Seat Altea XL 2015 Owner's Manual

Manufacturer: SEAT, Model Year: 2015, Model line: Altea XL, Model: Seat Altea XL 2015Pages: 236, PDF Size: 4.23 MB

Page 191 of 236

Emergencies

● If the indicated pressure still cannot be

reached, the tyre is too badly damaged. The

tyre cannot be sealed with the anti-puncture

kit. Do not continue driving. You should ob-

tain professional assistance ››› .

● Disconnect the air compressor and unscrew

the flexible inflator tube from the tyre valve.

● When the tyre pressure is between 2.5 and

2.0 bars, immediately continue driving with-

out exceeding 80 km/h (50 mph).

● After 10 minutes

, Check the pressure again

›

›› page 189. WARNING

When inflating the wheel, the air compressor

and the inflator tube may become hot.

● Protect hands and skin from hot parts.

● Do not place the hot flexible inflator tube or

hot air compressor on flammable material.

● Allow them to cool before storing the de-

vice.

● If it is not possible to inflate the tyre to at

least 2.0 bars (29 psi / 200 kPa), the tyre is

too badly damaged. The sealant is not in a

good condition to seal the tyre. Do not con-

tinue driving. Seek specialist assistance. CAUTION

Switch off the air compressor after a maxi-

mum of 8 operational minutes to prevent it

from overheating! Before switching on the air compressor again, let it cool for several mi-

nutes.

Check after 10 minutes of driving

Screw the inflator tube

››› Fig. 162 5 again

and check the pressure on the gauge 6 .

1.3 bar (19 psi / 130 kPa) and lower:

● Stop the vehicle! The tyre cannot be sealed

sufficiently with the tyre mobility set.

● You should obtain professional assistance

››› .

1.4 bar (20 psi / 140 kPa) and higher:

● Set the tyre pressure to the correct value

again.

● Carefully resume your journey until you

reach the nearest specialised workshop with-

out exceeding 80 km/h (50 mph).

● Have the damaged tyre replaced. WARNING

Driving with an unsealed tyre is dangerous

and can cause accidents and serious injury.

● Do not continue driving if the tyre pressure

is 1.3 bar (19 psi / 130 kPa) and lower.

● Seek specialist assistance. Jump-starting

Jump leads The jump lead must have a sufficient wire

cross section.

If the engine fails to start because of a dis-

charged battery, the battery can be connec-

ted to the battery of another vehicle to start

the engine.

Jump leads

Jump leads must comply with standard

DIN

72553 (see cable manufacturer's instruc-

tion s).

The wire cross section must be at least

25 mm 2

for petrol engines and at least

35 mm 2

for diesel engines. Note

● The vehicles must not touch each other,

otherwise electricity could flow as soon as

the positive terminals are connected.

● The discharged battery must be properly

connected to the on-board network. 189

Technical specifications

Advice

Operation

Safety

Page 192 of 236

Advice

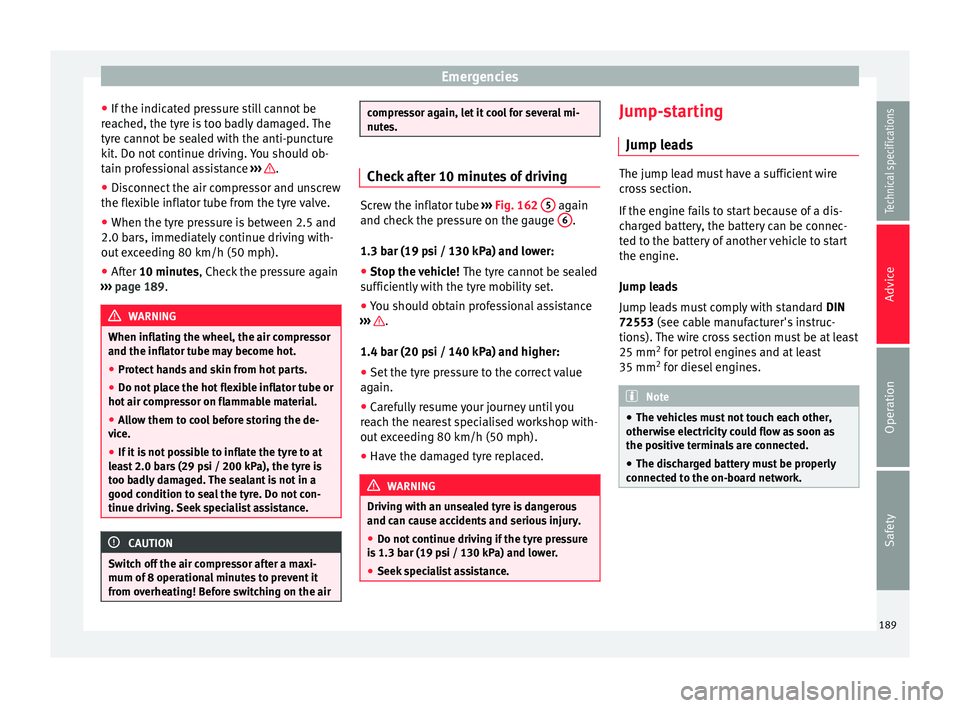

How to jump start: description Fig. 163

Diagram of connections for vehicles

without Start-Stop system. Fig. 164

Diagram of connections for vehicles

with Start-Stop system. Jump lead terminal connections

1. Switch off the ignition of both vehicles

››› . 2. Connect one end of the

red jump lead to

the po s

itive + terminal of the vehicle

with the flat battery A

››› Fig. 163 .

3. C

onnect the other end of the red

jump

lead to the positive terminal + in the ve-

hicle providing assistance B .

4. For vehicles without Start-Stop system:

connect one end of the black jump lead to

the negative terminal – in the vehicle

providing assistance B

››› Fig. 163 .

– For

vehicles with Start-Stop system: Con-

nect one end of the black jump lead X to a

suitable ground terminal, a solid piece of

metal in the engine block, or to the engine

block itself ››› Fig. 164.

5. Connect the other end of the black jump

lead X to a solid metal component bolted

to the engine block or to the engine block

itself of the vehicle with the flat battery.

Do not connect it to a point near the bat-

tery A .

6. Position the leads in such a way that they cannot come into contact with any moving

parts in the engine compartment.

Starting

7. Start the vehicle's engine with the boost- ing battery and let it run at idling speed.

8. Start the engine of the vehicle with the flat battery and wait 2 or 3 minutes until the

engine is “running”. Removing the jump leads

9. Before you remove the jump leads, switch

off the dipped beam headlights (if they

are switched on).

10.Turn on the heater blower and heated rear window in the vehicle with the flat battery.

This helps minimise voltage peaks which

are generated when the leads are discon-

nected.

11. When the engine is running, disconnect

the l e

ads in reverse order to the details

given above.

Connect the battery clamps so they have

good metal-to-metal contact with the battery

terminals.

If the engine fails to start, switch off the start-

er after about 10 seconds and try again after

about a minute. WARNING

● Please note the safety warnings referring to

working in the engine compartment

››› page 163, Working in the engine compart-

ment.

● The b att

ery providing assistance must have

the same voltage as the flat battery (12 V)

and approximately the same capacity (see

imprint on battery). Failure to comply could

result in an explosion.

● Never use jump leads when one of the bat-

teries is frozen. Danger of explosion! Even 190

Page 193 of 236

Emergencies

after the battery has thawed, battery acid

could leak and cause chemical burns. If a bat-

tery freezes, it should be replaced.

●

Keep sparks, flames and lighted cigarettes

away from batteries, danger of explosion.

Failure to comply could result in an explo-

sion.

● Observe the instructions provided by the

manufacturer of the jump leads.

● Do not connect the negative cable from the

other vehicle directly to the negative terminal

of the flat battery. The gas emitted from the

battery could be ignited by sparks. Danger of

explosion.

● Do not attach the negative cable from the

other vehicle to parts of the fuel system or to

the brake line.

● The non-insulated parts of the battery

clamps must not be allowed to touch. The

jump lead attached to the positive battery

terminal must not touch metal parts of the ve-

hicle, this can cause a short circuit.

● Position the leads in such a way that they

cannot come into contact with any moving

parts in the engine compartment.

● Do not lean on the batteries. This could re-

sult in chemical burns. Note

The vehicles must not touch each other, oth-

erwise electricity could flow as soon as the

positive terminals are connected. Towing and tow-starting

Tow-starting We recommend that you do

not tow-start your

v ehic

le. Jump-starting is preferable

››› page 189.

How

ever, if your vehicle has to be tow-

started:

– Engage 2 nd

or 3 rd

gear.

– Keep the clutch pressed down.

– Switch the ignition on.

– Once both vehicles are moving, release the

clutch.

– As soon as the engine starts, press the

clutch and move the gear lever into neutral.

This helps to prevent driving into the tow-

ing vehicle. WARNING

The risk of accidents is high when tow-start-

ing. The vehicle being towed can easily col-

lide with the towing vehicle. CAUTION

When tow-starting, fuel could enter the cata-

lytic converter and damage it. General notes

Please observe the following points if you

use a tow rope:

Notes for the driver of the towing vehicle

– Drive slowly at first until the tow rope is

taut. Then accelerate gradually.

– Begin and change gears cautiously. If you

are driving an automatic vehicle, accelerate

gently.

– Remember that the brake servo and power

steering are not working in the vehicle you

are towing. Brake sooner than normal and

pressing the pedal gently.

Notes for the driver of the towed vehicle

– Ensure that the tow rope remains taut at all

times when towing.

Tow rope or tow bar

It is easier and safer for the vehicle to be tow-

ed using a tow bar. You should only use a

tow-rope if you do not have a tow-bar.

A tow rope should be slightly elastic to re-

duce the loading on both vehicles. It is advis-

able to use a tow rope made of synthetic fi-

bre or similarly elastic material.

Attach the tow rope or the tow bar only to the

towline anchorages provided or a towing

bracket. »

191Technical specifications

Advice

Operation

Safety

Page 194 of 236

Advice

Driving style

Towing requires some experience, especially

when using a tow rope. Both drivers should

be familiar with the technique required for

towing. Inexperienced drivers should not at-

tempt to tow.

Do not pull too hard with the towing vehicle

and take care to avoid jerking the tow rope.

When towing on an unpaved road, there is al-

ways a risk of overloading and damaging the

anchorage points.

The ignition of the vehicle being towed must

be switched on to prevent the steering wheel

from locking and also to allow the use of the

turn signals, horn, windscreen wipers and

washers.

The brake servo only works when the engine

is running. When not running, you must ap-

ply considerably more pressure to the brake

pedal.

As the power assisted steering does not work

if the engine is not running, you will need

more strength to steer than you normally

would.

● The vehicle must not be towed faster than

50 km/h (31 mph).

Towing vehicles with an automatic gearbox

● Put the selector lever into position “N”.

● Do not drive faster than 50 km/h (31 mph). ●

Do not tow further than 50 km.

● If a breakdown vehicle is used, the vehicle

must be towed with the front wheels raised. Note

● Observe legal requirements when towing or

tow-starting.

● Switch on the hazard warning lights of both

vehicles. However, observe any regulations

to the contrary.

● For technical reasons, vehicles with an au-

tomatic gearbox must not be tow-started.

● If there is no lubricant in the gearbox as the

result of a fault, you must raise the driven

wheels while the vehicle is being towed.

● If the vehicle has to be towed more than

50 km, the front wheels should be raised dur-

ing towing, and towing should be carried out

by a qualified person.

● The steering wheel is locked when the vehi-

cle has no electrical power. The vehicle must

then be towed with the front wheels raised.

Towing should be carried out by a qualified

person.

● The towline anchorage should always be

kept in the vehicle. Please refer to the notes

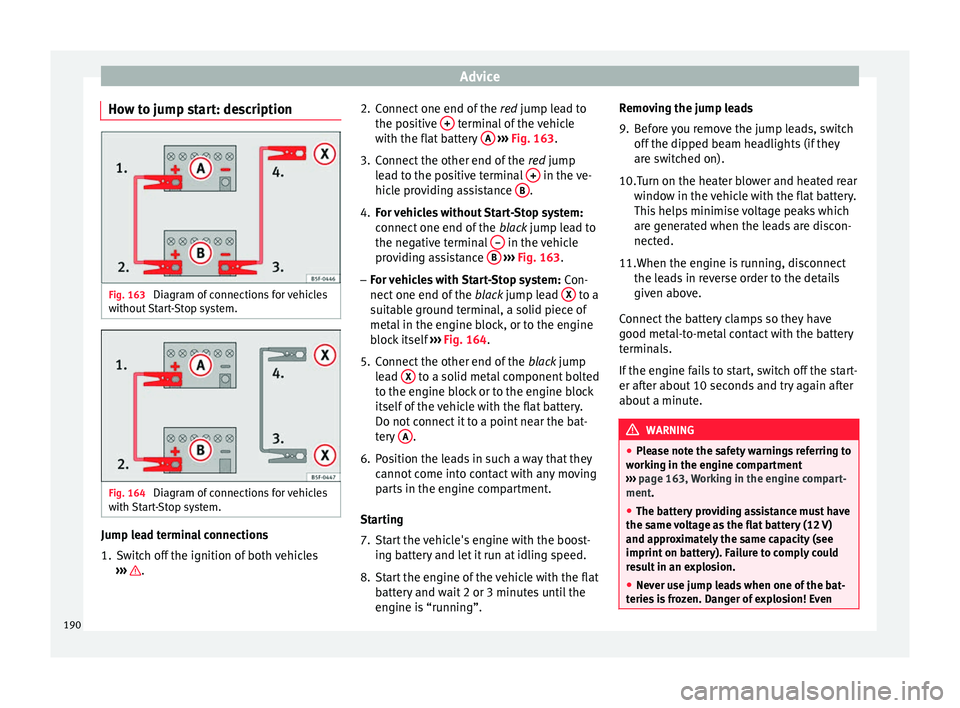

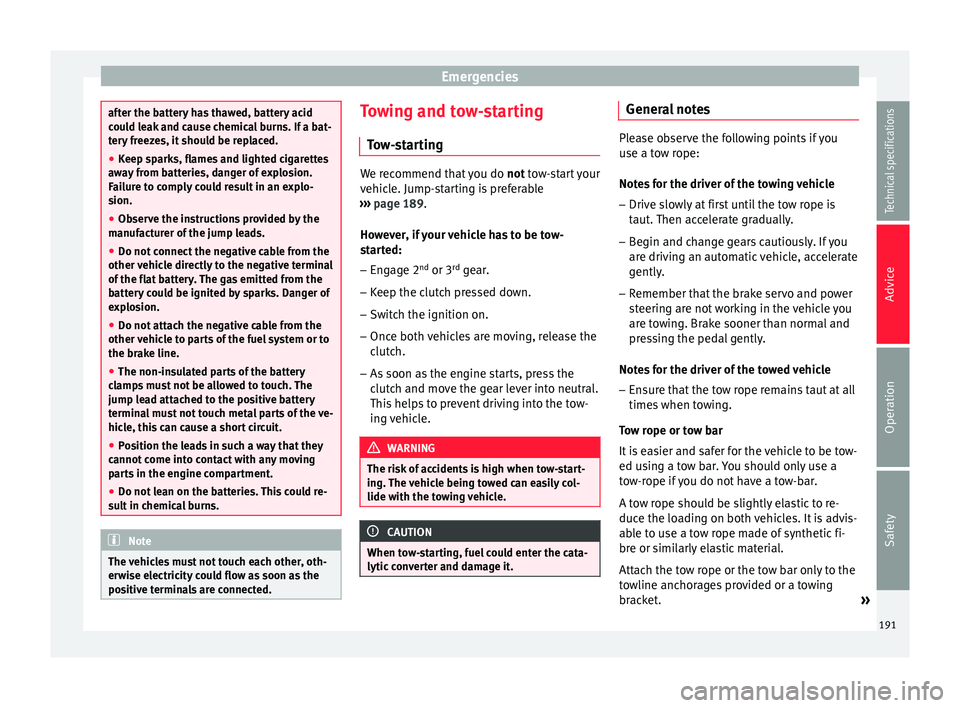

on ››› page 191, Tow-starting. Towline anchorages

Fig. 165

Fitting the front towline anchorage

to the front right section of the vehicle. Fig. 166

Fitting the towline anchorage to the

rear of the vehicle. Front towline anchorage

– Take the towline anchorage from the on-

board tool set.

– Remove the cover by pressing down on its

left-hand side.

192

Page 195 of 236

Emergencies

– Bolt the anchorage to its limit to the left, in

the dir ection of

the arrow ››› Fig. 165.

Re

ar towline anchorage

– Take the towline anchorage from the on-

board tool set.

– Remove the cover by pressing down on its

right-hand side.

– Bolt the anchorage to its limit to the left

, in

the direction of the arrow ››› Fig. 166.

Aft

er use, unscrew the towline anchorage

and put it back in the vehicle tool kit. Replace

the cover on the bumper. The towline anchor-

age should always be kept in the vehicle. Emergency locking and

unlocking

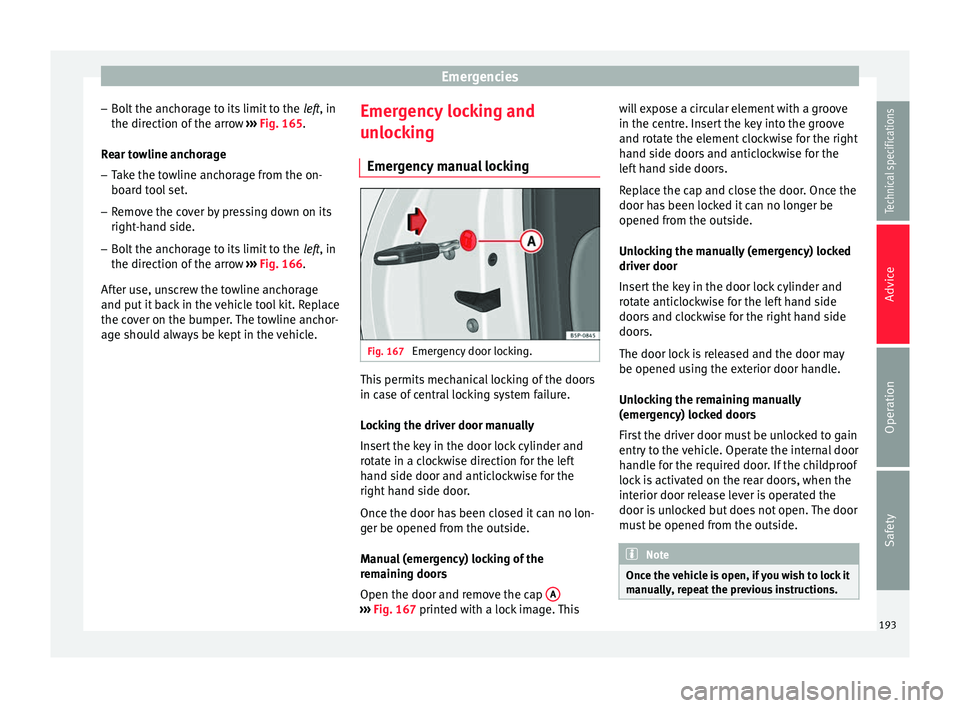

Emergency manual locking Fig. 167

Emergency door locking. This permits mechanical locking of the doors

in case of central locking system failure.

Locking the driver door manually

Insert the key in the door lock cylinder and

rotate in a clockwise direction for the left

hand side door and anticlockwise for the

right hand side door.

Once the door has been closed it can no lon-

ger be opened from the outside.

Manual (emergency) locking of the

remaining doors

Open the door and remove the cap

A ›››

Fig. 167 printed with a lock image. This w

i

ll expose a circular element with a groove

in the centre. Insert the key into the groove

and rotate the element clockwise for the right

hand side doors and anticlockwise for the

left hand side doors.

Replace the cap and close the door. Once the

door has been locked it can no longer be

opened from the outside.

Unlocking the manually (emergency) locked

driver door

Insert the key in the door lock cylinder and

rotate anticlockwise for the left hand side

doors and clockwise for the right hand side

doors.

The door lock is released and the door may

be opened using the exterior door handle.

Unlocking the remaining manually

(emergency) locked doors

First the driver door must be unlocked to gain

entry to the vehicle. Operate the internal door

handle for the required door. If the childproof

lock is activated on the rear doors, when the

interior door release lever is operated the

door is unlocked but does not open. The door

must be opened from the outside. Note

Once the vehicle is open, if you wish to lock it

manually, repeat the previous instructions. 193

Technical specifications

Advice

Operation

Safety

Page 196 of 236

Advice

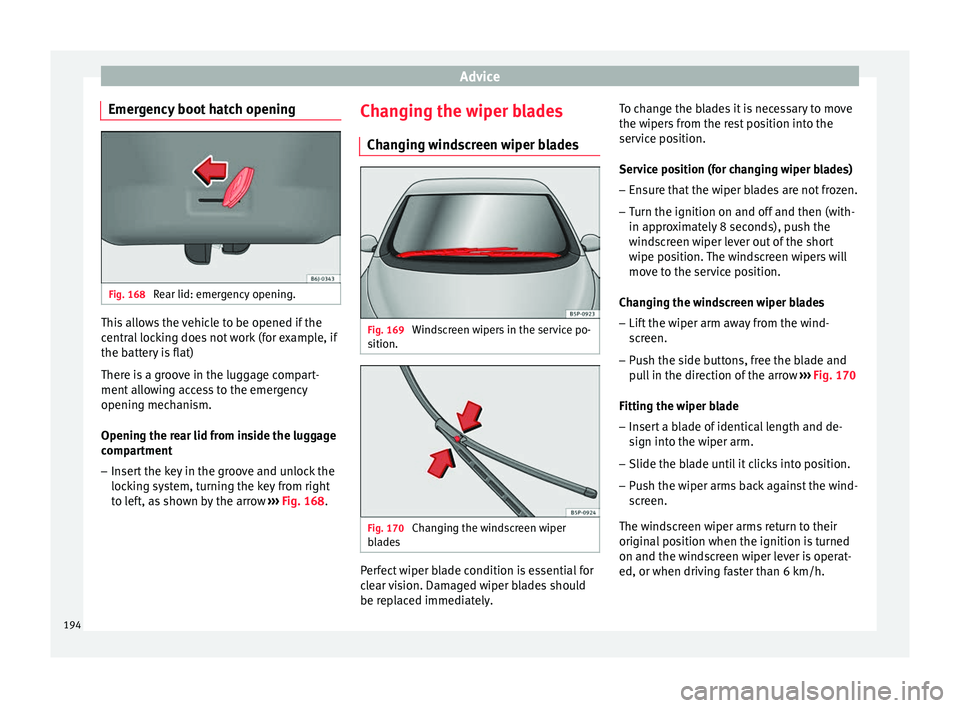

Emergency boot hatch opening Fig. 168

Rear lid: emergency opening. This allows the vehicle to be opened if the

central locking does not work (for example, if

the battery is flat)

There is a groove in the luggage compart-

ment allowing access to the emergency

opening mechanism.

Opening the rear lid from inside the luggage

compartment

– Insert the key in the groove and unlock the

locking system, turning the key from right

to left, as shown by the arrow ››› Fig. 168 .Ch

an ging the wiper blades

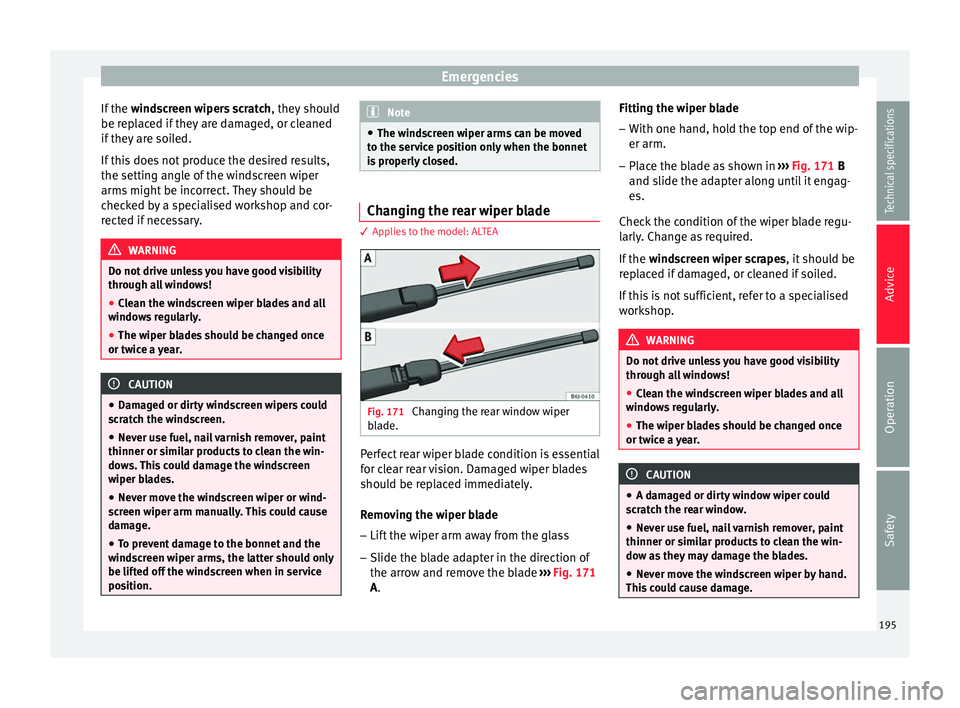

Changing windscreen wiper blades Fig. 169

Windscreen wipers in the service po-

sition. Fig. 170

Changing the windscreen wiper

blades Perfect wiper blade condition is essential for

clear vision. Damaged wiper blades should

be replaced immediately.To change the blades it is necessary to move

the wipers from the rest position into the

service position.

Service position (for changing wiper blades)

–

Ensure that the wiper blades are not frozen.

– Turn the ignition on and off and then (with-

in approximately 8 seconds), push the

windscreen wiper lever out of the short

wipe position. The windscreen wipers will

move to the service position.

Changing the windscreen wiper blades – Lift the wiper arm away from the wind-

screen.

– Push the side buttons, free the blade and

pull in the direction of the arrow ››› Fig. 170

Fitting the wiper blade

– Insert a blade of identical length and de-

sign into the wiper arm.

– Slide the blade until it clicks into position.

– Push the wiper arms back against the wind-

screen.

The windscreen wiper arms return to their

original position when the ignition is turned

on and the windscreen wiper lever is operat-

ed, or when driving faster than 6 km/h.

194

Page 197 of 236

Emergencies

If the windscreen wipers scratch , they should

be replaced if they are damaged, or cleaned

if they are soiled.

If this does not produce the desired results,

the setting angle of the windscreen wiper

arms might be incorrect. They should be

checked by a specialised workshop and cor-

rected if necessary. WARNING

Do not drive unless you have good visibility

through all windows!

● Clean the windscreen wiper blades and all

windows regularly.

● The wiper blades should be changed once

or twice a year. CAUTION

● Damaged or dirty windscreen wipers could

scratch the windscreen.

● Never use fuel, nail varnish remover, paint

thinner or similar products to clean the win-

dows. This could damage the windscreen

wiper blades.

● Never move the windscreen wiper or wind-

screen wiper arm manually. This could cause

damage.

● To prevent damage to the bonnet and the

windscreen wiper arms, the latter should only

be lifted off the windscreen when in service

position. Note

● The windscreen wiper arms can be moved

to the service position only when the bonnet

is properly closed. Changing the rear wiper blade

3 Applies to the model: ALTEA

Fig. 171

Changing the rear window wiper

blade. Perfect rear wiper blade condition is essential

for clear rear vision. Damaged wiper blades

should be replaced immediately.

Removing the wiper blade

– Lift the wiper arm away from the glass

– Slide the blade adapter in the direction of

the arrow and remove the blade ››› Fig. 171

A . Fittin

g the w iper blade

– With one hand, hold the top end of the wip-

er arm.

– Place the blade as shown in ››› Fig. 171

B

and slide the adapter along until it engag-

es.

Check the condition of the wiper blade regu-

larly. Change as required.

If the windscreen wiper scrapes, it should be

replaced if damaged, or cleaned if soiled.

If this is not sufficient, refer to a specialised

workshop. WARNING

Do not drive unless you have good visibility

through all windows!

● Clean the windscreen wiper blades and all

windows regularly.

● The wiper blades should be changed once

or twice a year. CAUTION

● A damaged or dirty window wiper could

scratch the rear window.

● Never use fuel, nail varnish remover, paint

thinner or similar products to clean the win-

dow as they may damage the blades.

● Never move the windscreen wiper by hand.

This could cause damage. 195

Technical specifications

Advice

Operation

Safety

Page 198 of 236

Advice

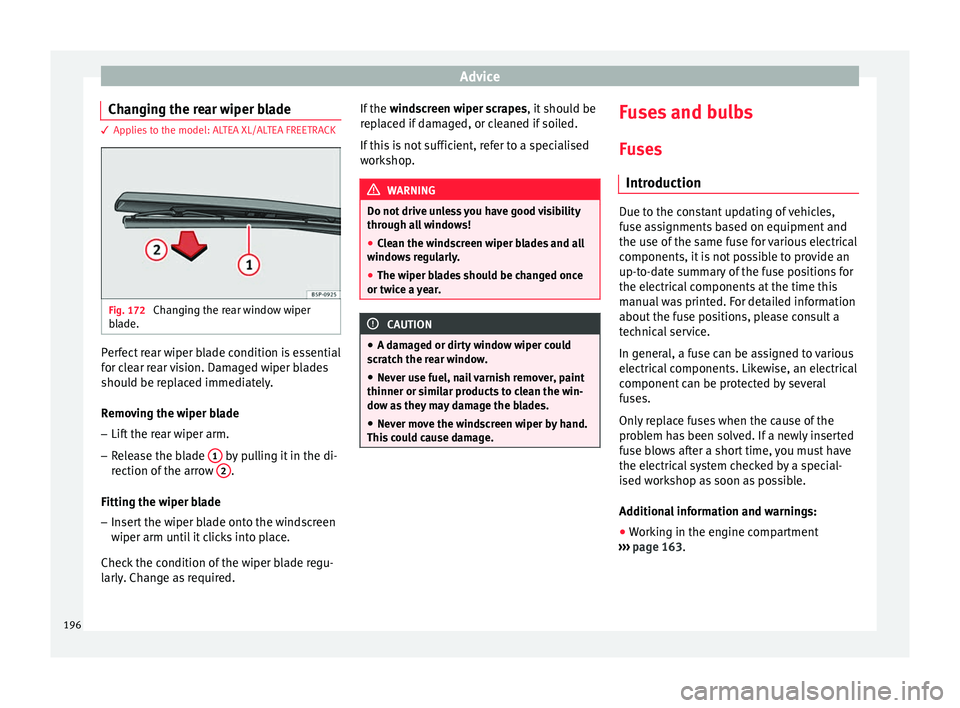

Changing the rear wiper blade 3 Applies to the model: ALTEA XL/ALTEA FREETRACK

Fig. 172

Changing the rear window wiper

blade. Perfect rear wiper blade condition is essential

for clear rear vision. Damaged wiper blades

should be replaced immediately.

Removing the wiper blade

– Lift the rear wiper arm.

– Release the blade 1 by pulling it in the di-

rection of the arrow 2 .

Fitting the wiper blade – Insert the wiper blade onto the windscreen

wiper arm until it clicks into place.

Check the condition of the wiper blade regu-

larly. Change as required. If the

windscreen wiper scrapes, it should be

replaced if damaged, or cleaned if soiled.

If this is not sufficient, refer to a specialised

workshop. WARNING

Do not drive unless you have good visibility

through all windows!

● Clean the windscreen wiper blades and all

windows regularly.

● The wiper blades should be changed once

or twice a year. CAUTION

● A damaged or dirty window wiper could

scratch the rear window.

● Never use fuel, nail varnish remover, paint

thinner or similar products to clean the win-

dow as they may damage the blades.

● Never move the windscreen wiper by hand.

This could cause damage. Fuses and bulbs

Fuses Introduction Due to the constant updating of vehicles,

fuse assignments based on equipment and

the use of the same fuse for various electrical

components, it is not possible to provide an

up-to-date summary of the fuse positions for

the electrical components at the time this

manual was printed. For detailed information

about the fuse positions, please consult a

technical service.

In general, a fuse can be assigned to various

electrical components. Likewise, an electrical

component can be protected by several

fuses.

Only replace fuses when the cause of the

problem has been solved. If a newly inserted

fuse blows after a short time, you must have

the electrical system checked by a special-

ised workshop as soon as possible.

Additional information and warnings:

● Working in the engine compartment

››› page 163 .

196

Page 199 of 236

Fuses and bulbs

WARNING

The high voltages in the electrical system can

give serious electrical shocks, causing burns

and even death!

● Never touch the electrical wiring of the igni-

tion system.

● Take care not to cause short circuits in the

electrical system. WARNING

Using unsuitable fuses, repairing fuses or

bridging a current circuit without fuses can

cause a fire and serious injury.

● Never use a fuse with a higher value. Only

replace fuses with a fuse of the same amper-

age (same colour and markings) and size.

● Never repair a fuse.

● Never replace a fuse by a metal strip, staple

or similar. CAUTION

● To prevent damage to the vehicle's electric

system, before replacing a fuse turn off the

ignition, the lights and all electrical elements

and remove the key from the ignition.

● If you replace a fuse with higher-rating

fuse, you could cause damage to another part

of the electrical system.

● Protect the fuse boxes when open to pre-

vent the entry of dust or humidity as they can

damage the electrical system. Note

● One component may have more than one

fuse.

● Several components may run on a single

fuse. Vehicle fuses

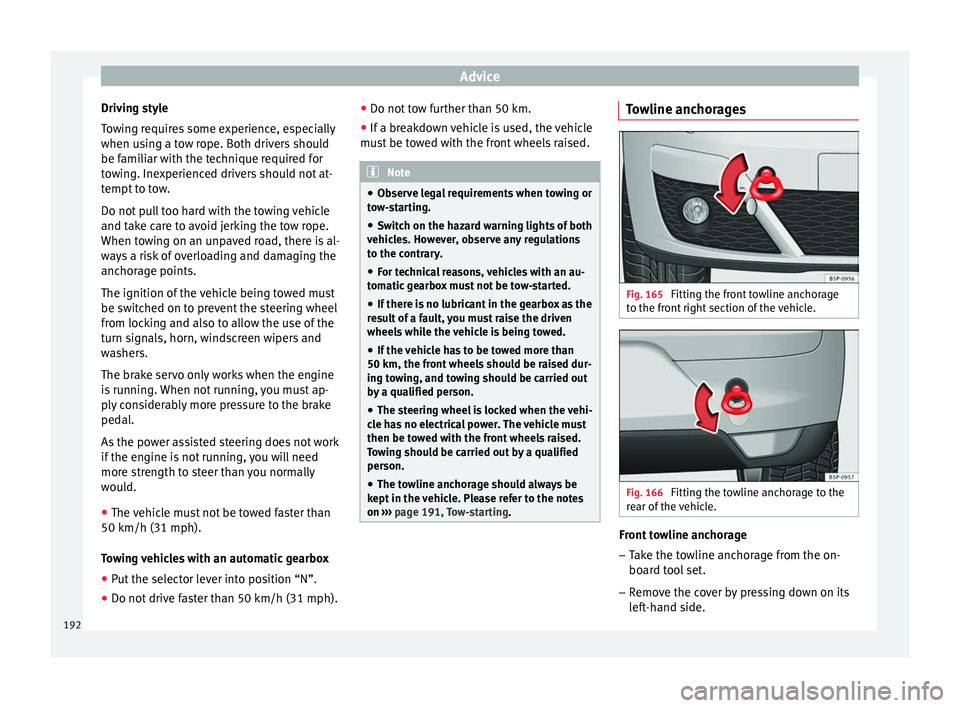

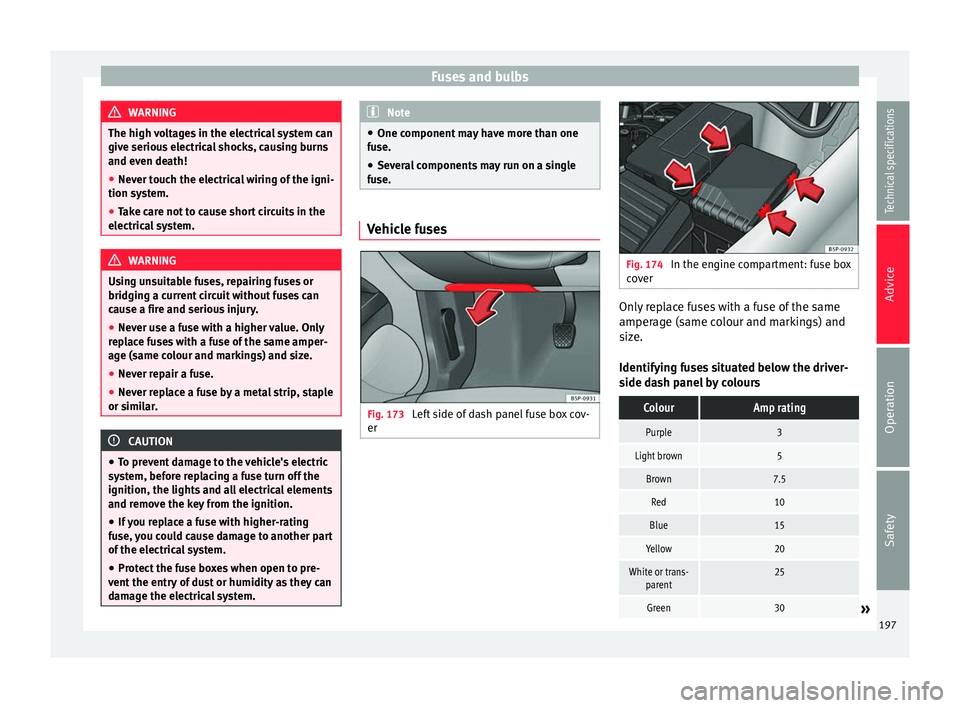

Fig. 173

Left side of dash panel fuse box cov-

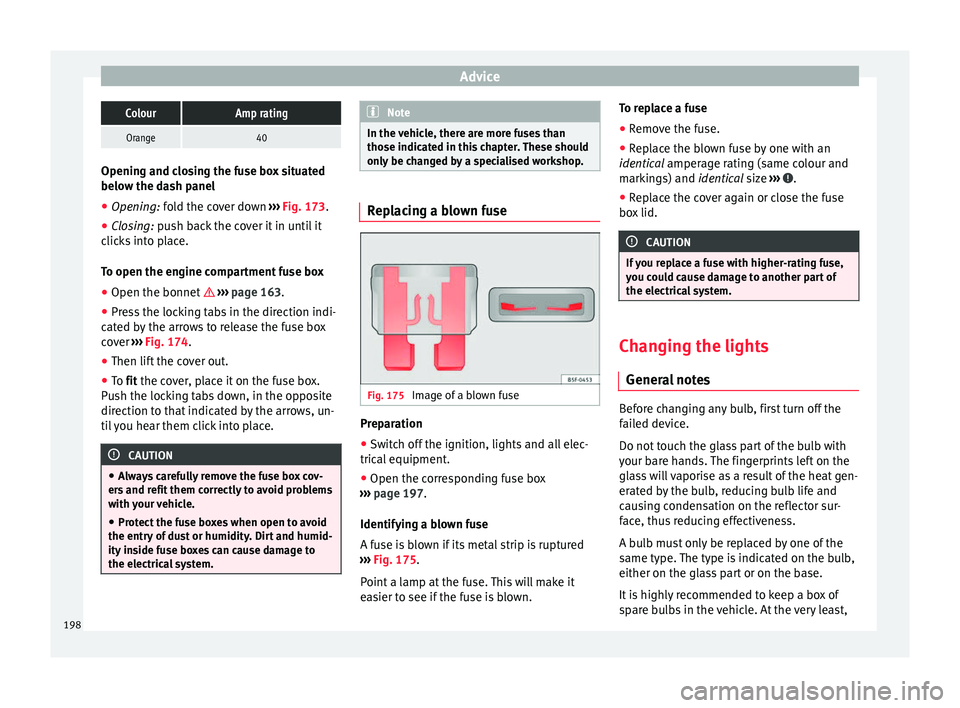

er Fig. 174

In the engine compartment: fuse box

cover Only replace fuses with a fuse of the same

amperage (same colour and markings) and

size.

Identifying fuses situated below the driver-

side dash panel by coloursColourAmp rating

Purple3

Light brown5

Brown7.5

Red10

Blue15

Yellow20

White or trans-

parent25

Green30» 197

Technical specifications

Advice

Operation

Safety

Page 200 of 236

AdviceColourAmp rating

Orange40

Opening and closing the fuse box situated

below the dash panel

●

Opening: fold the cover down ››

› Fig. 173.

● Closing:

push back the cover it in until it

clicks into place.

To open the engine compartment fuse box

● Open the bonnet ›››

page 163.

● Press the locking tabs in the direction indi-

cated by the arrows to release the fuse box

cover ›››

Fig. 174.

● Then lif t

the cover out.

● To

fit the cover, place it on the fuse box.

Push the locking tabs down, in the opposite

direction to that indicated by the arrows, un-

til you hear them click into place. CAUTION

● Always carefully remove the fuse box cov-

ers and refit them correctly to avoid problems

with your vehicle.

● Protect the fuse boxes when open to avoid

the entry of dust or humidity. Dirt and humid-

ity inside fuse boxes can cause damage to

the electrical system. Note

In the vehicle, there are more fuses than

those indicated in this chapter. These should

only be changed by a specialised workshop. Replacing a blown fuse

Fig. 175

Image of a blown fuse Preparation

● Switch off the ignition, lights and all elec-

trical equipment.

● Open the corresponding fuse box

››› page 197 .

Identif y

ing a blown fuse

A fuse is blown if its metal strip is ruptured

››› Fig. 175

.

Point a lamp at the fuse. This will make it

easier to see if the fuse is blown. To replace a fuse

● Remove the fuse.

● Replace the blown fuse by one with an

identical amperage rating (same colour and

mark

ings) and identical size ››› .

● Replace the cover again or close the fuse

box lid. CAUTION

If you replace a fuse with higher-rating fuse,

you could cause damage to another part of

the electrical system. Changing the lights

General notes Before changing any bulb, first turn off the

failed device.

Do not touch the glass part of the bulb with

your bare hands. The fingerprints left on the

glass will vaporise as a result of the heat gen-

erated by the bulb, reducing bulb life and

causing condensation on the reflector sur-

face, thus reducing effectiveness.

A bulb must only be replaced by one of the

same type. The type is indicated on the bulb,

either on the glass part or on the base.

It is highly recommended to keep a box of

spare bulbs in the vehicle. At the very least,

198