start the engine when the vehicle is

on the jack. Risk of accident.

● If work is to be carried out underneath the

vehicle, this must be secured by suitable

stands. Otherwise, there is a risk of injury. Note

The jack does not generally require any main-

tenance. If required, it should be greased us-

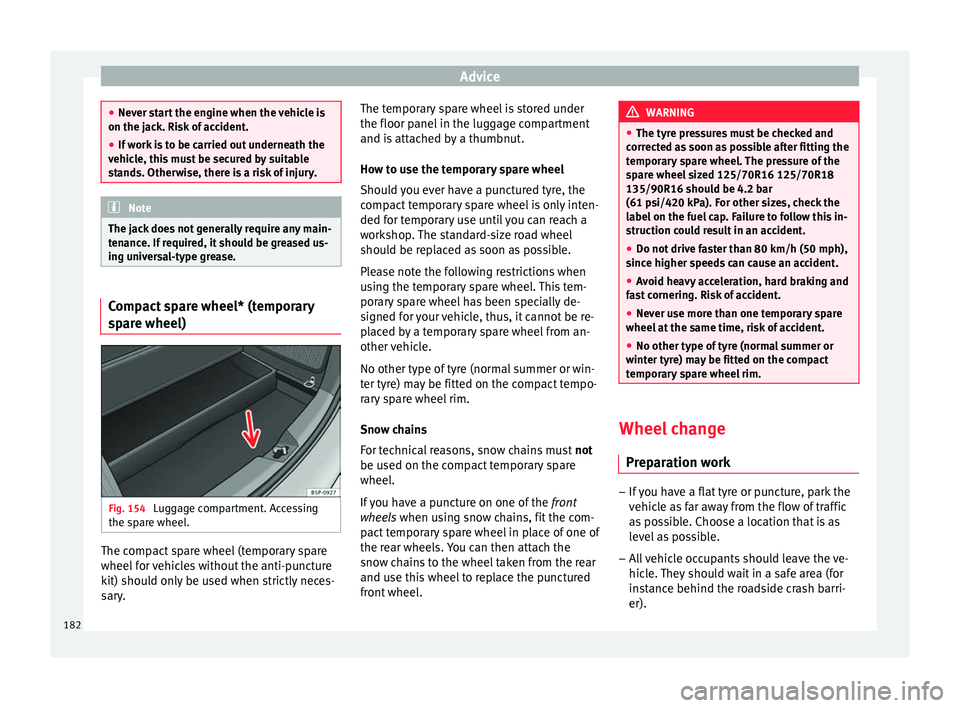

ing universal-type grease. Compact spare wheel* (temporary

spare wheel)

Fig. 154

Luggage compartment. Accessing

the spare wheel. The compact spare wheel (temporary spare

wheel for vehicles without the anti-puncture

kit) should only be used when strictly neces-

sary. The temporary spare wheel is stored under

the floor panel in the luggage compartment

and is attached by a thumbnut.

How to use the temporary spare wheel

Should you ever have a punctured tyre, the

compact temporary spare wheel is only inten-

ded for temporary use until you can reach a

workshop. The standard-size road wheel

should be replaced as soon as possible.

Please note the following restrictions when

using the temporary spare wheel. This tem-

porary spare wheel has been specially de-

signed for your vehicle, thus, it cannot be re-

placed by a temporary spare wheel from an-

other vehicle.

No other type of tyre (normal summer or win-

ter tyre) may be fitted on the compact tempo-

rary spare wheel rim.

Snow chains

For technical reasons, snow chains must

not

be used on the compact temporary spare

wheel.

If you have a puncture on one of the front

wheels when using snow chains, fit the com-

p act

temporary spare wheel in place of one of

the rear wheels. You can then attach the

snow chains to the wheel taken from the rear

and use this wheel to replace the punctured

front wheel. WARNING

● The tyre pressures must be checked and

corrected as soon as possible after fitting the

temporary spare wheel. The pressure of the

spare wheel sized 125/70R16 125/70R18

135/90R16 should be 4.2 bar

(61 psi/420 kPa). For other sizes, check the

label on the fuel cap. Failure to follow this in-

struction could result in an accident.

● Do not drive faster than 80 km/h (50 mph),

since higher speeds can cause an accident.

● Avoid heavy acceleration, hard braking and

fast cornering. Risk of accident.

● Never use more than one temporary spare

wheel at the same time, risk of accident.

● No other type of tyre (normal summer or

winter tyre) may be fitted on the compact

temporary spare wheel rim. Wheel change

Preparation work –

If you have a flat tyre or puncture, park the

vehicle as far away from the flow of traffic

as possible. Choose a location that is as

level as possible.

– All vehicle occupants should leave the ve-

hicle. They should wait in a safe area (for

instance behind the roadside crash barri-

er).

182

Page 193 of 236

Emergencies

after the battery has thawed, battery acid

could leak and cause chemical burns. If a bat-

tery freezes, it should be replaced.

●

Keep sparks, flames and lighted cigarettes

away from batteries, danger of explosion.

Failure to comply could result in an explo-

sion.

● Observe the instructions provided by the

manufacturer of the jump leads.

● Do not connect the negative cable from the

other vehicle directly to the negative terminal

of the flat battery. The gas emitted from the

battery could be ignited by sparks. Danger of

explosion.

● Do not attach the negative cable from the

other vehicle to parts of the fuel system or to

the brake line.

● The non-insulated parts of the battery

clamps must not be allowed to touch. The

jump lead attached to the positive battery

terminal must not touch metal parts of the ve-

hicle, this can cause a short circuit.

● Position the leads in such a way that they

cannot come into contact with any moving

parts in the engine compartment.

● Do not lean on the batteries. This could re-

sult in chemical burns. Note

The vehicles must not touch each other, oth-

erwise electricity could flow as soon as the

positive terminals are connected. Towing and tow-starting

Tow-starting We recommend that you do

not tow-start your

v ehic

le. Jump-starting is preferable

››› page 189.

How

ever, if your vehicle has to be tow-

started:

– Engage 2 nd

or 3 rd

gear.

– Keep the clutch pressed down.

– Switch the ignition on.

– Once both vehicles are moving, release the

clutch.

– As soon as the engine starts, press the

clutch and move the gear lever into neutral.

This helps to prevent driving into the tow-

ing vehicle. WARNING

The risk of accidents is high when tow-start-

ing. The vehicle being towed can easily col-

lide with the towing vehicle. CAUTION

When tow-starting, fuel could enter the cata-

lytic converter and damage it. General notes

Please observe the following points if you

use a tow rope:

Notes for the driver of the towing vehicle

– Drive slowly at first until the tow rope is

taut. Then accelerate gradually.

– Begin and change gears cautiously. If you

are driving an automatic vehicle, accelerate

gently.

– Remember that the brake servo and power

steering are not working in the vehicle you

are towing. Brake sooner than normal and

pressing the pedal gently.

Notes for the driver of the towed vehicle

– Ensure that the tow rope remains taut at all

times when towing.

Tow rope or tow bar

It is easier and safer for the vehicle to be tow-

ed using a tow bar. You should only use a

tow-rope if you do not have a tow-bar.

A tow rope should be slightly elastic to re-

duce the loading on both vehicles. It is advis-

able to use a tow rope made of synthetic fi-

bre or similarly elastic material.

Attach the tow rope or the tow bar only to the

towline anchorages provided or a towing

bracket. »

191Technical specifications

Advice

Operation

Safety

Page 198 of 236

Advice

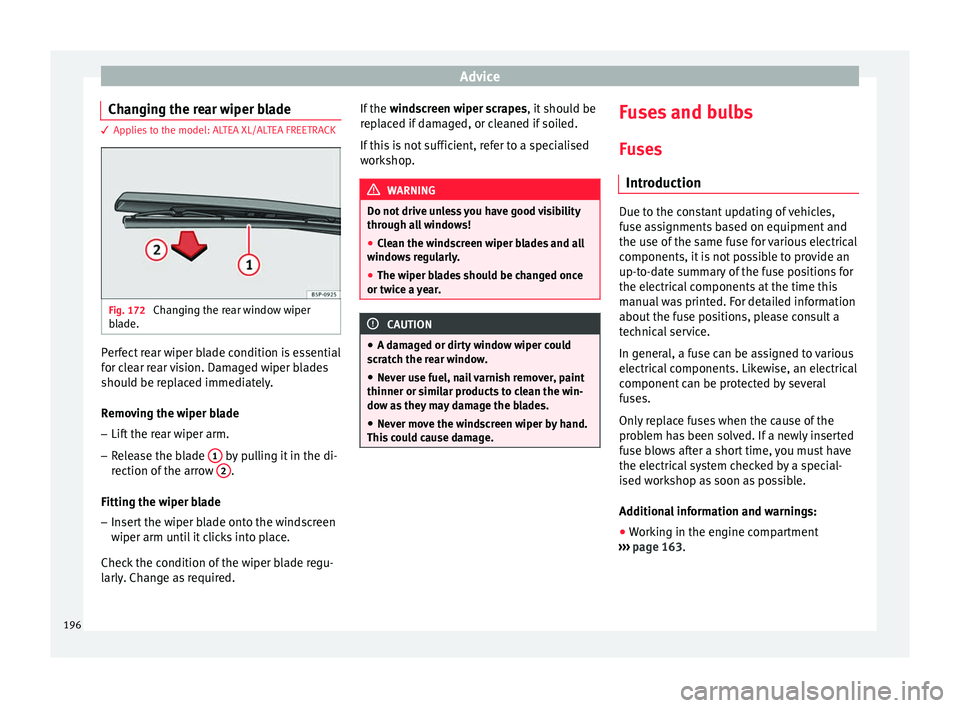

Changing the rear wiper blade 3 Applies to the model: ALTEA XL/ALTEA FREETRACK

Fig. 172

Changing the rear window wiper

blade. Perfect rear wiper blade condition is essential

for clear rear vision. Damaged wiper blades

should be replaced immediately.

Removing the wiper blade

– Lift the rear wiper arm.

– Release the blade 1 by pulling it in the di-

rection of the arrow 2 .

Fitting the wiper blade – Insert the wiper blade onto the windscreen

wiper arm until it clicks into place.

Check the condition of the wiper blade regu-

larly. Change as required. If the

windscreen wiper scrapes, it should be

replaced if damaged, or cleaned if soiled.

If this is not sufficient, refer to a specialised

workshop. WARNING

Do not drive unless you have good visibility

through all windows!

● Clean the windscreen wiper blades and all

windows regularly.

● The wiper blades should be changed once

or twice a year. CAUTION

● A damaged or dirty window wiper could

scratch the rear window.

● Never use fuel, nail varnish remover, paint

thinner or similar products to clean the win-

dow as they may damage the blades.

● Never move the windscreen wiper by hand.

This could cause damage. Fuses and bulbs

Fuses Introduction Due to the constant updating of vehicles,

fuse assignments based on equipment and

the use of the same fuse for various electrical

components, it is not possible to provide an

up-to-date summary of the fuse positions for

the electrical components at the time this

manual was printed. For detailed information

about the fuse positions, please consult a

technical service.

In general, a fuse can be assigned to various

electrical components. Likewise, an electrical

component can be protected by several

fuses.

Only replace fuses when the cause of the

problem has been solved. If a newly inserted

fuse blows after a short time, you must have

the electrical system checked by a special-

ised workshop as soon as possible.

Additional information and warnings:

● Working in the engine compartment

››› page 163 .

196

Page 201 of 236

Fuses and bulbs

the following spare bulbs, which are essen-

tial for road safety, should be kept in the ve-

hicle.

Main headlights - H7

- H1

- W5W - PY21W

Xenon headlights 1)

/adaptive*

- D1S 2)

- P21W SLL

- W5W - PY21W

Front fog light - H3

Dipped beam

Main beam

Position

Turn signal

Dipped and full beam

Daylight

Position

Turn signals

Front fog light Upper tail light (ALTEA)

- P21W3)

- R10W

Lower tail light (ALTEA) - P21W- P21W

Fixed tail light (ALTEA XL / ALTEA FREETRACK) - P21W3)

- P21W

Mobile tail light (ALTEA XL / ALTEA

FREETRACK) - P21W- P21W

- W5W

Stop/Position

Turn signal

Fog light

Reverse light

Stop/Position

Turn signal

Fog light (driver side)

Reverse (passenger side)

Position Side turn signal

- W5W

Number plate light - C5W Note

● Depending on weather conditions (cold or

wet), the headlights, the fog lights, the tail

lights and the turn signals may be temporari-

ly misted. This has no influence on the useful

life of the lighting system. By switching on

the lights, the area through which the beam

of light is projected will quickly be demisted.

However, the edges may continue to be mis-

ted.

● Please check at regular intervals that all

lighting (especially the exterior lighting) on

your vehicle is functioning properly. This is » Side turn signal

Number plate light

1)

On this type of headlight, the bulb changes must

be made by the technical service, given that complex

elements must be removed from the vehicle and the

incorporated automatic control system must be re-

set.

2) The Xenon bulbs discharge 2.5 times the light flux

and have an average lifespan of 5 times more than

that of halogen bulbs, this means that, except due to

unusual circumstances, there is no need to change

the bulbs for the whole life of the vehicle.

3) Electronically controlled single filament bulb for

Stop/side bulbs. If the bulb blows it will not work in

either position or Stop. 199Technical specifications

Advice

Operation

Safety

Page 202 of 236

Advice

not only in the interest of your own safety,

but also that of all other road users.

● Due to difficulty of access to some of the

bulbs, any replacement work should be done

by a technical service. However, the following

is a description of how to change the lamps

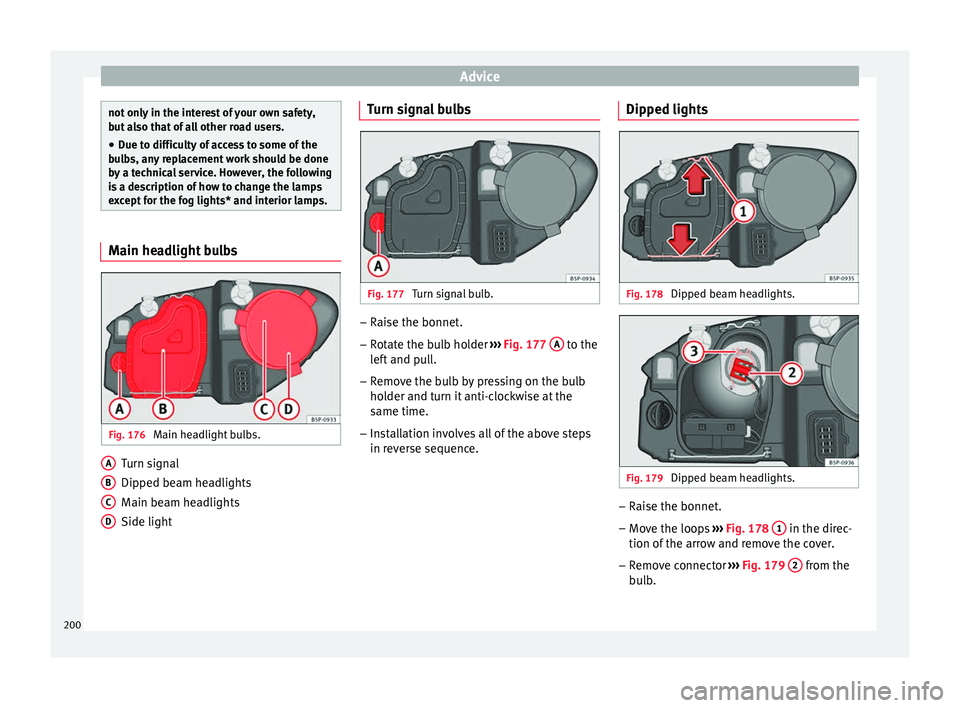

except for the fog lights* and interior lamps. Main headlight bulbs

Fig. 176

Main headlight bulbs. Turn signal

Dipped beam headlights

Main beam headlights

Side light

A B

C

D Turn signal bulbs

Fig. 177

Turn signal bulb. –

Raise the bonnet.

– Rotate the bulb holder ››› Fig. 177 A to the

left and pull.

– Remove the bulb by pressing on the bulb

holder and turn it anti-clockwise at the

same time.

– Installation involves all of the above steps

in reverse sequence. Dipped lights Fig. 178

Dipped beam headlights. Fig. 179

Dipped beam headlights. –

Raise the bonnet.

– Move the loops ››› Fig. 178 1 in the direc-

tion of the arrow and remove the cover.

– Remove connector ››› Fig. 179 2 from the

bulb.

200

Page 205 of 236

Fuses and bulbs

– Pull out the turn signal bulb holder using a

screw driver in the direction of the arrow

››› Fig. 187 .

– Fit the r

eplacement bulb by pressing it

down and rotating to the left.

– Installation involves all of the above steps

in reverse sequence.

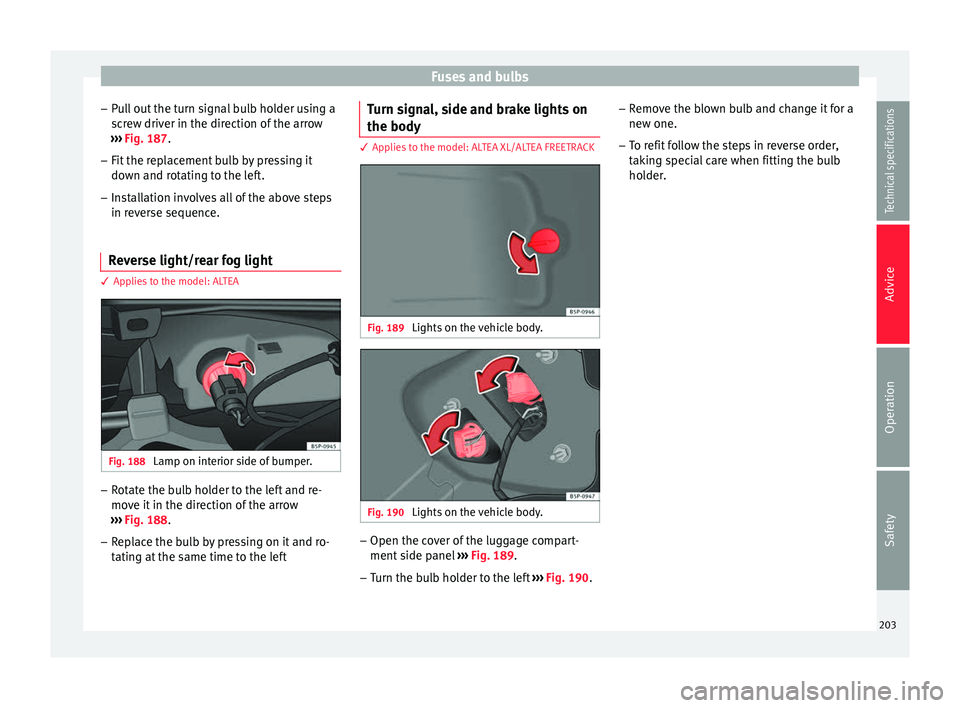

Reverse light/rear fog light 3 Applies to the model: ALTEA

Fig. 188

Lamp on interior side of bumper. –

Rotate the bulb holder to the left and re-

move it in the direction of the arrow

››› Fig. 188.

– Replace the bulb by pressing on it and ro-

tating at the same time to the left Turn signal, side and brake lights on

the body 3 Applies to the model: ALTEA XL/ALTEA FREETRACK

Fig. 189

Lights on the vehicle body. Fig. 190

Lights on the vehicle body. –

Open the cover of the luggage compart-

ment side panel ››› Fig. 189 .

– Turn the b

ulb holder to the left ››› Fig. 190. –

Remove the blown bulb and change it for a

new one.

– To refit follow the steps in reverse order,

taking special care when fitting the bulb

holder.

203

Technical specifications

Advice

Operation

Safety