ACC Seat Arona 2018 Service Manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2018, Model line: Arona, Model: Seat Arona 2018Pages: 316, PDF Size: 6.77 MB

Page 96 of 316

Safety

Categorisation of child seats into

gr oup

s Use only child seats that are officially ap-

pro

v

ed and suitable for the child.

These seats are subject to the ECE-R 44 or

ECE-R 129 standard. ECE-R stands for: Eco-

nomic Commission for Europe Regulation.

The child seats are grouped into 5 catego-

ries:

Group 0: Up to 10 kg (up to around 9

months)

Group 0+: Up to 13 kg (up to around 18

months)

Group 1: from 9 to 18 kg (up to approx. 4

years old)

Group 2: from 15 to 25 kg (up to approx. 7

years old)

Group 3: From 22 to 36 kg (over around 7

years old)

Child seats that have been tested and ap-

proved under the ECE-R 44 or ECE-R 129

standard bear the test mark ECE-R 44 or ECE-

R 129 on the seat (the letter E in a circle with

the test number below it).

Follow the manufacturer's instructions and

observe any statutory requirements when in-

stalling and using child seats. We recommend you to always include the

manuf

act

urer's Child Seat Instruction Manual

together with the on-board documentation.

SEAT recommends you use child seats from

the Original Accessories Catalogue . These

child seats have been designed and tested

for use in SEAT vehicles. You can find the

right child seat for your model and age group

at SEAT dealers.

Child seats by approval category

Child seats may have the approval category

of universal, semi-universal, vehicle specific

(all according to the ECE-R 44 standard) or i-

Size (according to the ECE-R 129 standard).

● Universal: Child se

ats with universal appro-

val can be installed in all vehicles. There is

no need to consult any list of models. In the

case of universal approval for ISOFIX, the

child seat is additionally provided with a Top

Tether belt.

● Semi-universal: semi-univer

sal approval, in

addition to the standard requirements of uni-

versal approval, requires safety devices to

lock the child seat, which require additional

testing. Child seats with semi-universal ap-

proval include a list of vehicle models for

which they can be installed.

● Vehicle-specific: vehic

le-specific approval

requires a dynamic test of the child seat for

each vehicle model separately. Child seats

with vehicle-specific approval also include a list of vehicle models for which they can be

inst

alled.

● i-Size: Child seats with i-Size approval must

meet the r

equirements prescribed in the ECE-

R 129 standard in relation to installation and

safety. Child seat manufacturers can tell you

which seats have i-Size approval for this vehi-

cle.

Attachment systems Depending on the country, different attach-

ment

sy

s

tems are used for safely installing

child seats.

Attachment systems overview

● ISOFIX: ISOFIX is

a standardised attach-

ment system allowing quick and safe attach-

ment of child seats in the vehicle. ISOFIX at-

tachment establishes a rigid connection be-

tween the child seat and the car body.

The child seat has two rigid attachment clips,

called connectors. These connectors are fit-

ted into the ISOFIX attachment rings found

between the seat cushion and the backrest of

the vehicle's back seat (on the sides). ISOFIX

attachment systems are used mainly in Eu-

rope ›››

page 27. If necessary, ISOFIX at-

tachment may have to be supplemented with

a Top Tether belt or a support bracket.

94

Page 98 of 316

Safety

Event Data Recorder D e

s

cription and operation Your vehicle has an event data recorder

(EDR).

The EDR’s f

u

nction is to record data in the

event of a mild or serious accident. These da-

ta are used to support the analysis of how

different vehicle systems behaved.

The EDR records, over a reduced time range

(normally 10 seconds or less), dynamic driv-

ing data and data from the restraint systems,

such as:

● How different vehicle systems worked.

● Whether the driver and the occupants were

we arin

g their seatbelts.

● How hard the acceleration or brake pedal

was

pressed.

● Vehicle speed.

These dat

a will provide a better understand-

ing of the circumstances of the accident.

Data from the driving assist systems are also

recorded. This includes data such as whether

the systems were inactive or active and if

such action had an impact on the vehicle’s

dynamic behaviour, changing its path in the

aforementioned situations, accelerating or

decelerating the vehicle. Depending on vehicle equipment, this in-

cludes

data from systems such as:

● Adaptive Cruise Control (ACC)

● Emergency brake assist system (Front As-

sis

t)

● Park Pilot system

The EDR data ar

e only recorded in specific ac-

cident situations. No data are recorded in

normal driving conditions.

No audio or video data inside or around the

vehicle are recorded. Under no circumstances

are personal data such as name, age, or gen-

der recorded. Nevertheless, third parties

(such as criminal proceedings authorities)

may relate the contents of the EDR data to

other data sources and create a personal ref-

erence in the context of an accident investi-

gation.

In order to read the EDR data it is necessary

to access (if legally permitted to do so) the

vehicle's ODB (“On-Board-Diagnose”) inter-

face while the vehicle is switched on.

SEAT will not have access to EDR data unless

the owner (or, in “Leasing” cases, the lessee

or hirer) gives their consent. There may be ex-

ceptions to this, depending on legal or con-

tractual provisions.

Due to legal requirements in safety-related

products, SEAT may use the EDR data for field

research and in order to improve vehicle sys- tem quality. Any data used for the purposes

of re

search will be treated anonymously (in

other words, no reference will be made to the

vehicle, their owner or the lessee/hirer).

96

Page 99 of 316

Self-help

Emergencies

Self -help

Emer g

ency equipment

Emergency warning triangle* The use of reflective warning triangles is

ob

lig

atory in emergencies in some countries.

As are the first aid kit and a set of spare light

bulbs.

The warning triangle is under the storage

compartment which is located under the lug-

gage compartment floor. Note

● The warnin g tri

angle is not part of the vehi-

cle's standard equipment.

● The warning triangle should meet legal re-

quirements. First-aid kit and fire extinguisher*

The first-aid kit can go in the storage com-

p

ar

tment

which is located under the luggage

compartment floor.

The fire extinguisher* is attached to the lug-

gage compartment carpet with Velcro. Note

● The firs t

-aid kit and the fire extinguisher

are not part of the vehicle's standard equip-

ment.

● The first aid kit must comply with legal re-

quirements.

● O

bserve the expiry date of the contents of

the first

aid kit. After it has expired you

should purchase a new one.

● The fire extinguisher must comply with le-

gal

requirements.

● Ensure that the fire extinguisher is fully

function

al. The fire extinguisher should,

therefore, be checked regularly. The sticker

on the fire extinguisher will inform you of the

next date for checking.

● Before acquiring accessories and emergen-

cy equipment see the in

structions in “Acces-

sories and spares” ››› page 259. Vehicle tools

Read the additional information carefully

› ›

›

page 65

Depending on the equipment, the tools and

anti-puncture kit* are stored under the floor

panel in the luggage compartment.

The tool kit includes:

● Adapter for anti-theft wheel bolts*

● Towline anchorage ●

Box s

panner for wheel bolts*

● Jack*

● Wire hook for pulling off the wheel cov-

ers* / wheel bo

lt cap clip.

Some of the items listed are only provided in

certain model versions, or are optional ex-

tras. WARNING

● The fact or

y-supplied jack is only designed

for changing wheels on this model. On no ac-

count attempt to use it for lifting heavier ve-

hicles or other loads. Risk of injury.

● Use the jack only on a firm, level ground.

● Never start the engine when the vehicle is

on the jack. Ri

sk of accident.

● If work is to be carried out underneath the

vehicl

e, this must be secured by suitable

means. Otherwise, there is a risk of injury. Note

The jack does not generally require any main-

ten anc

e. If required, it should be greased us-

ing universal type grease. 97

Technical data

Advice

Operation

Emergencies

Safety

Page 100 of 316

Emergencies

Tyre repair TM S

(T

yre Mobility System)* Read the additional information carefully

›› ›

page 64

The Anti-puncture kit* (Tyre Mobility System)

will reliably seal punctures caused by the

penetration of a foreign body of up to about

4 mm in diameter. Do not remove foreign ob-

jects, e.g. screws or nails, from the tyre.

After inserting the sealant residue in the tyre,

you must again check the tyre pressure about

10 minutes after starting the engine.

You should only use the tyre mobility set if

the vehicle is parked in a safe place, you are

familiar with the procedure and you have the

necessary tyre mobility set! Otherwise, you

should seek professional assistance.

Do not use the tyre sealant in the following

cases:

● If the wheel rim has been damaged.

● In outside temperatures below -20°C (-4°F).

● In the event of cuts or perforations in the

tyr e gr

eater than 4 mm.

● If you have been driving with very low pres-

sure or a c

ompletely flat tyre.

● If the sealant bottle has passed its use by

date. WARNING

Using the tyre mobility system can be dan-

ger ou

s, especially when filling the tyre at the

roadside. Please observe the following rules

to minimise the risk of injury:

● Stop the vehicle safely as soon as possible.

Park it

at a safe distance from surrounding

traffic to fill the tyre.

● Ensure the ground on which you park is flat

and solid.

● Al

l passengers and particularly children

must

keep a safe distance from the work area.

● Turn on the hazard warning lights to warn

other roa

d users.

● Use the tyre mobility system only if you are

famili

ar with the necessary procedures. Oth-

erwise, you should seek professional assis-

tance.

● The tyre mobility set is intended for tempo-

rary

emergency use only until you can reach

the nearest specialised workshop.

● Replace the repaired tyre with the tyre mo-

bility

set as soon as possible.

● The sealant is a health hazard and must be

cle

aned immediately if it comes into contact

with the skin.

● Always keep the tyre mobility set out of the

reac

h of small children.

● Never use a jack, even if it has been ap-

prov

ed for your vehicle.

● Always stop the engine, apply the hand-

brake l

ever firmly and engage gear if using a manual gearbox, in order to reduce the risk of

vehic

l

e involuntary movement. WARNING

A tyre filled with sealant does not have the

s ame per f

ormance properties as a conven-

tional tyre.

● Never drive faster than 80 km/h (50 mph).

● Avoid heavy acceleration, hard braking and

fas

t cornering.

● Drive for only 10 minutes at a maximum

speed of 80

km/h (50 mph) and then check

the tyre. For the sake of the environment

Dispose of used or expired sealant observing

any l

egal requirements. Note

● A new bottle of se

alant can be purchased at

SEAT dealerships.

● Take into account the separate instruction

manual

of the tyre mobility set* manufactur-

er. 98

Page 101 of 316

Self-help

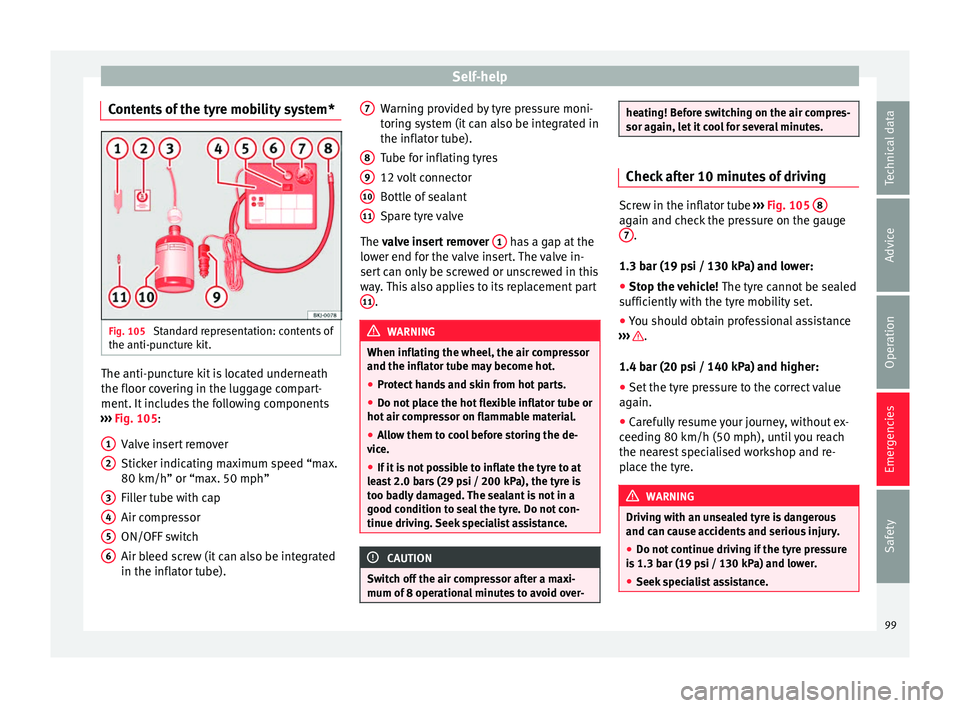

Contents of the tyre mobility system* Fig. 105

Standard representation: contents of

the anti-p u

nct

ure kit. The anti-puncture kit is located underneath

the floor c

o

v

ering in the luggage compart-

ment. It includes the following components

››› Fig. 105:

Valve insert remover

Sticker indicating maximum speed “max.

80 km/h” or “max. 50 mph”

Filler tube with cap

Air compressor

ON/OFF switch

Air bleed screw (it can also be integrated

in the inflator tube).

1 2

3

4

5

6 Warning provided by tyre pressure moni-

t

orin

g sy

stem (it can also be integrated in

the inflator tube).

Tube for inflating tyres

12 volt connector

Bottle of sealant

Spare tyre valve

The valve insert remover 1 has a gap at the

lo w

er end f

or the valve insert. The valve in-

sert can only be screwed or unscrewed in this

way. This also applies to its replacement part 11 .

WARNING

When inflating the wheel, the air compressor

and the inflat or t

ube may become hot.

● Protect hands and skin from hot parts.

● Do not place the hot flexible inflator tube or

hot air compr

essor on flammable material.

● Allow them to cool before storing the de-

vice.

● If

it is not possible to inflate the tyre to at

lea

st 2.0 bars (29 psi / 200 kPa), the tyre is

too badly damaged. The sealant is not in a

good condition to seal the tyre. Do not con-

tinue driving. Seek specialist assistance. CAUTION

Switch off the air compressor after a maxi-

mum of 8 oper ation

al minutes to avoid over- 7

8

9

10

11 heating! Before switching on the air compres-

sor again, l

et

it cool for several minutes. Check after 10 minutes of driving

Screw in the inflator tube

›››

Fig. 105 8 again and check the pressure on the gauge

7 .

1.3 bar (19 p s

i / 130 kPa) and lower:

● Stop the vehicle! The tyre c

annot be sealed

sufficiently with the tyre mobility set.

● You should obtain professional assistance

›››

.

1.4 b ar (20 p

s

i / 140 kPa) and higher:

● Set the tyre pressure to the correct value

again.

● Car

efully resume your journey, without ex-

ceeding 80 km/h (50 mph), u

ntil you reach

the nearest specialised workshop and re-

place the tyre. WARNING

Driving with an unsealed tyre is dangerous

and can c au

se accidents and serious injury.

● Do not continue driving if the tyre pressure

is 1.3

bar (19 psi / 130 kPa) and lower.

● Seek specialist assistance. 99

Technical data

Advice

Operation

Emergencies

Safety

Page 102 of 316

Emergencies

Changing the windscreen wiper

b l

a

des

Changing the windscreen and rear

window wiper blades Read the additional information carefully

›› ›

page 73.

Perfect windscreen wiper blade condition is

essential for clear vision. Damaged wiper

blades should be replaced immediately.

The windscreen wiper blades are supplied as

standard with a layer of graphite. This layer is

responsible for ensuring that the wipe is si-

lent. If the graphite layer is damaged, the

noise of the water as it is wiped across the

windscreen will be louder.

Check the condition of the wiper blades regu-

larly. If the wipers scrape across the glass ,

they should be changed if they are damaged,

or cleaned if they are dirty ››› .

If thi

s

does not produce the desired results,

the setting angle of the windscreen wiper

arms might be incorrect. They should be

checked by a specialised workshop and cor-

rected if necessary. WARNING

Do not drive unless you have good visibility

through a l

l windows! ●

Cle

an the windscreen wiper blades and all

windows regularly.

● The wiper blades should be changed once

or twice a

year. CAUTION

● Dam aged or dir

ty windscreen wipers could

scratch the glass.

● Never use fuel, nail varnish remover, paint

thinner or simil

ar products to clean the win-

dows. This could damage the windscreen

wiper blades.

● Never move any windscreen wiper by hand.

This c

ould cause damage.

● To prevent damage to the bonnet and the

winds

creen wiper arms, the latter should only

be lifted off the windscreen when in service

position. Note

● The wind s

creen wiper arms can be moved

to the service position only when the bonnet

is properly closed.

● You can also use the service position, for

examp

le, if you want to fix a cover over the

windscreen in the winter to keep it clear of

ice. Towing or tow-starting

Gener a

l

information Read the additional information carefully

›› ›

page 70.

Tow-starting means starting the engine of

the vehicle while another pulls it.

Towing means one vehicle pulling another

that is not roadworthy.

If the vehicle comes with the Keyless Access

system, towing is only allowed with the igni-

tion on!

The vehicle battery drains if the vehicle is

towed with the engine switched off and the

ignition connected. Depending on the battery

charge status, the drop in voltage may be so

large, even after just a few minutes, that no

electrical device in the vehicle may work e.g.

the hazard warning lights. In vehicles with

the Keyless Access system, the steering

wheel could lock up. WARNING

If the vehicle has no electrical power, the

brak e light

s, turn signals and all other lights

will no longer function. Do not have the vehi-

cle towed away. Failure to follow this instruc-

tion could result in an accident. 100

Page 103 of 316

Self-help

WARNING

The risk of accidents is high when tow-start-

ing, f or e

xample, the towed vehicle can easily

be driven into the towing vehicle. CAUTION

If there is no oil in the gearbox or no lubricant

in the autom atic

transmission the car may

only be towed with the driven wheels lifted

clear of the road, or transported on a special

car transporter or trailer. CAUTION

Do not tow a vehicle for more than 50 m in at-

tempt t

o start it. There is risk of damage to

the catalytic converter. Note

● Ple a

se observe related legal requirements.

● Switch on the hazard warning lights of both

vehicl

es. However, observe any regulations

to the contrary.

● The tow rope must not be twisted. Other-

wise the fr

ont tow line anchorage could be

pulled off the vehicle. Indications for tow-starting

Vehicle's should not generally be tow-star-

t

ed.

The jump s

tart should be used instead

››› page 71. For technical reasons, towing the following

vehicl

es is not allowed:

● Vehicles with an automatic gearbox.

● If the vehicle battery is discharged, be-

cause in

vehicles with the Keyless Access

locking and ignition system the steering re-

mains locked and the electronic parking

brake cannot be deactivated nor can the elec-

tronic lock of the steering column be re-

leased if they are activated.

● If the battery is flat, it is possible that the

engine contr

ol units may not operate correct-

ly.

However, if the vehicle must absolutely be

tow-started (in the case of manual gearbox-

es):

● Engage the 2nd or 3rd gear.

● Keep the clutch pressed down.

● Switch on the ignition and the hazard warn-

ing lights.

● Once both

vehicles are moving, release the

clutc

h.

● Once the engine starts, press the clutch

and diseng

age the gear to avoid colliding

with the towing vehicle. Note

The vehicle can only be tow-started if the

electr onic

parking brake and, if appropriate,

the electronic lock of the steering column are deactivated. If the vehicle has no power sup-

ply

or ther

e is an electric system fault, the

engine must be tow-started to deactivate the

electronic parking brake and the electronic

lock of the steering column. 101

Technical data

Advice

Operation

Emergencies

Safety

Page 105 of 316

Self-help

WARNING

● If the t o

wline anchorage is not screwed in

as far as the stop, there is a risk of the screw

connection shearing off during towing (acci-

dent risk).

● If your car has a towing bracket, only use

speci

al towing ropes. Risk of accident! CAUTION

In vehicles fitted with a towing bracket, only

use s pec

ial tow bars to prevent damage to

the ball joint. These tow bars have been spe-

cially approved for use with towing brackets. Towing vehicles with a manual gear-

bo

x Towing is relatively straightforward.

Pl

e

a

se observe the relevant instructions

››› page 100.

The vehicle can be towed using a tow bar or

tow rope in the normal way, with all four

wheels on the road; it can also be towed with

either the front or rear wheels lifted off the

road. The maximum towing speed is 50 km/h

(30 mph). Towing a vehicle equipped with auto-

matic g

earbox Certain restrictions must be observed when

to

w

ing your vehicle.

Please observe the relevant instructions

››› page 100.

The vehicle can be towed with a tow bar or

tow rope in the normal way, with all four

wheels on the ground. When doing so,

please note the following points:

● Make sure the select or l

ever is in the N po-

sition.

● The vehicle must not be towed faster than

50 km/h (30 mph).

● The vehicle must not be towed further than

50 km (30 mile

s). Reason: when the engine

is not running, the gearbox oil pump does

not work and the gearbox is not adequately

lubricated for higher speeds or longer distan-

ces.

If the vehicle has to be towed with a break-

down truck, it must only be suspended at the

front wheels. Reason: the drive shafts are lo-

cated on the front wheels. If the car is towed

with the rear wheels lifted off the road (I.e.

travelling backwards), the drive shafts also

turn backwards. The planetary gears in the

automatic gearbox then turn at such high

speeds that the gearbox will be severely

damaged in a short time. Note

● If it i

s not possible to tow the vehicle in the

normal way, or if it has to be towed further

than 50 km (30 miles), it must be transported

on a special car transporter or trailer.

● Should the power supply to the selector

lever be int

errupted in position P, the selector

lever will be locked. Before the vehicle can be

recovered/manoeuvred you must manually

release the selector lever. 103Technical data

Advice

Operation

Emergencies

Safety

Page 111 of 316

Fuses and bulbs

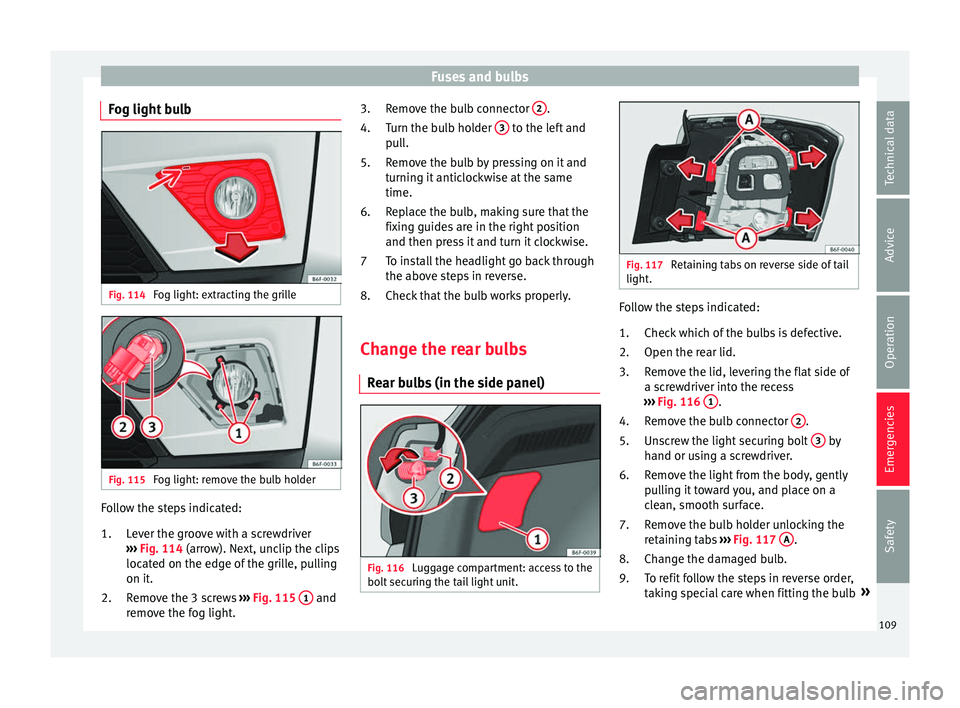

Fog light bulb Fig. 114

Fog light: extracting the grille Fig. 115

Fog light: remove the bulb holder Follow the steps indicated:

Lev

er the gr

oove with a screwdriver

››› Fig. 114 (arrow). Next, unclip the clips

located on the edge of the grille, pulling

on it.

Remove the 3 screws ››› Fig. 115 1 and

r emo

v

e the fog light.

1.

2. Remove the bulb connector

2 .

T urn the b

u

lb holder 3 to the left and

p u

l

l.

Remove the bulb by pressing on it and

turning it anticlockwise at the same

time.

Replace the bulb, making sure that the

fixing guides are in the right position

and then press it and turn it clockwise.

To install the headlight go back through

the above steps in reverse.

Check that the bulb works properly.

Change the rear bulbs Rear b

ulbs (in the side panel) Fig. 116

Luggage compartment: access to the

bo lt

sec

uring the tail light unit. 3.

4.

5.

6.

7

8.

Fig. 117

Retaining tabs on reverse side of tail

light. Follow the steps indicated:

Chec k

whic

h of the bulbs is defective.

Open the rear lid.

Remove the lid, levering the flat side of

a screwdriver into the recess

››› Fig. 116 1 .

R emo

v

e the bulb connector 2 .

Un s

c

rew the light securing bolt 3 by

h and or u

s

ing a screwdriver.

Remove the light from the body, gently

pulling it toward you, and place on a

clean, smooth surface.

Remove the bulb holder unlocking the

retaining tabs ››› Fig. 117 A .

Ch an

g

e the damaged bulb.

To refit follow the steps in reverse order,

taking special care when fitting the bulb »

1.

2.

3.

4.

5.

6.

7.

8.

9.

109

Technical data

Advice

Operation

Emergencies

Safety

Page 117 of 316

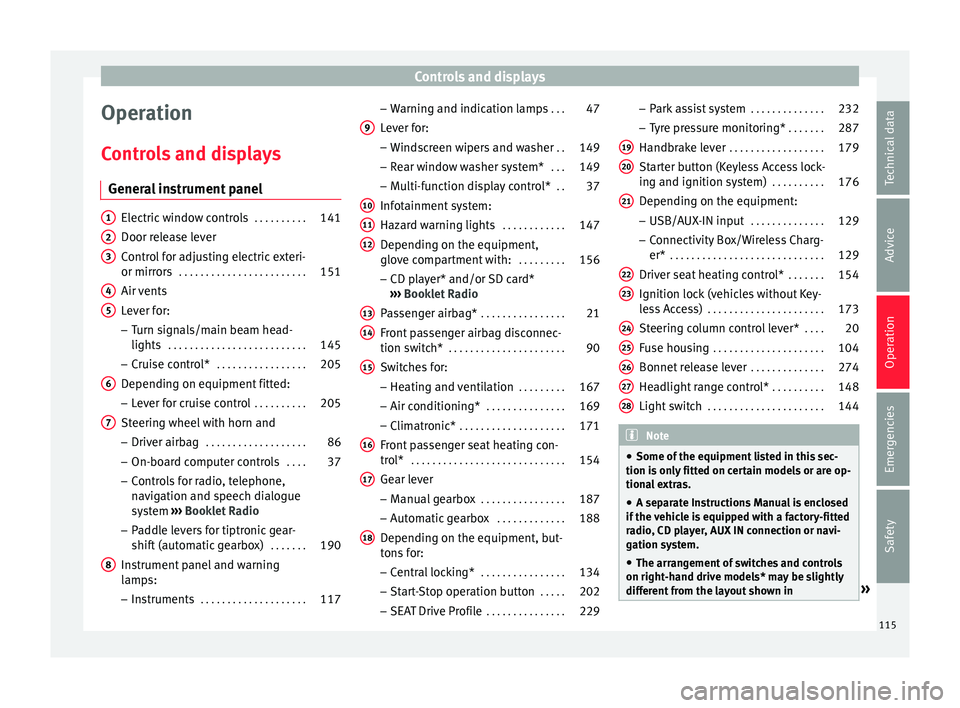

Controls and displays

Operation

C ontr

o

ls and displays

General instrument panel Electric window controls

. . . . . . . . . .141

Door release lever

Contr o

l for adjusting electric exteri-

or mirrors . . . . . . . . . . . . . . . . . . . . . . . . 151

Air vents

Lev er f

or:

– Turn signals/main beam head-

lights . . . . . . . . . . . . . . . . . . . . . . . . . . 145

– Crui se c

ontrol* . . . . . . . . . . . . . . . . . 205

Depending on equipment fitted:

– Lev er f

or cruise control . . . . . . . . . .205

Steering wheel with horn and – Driver airbag . . . . . . . . . . . . . . . . . . . 86

– On-boar d c

omputer controls . . . .37

– Contro

ls for radio, telephone,

navigation and speech dialogue

system ›››

Booklet Radio

– Paddle levers for tiptronic gear-

shift (automatic gearbox) . . . . . . .190

Instrument panel and warning

lamp s:

– In

struments . . . . . . . . . . . . . . . . . . . . 117

1 2

3

4

5

6

7

8 –

Warnin

g and indic

ation lamps . . .47

Lever for:

– Winds

creen wipers and washer . .149

– Rear w

indow washer system* . . .149

– Multi-f

unction display control* . .37

Infotainment system:

Hazard w

arning lights . . . . . . . . . . . . 147

Depending on the equipment,

glove c

ompartment with: . . . . . . . . .156

– CD pla

yer* and/or SD card*

››› Booklet Radio

Passenger airbag* . . . . . . . . . . . . . . . . 21

Front passenger airbag disconnec-

tion switc

h* . . . . . . . . . . . . . . . . . . . . . . 90

Switches for: – Heating and

ventilation . . . . . . . . . 167

– Air conditionin g* . . . . . . . . . . . . . . . 169

– C

limatr

onic* . . . . . . . . . . . . . . . . . . . . 171

Front passenger seat heating con-

tro l* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Ge

ar lever

– Manual g

earbox . . . . . . . . . . . . . . . . 187

– Autom atic

gearbox . . . . . . . . . . . . . 188

Depending on the equipment, but-

ton s

for:

– Central locking* . . . . . . . . . . . . . . . . 134

– Star t

-Stop operation button . . . . .202

– SEAT Driv

e Profile . . . . . . . . . . . . . . . 229

9

10

11

12

13

14

15

16

17

18 –

Park

a

ssist system . . . . . . . . . . . . . . 232

– Tyr

e pressure monitoring* . . . . . . .287

Handbrake lever . . . . . . . . . . . . . . . . . . 179

Starter button (Keyless Access lock-

ing and ignition sys

tem) . . . . . . . . . . 176

Depending on the equipment:

– USB/AUX-IN inp

ut . . . . . . . . . . . . . . 129

– Connectivity

Box/Wireless Charg-

er* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Driver seat heating control* . . . . . . .154

Ignition lock (vehicles without Key-

les

s Access) . . . . . . . . . . . . . . . . . . . . . . 173

Steering column control lever* . . . .20

Fuse housing . . . . . . . . . . . . . . . . . . . . . 104

Bonnet release lever . . . . . . . . . . . . . .274

Headlight range control* . . . . . . . . . .148

Light switch . . . . . . . . . . . . . . . . . . . . . . 144 Note

● Some of the equipment li

sted in this sec-

tion is only fitted on certain models or are op-

tional extras.

● A separate Instructions Manual is enclosed

if the v

ehicle is equipped with a factory-fitted

radio, CD player, AUX IN connection or navi-

gation system.

● The arrangement of switches and controls

on right-hand driv

e models* may be slightly

different from the layout shown in » 19

20

21

22

23

24

25

26

27

28

115

Technical data

Advice

Operation

Emergencies

Safety