technical specifications Seat Altea XL 2015 Owners Manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2015, Model line: Altea XL, Model: Seat Altea XL 2015Pages: 236, PDF Size: 4.23 MB

Page 181 of 236

Wheels

the vehicle is impaired and there is a risk of

accident.

Note

● The run-flat tyres do not “deflate” on losing

pressure because they are supported on the

reinforced sides. Therefore defects in the tyre

cannot be detected with a visual inspection.

● Snow chains must not be used on front

tyres used in emergency conditions. New tyres and wheels

New tyres and wheels have to be run in.

The tyres and wheel rims are an essential

part of the vehicle's design. Those approved

by SEAT are specially matched to the charac-

teristics of the vehicle and make a major con-

tribution to good road-holding and safe han-

dling

››› .

Note for Italy: A SEAT Service Centre should

be c on

sulted whether different sized wheels

or tyres to those originally fitted by SEAT may

be fitted, as well as the combinations al-

lowed between the front axle (axle 1) and

back axle (axle 2).

Tyres should be replaced at least in pairs and

not individually (i.e. both front tyres or both

rear tyres together). A knowledge of tyre des-

ignations makes it easier to choose the cor- rect tyres. Radial tyres have the tyre designa-

tions marked on the sidewall, for example:

195/65 R15 91T

This contains the following information:

Tyre width in mm

Height/width ratio in %

Tyre construction: Radial

Rim di

ameter in inches

Load rating code

Speed rating

The tyres could also have the following infor-

mation:

● A direction of rotation symbol

● “Reinforced” denotes heavy-duty tyres.

The manufacturing date is also indicated on

the tyre sidewall (possibly only on the inner

side of the wheel).

“DOT... 1103...” means, for example, that the

tyre was produced in the 11th week of 2003.

We recommend that work on tyres and

wheels be carried out by a Technical Service.

They are familiar with the procedure and

have the necessary special tools and spare

parts as well as the proper facilities for dis-

posing of the old tyres. 195

65

R

15

91

T Any technical service has full information on

the technical requirements when installing or

changing tyres, wheels or wheel trims.

On vehicles with

all-wheel drive, all four tyres

must always be fitted with tyres of the same

type, make and tread pattern, as otherwise

the driveline can be damaged by continuous

differences in the wheel speeds. For this rea-

son, the spare wheel should have the same

wheel dimensions as the normal wheels so

that it will fit if there is a puncture. You may

also use the factory-supplied compact tem-

porary spare wheel. WARNING

● We recommend that you use only wheels

and tyres which have been approved by SEAT

for your model. Failure to do so could impair

vehicle handling. Risk of accident.

● Avoid running the vehicle on tyres that are

more than 6 years old. If you have no alterna-

tive, you should drive slowly and with extra

care at all times.

● Never use old tyres or those with an un-

known “history of use”.

● If wheel trims are retrofitted, you must en-

sure that the flow of air to the brakes is not

restricted. This could cause the brake system

to overheat.

● All four wheels must be fitted with radial

tyres of the same type, size (rolling circumfer-

ence) and the same tread pattern. » 179

Technical specifications

Advice

Operation

Safety

Page 183 of 236

Emergencies

handle better when the roads are free of

snow and ice.

If you have a flat tyre, please refer to the

notes on the spare wheel ››› page 179, New

tyres and wheels .WARNING

The maximum speed for the winter tyres must

not be exceeded. Otherwise, this could lead

to damage and risk of accident. For the sake of the environment

Fit your summer tyres again as soon as possi-

ble. They are quieter, do not wear so quickly

and reduce fuel consumption. Snow chains

Snow chains are only permitted on front

wheels and only for tyres 195/65R15 and

205/55R16. These tyres may only be fitted

with fine-pitch link chains which do not pro-

trude more than 15 mm

›››

page 210.

Other tyres may use fine-pitch links which do

not protrude more than 9 mm, including ten-

sion device.

Remove wheel hub covers and trim rings be-

fore fitting snow chains. For safety reasons,

cover caps, available at any technical service,

must then be fitted over the wheel bolts. All-wheel drive

: where snow chains are com-

pulsory, this normally also applies to all-

wheel drive vehicles. Snow chains may only

be fitted to the front

wheels (also on vehicles

w

ith all-wheel drive). WARNING

Snow chains should be correctly tightened in

accordance with the manufacturer's instruc-

tions. This will prevent the chains coming in-

to contact with the wheel housing. CAUTION

Remove the snow chains to drive on roads

without snow. Otherwise they will impair

handling, damage the tyres and wear out very

quickly. Note

● In some countries, the maximum permitted

speed with snow chains is 50 km/h (31 mph).

The legal requirements of each country must

be followed.

● We recommend that you ask your technical

service for information about appropriate

wheel, tyre and snow chain size. Emergencies

Vehicle tools, spare wheel Vehicle Tools The vehicle tools are located under the floor

panel in the luggage compartment.

– Lift the cover of the luggage compartment,

by pulling it up with a finger in the fitting.

– Take the vehicle tools out of the vehicle.

The vehicle tool kit includes:

● Jack.*

● Hook for removing wheel covers* or wheel

trims*

● Box spanner for wheel bolts.*

● Towing ring.

● Adapter for the anti-theft wheel bolts*

Some of the items listed are only provided in

certain model versions, or are optional ex-

tras. WARNING

● The factory-supplied jack is only designed

for changing wheels on this model. On no ac-

count attempt to use it for lifting heavier ve-

hicles or other loads. Risk of injury.

● Use the jack only on a firm, level ground.

» 181

Technical specifications

Advice

Operation

Safety

Page 185 of 236

Emergencies

– Switch off the engine. Switch on the hazard

warning lights.

– Apply the handbrake firmly.

– En g

age the first gear , or put

the selector

lever to position P for those vehicles with

an automatic gearbox.

– If you are towing a trailer, unhitch it from

your vehicle.

– Take the vehicle tools and the spare wheel

out of

the luggage compartment. WARNING

Put the hazard warning lights on and place

the warning triangle in position. This is for

your own safety and also warns other road

users. CAUTION

If you have to change the tyre on a gradient,

block the wheel opposite the wheel being

changed by placing a stone or similar object

under it to prevent the vehicle from rolling

away. Note

Please observe related legal requirements. Changing a wheel

Change the wheel as described below: –

Remove the wheel cover

. A

l

so refer to

››› Fig. 155.

– Slac

ken the wheel bolts .

– Rai

se the vehicle with the jack at the corre-

spondin

g area.

– Remove the wheel and put

on the spare

one.

– Lower the vehicle.

– Tighten the wheel

bolts firmly with the box

sp

anner.

– Replace the hub cap.

Aft

er changing a wheel –

Put the tools back in their storage location.

– Place the wheel with the defective tyre in

the luggage compartment and secure it.

– Check the tyre pressure of the newly fitted

tyre as soon as possible.

– Have the tightening torque of the wheel

bolts checked as soon as possible with a

torque wrench. The prescribed torque must

be 120 Nm. Note

● If you notice that the wheel bolts are corro-

ded and difficult to turn when changing a wheel, they must be replaced before having

the wheel bolt tightening torque checked.

● For safety reasons, drive at moderate

speeds until the wheel bolt tightening torque

has been checked. Wheel trims

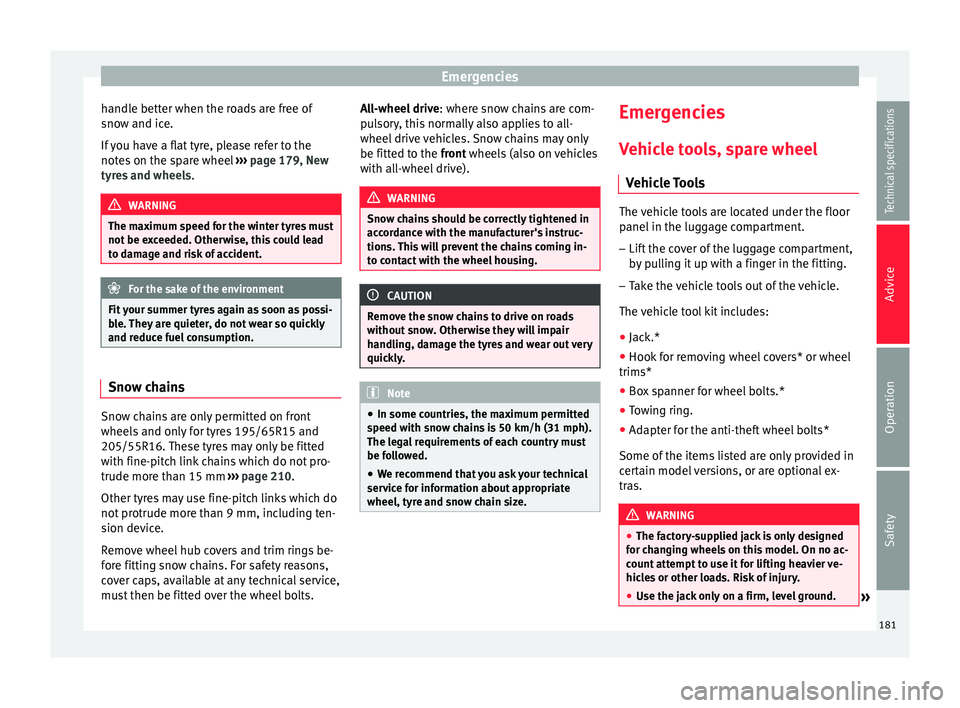

Fig. 155

Changing a wheel: remove the wheel

trim. The wheel trims must be removed to gain ac-

cess to the wheel bolts.

Removing

– Insert the extraction hook from the tools in-

to the designated ring, located in one of

the bolt hole covers of the wheel cover

››› Fig. 155 .

»

183

Technical specifications

Advice

Operation

Safety

Page 187 of 236

Emergencies

Lifting the vehicle Fig. 158

Jack position points Fig. 159

Fitting the jack. In order to remove the wheel, the vehicle

must be raised with a jack.

– Locate the jacking point under the door sill

closest to the punctured wheel ››› Fig. 158.

– Place the jack under the jacking point and

turn the crank until the arm of the jack is di- rectly below the vertical rib under the door

sill.

– Align the jack so that the arm of the jack

fits around the rib under the door sill and

the movable base plate of the jack is flat on

the ground ››› Fig. 159 .

– Rai

se the vehicle until the defective wheel

is just clear of the ground.

Recesses at the front and rear of the door

sills mark the jacking points ››› Fig. 158.

There i

s only one jacking point for each

wheel. Do not fit the jack anywhere else.

An

unstable surface under the jack may

cause the vehicle to slip off the jack. There-

fore, it must be fitted on solid ground offer-

ing good support. Use a large and stable

base, if necessary. On a hard, slippery sur-

face (such as tile) use a rubber mat or similar

to prevent the jack from slipping. WARNING

● Take all precautions so that the base of the

jack does not slip. Failure to follow this in-

struction could result in an accident.

● The vehicle can be damaged if the jack is

not applied at the correct jacking points.

There is also a risk of injury since the jack can

slip off suddenly if it is not properly engaged. Jack position points for vehicles with

sill panel trim*

Fig. 160

Plastic sill panel trim with jack an-

chor cover. Vehicles with plastic sill panel trim, with

cover*

– Remove the cap A to access the anchor

point for the vehicle jack ››› Fig. 160 .

– Pull on the cover and remove it from its al-

lotment in the direction of the arrow

››› Fig. 160 .

– Onc e the c

over has been released, it will re-

main connected to its strap so that is not

lost.

185

Technical specifications

Advice

Operation

Safety

Page 189 of 236

Emergencies

After inserting the sealant residue in the tyre,

you must again check the tyre pressure about

10 minutes after starting the engine.

You should only use the tire mobility set if

the vehicle is parked in a safe place, you are

familiar with the procedure and you have the

necessary tire mobility set! Otherwise, you

should seek professional assistance.

The tyre sealant must not be used in the

following cases:

● If the wheel rim has been damaged.

● In outside temperatures below -20 °C

(-4 °F).

● In the event of cuts or perforations in the

tyre greater than 4 mm.

● If you have been driving with very low pres-

sure or a completely flat tyre.

● If the sealant bottle has passed its use by

date. WARNING

Using the tyre mobility system can be dan-

gerous, especially when filling the tyre at the

roadside. Please observe the following rules

to minimise the risk of injury:

● Stop the vehicle safely as soon as possible.

Park it at a safe distance from surrounding

traffic to fill the tyre.

● Ensure the ground on which you park is flat

and solid. ●

All passengers and particularly children

must keep a safe distance from the work area.

● Turn on the hazard warning lights to warn

other road users.

● Use the tyre mobility system only if you are

familiar with the necessary procedures. Oth-

erwise, you should seek professional assis-

tance.

● The tyre mobility set is intended for tempo-

rary emergency use only until you can reach

the nearest specialised workshop.

● Replace the repaired tyre with the tire mo-

bility set as soon as possible.

● The sealant is a health hazard and must be

cleaned immediately if it comes into contact

with the skin.

● Always keep the tire mobility set out of the

reach of small children.

● Never use an equivalent jack, even if it has

been approved for your vehicle.

● Always stop the engine, apply the hand-

brake lever firmly and engage gear if using a

manual gearbox, in order to reduce the risk of

vehicle involuntary movement. WARNING

A tyre filled with sealant does not have the

same performance properties as a conven-

tional tyre.

● Never drive faster than 80 km/h (50 mph).

● Avoid heavy acceleration, hard braking and

fast cornering. ●

Drive only during 10 minutes at a maximum

speed of 80 km/h (50 mph) and subsequently

check the tyre. For the sake of the environment

Dispose of used or expired sealant observing

any legal requirements. Note

● A new bottle of sealant can be purchased at

SEAT dealerships.

● Take into account the separate instruction

manual from the tyre mobility set* manufac-

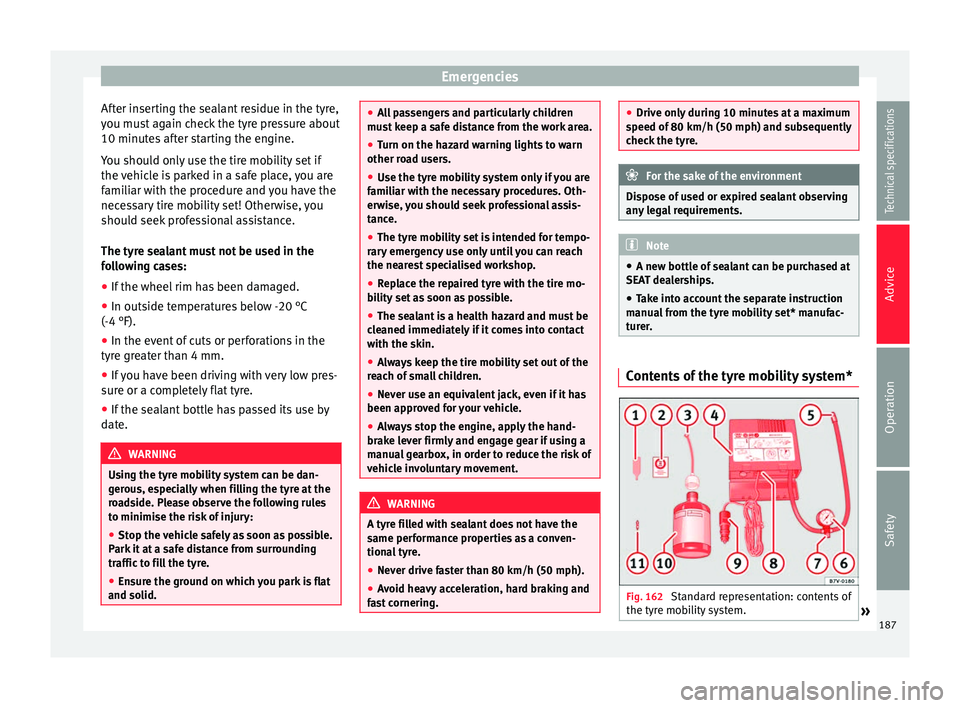

turer. Contents of the tyre mobility system*

Fig. 162

Standard representation: contents of

the tyre mobility system. » 187Technical specifications

Advice

Operation

Safety

Page 191 of 236

Emergencies

● If the indicated pressure still cannot be

reached, the tyre is too badly damaged. The

tyre cannot be sealed with the anti-puncture

kit. Do not continue driving. You should ob-

tain professional assistance ››› .

● Disconnect the air compressor and unscrew

the flexible inflator tube from the tyre valve.

● When the tyre pressure is between 2.5 and

2.0 bars, immediately continue driving with-

out exceeding 80 km/h (50 mph).

● After 10 minutes

, Check the pressure again

›

›› page 189. WARNING

When inflating the wheel, the air compressor

and the inflator tube may become hot.

● Protect hands and skin from hot parts.

● Do not place the hot flexible inflator tube or

hot air compressor on flammable material.

● Allow them to cool before storing the de-

vice.

● If it is not possible to inflate the tyre to at

least 2.0 bars (29 psi / 200 kPa), the tyre is

too badly damaged. The sealant is not in a

good condition to seal the tyre. Do not con-

tinue driving. Seek specialist assistance. CAUTION

Switch off the air compressor after a maxi-

mum of 8 operational minutes to prevent it

from overheating! Before switching on the air compressor again, let it cool for several mi-

nutes.

Check after 10 minutes of driving

Screw the inflator tube

››› Fig. 162 5 again

and check the pressure on the gauge 6 .

1.3 bar (19 psi / 130 kPa) and lower:

● Stop the vehicle! The tyre cannot be sealed

sufficiently with the tyre mobility set.

● You should obtain professional assistance

››› .

1.4 bar (20 psi / 140 kPa) and higher:

● Set the tyre pressure to the correct value

again.

● Carefully resume your journey until you

reach the nearest specialised workshop with-

out exceeding 80 km/h (50 mph).

● Have the damaged tyre replaced. WARNING

Driving with an unsealed tyre is dangerous

and can cause accidents and serious injury.

● Do not continue driving if the tyre pressure

is 1.3 bar (19 psi / 130 kPa) and lower.

● Seek specialist assistance. Jump-starting

Jump leads The jump lead must have a sufficient wire

cross section.

If the engine fails to start because of a dis-

charged battery, the battery can be connec-

ted to the battery of another vehicle to start

the engine.

Jump leads

Jump leads must comply with standard

DIN

72553 (see cable manufacturer's instruc-

tion s).

The wire cross section must be at least

25 mm 2

for petrol engines and at least

35 mm 2

for diesel engines. Note

● The vehicles must not touch each other,

otherwise electricity could flow as soon as

the positive terminals are connected.

● The discharged battery must be properly

connected to the on-board network. 189

Technical specifications

Advice

Operation

Safety

Page 193 of 236

Emergencies

after the battery has thawed, battery acid

could leak and cause chemical burns. If a bat-

tery freezes, it should be replaced.

●

Keep sparks, flames and lighted cigarettes

away from batteries, danger of explosion.

Failure to comply could result in an explo-

sion.

● Observe the instructions provided by the

manufacturer of the jump leads.

● Do not connect the negative cable from the

other vehicle directly to the negative terminal

of the flat battery. The gas emitted from the

battery could be ignited by sparks. Danger of

explosion.

● Do not attach the negative cable from the

other vehicle to parts of the fuel system or to

the brake line.

● The non-insulated parts of the battery

clamps must not be allowed to touch. The

jump lead attached to the positive battery

terminal must not touch metal parts of the ve-

hicle, this can cause a short circuit.

● Position the leads in such a way that they

cannot come into contact with any moving

parts in the engine compartment.

● Do not lean on the batteries. This could re-

sult in chemical burns. Note

The vehicles must not touch each other, oth-

erwise electricity could flow as soon as the

positive terminals are connected. Towing and tow-starting

Tow-starting We recommend that you do

not tow-start your

v ehic

le. Jump-starting is preferable

››› page 189.

How

ever, if your vehicle has to be tow-

started:

– Engage 2 nd

or 3 rd

gear.

– Keep the clutch pressed down.

– Switch the ignition on.

– Once both vehicles are moving, release the

clutch.

– As soon as the engine starts, press the

clutch and move the gear lever into neutral.

This helps to prevent driving into the tow-

ing vehicle. WARNING

The risk of accidents is high when tow-start-

ing. The vehicle being towed can easily col-

lide with the towing vehicle. CAUTION

When tow-starting, fuel could enter the cata-

lytic converter and damage it. General notes

Please observe the following points if you

use a tow rope:

Notes for the driver of the towing vehicle

– Drive slowly at first until the tow rope is

taut. Then accelerate gradually.

– Begin and change gears cautiously. If you

are driving an automatic vehicle, accelerate

gently.

– Remember that the brake servo and power

steering are not working in the vehicle you

are towing. Brake sooner than normal and

pressing the pedal gently.

Notes for the driver of the towed vehicle

– Ensure that the tow rope remains taut at all

times when towing.

Tow rope or tow bar

It is easier and safer for the vehicle to be tow-

ed using a tow bar. You should only use a

tow-rope if you do not have a tow-bar.

A tow rope should be slightly elastic to re-

duce the loading on both vehicles. It is advis-

able to use a tow rope made of synthetic fi-

bre or similarly elastic material.

Attach the tow rope or the tow bar only to the

towline anchorages provided or a towing

bracket. »

191Technical specifications

Advice

Operation

Safety

Page 195 of 236

Emergencies

– Bolt the anchorage to its limit to the left, in

the dir ection of

the arrow ››› Fig. 165.

Re

ar towline anchorage

– Take the towline anchorage from the on-

board tool set.

– Remove the cover by pressing down on its

right-hand side.

– Bolt the anchorage to its limit to the left

, in

the direction of the arrow ››› Fig. 166.

Aft

er use, unscrew the towline anchorage

and put it back in the vehicle tool kit. Replace

the cover on the bumper. The towline anchor-

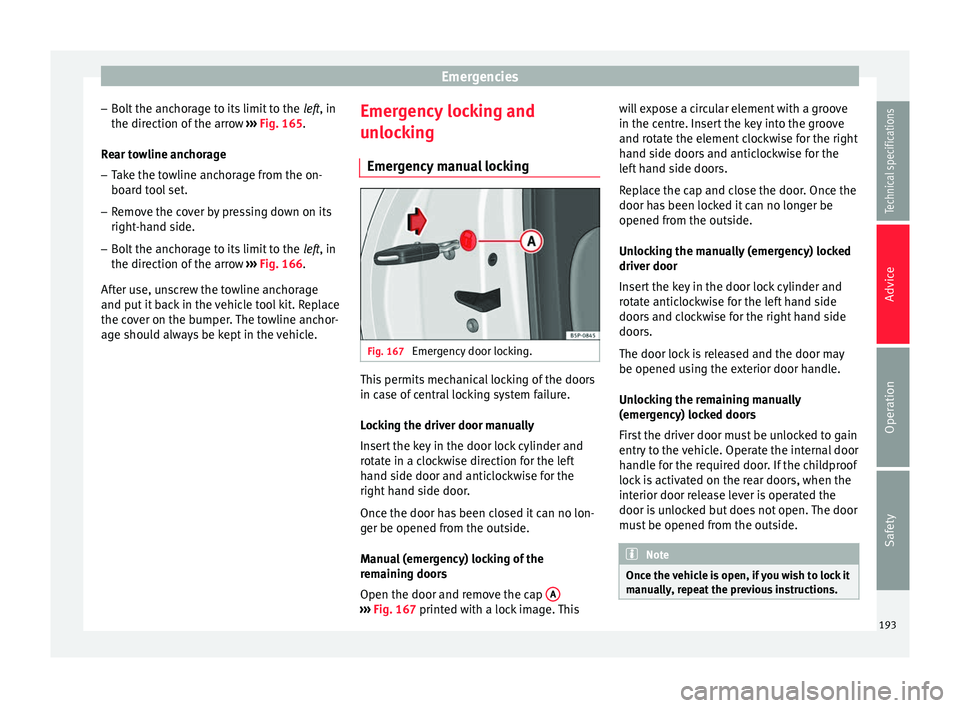

age should always be kept in the vehicle. Emergency locking and

unlocking

Emergency manual locking Fig. 167

Emergency door locking. This permits mechanical locking of the doors

in case of central locking system failure.

Locking the driver door manually

Insert the key in the door lock cylinder and

rotate in a clockwise direction for the left

hand side door and anticlockwise for the

right hand side door.

Once the door has been closed it can no lon-

ger be opened from the outside.

Manual (emergency) locking of the

remaining doors

Open the door and remove the cap

A ›››

Fig. 167 printed with a lock image. This w

i

ll expose a circular element with a groove

in the centre. Insert the key into the groove

and rotate the element clockwise for the right

hand side doors and anticlockwise for the

left hand side doors.

Replace the cap and close the door. Once the

door has been locked it can no longer be

opened from the outside.

Unlocking the manually (emergency) locked

driver door

Insert the key in the door lock cylinder and

rotate anticlockwise for the left hand side

doors and clockwise for the right hand side

doors.

The door lock is released and the door may

be opened using the exterior door handle.

Unlocking the remaining manually

(emergency) locked doors

First the driver door must be unlocked to gain

entry to the vehicle. Operate the internal door

handle for the required door. If the childproof

lock is activated on the rear doors, when the

interior door release lever is operated the

door is unlocked but does not open. The door

must be opened from the outside. Note

Once the vehicle is open, if you wish to lock it

manually, repeat the previous instructions. 193

Technical specifications

Advice

Operation

Safety

Page 197 of 236

Emergencies

If the windscreen wipers scratch , they should

be replaced if they are damaged, or cleaned

if they are soiled.

If this does not produce the desired results,

the setting angle of the windscreen wiper

arms might be incorrect. They should be

checked by a specialised workshop and cor-

rected if necessary. WARNING

Do not drive unless you have good visibility

through all windows!

● Clean the windscreen wiper blades and all

windows regularly.

● The wiper blades should be changed once

or twice a year. CAUTION

● Damaged or dirty windscreen wipers could

scratch the windscreen.

● Never use fuel, nail varnish remover, paint

thinner or similar products to clean the win-

dows. This could damage the windscreen

wiper blades.

● Never move the windscreen wiper or wind-

screen wiper arm manually. This could cause

damage.

● To prevent damage to the bonnet and the

windscreen wiper arms, the latter should only

be lifted off the windscreen when in service

position. Note

● The windscreen wiper arms can be moved

to the service position only when the bonnet

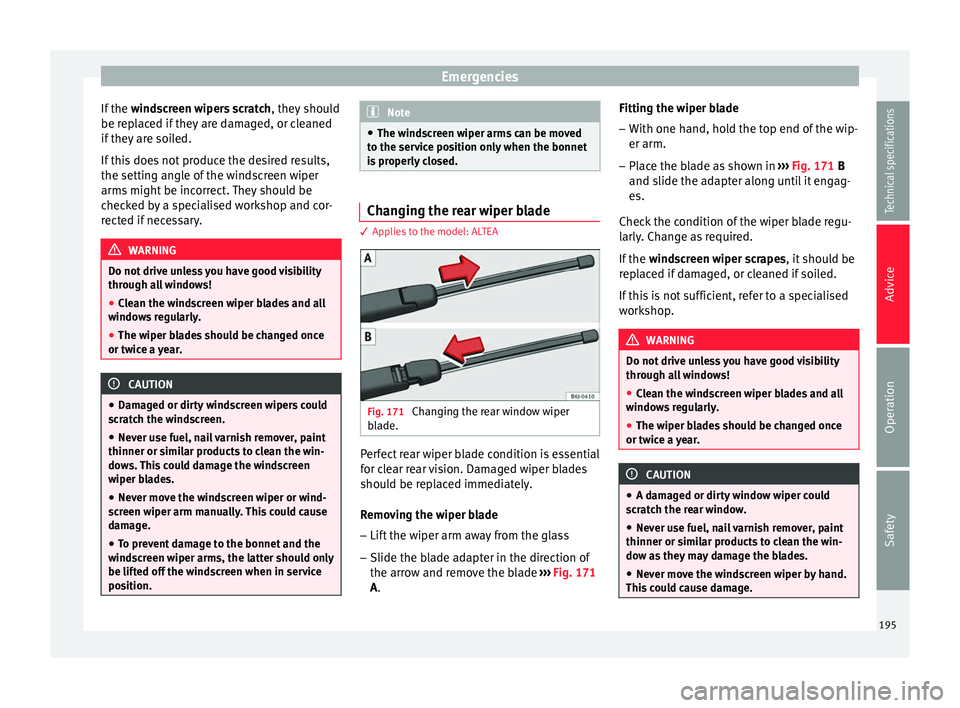

is properly closed. Changing the rear wiper blade

3 Applies to the model: ALTEA

Fig. 171

Changing the rear window wiper

blade. Perfect rear wiper blade condition is essential

for clear rear vision. Damaged wiper blades

should be replaced immediately.

Removing the wiper blade

– Lift the wiper arm away from the glass

– Slide the blade adapter in the direction of

the arrow and remove the blade ››› Fig. 171

A . Fittin

g the w iper blade

– With one hand, hold the top end of the wip-

er arm.

– Place the blade as shown in ››› Fig. 171

B

and slide the adapter along until it engag-

es.

Check the condition of the wiper blade regu-

larly. Change as required.

If the windscreen wiper scrapes, it should be

replaced if damaged, or cleaned if soiled.

If this is not sufficient, refer to a specialised

workshop. WARNING

Do not drive unless you have good visibility

through all windows!

● Clean the windscreen wiper blades and all

windows regularly.

● The wiper blades should be changed once

or twice a year. CAUTION

● A damaged or dirty window wiper could

scratch the rear window.

● Never use fuel, nail varnish remover, paint

thinner or similar products to clean the win-

dow as they may damage the blades.

● Never move the windscreen wiper by hand.

This could cause damage. 195

Technical specifications

Advice

Operation

Safety

Page 199 of 236

Fuses and bulbs

WARNING

The high voltages in the electrical system can

give serious electrical shocks, causing burns

and even death!

● Never touch the electrical wiring of the igni-

tion system.

● Take care not to cause short circuits in the

electrical system. WARNING

Using unsuitable fuses, repairing fuses or

bridging a current circuit without fuses can

cause a fire and serious injury.

● Never use a fuse with a higher value. Only

replace fuses with a fuse of the same amper-

age (same colour and markings) and size.

● Never repair a fuse.

● Never replace a fuse by a metal strip, staple

or similar. CAUTION

● To prevent damage to the vehicle's electric

system, before replacing a fuse turn off the

ignition, the lights and all electrical elements

and remove the key from the ignition.

● If you replace a fuse with higher-rating

fuse, you could cause damage to another part

of the electrical system.

● Protect the fuse boxes when open to pre-

vent the entry of dust or humidity as they can

damage the electrical system. Note

● One component may have more than one

fuse.

● Several components may run on a single

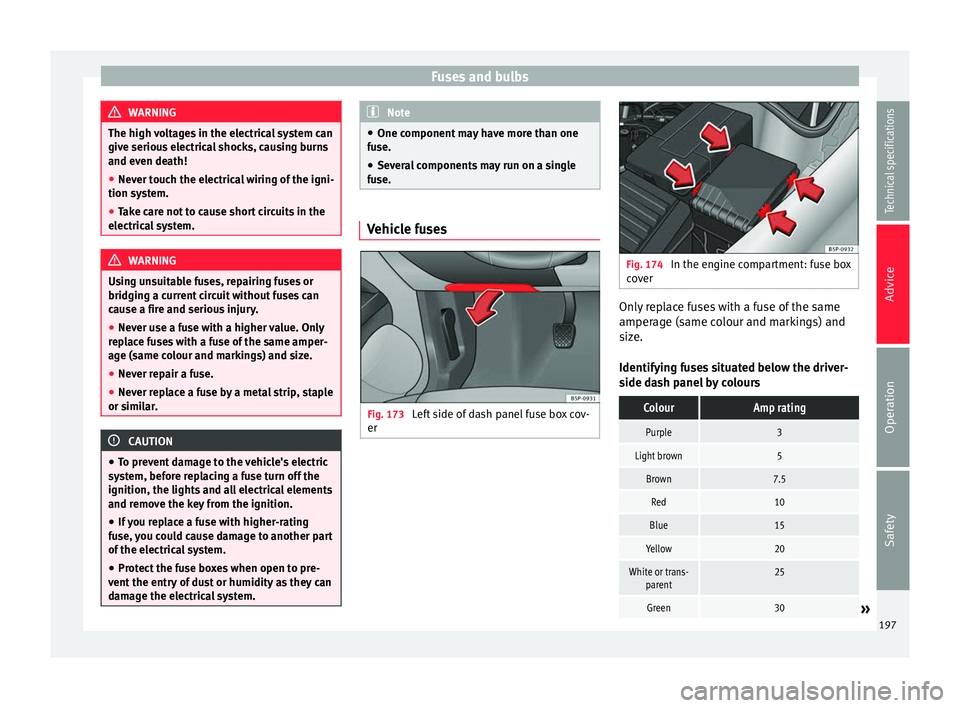

fuse. Vehicle fuses

Fig. 173

Left side of dash panel fuse box cov-

er Fig. 174

In the engine compartment: fuse box

cover Only replace fuses with a fuse of the same

amperage (same colour and markings) and

size.

Identifying fuses situated below the driver-

side dash panel by coloursColourAmp rating

Purple3

Light brown5

Brown7.5

Red10

Blue15

Yellow20

White or trans-

parent25

Green30» 197

Technical specifications

Advice

Operation

Safety