lock Seat Ateca 2018 User Guide

[x] Cancel search | Manufacturer: SEAT, Model Year: 2018, Model line: Ateca, Model: Seat Ateca 2018Pages: 348, PDF Size: 7.32 MB

Page 49 of 348

The essentials

Front brake pads worn.›››

page

188

it lights up:

Fault in the ESC, or dis-

connection caused by the system.››› page

189

flashes: ESC or ASR activated.

ASR manually deactivated.›››

page

189ESC in Sport mode.

ABS faulty or does not work.

Rear fog light switched on.›››

page

144

lights up or flashes:

fault in the

emission control system.››› page

204

it lights up:

pre-heating of diesel

engine.

››› page

205

flashes: fault in the diesel engine

management.

fault in the petrol engine manage-

ment.›››

page

205

lights up or flashes:

fault in the

steering system.››› page

200

Tyre pressure too low, or fault in

the tyre pressure monitoring sys-

tem.›››

page

311

Fuel tank almost empty.›››

page

118

Fault in airbag system and seat

belt tensioners.›››

page

89

Lane Assist is switched on, but not

active.›››

page

230 Other warning lamps

Left or right turn signal.›››

page

145

Hazard warning lights on.››› page

149

Trailer turn signals.›››

page

273

it lights up green:

Auto Hold activa-

ted.››› page

211

it lights up green:

Press the brake

pedal!

It blinks in green: the selector lever

locking button has not engaged.››› page

193

it lights up green:

cruise control ac-

tivated or speed limiter switched

on and active.

››› page

212

it blinks in green: the speed set by

the speed limiter has been excee-

ded.

it lights up green:

Lane Assist is

switched on and active.››› page

230

Main beam on or flasher on.›››

page

145

››› in Warning and control lamps on

page 119

››› page 119 On the instrument panel display

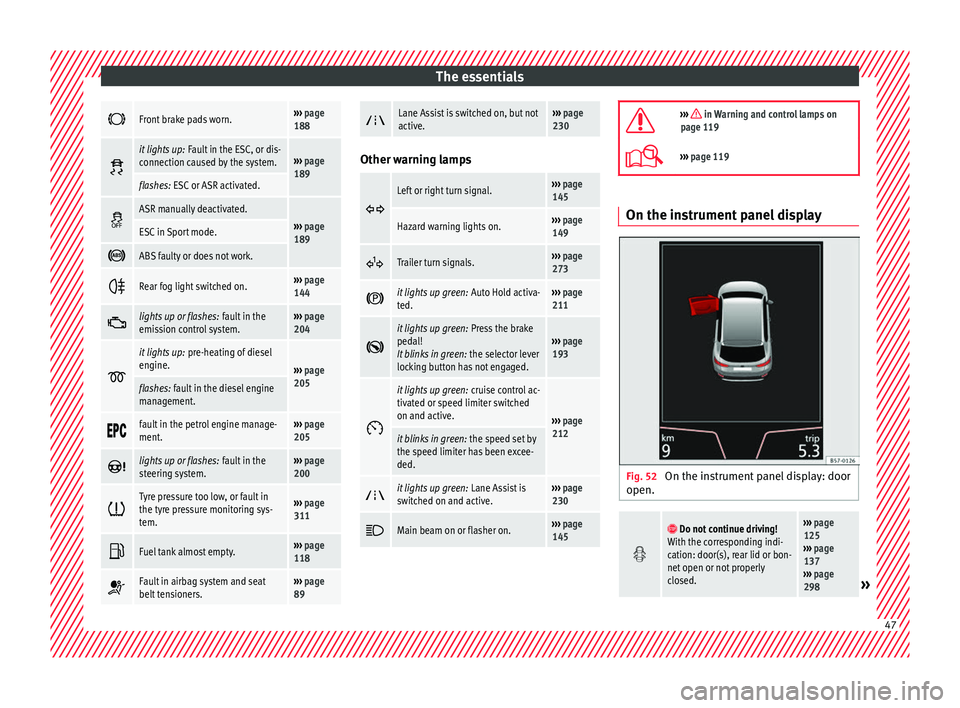

Fig. 52

On the instrument panel display: door

open.

Do not continue driving!

With the corresponding indi-

cation: door(s), rear lid or bon-

net open or not properly

closed.››› page

125

››› page

137

››› page

298

» 47

Page 50 of 348

The essentials

Ignition: Do not carry on

driving! Engine coolant level

too low, coolant temperature

too high

››› page

302

Flashing: Fault in the engine

coolant system.

Do not continue driving!

Engine oil pressure too low. If

the warning lamp flashes,

stop driving, even if the oil

level is correct. Do not even

run the engine at idle speed!

››› page

300

Fault in the battery.›››

page

305

Driving light totally or partially

faulty.›››

page

106

Fault in the cornering light

system.››› page

148

Diesel particulate filter

blocked›››

page

205

Level of windscreen washer

fluid too low.›››

page

153

Flashing: Fault in the oil level

detection. Control manually.

›››

page

300

Ignition: Insufficient engine

oil.

Fault in the gearbox.›››

page

200

Light Assist on.›››

page

146

it lights up white:

Hill Descent

Control (HDC) is active.

it lights up grey: Hill Descent

Control (HDC) is not active.

The system is switched on, but

is not adjusting.

››› page

210

Immobiliser active.›››

page

133

Service interval display›››

page 43

Mobile telephone is connec-

ted via Bluetooth to the origi-

nal telephone device.

›››

Booklet

Audio or

navigation

system

Mobile telephone battery

charge meter. Available only

for devices pre-installed in fac-

tory.

Freezing warning. The outside

temperature is lower than

+4°C (+39°F).›››

page 41

Start-Stop system activated.›››

page

208

Start-Stop system unavailable.

Low consumption driving sta-

tus›››

page

116

›››

page 115 On the instrument panel

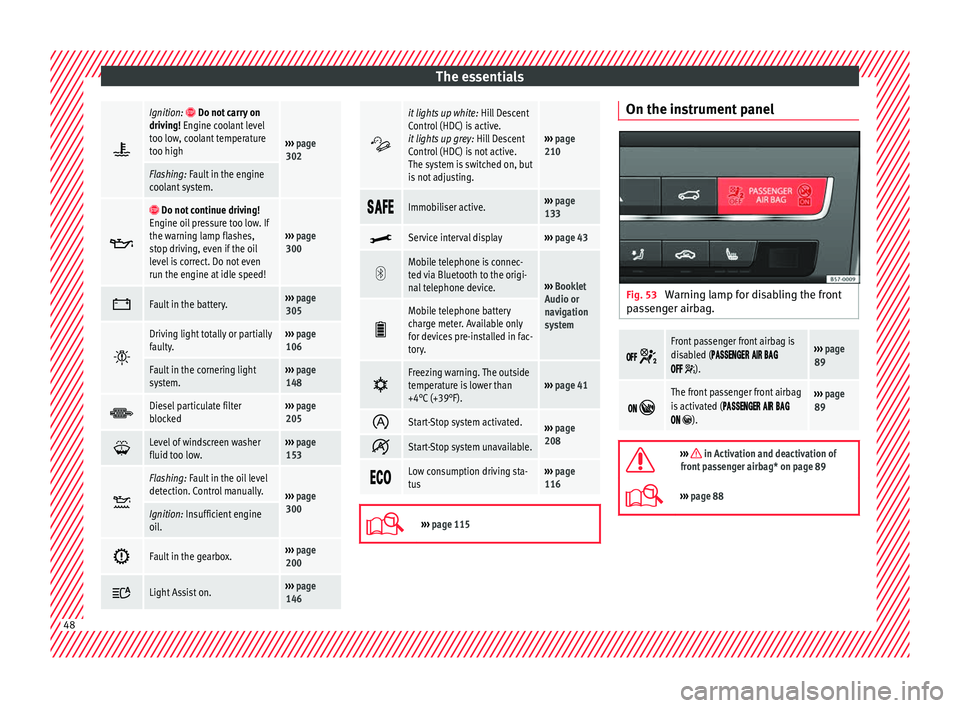

Fig. 53

Warning lamp for disabling the front

p a

s

senger airbag.

Front passenger front airbag is

disabled (

).

››› page

89

The front passenger front airbag

is activated (

).

››› page

89

››› in Activation and deactivation of

front passenger airbag* on page 89

››› page 88 48

Page 51 of 348

The essentials

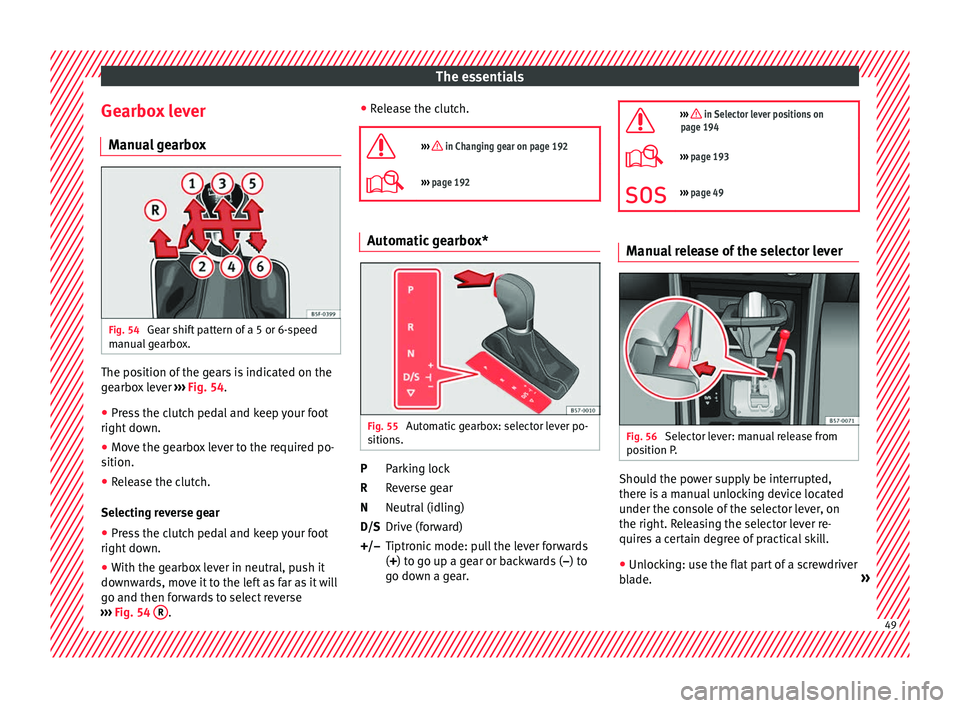

Gearbox lever M anua

l

gearbox Fig. 54

Gear shift pattern of a 5 or 6-speed

m anual

g

earbox. The position of the gears is indicated on the

g

e

arbo

x lever ››› Fig. 54.

● Press the clutch pedal and keep your foot

right down.

● Mo

ve the gearbox lever to the required po-

sition.

● Rel

ease the clutch.

Selecting r

everse gear

● Press the clutch pedal and keep your foot

right down.

● W

ith the gearbox lever in neutral, push it

downw

ards, move it to the left as far as it will

go and then forwards to select reverse

››› Fig. 54 R . ●

Rel

e

ase the clutch.

››› in Changing gear on page 192

››› page 192 Automatic gearbox*

Fig. 55

Automatic gearbox: selector lever po-

s ition

s. Parking lock

R

ev

er

se gear

Neutral (idling)

Drive (forward)

Tiptronic mode: pull the lever forwards

(+) to go up a gear or backwards ( –) to

go down a gear.

P

R

N

D/S

+/–

››› in Selector lever positions on

page 194

››› page 193

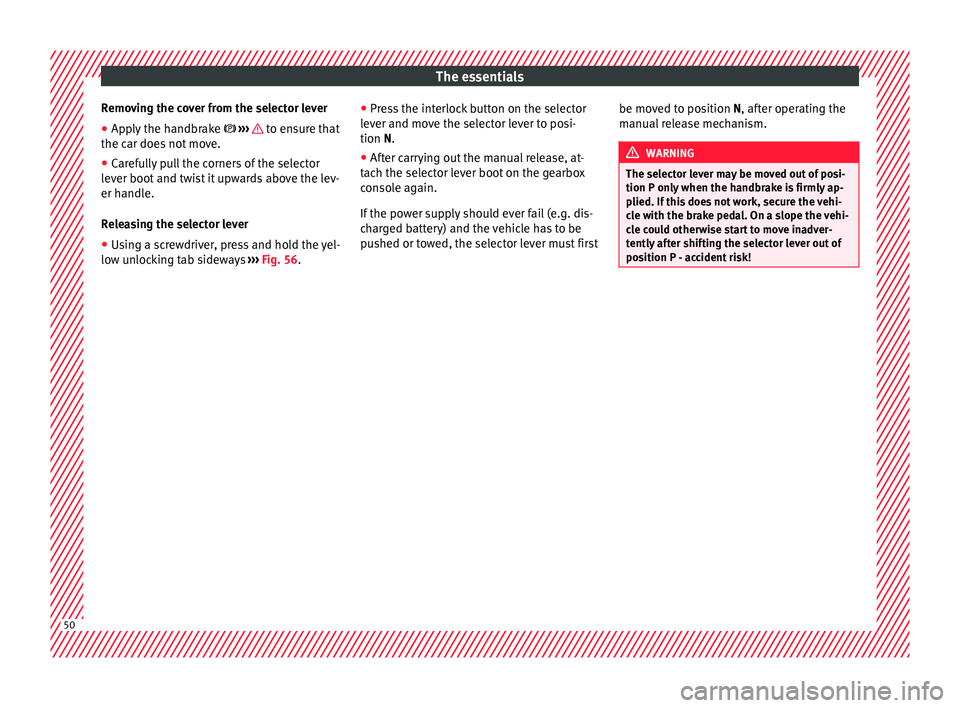

››› page 49 Manual release of the selector lever

Fig. 56

Selector lever: manual release from

po s

ition P

. Should the power supply be interrupted,

ther

e i

s

a manual unlocking device located

under the console of the selector lever, on

the right. Releasing the selector lever re-

quires a certain degree of practical skill.

● Unlocking: use the flat part of a screwdriver

bla

de. » 49

Page 52 of 348

The essentials

Removing the cover from the selector lever

● Apply the handbrake › ›

› to ensure that

the c ar doe

s

not move.

● Carefully pull the corners of the selector

lever boot

and twist it upwards above the lev-

er handle.

Releasing the selector lever

● Using a screwdriver, press and hold the yel-

low un

locking tab sideways ››› Fig. 56. ●

Pres

s the interlock button on the selector

lever and move the selector lever to posi-

tion N.

● After carrying out the manual release, at-

tach the sel

ector lever boot on the gearbox

console again.

If the power supply should ever fail (e.g. dis-

charged battery) and the vehicle has to be

pushed or towed, the selector lever must first be moved to position N, after oper

ating the

manual release mechanism. WARNING

The selector lever may be moved out of posi-

tion P only when the h

andbrake is firmly ap-

plied. If this does not work, secure the vehi-

cle with the brake pedal. On a slope the vehi-

cle could otherwise start to move inadver-

tently after shifting the selector lever out of

position P - accident risk! 50

Page 58 of 348

The essentials

Fluid Level control Fi l

lin

g capacities

Tank level

Petrol and diesel

engines

Front-wheel drive vehicles :

50 l, of which approx. 7 l reserve

Four-wheel drive vehicles :

55 l, of which approx. 8.5 l reserve

Capacity of the windscreen washer fluid container

Versions without

headlight washer

systemapprox. 3 litres

Versions with

headlight washer

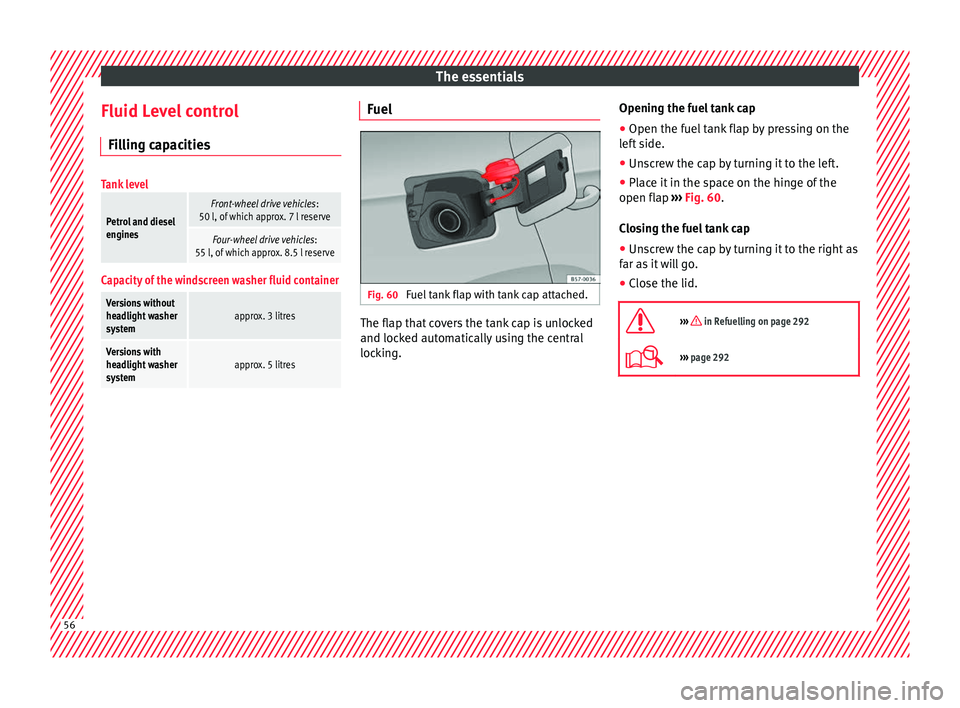

systemapprox. 5 litres Fuel

Fig. 60

Fuel tank flap with tank cap attached. The flap that covers the tank cap is unlocked

and loc

k

ed aut

omatically using the central

locking. Opening the fuel tank cap

● Open the fuel tank flap by pressing on the

left

side.

● Unscrew the cap by turning it to the left.

● Place it in the space on the hinge of the

open flap ››

› Fig. 60.

Closing the fuel tank cap

● Unscrew the cap by turning it to the right as

far as

it will go.

● Close the lid.

››› in Refuelling on page 292

››› page 292 56

Page 63 of 348

The essentials

Emergencies F u

se

s

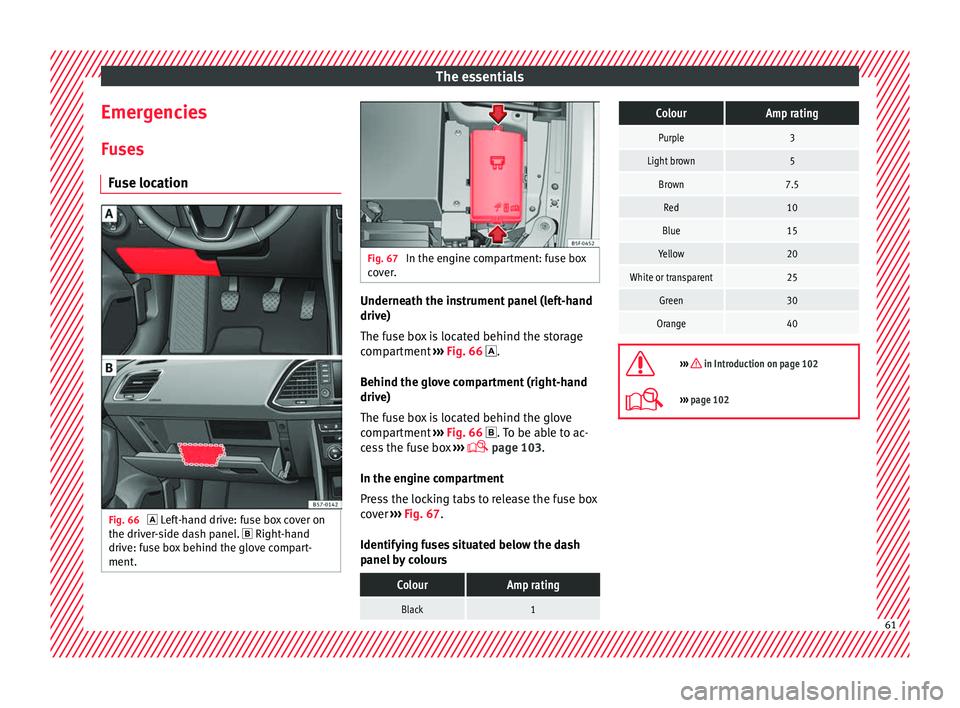

Fuse location Fig. 66

Left-hand drive: fuse box cover on

the driv

er-side dash panel. Right-hand

drive: fuse box behind the glove compart-

ment. Fig. 67

In the engine compartment: fuse box

co v

er. Underneath the instrument panel (left-hand

driv

e)

The f u

se box is located behind the storage

compartment ››› Fig. 66 .

Behind the glove compartment (right-hand

drive)

The fuse box is located behind the glove

compartment ››› Fig. 66 . To be able to ac-

cess the fuse box ›››

page 103.

In the engine compartment

Press the locking tabs to release the fuse box

cover ››› Fig. 67.

Identifying fuses situated below the dash

panel by colours

ColourAmp rating

Black1

ColourAmp rating

Purple3

Light brown5

Brown7.5

Red10

Blue15

Yellow20

White or transparent25

Green30

Orange40

››› in Introduction on page 102

›››

page 102 61

Page 65 of 348

The essentials

● Automatic

ge

arbox: Move the selector lever

to position P.

● If you are towing a trailer, unhitch it from

your v

ehicle.

● Have the vehicle tool kit ›››

page 95

and the spare wheel* ready

››› page 314.

● Observe the applicable legislation for each

countr

y (reflective vest, warning triangles,

etc.).

● All occupants should leave the vehicle and

wait in a s

afe place (for instance behind the

roadside crash barrier). WARNING

● Alw a

ys observe the above steps and pro-

tect yourself and other road users.

● If you change the wheel on a slope, block

the wheel on the oppo

site side of the car with

a stone or similar to prevent the vehicle from

moving. Repairing a tyre with the anti-punc-

t

ur

e k

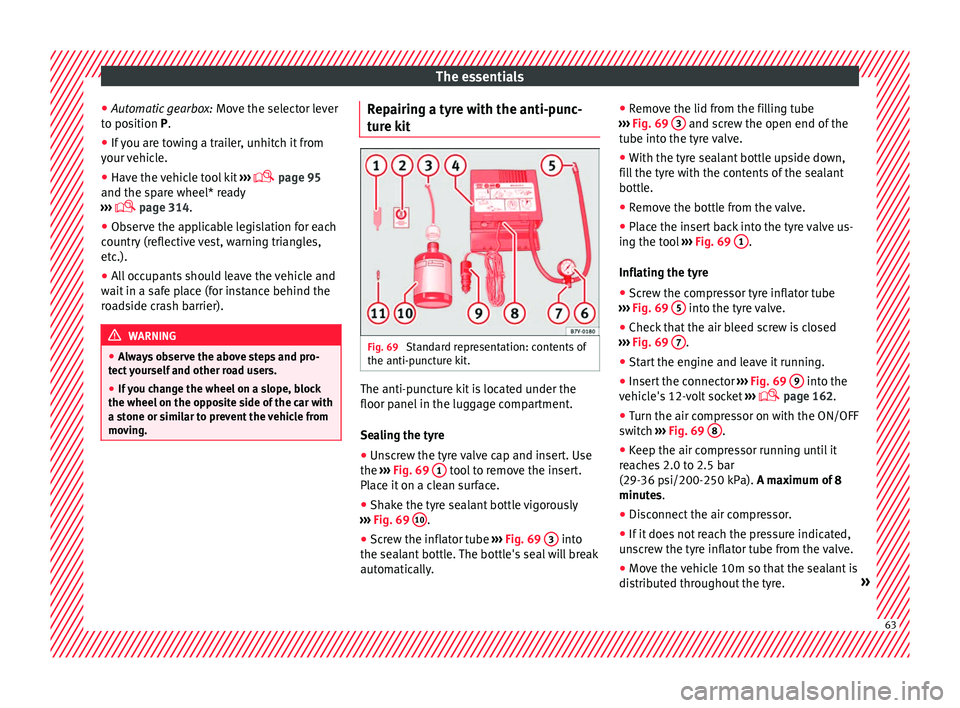

it Fig. 69

Standard representation: contents of

the anti-p u

nct

ure kit. The anti-puncture kit is located under the

floor p

anel

in the lug

gage compartment.

Sealing the tyre

● Unscrew the tyre valve cap and insert. Use

the ›››

Fig. 69 1 tool to remove the insert.

Pl ac

e it

on a clean surface.

● Shake the tyre sealant bottle vigorously

›››

Fig. 69 10 .

● Screw the inflator tube ››

›

Fig. 69 3 into

the se al

ant

bottle. The bottle's seal will break

automatically. ●

Remov

e the lid from the filling tube

››› Fig. 69 3 and screw the open end of the

t ube int

o the ty

re valve.

● With the tyre sealant bottle upside down,

fill

the tyre with the contents of the sealant

bottle.

● Remove the bottle from the valve.

● Place the insert back into the tyre valve us-

ing the too

l ››› Fig. 69 1 .

Infl atin

g the ty

re

● Screw the compressor tyre inflator tube

›››

Fig. 69 5 into the tyre valve.

● Check that the air bleed screw is closed

› ›

›

Fig. 69 7 .

● Start the engine and leave it running.

● Insert the connector ››

›

Fig. 69 9 into the

v ehic

l

e's 12-volt socket ›››

page 162.

● Turn the air compressor on with the ON/OFF

switc

h ››› Fig. 69 8 .

● Keep the air compressor running until it

r e

ac

hes 2.0 to 2.5 bar

(29-36 psi/200-250 kPa). A maximum of 8

minutes.

● Disconnect the air compressor.

● If it does not reach the pressure indicated,

uns

crew the tyre inflator tube from the valve.

● Move the vehicle 10m so that the sealant is

dis trib

uted throughout the tyre. » 63

Page 66 of 348

The essentials

● Sc r

ew the c

ompressor tyre inflator into the

valve.

● Repeat the inflation process.

● If the indicated pressure still cannot be

reac

hed, the tyre is too badly damaged. Stop

and request assistance from an authorised

technician.

● Disconnect the air compressor. Unscrew

the tyre infl

ator tube from the tyre valve.

● When the tyre pressure is between 2.5 and

2.0 bars, c

ontinue driving without exceeding

80 km/h (50 mph).

● Check the pressure again after 10 minutes

›››

page 97.

››› in TMS (Tyre Mobility System)* on

page 95

››› page 95 Changing a wheel

V ehic

l

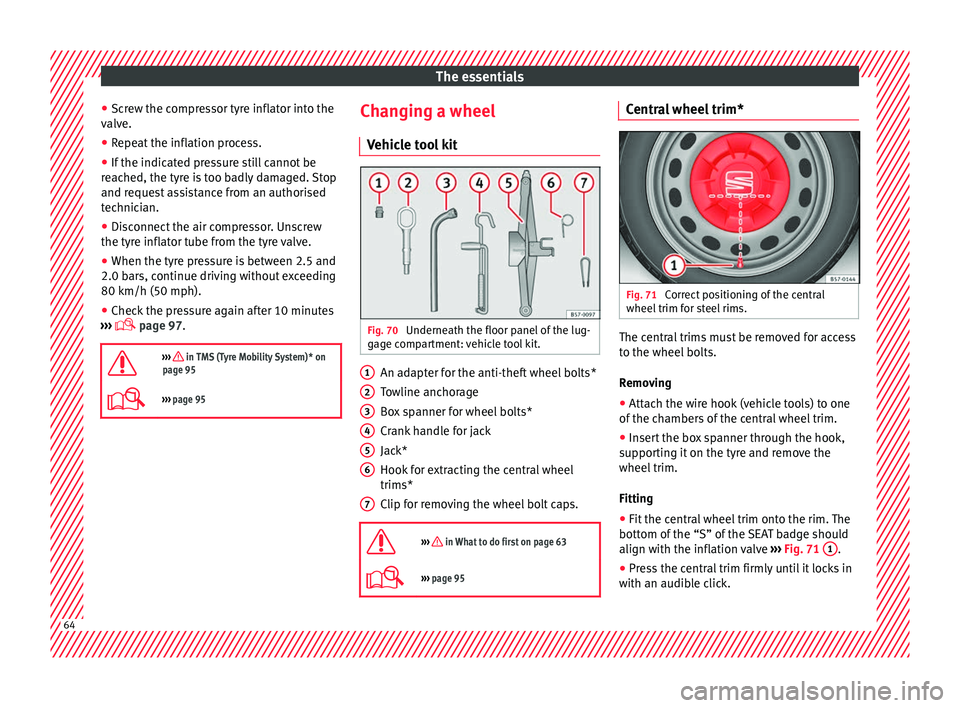

e tool kit Fig. 70

Underneath the floor panel of the lug-

g ag

e c

ompartment: vehicle tool kit. An adapter for the anti-theft wheel bolts*

T

o

wline anc

horage

Box spanner for wheel bolts*

Crank handle for jack

Jack*

Hook for extracting the central wheel

trims*

Clip for removing the wheel bolt caps.

››› in What to do first on page 63

››› page 95 1

2

3

4

5

6

7 Central wheel trim*

Fig. 71

Correct positioning of the central

wheel trim f

or s

teel rims. The central trims must be removed for access

t

o the wheel

bo

lts.

Removing

● Attach the wire hook (vehicle tools) to one

of the ch

ambers of the central wheel trim.

● Insert the box spanner through the hook,

suppor

ting it on the tyre and remove the

wheel trim.

Fitting

● Fit the central wheel trim onto the rim. The

bottom of the

“S” of the SEAT badge should

align with the inflation valve ›››

Fig. 71 1 .

● Press the central trim firmly until it locks in

w ith an audib

l

e click.64

Page 70 of 348

The essentials

Emergency towing of the vehi-

c l

e

T

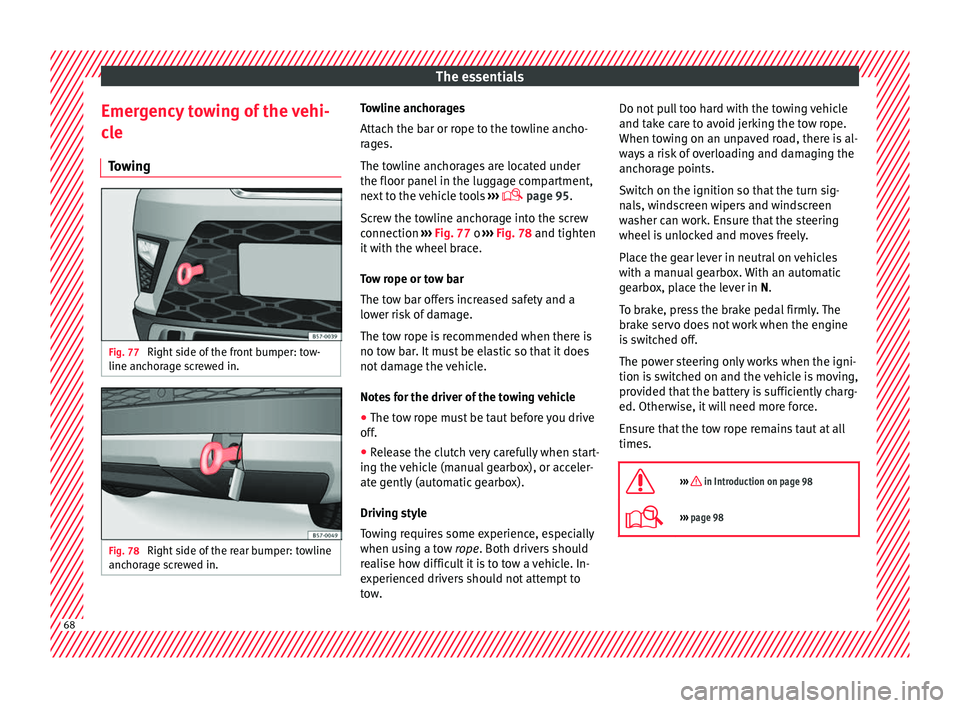

owing Fig. 77

Right side of the front bumper: tow-

line anc hor

ag

e screwed in. Fig. 78

Right side of the rear bumper: towline

anc hor

ag

e screwed in. Towline anchorages

Att

ac

h the b

ar or rope to the towline ancho-

rages.

The towline anchorages are located under

the floor panel in the luggage compartment,

next to the vehicle tools ›››

page 95.

Screw the towline anchorage into the screw

connection ››› Fig. 77 o ››› Fig. 78 and tighten

it with the wheel brace.

Tow rope or tow bar

The tow bar offers increased safety and a

lower risk of damage.

The tow rope is recommended when there is

no tow bar. It must be elastic so that it does

not damage the vehicle.

Notes for the driver of the towing vehicle

● The tow rope must be taut before you drive

off.

● Rel

ease the clutch very carefully when start-

ing the v

ehicle (manual gearbox), or acceler-

ate gently (automatic gearbox).

Driving style

Towing requires some experience, especially

when using a tow rope. Both drivers should

realise how difficult it is to tow a vehicle. In-

experienced drivers should not attempt to

tow. Do not pull too hard with the towing vehicle

and take c

are to avoid jerking the tow rope.

When towing on an unpaved road, there is al-

ways a risk of overloading and damaging the

anchorage points.

Switch on the ignition so that the turn sig-

nals, windscreen wipers and windscreen

washer can work. Ensure that the steering

wheel is unlocked and moves freely.

Place the gear lever in neutral on vehicles

with a manual gearbox. With an automatic

gearbox, place the lever in N.

To brake, press the brake pedal firmly. The

brake servo does not work when the engine

is switched off.

The power steering only works when the igni-

tion is switched on and the vehicle is moving,

provided that the battery is sufficiently charg-

ed. Otherwise, it will need more force.

Ensure that the tow rope remains taut at all

times.

››› in Introduction on page 98

››› page 98 68

Page 71 of 348

The essentials

Tow-starting If the engine will not start, first try starting it

us

in

g the battery of another vehicle

››› page 69. You should only attempt to tow-

start a vehicle if charging the battery does

not work. This is done by leveraging wheel

movement.

When tow-starting a vehicle with a petrol en-

gine, do not tow it more than a short dis-

tance, otherwise unburned fuel can enter the

catalytic converter.

● Engage 2nd or 3rd gear before moving off.

● Press the clutch and hold the pedal down.

● Switch the ignition on.

● Once both vehicles are moving, release the

clut c

h.

● As soon as the engine has started, press

the clutc

h and move the gear lever to neutral.

How to jump start Jump lea

dsThe jump lead must have a sufficient wire

c

r

o

ss section.

If the engine fails to start because of a dis-

charged battery, the battery can be connec-

ted to the battery of another vehicle to start

the engine. Jump leads must comply with standard

DIN

72553 (see cabl

e manufacturer's instruc-

tions). The wire cross section must be at least

25 mm 2

for petrol engines and at least

35 mm 2

for diesel engines. Note

● The v ehic

les must not touch each other,

otherwise electricity could flow as soon as

the positive terminals are connected.

● The discharged battery must be properly

connected t

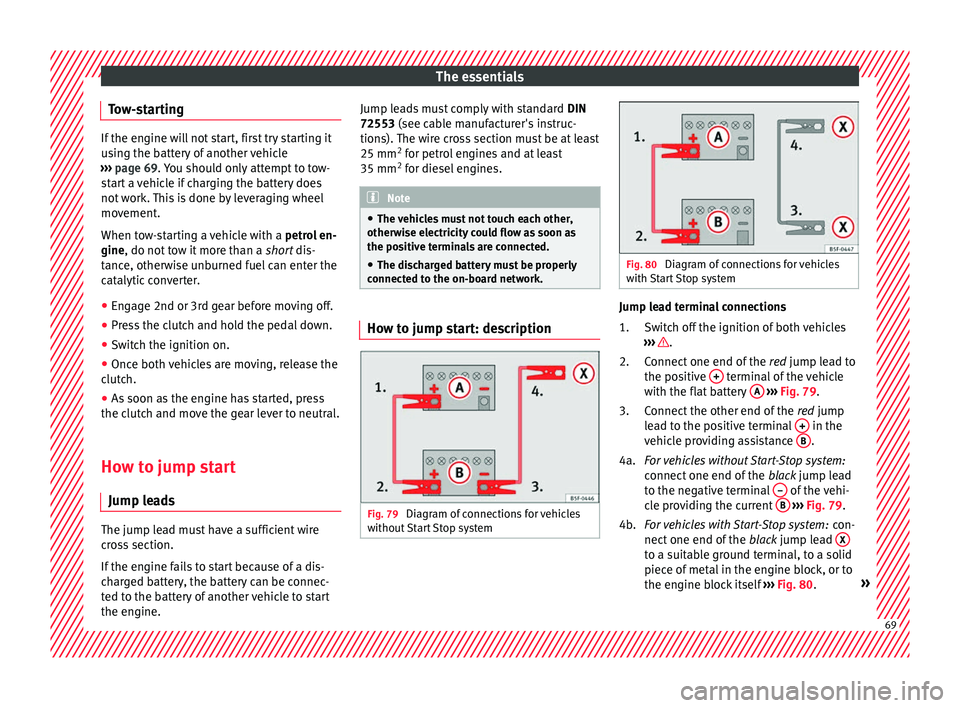

o the on-board network. How to jump start: description

Fig. 79

Diagram of connections for vehicles

w ithout

Start Stop system Fig. 80

Diagram of connections for vehicles

with St

art Stop system Jump lead terminal connections

Swit

c

h off the ignition of both vehicles

››› .

C onnect

one end of

the red jump lead to

the positive + terminal of the vehicle

w ith the fl

at

battery A

› ›

› Fig. 79 .

Connect the other end of the red jump

lead to the positive terminal + in the

v ehic

l

e providing assistance B .

F or

vehicles without Start-Stop system:

connect one end of the black jump lead

to the negative terminal – of the vehi-

c l

e pr

oviding the current B

› ›

› Fig. 79 .

For vehicles with Start-Stop system: con-

nect one end of the black jump lead X to a suitable ground terminal, to a solid

piec

e of

met

al in the engine block, or to

the engine block itself ››› Fig. 80. »

1.

2.

3.

4a.

4b.

69