oil change Seat Altea 2015 Owner's Manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2015, Model line: Altea, Model: Seat Altea 2015Pages: 236, PDF Size: 4.23 MB

Page 5 of 236

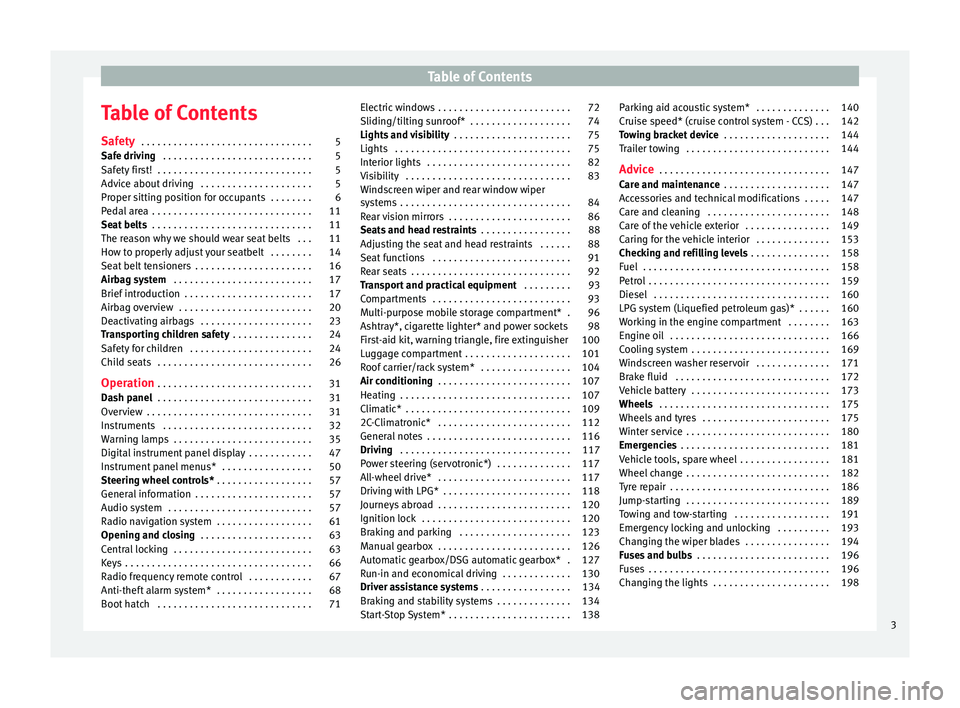

Table of Contents

Table of Contents

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Safe driving . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Safety first! . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Advice about driving . . . . . . . . . . . . . . . . . . . . . 5

Proper sitting position for occupants . . . . . . . . 6

Pedal area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Seat belts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

The reason why we should wear seat belts . . . 11

How to properly adjust your seatbelt . . . . . . . . 14

Seat belt tensioners . . . . . . . . . . . . . . . . . . . . . . 16

Airbag system . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Brief introduction . . . . . . . . . . . . . . . . . . . . . . . . 17

Airbag overview . . . . . . . . . . . . . . . . . . . . . . . . . 20

Deactivating airbags . . . . . . . . . . . . . . . . . . . . . 23

Transporting children safety . . . . . . . . . . . . . . . 24

Safety for children . . . . . . . . . . . . . . . . . . . . . . . 24

Child seats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Dash panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Instruments . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Warning lamps . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Digital instrument panel display . . . . . . . . . . . . 47

Instrument panel menus* . . . . . . . . . . . . . . . . . 50

Steering wheel controls* . . . . . . . . . . . . . . . . . . 57

General information . . . . . . . . . . . . . . . . . . . . . . 57

Audio system . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Radio navigation system . . . . . . . . . . . . . . . . . . 61

Opening and closing . . . . . . . . . . . . . . . . . . . . . 63

Central locking . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Radio frequency remote control . . . . . . . . . . . . 67

Anti-theft alarm system* . . . . . . . . . . . . . . . . . . 68

Boot hatch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71 Electric windows . . . . . . . . . . . . . . . . . . . . . . . . . 72

Sliding/tilting sunroof* . . . . . . . . . . . . . . . . . . . 74

Lights and visibility

. . . . . . . . . . . . . . . . . . . . . . 75

Lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Interior lights . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Visibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Windscreen wiper and rear window wiper

systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Rear vision mirrors . . . . . . . . . . . . . . . . . . . . . . . 86

Seats and head restraints . . . . . . . . . . . . . . . . . 88

Adjusting the seat and head restraints . . . . . . 88

Seat functions . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Rear seats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Transport and practical equipment . . . . . . . . . 93

Compartments . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Multi-purpose mobile storage compartment* . 96

Ashtray*, cigarette lighter* and power sockets 98

First-aid kit, warning triangle, fire extinguisher 100

Luggage compartment . . . . . . . . . . . . . . . . . . . . 101

Roof carrier/rack system* . . . . . . . . . . . . . . . . . 104

Air conditioning . . . . . . . . . . . . . . . . . . . . . . . . . 107

Heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Climatic* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

2C-Climatronic* . . . . . . . . . . . . . . . . . . . . . . . . . 112

General notes . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Driving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Power steering (servotronic*) . . . . . . . . . . . . . . 117

All-wheel drive* . . . . . . . . . . . . . . . . . . . . . . . . . 117

Driving with LPG* . . . . . . . . . . . . . . . . . . . . . . . . 118

Journeys abroad . . . . . . . . . . . . . . . . . . . . . . . . . 120

Ignition lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Braking and parking . . . . . . . . . . . . . . . . . . . . . 123

Manual gearbox . . . . . . . . . . . . . . . . . . . . . . . . . 126

Automatic gearbox/DSG automatic gearbox* . 127

Run-in and economical driving . . . . . . . . . . . . . 130

Driver assistance systems . . . . . . . . . . . . . . . . . 134

Braking and stability systems . . . . . . . . . . . . . . 134

Start-Stop System* . . . . . . . . . . . . . . . . . . . . . . . 138 Parking aid acoustic system* . . . . . . . . . . . . . . 140

Cruise speed* (cruise control system - CCS) . . . 142

Towing bracket device

. . . . . . . . . . . . . . . . . . . . 144

Trailer towing . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Advice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Care and maintenance . . . . . . . . . . . . . . . . . . . . 147

Accessories and technical modifications . . . . . 147

Care and cleaning . . . . . . . . . . . . . . . . . . . . . . . 148

Care of the vehicle exterior . . . . . . . . . . . . . . . . 149

Caring for the vehicle interior . . . . . . . . . . . . . . 153

Checking and refilling levels . . . . . . . . . . . . . . . 158

Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Petrol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Diesel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

LPG system (Liquefied petroleum gas)* . . . . . . 160

Working in the engine compartment . . . . . . . . 163

Engine oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

Cooling system . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Windscreen washer reservoir . . . . . . . . . . . . . . 171

Brake fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Vehicle battery . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Wheels and tyres . . . . . . . . . . . . . . . . . . . . . . . . 175

Winter service . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Emergencies . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Vehicle tools, spare wheel . . . . . . . . . . . . . . . . . 181

Wheel change . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Tyre repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

Jump-starting . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Towing and tow-starting . . . . . . . . . . . . . . . . . . 191

Emergency locking and unlocking . . . . . . . . . . 193

Changing the wiper blades . . . . . . . . . . . . . . . . 194

Fuses and bulbs . . . . . . . . . . . . . . . . . . . . . . . . . 196

Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

Changing the lights . . . . . . . . . . . . . . . . . . . . . . 198

3

Page 41 of 236

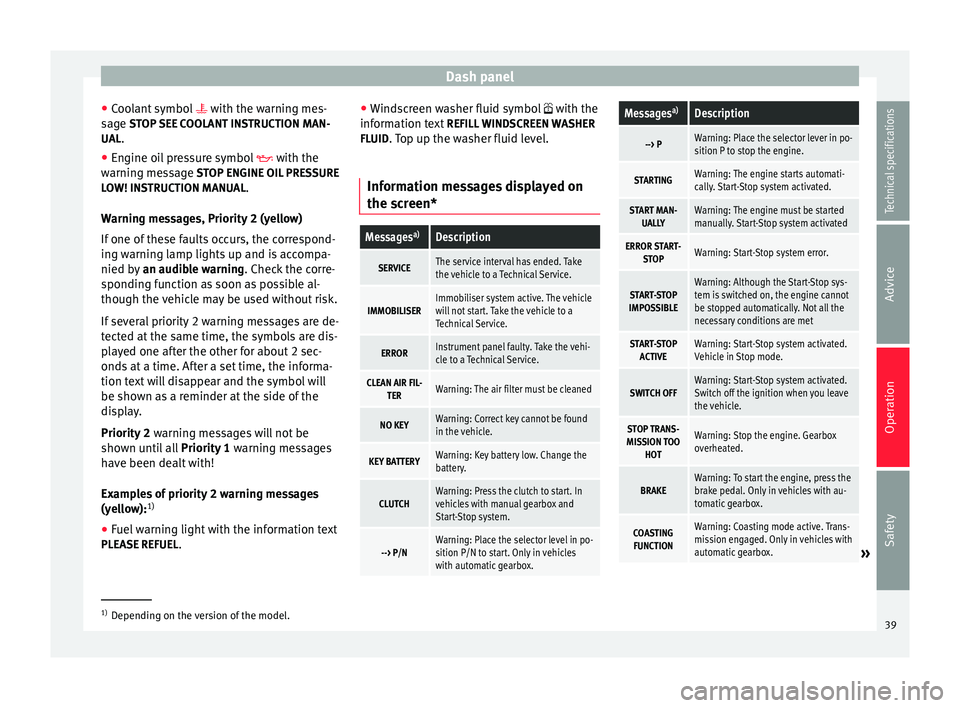

Dash panel

● Coolant symbol with the warning mes-

s ag

e STOP SEE COOLANT INSTRUCTION MAN-

UAL.

● Engine oil pressure symbol with the

warnin

g message STOP ENGINE OIL PRESSURE

LOW! INSTRUCTION MANUAL.

Warning messages, Priority 2 (yellow)

If one of these faults occurs, the correspond-

ing warning lamp lights up and is accompa-

nied by an audible warning. Check the corre-

sponding function as soon as possible al-

though the vehicle may be used without risk.

If several priority 2 warning messages are de-

tected at the same time, the symbols are dis-

played one after the other for about 2 sec-

onds at a time. After a set time, the informa-

tion text will disappear and the symbol will

be shown as a reminder at the side of the

display.

Priority 2 warning messages will not be

shown until all Priority 1 warning messages

have been dealt with!

Examples of priority 2 warning messages

(yellow): 1)

● Fuel warning light with the information text

PLEASE REFUEL . ●

Windscreen washer fluid symbol with the

inform

ation text REFILL WINDSCREEN WASHER

FLUID. Top up the washer fluid level.

Information messages displayed on

the screen*

Messages a)Description

SERVICEThe service interval has ended. Take

the vehicle to a Technical Service.

IMMOBILISERImmobiliser system active. The vehicle

will not start. Take the vehicle to a

Technical Service.

ERRORInstrument panel faulty. Take the vehi-

cle to a Technical Service.

CLEAN AIR FIL-

TERWarning: The air filter must be cleaned

NO KEYWarning: Correct key cannot be found

in the vehicle.

KEY BATTERYWarning: Key battery low. Change the

battery.

CLUTCHWarning: Press the clutch to start. In

vehicles with manual gearbox and

Start-Stop system.

--> P/NWarning: Place the selector level in po-

sition P/N to start. Only in vehicles

with automatic gearbox.

Messages a)Description

--> PWarning: Place the selector lever in po-

sition P to stop the engine.

STARTINGWarning: The engine starts automati-

cally. Start-Stop system activated.

START MAN-

UALLYWarning: The engine must be started

manually. Start-Stop system activated

ERROR START- STOPWarning: Start-Stop system error.

START-STOP

IMPOSSIBLEWarning: Although the Start-Stop sys-

tem is switched on, the engine cannot

be stopped automatically. Not all the

necessary conditions are met

START-STOP ACTIVEWarning: Start-Stop system activated.

Vehicle in Stop mode.

SWITCH OFFWarning: Start-Stop system activated.

Switch off the ignition when you leave

the vehicle.

STOP TRANS-

MISSION TOO HOTWarning: Stop the engine. Gearbox

overheated.

BRAKEWarning: To start the engine, press the

brake pedal. Only in vehicles with au-

tomatic gearbox.

COASTINGFUNCTIONWarning: Coasting mode active. Trans-

mission engaged. Only in vehicles with

automatic gearbox.

» 1)

Depending on the version of the model.

39

Technical specifications

Advice

Operation

Safety

Page 50 of 236

Operation

to the gear display indicating whether you

should change up or down. Note

The gear change indication should not be tak-

en into account when quick acceleration is re-

quired (for example when overtaking). Odometer

The left-hand counter in the display registers

the total amount of distance covered by the

vehicle.

The right-hand counter registers the short

journeys. The last digit indicates steps of 100

metres. The trip recorder counter may be re-

set by holding down the reset button for a

few seconds.

Flexible service interval display Vehicles with

Service intervals dependent on

time/distance travelled already have certain

service intervals set. The intervals are calcu-

lated individually in vehicles with LongLife

service .

The ser v

ice interval display only indicates the

dates of services that include engine oil

change. The dates of all other services, such

as the Inspection Service or brake fluid change, appear in the sticker on the door pil-

lar or in the Maintenance Programme.

A

Service pre-warning will appear in the od-

ometer if a service is due soon. A “spanner”

symbol appears and the display “km” with

the distance that can be driven until the next

service appointment is due. This signal

changes after around 10 seconds. A “clock

symbol” appears and the number of days un-

til the service appointment should be carried

out. The following message is shown in the

instrument panel display*:

Service in

[XXXX]

kmor

[XXXX]

days

The service message will disappear approxi-

mately 20 seconds after the ignition is

switched on or the engine is running. The

normal display can be resumed by briefly

pressing the reset button on the trip counter

or by pressing the OK button on the steering

wheel controls.

With the ignition on, you can check the cur-

rent service message at any moment in the

Vehicle status menu or turning the reset but-

ton to access the service display. An

overdue service

is indicated by a minus

s

ign in front of the mileage or day informa-

tion.

Indications for vehicles with LongLife service

Technical progress has made it possible to

considerably reduce servicing requirements.

With the LongLife System, SEAT ensures that

your vehicle only has an Interval Service

when it is necessary. The length of the Inter-

val Services (max. 2 years) is determined by

factors such as conditions under which the

vehicle is used and personal driving style.

The service pre-warning will first appear 20

days before the date on which the service is

due. The distance travelled is rounded off to

the nearest 100 km and the time to full days.

The current service message can only be con-

sulted 500 km after the last service. Until

that time, only dashes are displayed. Note

● If you reset the display manually, the next

service interval will be indicated after

15,000 km or one year and will not be calcu-

lated individually.

● Do not reset the display between service

intervals as the display will otherwise be in-

correct. 48

Page 133 of 236

Driving

From 1,000 to 1,500 kilometres

– Speeds can be gradually increased to the

maximum road speed or maximum

permissible engine speed (rpm).

During its first few hours of running, the in-

ternal friction in the engine is greater than

later on, when all the moving parts have bed-

ded in. For the sake of the environment

If the engine is run in gently, its life will be in-

creased and its oil consumption reduced. Environmental friendliness

Environmental protection is a top priority in

the design, choice of materials and manufac-

ture of your new SEAT.

Constructive measures to encourage

recycling

● Joints and connections designed for easy

dismantling

● Modular construction to facilitate disman-

tling

● Increased use of single-grade materials.

● Plastic parts and elastomers are marked in

accordance with ISO 1043, ISO 11469 and

ISO 1629. Choice of materials

●

Use of recycled materials.

● Use of compatible plastics in the same part

if its components are not easily separated.

● Use of recycled materials and/or materials

originating from renewable sources.

● Reduction of volatile components, includ-

ing odour, in plastic materials.

● Use of CFC-free coolants.

Ban on heavy metals, with the exceptions

dictated by law (Annex II of ELV Directive

2000/53/EC): cadmium, lead, mercury, hexa-

v al

ent chromium.

Manufacturing methods

● Reduction of the quantity of thinner in the

protective wax for cavities.

● Use of plastic film as protection during ve-

hicle transport.

● Use of solvent-free adhesives.

● Use of CFC-free coolants in cooling sys-

tems.

● Recycling and energy recovery from resi-

dues (RDF).

● Improvement in the quality of waste water.

● Use of systems for the recovery of residual

heat (thermal recovery, enthalpy wheels,

etc.).

● Use of water-soluble paints. Catalytic converter To maintain the useful life of the catalytic

converter

– Use only unleaded petrol with petrol en-

gines, as lead damages the catalytic con-

verter.

– Do not let the fuel get too low in the tank.

– For engine oil changes, do not replenish

with too much engine oil ››› page 168, Top-

ping up engine oil .

– Never tow the vehicle to start it, use jump

leads if necessary ›››

page 189.

If you notice misfiring, uneven running or

loss of power when the vehicle is moving, re-

duce speed immediately and have the vehi-

cle inspected at the nearest specialised

workshop. In general, the exhaust warning

lamp will light up when any of the described

symptoms occur ›››

page 35 . If this happens,

u nb

urnt fuel can enter the exhaust system

and escape into the environment. The cata-

lytic converter can also be damaged by over-

heating. WARNING

The catalytic converter reaches very high

temperatures! Risk of fire!

● Never park where the catalytic converter

could come into contact with dry grass or

flammable materials under the vehicle. » 131

Technical specifications

Advice

Operation

Safety

Page 168 of 236

Advice

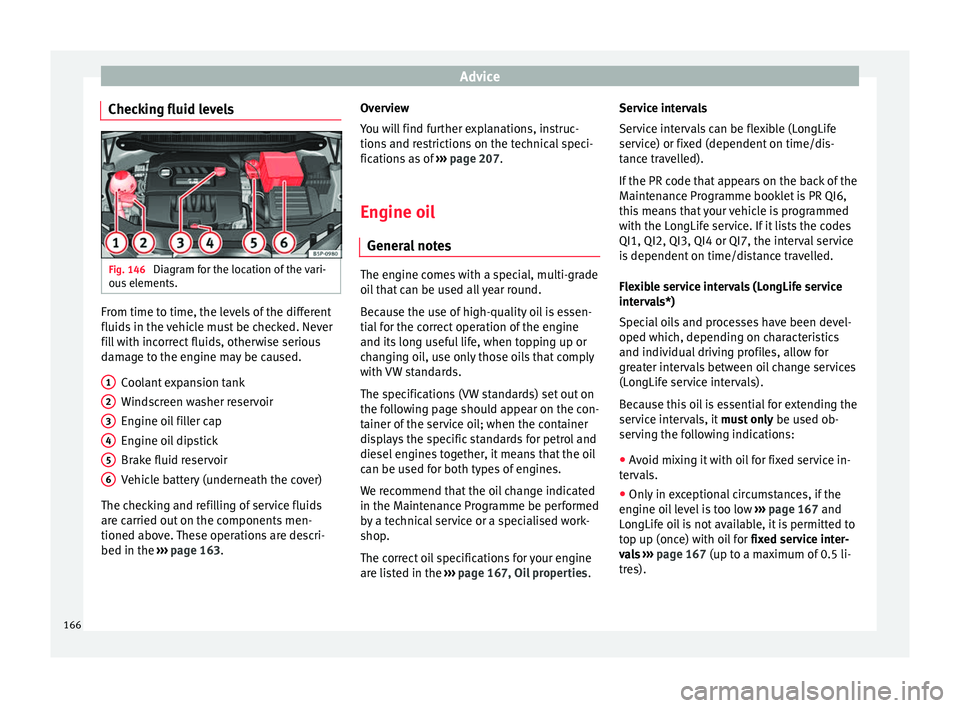

Checking fluid levels Fig. 146

Diagram for the location of the vari-

ous elements. From time to time, the levels of the different

fluids in the vehicle must be checked. Never

fill with incorrect fluids, otherwise serious

damage to the engine may be caused.

Coolant expansion tank

Windscreen washer reservoir

Engine oil filler cap

Engine oil dipstick

Brake fluid reservoir

Vehicle battery (underneath the cover)

The checking and refilling of service fluids

are carried out on the components men-

tioned above. These operations are descri-

bed in the ››› page 163 .

1 2

3

4

5

6 Overview

You will find further explanations, instruc-

tions and restrictions on the technical speci-

fications as of

››› page 207 .

En gine oi

l

General notes The engine comes with a special, multi-grade

oil that can be used all year round.

Because the use of high-quality oil is essen-

tial for the correct operation of the engine

and its long useful life, when topping up or

changing oil, use only those oils that comply

with VW standards.

The specifications (VW standards) set out on

the following page should appear on the con-

tainer of the service oil; when the container

displays the specific standards for petrol and

diesel engines together, it means that the oil

can be used for both types of engines.

We recommend that the oil change indicated

in the Maintenance Programme be performed

by a technical service or a specialised work-

shop.

The correct oil specifications for your engine

are listed in the

›››

page 167, Oil properties .Service intervals

Service intervals can be flexible (LongLife

service) or fixed (dependent on time/dis-

tance travelled).

If the PR code that appears on the back of the

Maintenance Programme booklet is PR QI6,

this means that your vehicle is programmed

with the LongLife service. If it lists the codes

QI1, QI2, QI3, QI4 or QI7, the interval service

is dependent on time/distance travelled.

Flexible service intervals (LongLife service

intervals*)

Special oils and processes have been devel-

oped which, depending on characteristics

and individual driving profiles, allow for

greater intervals between oil change services

(LongLife service intervals).

Because this oil is essential for extending the

service intervals, it

must only be used ob-

serving the following indications:

● Avoid mixing it with oil for fixed service in-

tervals.

● Only in exceptional circumstances, if the

engine oil level is too low ››› page 167 and

LongLife oil is not available, it is permitted to

top up (once) with oil for fixed service inter-

vals › ›

›

page 167 (up to a maximum of 0.5 li-

tres).

166

Page 171 of 236

Checking and refilling levels

Changing engine oil The engine oil must be changed at the inter-

vals given in the service schedule.

We recommend that you have the engine oil

changed by a Technical Service.

The oil change intervals are shown in the

Maintenance Programme.

WARNING

Only change the engine oil yourself if you

have the specialist knowledge required!

● Before opening the bonnet, read and ob-

serve the warnings ››› page 163, Safety in-

structions on working in the engine compart-

ment.

● Wait

for the engine to cool down. Hot oil

may cause burn injuries.

● Wear eye protection to avoid injuries, such

as acid burns, caused by splashes of oil.

● When removing the oil drain plug with your

fingers, keep your arm horizontal to help pre-

vent oil from running down your arm.

● Wash your skin thoroughly if it comes into

contact with engine oil.

● Engine oil is poisonous! Used oil must be

stored in a safe place out of the reach of chil-

dren. CAUTION

No additives should be used with engine oil.

This could result in engine damage. Any dam-

age caused by the use of such additives

would not be covered by the factory warranty. For the sake of the environment

● Because of disposal problems and the spe-

cial tools and specialist knowledge required,

we recommend that you have the engine oil

and filter changed by a Technical Service.

● Never pour oil down drains or into the

ground.

● Use a suitable container when draining the

used oil. It must be large enough to hold all

the engine oil. Cooling system

Engine coolant specifications The engine cooling system is supplied from

the factory with a specially treated mixture of

water and, at least, 40 % of the additive

G 13

(TLVW 774 J). The engine coolant additive is

recognisable by its purple colour. This mix-

ture of water and additive gives the necessa-

ry frost protection down to -25°C (-13 F) and

protects the light alloy parts of the cooling

system against corrosion. It also prevents scaling and considerably raises the boiling

point of the coolant.

To protect the engine cooling system, the

percentage of additive must

always be at

l e

ast 40 %, even in warm climates where an-

ti-freeze protection is not required.

If greater frost protection is required in very

cold climates, the proportion of additive can

be increased. However, the percentage of ad-

ditive should not exceed 60%, as this would

reduce frost protection and, in turn, decrease

cooling capacity.

When the coolant is topped up, use a mixture

of distilled water and, at least, 40 % of the G

13 or G 12 plu

s-plus (TL-VW 774 G) additive

(both are purple) to obtain an optimum anti-

corrosion protection ››› . The mixture of G

13 with G 12 plus (TL-VW 774 F), G 12 (red) or

G 11 (green-blue) engine coolants will signifi-

cantly reduce the anticorrosion protection

and should, therefore be avoided ››› .

WARNING

If there is not enough anti-freeze in the cool-

ant system, the engine may fail leading to se-

rious damage.

● Please make sure that the percentage of

additive is correct with respect to the lowest

expected ambient temperature in the zone

where the vehicle is to be used.

● When the outside temperature is very low,

the coolant could freeze and the vehicle » 169

Technical specifications

Advice

Operation

Safety

Page 174 of 236

Advice

Brake fluid Checking the brake fluid level Fig. 151

Engine compartment: brake fluid

reservoir cap –

Read off the fluid level at the transparent

brake fluid reservoir. It should always be

between the “MIN” and “MAX” marks.

The position of the brake fluid reservoir is

shown in the corresponding engine compart-

ment illustration ››› page 166. The brake fluid

reservoir has a black and yellow cap.

The brake fluid level drops slightly when the

vehicle is being used as the brake pads are

automatically adjusted as they wear.

However, if the level goes down noticeably in

a short time, or drops below the “MIN” mark,

there may be a leak in the brake system. A

display on the instrument panel will warn you

if the brake fluid level is too low ››› page 35. WARNING

Before opening the bonnet to check the brake

fluid level, read and observe the warnings

››› page 163. Changing the brake fluid

The Maintenance Programme indicates brake

fluid change intervals.

We recommend that you have the brake fluid

changed by a Technical Service.

Before opening the bonnet, please read and

follow the warnings

››› in Safety instruc-

tions on working in the engine compartment

on page 163 in section “Safety notes for

w ork

ing in the engine compartment”.

In the course of time, brake fluid becomes

hygroscopic and absorbs water from the am-

bient air. If the water content in the brake flu-

id is too high, the brake system could cor-

rode. This also considerably reduces the boil-

ing point of the brake fluid. Heavy use of the

brakes may then cause a vapour lock which

could impair the braking effect.

Be sure to always use the correct brake fluid.

Only use brake fluid that expressly meets the

VW 501 14 standard.

You can buy VW 501 14 standard brake fluid

at a SEAT dealership or a SEAT Official Serv-

ice. If none is available, use only high-quality brake fluid that meets DIN ISO 4925 CLASS 4

standards, or USA Standards FMVSS 116 DOT

4.

Using any other kind of brake fluid or one

that is not of a high quality may affect opera-

tion of the brake system and reduce its effec-

tiveness. Never use a brake fluid if the con-

tainer does not state that it complies with VW

501 14, DIN ISO 4925 CLASS 4 standards, or

USA standards FMVSS 116 DOT 4.

WARNING

Brake fluid is poisonous. Old brake fluid im-

pairs the braking effect.

● Before opening the bonnet to check the

brake fluid level, read and observe the warn-

ings ››› page 163.

● Br ak

e fluid should be stored in the closed

original container in a safe place out of reach

of children. There is a toxic risk.

● Perform the brake fluid change according to

the Maintenance Programme. Heavy use of

the brakes may cause a vapour lock if the

brake fluid is left in the brake system for too

long. This would seriously affect the effec-

tiveness of the brakes and the safety of the

vehicle. This may cause an accident. CAUTION

Brake fluid damages the vehicle paintwork.

Wipe off any brake fluid from the paintwork

immediately. 172

Page 179 of 236

Wheels

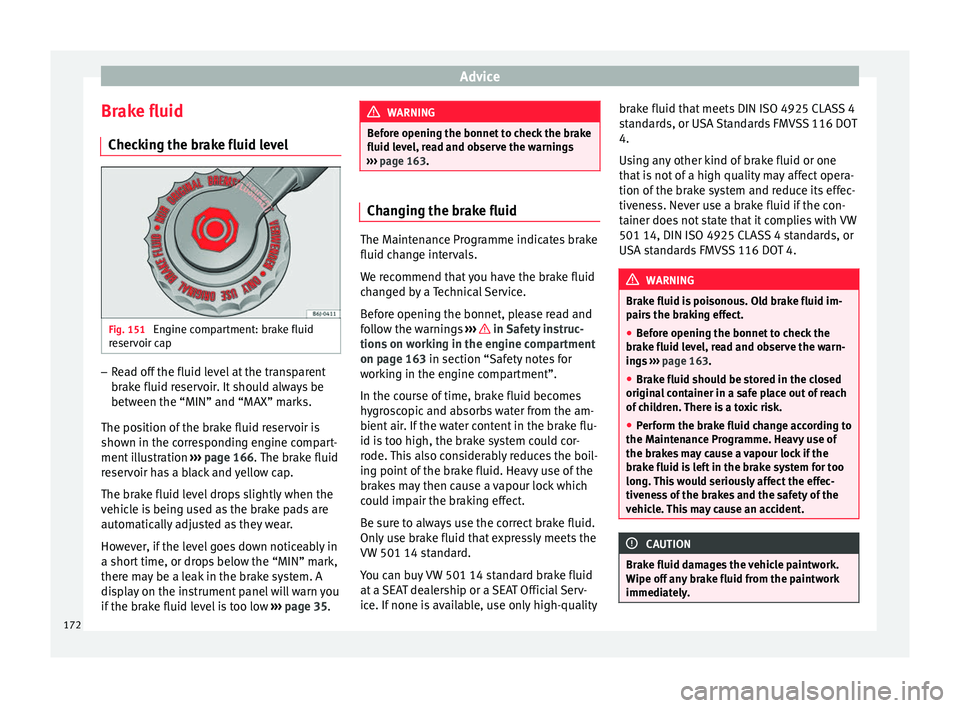

Tyre useful life Fig. 152

Tyre tread wear indicators. Fig. 153

Diagram for changing wheels The useful life of tyres is dependent on tyre

pressure, driving style and fitting.

Wear indicators

The original tyres on your vehicle have

1.6 mm high “tread wear indicators”

››› Fig. 152 , running across the tread. De- pendin

g on the m ake, there will be 6 to 8 of

them evenly spaced around the tyre. Mark-

ings on the tyre sidewall (for instance the let-

ters “TWI” or other symbols) indicate the po-

sitions of the tread wear indicators. The mini-

mum tread depth required by law is 1.6 mm

(measured in the tread grooves next to the

tread wear indicators). Worn tyres must be re-

placed. Different figures may apply in export

countries ››› .

Tyre pressure

Incorrect tyre pressure causes premature

wear and could cause tyre blow-out. For this

reason, the tyre pressure should be checked

at least once per month ››› page 175.

Driving style

Fast cornering, heavy acceleration and hard

braking all increase tyre wear.

Changing wheels around

If the front tyres are worn considerably more

than the rear ones it is advisable to change

them around as shown ››› Fig. 153 . The use-

f u

l life of all the tyres will then be about the

same time.

Wheel balance

The wheels on new vehicles are balanced.

However, various factors encountered in nor-

mal driving can cause them to become unbal-

anced, which results in steering vibration. Unbalanced wheels should be rebalanced, as

they otherwise cause excessive wear on

steering, suspension and tyres. A wheel must

also be rebalanced when a new tyre is fitted.

Incorrect wheel alignment

Incorrect wheel alignment causes excessive

tyre wear, impairing the safety of the vehicle.

If tyres show excessive wear, you should

have the wheel alignment checked by a Tech-

nical Service.

WARNING

There is a serious danger of accidents if a tyre

bursts during driving!

● The tyres must be replaced at the latest

when the tread wear indicators are worn

››› page 177. Failure to follow this instruction

could result in an accident. Worn tyres do not

grip well at high speeds on wet roads. There

is also a greater risk of “aquaplaning”.

● At continuously high speeds, a tyre with in-

sufficient pressure flexes more. This causes it

to overheat. This can cause tread separation

and tyre blow-out. Risk of accident. Always

observe the recommended tyre pressures.

● If tyres show excessive wear, you should

have the running gear checked by a Technical

Service.

● Keep chemicals such as oil, fuel and brake

fluid away from tyres.

● Damaged wheels and tyres must be re-

placed immediately! » 177

Technical specifications

Advice

Operation

Safety

Page 182 of 236

Advice

For the sake of the environment

Old tyres must be disposed of according to

the laws in the country concerned. Note

● For technical reasons, it is not generally

possible to use the wheels from other vehi-

cles. This can also apply to wheels of the

same model. The use of wheels or tyres

which have not been approved by SEAT for

use with your model may invalidate the vehi-

cle's type approval for use on public roads.

● If the spare tyre is not the same as the

tyres that are mounted on the vehicle (e.g.

winter tyres) you should only use the spare

tyre for a short period of time and drive with

extra care. Refit the normal road wheel as

soon as possible. Wheel bolts

The design of wheel bolts is matched to the

rims. If different wheel rims are fitted, the

correct wheel bolts with the right length and

correctly shaped bolt heads must be used.

This ensures that wheels are fitted securely

and that the brake system functions correctly.

In certain circumstances, you should not use

wheel bolts from a different vehicle, even if it

is the same model

›››

page 147. After the wheels have been changed, the

tightening torque of the wheel bolts should

be checked as soon as possible with a torque

wrench

››› . The tightening torque for steel

and alloy wheels is 120 Nm. WARNING

If the wheel bolts are not tightened correctly,

the wheel could become loose while driving.

Risk of accident.

● The wheel bolts must be clean and turn

easily. Never apply grease or oil to them.

● Use only wheel bolts which belong to the

wheel.

● If the tightening torque of the wheel bolts

is too low, they could loosen whilst the vehi-

cle is in motion. Risk of accident! If the tight-

ening torque is too high, the wheel bolts and

threads can be damaged. CAUTION

The prescribed tightening torque for wheel

bolts for steel and alloy wheels is 120 Nm. Winter service

Winter tyres In winter conditions winter tyres will consid-

erably improve the vehicle's handling. Sum-mer tyres (width, rubber compound, tread

pattern) provide less grip on ice and snow.

Winter tyres must be inflated to a

pressure of

0.2 bar (2.9 psi/20 kPa) higher than the pres-

sures specified for summer tyres (see sticker

on fuel tank flap).

Winter tyres must be fitted on all four wheels.

Information on permitted winter tyre sizes

can be found in the vehicle's registration

documentation. Use only radial winter tyres.

All tyre sizes listed in the vehicle documenta-

tion also apply to winter tyres.

Winter tyres lose their effectiveness when the

tread is worn down to a depth of 4 mm.

The speed rating code ››› page 179, New

tyres and wheels determines the following

speed limits for winter tyres:

›

› › max. 160 km/h

max. 180 km/h

max. 190 km/h

max. 210 km/h

In some countries, vehicles which can exceed

the speed rating of the fitted tyre must have

an appropriate sticker in the driver's field of

view. These stickers are available from your

technical service. The legal requirements of

each country must be followed.

Do not have winter tyres fitted for unnecessa-

rily long periods. Vehicles with summer tyres Q

S

T

H

180

Page 197 of 236

Emergencies

If the windscreen wipers scratch , they should

be replaced if they are damaged, or cleaned

if they are soiled.

If this does not produce the desired results,

the setting angle of the windscreen wiper

arms might be incorrect. They should be

checked by a specialised workshop and cor-

rected if necessary. WARNING

Do not drive unless you have good visibility

through all windows!

● Clean the windscreen wiper blades and all

windows regularly.

● The wiper blades should be changed once

or twice a year. CAUTION

● Damaged or dirty windscreen wipers could

scratch the windscreen.

● Never use fuel, nail varnish remover, paint

thinner or similar products to clean the win-

dows. This could damage the windscreen

wiper blades.

● Never move the windscreen wiper or wind-

screen wiper arm manually. This could cause

damage.

● To prevent damage to the bonnet and the

windscreen wiper arms, the latter should only

be lifted off the windscreen when in service

position. Note

● The windscreen wiper arms can be moved

to the service position only when the bonnet

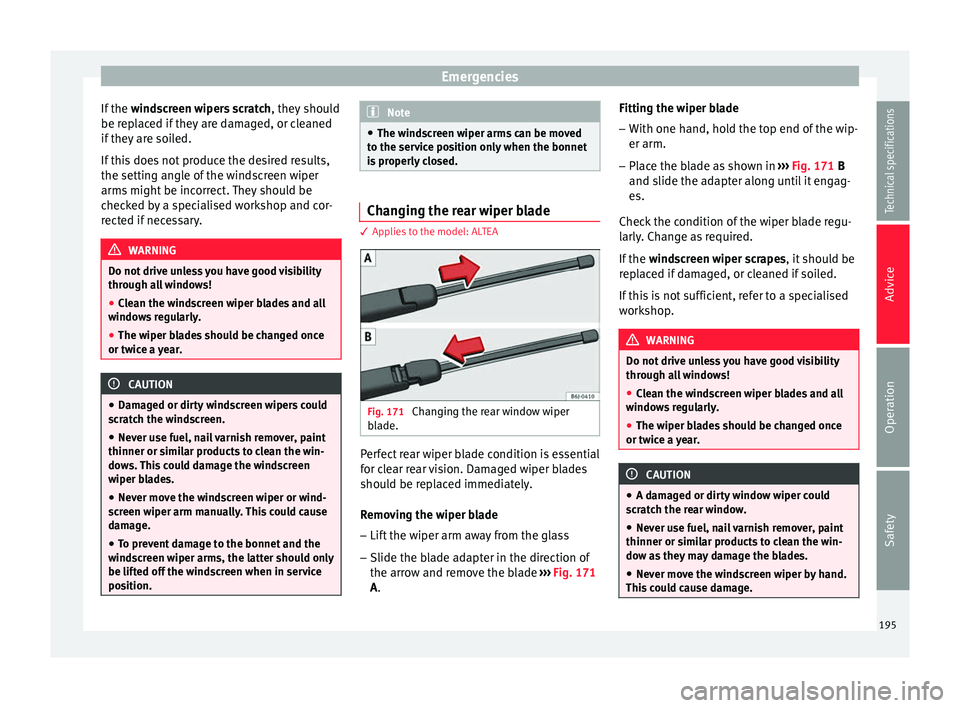

is properly closed. Changing the rear wiper blade

3 Applies to the model: ALTEA

Fig. 171

Changing the rear window wiper

blade. Perfect rear wiper blade condition is essential

for clear rear vision. Damaged wiper blades

should be replaced immediately.

Removing the wiper blade

– Lift the wiper arm away from the glass

– Slide the blade adapter in the direction of

the arrow and remove the blade ››› Fig. 171

A . Fittin

g the w iper blade

– With one hand, hold the top end of the wip-

er arm.

– Place the blade as shown in ››› Fig. 171

B

and slide the adapter along until it engag-

es.

Check the condition of the wiper blade regu-

larly. Change as required.

If the windscreen wiper scrapes, it should be

replaced if damaged, or cleaned if soiled.

If this is not sufficient, refer to a specialised

workshop. WARNING

Do not drive unless you have good visibility

through all windows!

● Clean the windscreen wiper blades and all

windows regularly.

● The wiper blades should be changed once

or twice a year. CAUTION

● A damaged or dirty window wiper could

scratch the rear window.

● Never use fuel, nail varnish remover, paint

thinner or similar products to clean the win-

dow as they may damage the blades.

● Never move the windscreen wiper by hand.

This could cause damage. 195

Technical specifications

Advice

Operation

Safety