engine Seat Cordoba 2006 Repair Manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2006, Model line: Cordoba, Model: Seat Cordoba 2006Pages: 255, PDF Size: 7.57 MB

Page 179 of 255

Checking and refilling levels177

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

CoolantCoolant specifications

Coolant is a mixture of water and at least 40% coolant addi-

tive.The cooling system must be filled with a mixture of water and at least 40 % of

our coolant additive G 12+ or an additive with the specification TT-VW 774 F

(it is dyed purple). This mixture gives the necessary frost protection down to

-25

°C and protects the alloy parts of the cooling system against corrosion. It

also prevents scaling and raises the boiling point of the coolant.

The concentration of coolant must always be at least 40% - even if frost

protection is not required.

If greater frost protection is required in very cold climates, the proportion of

the antifreeze additive G 12+ can be increased. However, the percentage of

coolant additives should not exceed 60%, as this would reduce the frost

protection. It would also reduce the cooling effect. A mixture with 60%

coolant additive will give frost protection to approx. -40

°C.

WARNING

•

The coolant additive is toxic. This represents a toxic danger. Always

keep the coolant additive in the original container which should be stored

out of the reach of children. The same applies to coolant which you have

drained off.

•

The coolant additive G 12+ must be added in sufficient quantities to

provide anti-freeze protection at the coldest ambient temperatures that

can be expected. At extremely cold ambient temperatures, the coolant

could freeze, causing the vehicle to br eakdown. As the heater would also

not work in this situation, there is a risk of suffering exposure!

Caution

•

Other additives may give considerably inferior corrosion protection. The

resulting corrosion in the cooling system can lead to a loss of coolant,

causing serious damage to the engine.

•

The coolant additive G 12+ (purple) can be mixed with the additive G 12

(red) or G 11. Never mix G12 (red colour) with G 11.

Checking the coolant level and topping up

The correct coolant level is important for fault-free func-

tioning of the engine cooling system.Before opening the bonnet, read and observe the warnings ⇒ in

“Safety instructions on working in the engine compartment” on

page 169 .

Fig. 122 In the engine

compartment: Coolant

expansion tank cap

cordoba_ingles Seite 177 Freitag, 7. Oktober 2005 6:00 18

Page 180 of 255

Checking and refilling levels

178

Opening the coolant expansion tank

– Switch off the engine and allow it to cool.

– To prevent scalding, cover the cap on the expansion tank with a thick cloth and carefully unscrew the cap ⇒ .

Checking coolant level

– Look into the open coolant ex pansion tank and read off the

coolant level.

– If the level is underneath the “MIN” mark, top up with coolant.

Topping up coolant

–Only use new coolant.

– Do not fill above the “MAX” mark.

Closing the coolant expansion tank

– Screw the cap on again tightly.The position of the coolant expansion tank is shown in the corresponding

engine compartment diagram ⇒page 224.

Make sure that the coolant meets the required specifications ⇒page 177.

Do not use a different type of additive if coolant additive G 12+ is not avail-

able. In this case use only water and bring the coolant concentration back up

to the correct level as soon as possible by putting in the specified additive

⇒ page 177.

Always top up with new coolant.

Do not fill above the “MAX” mark. Otherwise the excess coolant will be forced

out of the cooling system when the engine is hot. The coolant additive G 12+ (dyed purple

) may be mixed with G 12 (dyed red)

and also with G 11.

WARNING

Any work carried out in the engine compartment or on the engine must be

carried out cautiously.•

When working in the engine compartment, always observe the safety

warnings ⇒page 169

•

When the engine is warm or hot, the cooling system is pressurised! Do

not unscrew the cap on the expansion tank when the engine is hot. This is

a burn injury risk.Caution

•

When mixed with other additives the colour of G 12 will change to brown.

If this occurs you should have the coolant changed immediately. Failure to do

so will result in engine damage!

•

If a lot of coolant has been lost, wait for the engine to cool down before

putting in cold coolant. This avoi ds damaging the engine. Large coolant

losses are an indication of leaks in the cooling system. See a specialised

workshop immediately and have the cooling system checked. Otherwise,

there is a risk of engine damage.

cordoba_ingles Seite 178 Freitag, 7. Oktober 2005 6:00 18

Page 181 of 255

Checking and refilling levels179

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

Washer fluid and windscreen wiper bladesTopping up washer fluid

The water for cleaning the windscreen should always be

mixed with washer fluid.The windscreen washer and the headlight washing system are supplied with

fluid from the windscreen washer fluid container in the engine compartment.

The container holds approx. 2 litres; in vehicles with headlamp washers* it

holds approx. 4.5 litres.

The reservoir is located on the right-hand side of the engine compartment.

Plain water is not enough to clean the windscreen and headlights. We recom-

mend that you always add a product to the windscreen washer fluid.

Approved windscreen cleaning products exist on the market with high deter-

gent and anti-freeze properties, these may be added all-year-round. Please

follow the dilution instructions on the packaging.

WARNING

Any work carried out in the engine compartment or on the engine must be

carried out cautiously.•

When working in the engine compartm ent, always observe the safety

warnings ⇒page 169Caution

•

Never put radiator anti-freeze or other additives into the windscreen

washer fluid.

•

Always use approved windscreen cleansing products diluted as per

instructions. If you use other washer fl uids or soap solutions, the tiny aper-

tures in the fan-shaped nozzles could become blocked.

Fig. 123 In the engine

compartment: Cap of

windscreen washer fluid

reservoir.

cordoba_ingles Seite 179 Freitag, 7. Oktober 2005 6:00 18

Page 184 of 255

Checking and refilling levels

182Brake fluidChecking the brake fluid level

The brake fluid is checked at the intervals given in the service

schedule.– Read off the fluid level at the transparent brake fluid reservoir. It

should always be between the “MIN” and “MAX” marks.The position of the coolant expansion tank is shown in the corresponding

engine compartment diagram ⇒page 224. The brake fluid reservoir has a

black and yellow cap.

The brake fluid level drops slightly when the vehicle is being used as the

brake pads are automatically adjusted as they wear. However, if the level goes down noticeab

ly in a short time, or drops below the

“MIN” mark, there may be a leak in the brake system. A display on the instru-

ment panel will warn you if the brake fluid level is too low ⇒page 60.

WARNING

Before opening the bonnet to check the brake fluid level, read and observe

the warnings ⇒page 169.Changing the brake fluid

The brake fluid must be renewed every two years.We recommend that you have the brake fluid changed by an Authorised

Service Centre.

Before opening the bonnet, please read and follow the warnings ⇒ in

“Safety instructions on working in the engine compartment” on page 169 in

“Working in the engine compartment”.

Brake fluid absorbs moisture. In the cour se of time, it will absorb water from

the ambient air. If the water content in the brake fluid is too high, the brake

system could corrode. This also consider ably reduces the boiling point of the

brake fluid. Heavy use of the brakes may then cause a vapour lock which

could impair the braking effect.

For this reason the brake fluid must be renewed every two years.

It important that you use only use brake fluid compliant with the US standard

FMVSS 116 DOT 4. We recommend the use of Genuine SEAT brake fluid.

WARNING

Brake fluid is poisonous. Old brake fluid impairs the braking effect.

Fig. 126 In the engine

compartment: Brake fluid

reservoir cover

cordoba_ingles Seite 182 Freitag, 7. Oktober 2005 6:00 18

Page 186 of 255

Checking and refilling levels

184charge. Never short the battery terminals. High-energy sparks can cause

injury.•

A highly explosive mixture of gases is given off when the battery is

under charge. The batteries should be charged in a well-ventilated room

only.

•

Keep children away from acid and batteries.

•

Before working on the electrical system, you must switch off the

engine, the ignition and all consumers. The minus cable on the battery

must be disconnected. When a light bulb is changed, you need only switch

off the light.

•

Deactivate the anti-theft alarm by unlocking the vehicle before you

disconnect the battery! The alarm will otherwise be triggered.

•

When disconnecting the battery from the vehicle electrical system,

disconnect first the negative cable and then the positive cable.

•

Switch off all electrical consumers before reconnecting the battery.

Reconnect first the positive cable and then the negative cable. Never

reverse the polarity of the connections. This could cause an electrical fire.

•

Never charge a frozen battery, or one which has thawed. This could

result in explosions and chemical burns. Always replace a battery which

has frozen. A flat battery can freeze at temperatures around 0

°C.

•

Ensure that the vent hose is always connected to the battery.

•

Never use a defective battery. This may be fatally explosive. Replace a

damaged battery immediately.Caution

•

Never disconnect the battery if the ignition is switched on or if the engine

is running. This could damage the electrical system or electronic compo-

nents.

•

Do not expose the battery to direct sunlight over a long period of time, as

the intense ultraviolet radiation can damage the battery housing.

•

If the vehicle is left standing in cold conditions for a long period, protect

the battery from frost. If it “freezes” it will be damaged.

Checking the electrolyte level

The electrolyte level should be checked regularly in high-

mileage vehicles, in hot countries and in older batteries.– Open the bonnet and open the battery cover at the front ⇒ in

“Safety instructions on working in the engine compartment” on

page 169 ⇒ in “Warnings on handling the battery” on

page 183.

– Check the colour display in the magic eye on the top of the battery.

– If there are air bubbles in the window, tap the window gently until they disperse.The position of the battery is show n in the corresponding engine compart-

ment diagram ⇒page 224.

The round window (“magic eye”) on the top of the battery changes colour,

depending on the charge level and electrolyte level of the battery.

If the colour in the window is colourless or bright yellow, the electrolyte level

of the battery is too low. Have the battery checked by a qualified workshop.

The colours green and black are used by the workshops for diagnostic

purposes.

WARNING (continued)

cordoba_ingles Seite 184 Freitag, 7. Oktober 2005 6:00 18

Page 193 of 255

If and when191

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

If and whenVehicle tools, spare wheelVeh icle To ols

The tools and jack are stored under the floor panel in the

luggage compartment.–Lift floor panel

– Remove the tools or jack.The tool kit includes:•

Hook for removing wheel covers* or hub caps*

•

Box spanner for wheel bolts

•

Reversible screwdriver with handle (i ncluding hexagonal interior) for the

wheel bolts. The screwdriver is a combination tool.

•

Towing ring*

•

Adapter for the anti-theft wheel bolts*

Before replacing the jack in the storage area, wind the arm of the jack down

as far as it will go.

Some of the items listed are only provided on certain models, or are optional

extras.

WARNING

•

Do not use the hexagonal socket in the screwdriver handle to tighten

the wheel bolts. It is impossible to tighten the bolts with the torque neces-

sary, risk of accident.

•

The jack supplied by the factory is only designed for changing wheels

on this model. On no account attempt to use it for lifting heavier vehicles

or other loads, risk of injury.

•

Use the jack only on firm, level ground.

•

Never start the engine when the vehicle is on the jack, risk of accident.

•

I f w o r k is t o b e ca r r i e d o ut un d e r n ea t h t h e v e h i cle , t h is m u st b e s e c ure d

by suitable stands. Otherwise, there is a risk of injury in an accident.

Wheel changePreparation work

What you must do before changing a wheel.– If you have a flat tyre or puncture, park the vehicle as far away from the flow of traffic as possible. Choose a location that is as

level as possible.

– All passengers should leave the vehicle. They should wait in a

safe area (for instance behind the roadside crash barrier).

– Switch off the engine. Switch on the hazard warning lights.

–Apply the handbrake firmly.

WARNING (continued)

cordoba_ingles Seite 191 Freitag, 7. Oktober 2005 6:00 18

Page 201 of 255

If and when199

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

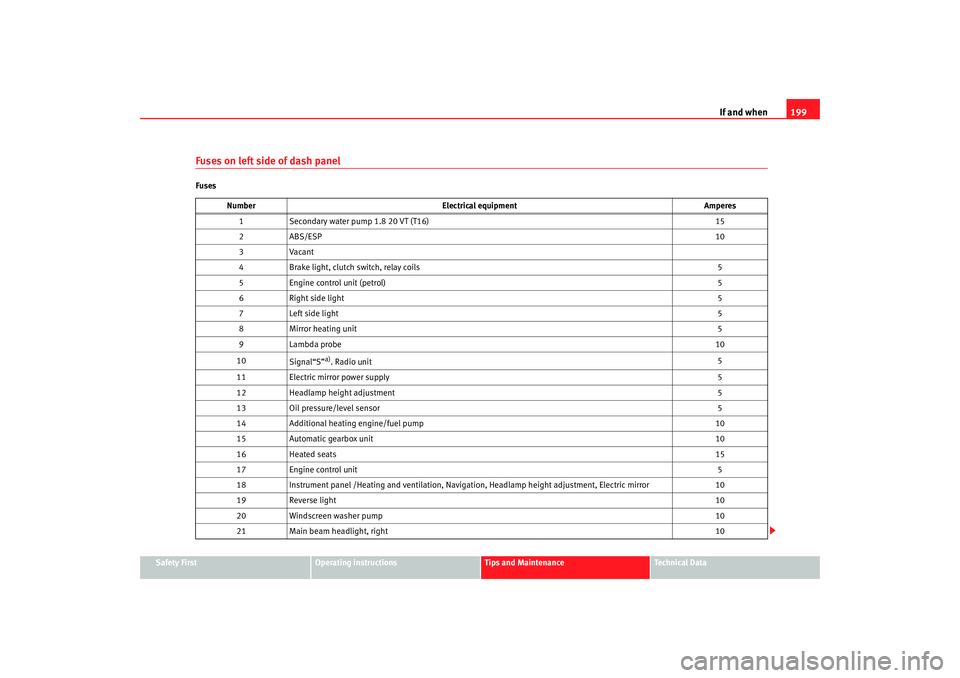

Fuses on left side of dash panelFuses

Number Electrical equipment Amperes

1 Secondary water pump 1.8 20 VT (T16) 15

2A BS/E S P 10

3 Vacant

4 Brake light, clutch switch, relay coils 5

5 Engine control unit (petrol) 5

6 Right side light 5

7 Left side light 5

8 Mirror heating unit 5

9 Lambda probe 10

10 Signal“S”

a). Radio unit 5

11 Electric mirror power supply 5

12 Headlamp height adjustment 5

13 Oil pressure/level sensor 5

14 Additional heating engine/fuel pump 10

15 Automatic gearbox unit 10

16 Heated seats 15

17 Engine control unit 5

18 Instrument panel /Heating and ventilation, Navigation, Headlamp height adjustment, Electric mirror 10

19 Reverse light 10

20 Windscreen washer pump 10

21 Main beam headlight, right 10

cordoba_ingles Seite 199 Freitag, 7. Oktober 2005 6:00 18

Page 202 of 255

If and when

200

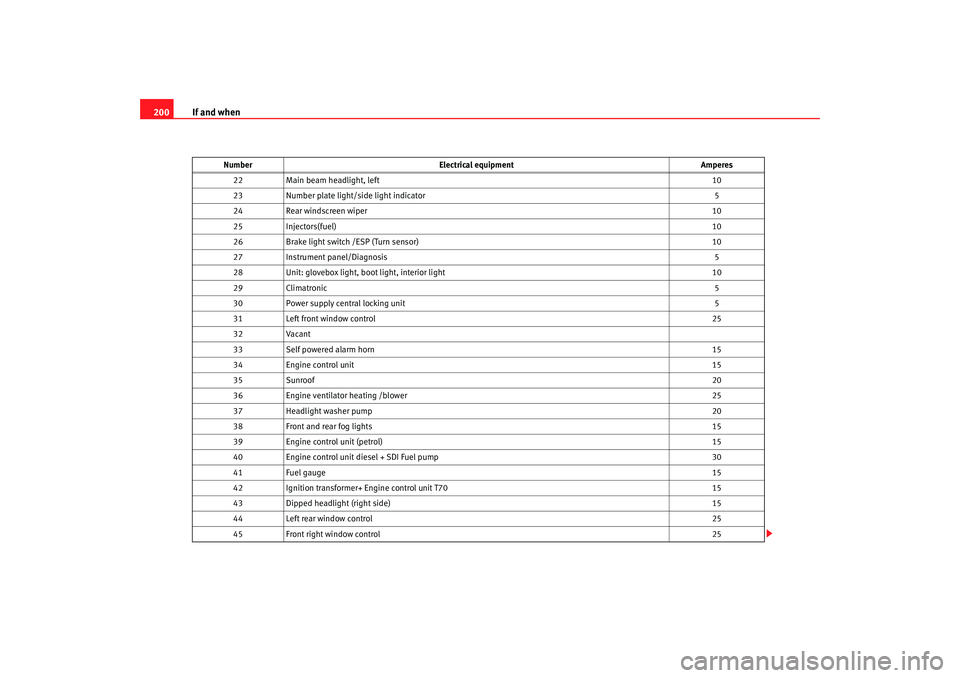

22 Main beam headlight, left 10

23 Number plate light/si de light indicator 5

24 Rear windscreen wiper 10

25 Injectors(fuel) 10

26 Brake light switch /ESP (Turn sensor) 10

27 Instrument panel/Diagnosis 5

28 Unit: glovebox light, boot light, interior light 10

29 Climatronic 5

30 Power supply central locking unit 5

31 Left front window control 25

32 Vacant

33 Self powered alarm horn 15

34 Engine control unit 15

35 Sunroof 20

36 Engine ventilator heating /blower 25

37 Headlight washer pump 20

38 Front and rear fog lights 15

39 Engine control unit (petrol) 15

40 Engine control unit diesel + SDI Fuel pump 30

41 Fuel gauge 15

42 Ignition transformer+ Engine control unit T70 15

43 Dipped headlight (right side) 15

44 Left rear window control 25

45 Front right window control 25

Number

Electrical equipment Amperes

cordoba_ingles Seite 200 Freitag, 7. Oktober 2005 6:00 18

Page 204 of 255

If and when

202Fuses in engine compartment above batteryMetal fuses

Fig. 137 Fuse box above

battery

Number Electrical equipment Amperes

1 Alternator/Starter motor 175

2 Power supply voltage distributor inside vehicle 110

3 Power assisted steering pump 50

4 Spark plug preheating (diesel) 50

5 Electroblower clima heater/fan 40

6 A BS u nit 40

cordoba_ingles Seite 202 Freitag, 7. Oktober 2005 6:00 18

Page 205 of 255

If and when203

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

Non-metal fuses

Position in engine compartment: side boxFuses

Number

Electrical equipment Amperes

7A BS u nit 25

8 Electroblower clima heater/fan 30

9A BS u nit 10

10 Cable control unit 5

11 Clima fan 5

12 Vacant

13 Jatco unit for automatic gearbox 5

14 Vacant

15 Vacant

16 Vacant

Number Electrical equipment Amperes

B1 Alternator < 140 W

150

Alternator > 140 W 200

C1 Power steering 80

D1 PTCs (Supplementary electrical heating using air) 100

E1 Ventilator > 500 W / Ventilator < 500 80/50

cordoba_ingles Seite 203 Freitag, 7. Oktober 2005 6:00 18