light Seat Cordoba 2006 Manual Online

[x] Cancel search | Manufacturer: SEAT, Model Year: 2006, Model line: Cordoba, Model: Seat Cordoba 2006Pages: 255, PDF Size: 7.57 MB

Page 194 of 255

If and when

192

– Engage the first gear, or put the selector lever to position P for

those vehicles with an automatic gearbox.

– If you are towing a trailer, unhitch it from your vehicle.

– Take the vehicle tools and the spare wheel out of the luggage

compartment.

WARNING

Put the hazard warning lights on and pl ace the warning triangle in position.

This is for your own safety and also warns other road users.

Caution

If you have to change the tyre on a gradient, block the wheel opposite the

wheel being changed by placing a stone or similar object under it to prevent

the vehicle from rolling away.

Note

Please observe legal requirements when doing so.Changing a wheelChange the wheel as described below

– Remove the wheel cover. Also refer to page 193, fig.

–Slacken the wheel bolts.

– Raise the car with the jack in the corresponding zone –

Ta k e o f f the wheel and then put on the spare wheel

– Lower the vehicle.

– Tighten the wheel bolts firmly in diagonal sequence with the box

spanner

–Replace the cover .

After changing a wheel

After changing the wheel there are still tasks to complete.– Put the tools and jack back in the luggage compartment.

– Place the wheel with the defective tyre in the luggage compart-

ment and secure it.

– Check the tyre pressure of the newly fitted tyre as soon as possible.

– Have the tightening torque of the wheel bolts checked as soon as possible with a torque wrench. The prescribed torque is 120 Nm.

Note•

If you notice that the wheel bolts are corroded and difficult to turn when

changing a wheel, they must be replaced before having the wheel bolt torque

checked.

•

In the interest of safety, drive at moderate speeds until the wheel bolt

torque has been checked.

cordoba_ingles Seite 192 Freitag, 7. Oktober 2005 6:00 18

Page 198 of 255

If and when

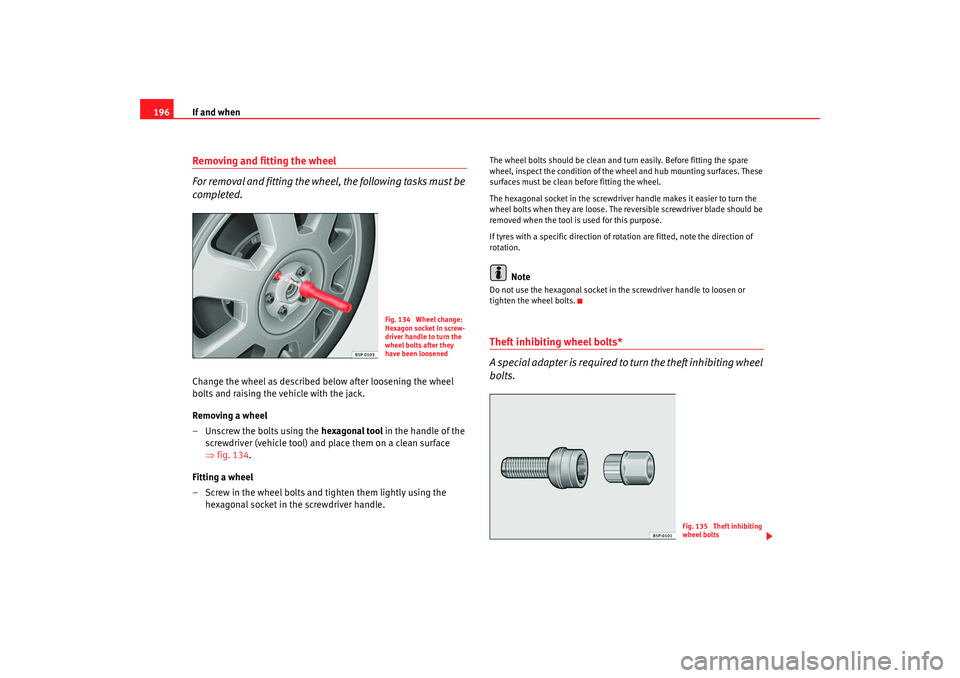

196Removing and fitting the wheel

For removal and fitting the wheel, the following tasks must be

completed.Change the wheel as described below after loosening the wheel

bolts and raising the vehicle with the jack.

Removing a wheel

– Unscrew the bolts using the hexagonal tool in the handle of the

screwdriver (vehicle tool) and place them on a clean surface

⇒ fig. 134.

Fitting a wheel

– Screw in the wheel bolts and tighten them lightly using the hexagonal socket in the screwdriver handle.

The wheel bolts should be clean and turn easily. Before fitting the spare

wheel, inspect the condition of the whe el and hub mounting surfaces. These

surfaces must be clean before fitting the wheel.

The hexagonal socket in the screwdriver handle makes it easier to turn the

wheel bolts when they are loose. The reversible screwdrive r blade should be

removed when the tool is used for this purpose.

If tyres with a specific di rection of rotation are fitt ed, note the direction of

rotation.

Note

Do not use the hexagonal socket in the screwdriver handle to loosen or

tighten the wheel bolts.Theft inhibiting wheel bolts*

A special adapter is required to turn the theft inhibiting wheel

bolts.

Fig. 134 Wheel change:

Hexagon socket in screw-

driver handle to turn the

wheel bolts after they

have been loosened

Fig. 135 Theft inhibiting

wheel bolts

cordoba_ingles Seite 196 Freitag, 7. Oktober 2005 6:00 18

Page 201 of 255

If and when199

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

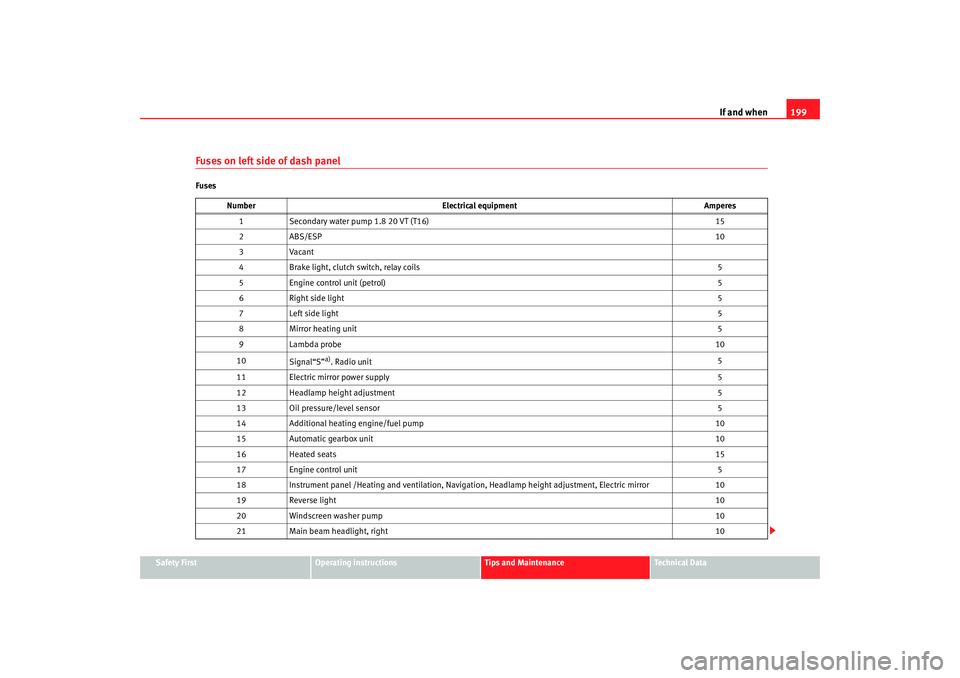

Fuses on left side of dash panelFuses

Number Electrical equipment Amperes

1 Secondary water pump 1.8 20 VT (T16) 15

2A BS/E S P 10

3 Vacant

4 Brake light, clutch switch, relay coils 5

5 Engine control unit (petrol) 5

6 Right side light 5

7 Left side light 5

8 Mirror heating unit 5

9 Lambda probe 10

10 Signal“S”

a). Radio unit 5

11 Electric mirror power supply 5

12 Headlamp height adjustment 5

13 Oil pressure/level sensor 5

14 Additional heating engine/fuel pump 10

15 Automatic gearbox unit 10

16 Heated seats 15

17 Engine control unit 5

18 Instrument panel /Heating and ventilation, Navigation, Headlamp height adjustment, Electric mirror 10

19 Reverse light 10

20 Windscreen washer pump 10

21 Main beam headlight, right 10

cordoba_ingles Seite 199 Freitag, 7. Oktober 2005 6:00 18

Page 202 of 255

If and when

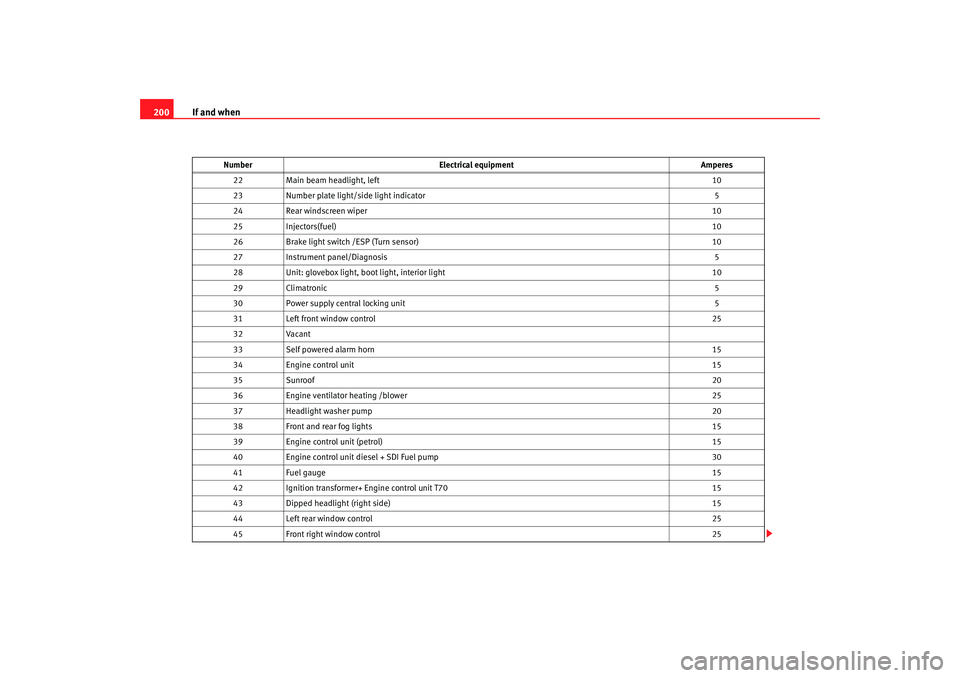

200

22 Main beam headlight, left 10

23 Number plate light/si de light indicator 5

24 Rear windscreen wiper 10

25 Injectors(fuel) 10

26 Brake light switch /ESP (Turn sensor) 10

27 Instrument panel/Diagnosis 5

28 Unit: glovebox light, boot light, interior light 10

29 Climatronic 5

30 Power supply central locking unit 5

31 Left front window control 25

32 Vacant

33 Self powered alarm horn 15

34 Engine control unit 15

35 Sunroof 20

36 Engine ventilator heating /blower 25

37 Headlight washer pump 20

38 Front and rear fog lights 15

39 Engine control unit (petrol) 15

40 Engine control unit diesel + SDI Fuel pump 30

41 Fuel gauge 15

42 Ignition transformer+ Engine control unit T70 15

43 Dipped headlight (right side) 15

44 Left rear window control 25

45 Front right window control 25

Number

Electrical equipment Amperes

cordoba_ingles Seite 200 Freitag, 7. Oktober 2005 6:00 18

Page 203 of 255

If and when201

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

Fuses below steering wheel in relay holderPTC fuses 46

Windscreen wiper unit 20

47 Heated rear window unit 20

48 Indicator unit 15

49 Cigarette lighter 15

50 Locking unit 15

51 Radio/CD/GPS/Telephone 20

52 Horn 20

53 Dipped headlight (left side) 15

54 Right rear window control 25a)The signal “S”is a system which includes the starter and steering lock and enables, after the ignition is switched off and with out removing the key from the steering and starter lock,

certain electrical components to be switched on, including for example, the radio, the courtesy light, etc. This function is de activated on removing the key from the steering and starter

lock.

Number Electrical equipment Amperes

1 PTCs (Supplementary electrical heating using air) 40

2 PTCs (Supplementary electrical heating using air) 40

3 PTCs (Supplementary electrical heating using air) 40

Number

Electrical equipment Amperes

cordoba_ingles Seite 201 Freitag, 7. Oktober 2005 6:00 18

Page 206 of 255

If and when

204Some of the electrical items listed in the table are only fitted on certain

models or are optional extras.

Please note that the above list, while corr ect at the time of printing, is subject

to alterations.Lamp changeGeneral notesBefore changing any lamp first turn off the equipment concerned.

Do not touch the lamp glass. Fingerprints vaporise in the heat, causing a

reduction in the lamp life and conden sation on the mirror surface, thus

reducing efficiency.

A lamp should only be placed by one of the same type. The designation is

inscribed on the bulb, either on the glass part or on the base.

It is highly recommended to keep a box of spare lamps in the vehicle. At the

very least, the lamps that most affect road safety should have spares in the

vehicle.

Rear lights on frame

Brake/side 12V/P21/5W

Indicator 12V/P21W Rear lights on tailgate

small side light 12V/W5W

fog light 12V/P21W

reverse 12V/P21W

Single reflector headlamps

main/dipped 12V 60/55W (H4)

indicator 12V/PY21W

side 12/W5W

Double reflector headlamps

dipped 12V/55W (H7)

main 12V/55W (H3)

indicator 12V/PY21W

side 12V/W5W

Xenon headlights

6)

dipped 12V/35W (D1S)

7)

main 12V/55W (H7)

indicator 12V/PY21W

side 12V/W5W

F1

Multi-terminal voltage supply “30”. Internal fuse box 100

G1 Trailer fuse voltage supply in internal fuse box 50

H1 Vacant

Number

Electrical equipment Amperes6)For these type of headlights, the bulbs must be changed by an Authorised Service

Centre, given that complex elements of the vehicle must be removed and that the au-

tomatic control system must be reset.7)Xenon discharge lamps emit 2.5 times as much light flux and have a useful life five

times greater than halogen lamps, this means that, except in case of an abnormal

fault, there is no need to change the bulbs during the vehicle life.

cordoba_ingles Seite 204 Freitag, 7. Oktober 2005 6:00 18

Page 207 of 255

If and when205

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

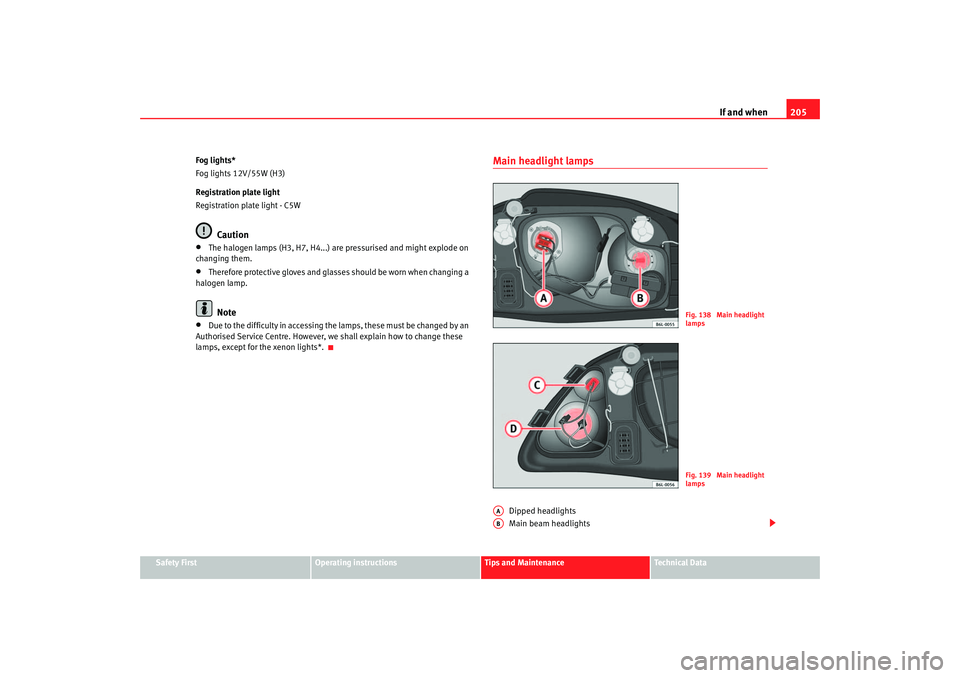

Fog lights*

Fog lights 12V/55W (H3)

Registration plate light

Registration plate light - C5W

Caution

•

The halogen lamps (H3, H7, H4...) are pressurised and might explode on

changing them.

•

Therefore protective gloves and glasses should be worn when changing a

halogen lamp.Note

•

Due to the difficulty in accessing the lamps, these must be changed by an

Authorised Service Centre. However, we shall explain how to change these

lamps, except for the xenon lights*.

Main headlight lamps

Dipped headlights

Main beam headlights

Fig. 138 Main headlight

lampsFig. 139 Main headlight

lamps

AAAB

cordoba_ingles Seite 205 Freitag, 7. Oktober 2005 6:00 18

Page 208 of 255

If and when

206

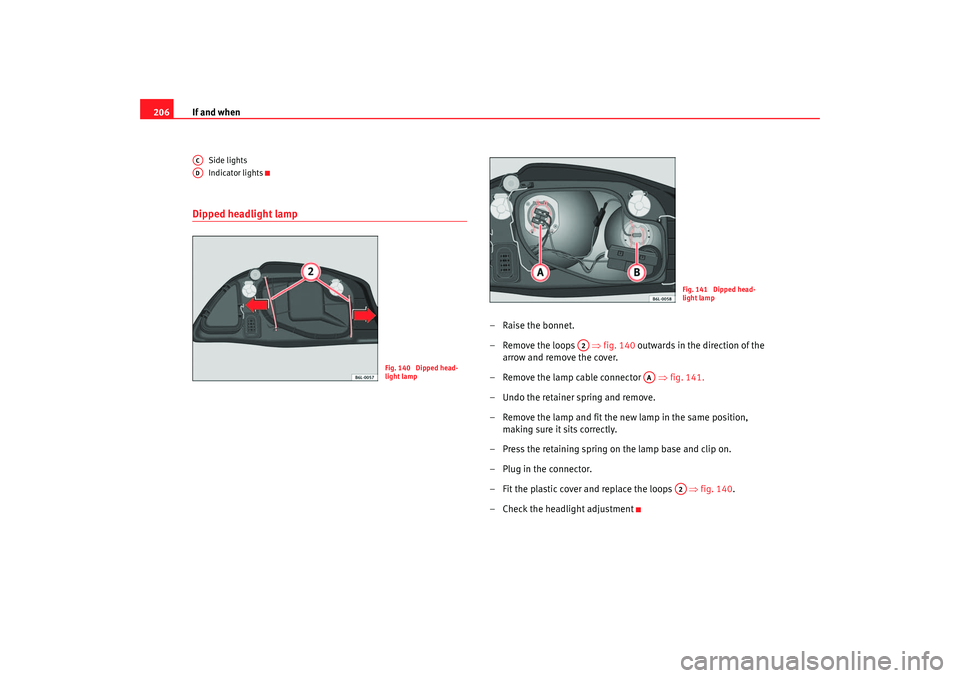

Side lights

Indicator lights

Dipped headlight lamp

–Raise the bonnet.

– Remove the loops ⇒fig. 140 outwards in the direction of the

arrow and remove the cover.

– Rem ove the lamp cable connector ⇒ fig. 141.

– Undo the retainer spring and remove.

– Remove the lamp and fit the new lamp in the same position, making sure it sits correctly.

– Press the retaining spring on the lamp base and clip on.

– Plug in the connector.

– Fit the plastic cover and replace the loops ⇒fig. 140.

– Check the headlight adjustment

ACAD

Fig. 140 Dipped head-

light lamp

Fig. 141 Dipped head-

light lamp

A2

AA

A2

cordoba_ingles Seite 206 Freitag, 7. Oktober 2005 6:00 18

Page 209 of 255

If and when207

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

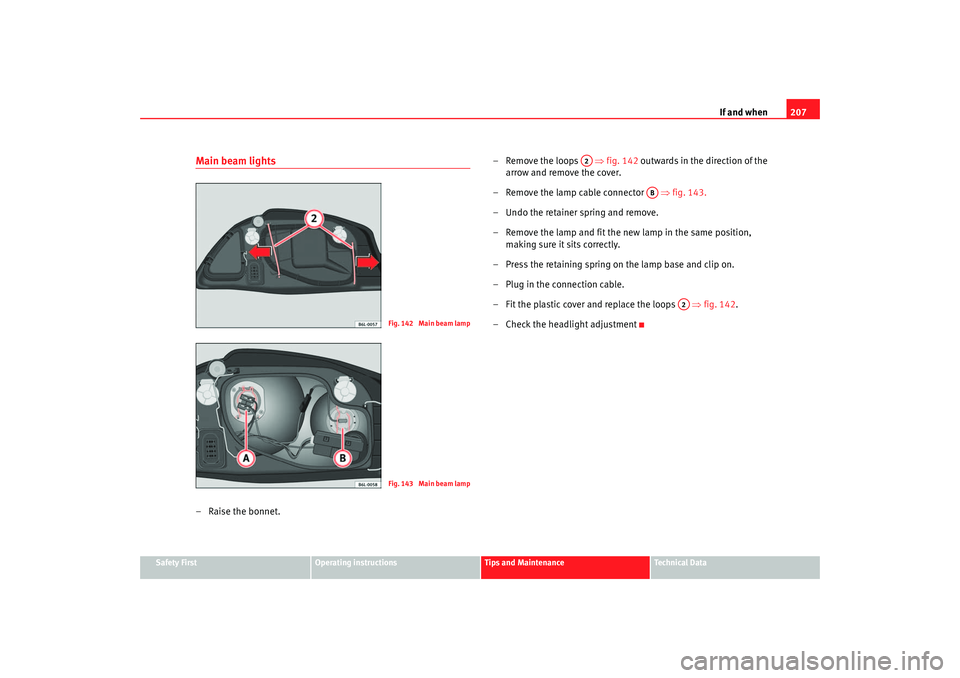

Main beam lights–Raise the bonnet. – Remove the loops

⇒fig. 142 outwards in the direction of the

arrow and remove the cover.

– Remove the lamp cable connector ⇒ fig. 143.

– Undo the retainer spring and remove.

– Remove the lamp and fit the new lamp in the same position, making sure it sits correctly.

– Press the retaining spring on the lamp base and clip on.

– Plug in the connection cable.

– Fit the plastic cover and replace the loops ⇒fig. 142.

– Check the headlight adjustment

Fig. 142 Main beam lampFig. 143 Main beam lamp

A2

AB

A2

cordoba_ingles Seite 207 Freitag, 7. Oktober 2005 6:00 18

Page 210 of 255

If and when

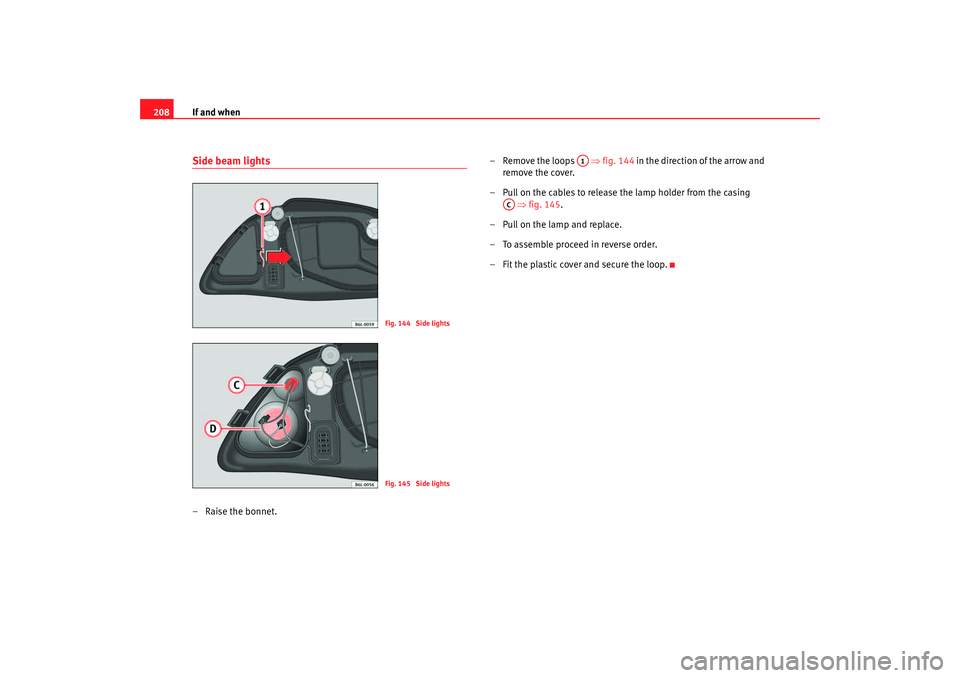

208Side beam lights– Raise the bonnet. – Remove the loops

⇒fig. 144 in the direction of the arrow and

remove the cover.

– Pull on the cables to release the lamp holder from the casing ⇒fig. 145.

–Pull on the lamp and replace.

– To assemble proceed in reverse order.

– Fit the plastic cover and secure the loop.

Fig. 144 Side lightsFig. 145 Side lights

A1

AC

cordoba_ingles Seite 208 Freitag, 7. Oktober 2005 6:00 18