lock Seat Exeo 2009 Manual PDF

[x] Cancel search | Manufacturer: SEAT, Model Year: 2009, Model line: Exeo, Model: Seat Exeo 2009Pages: 310, PDF Size: 8.54 MB

Page 218 of 310

Checking and refilling levels

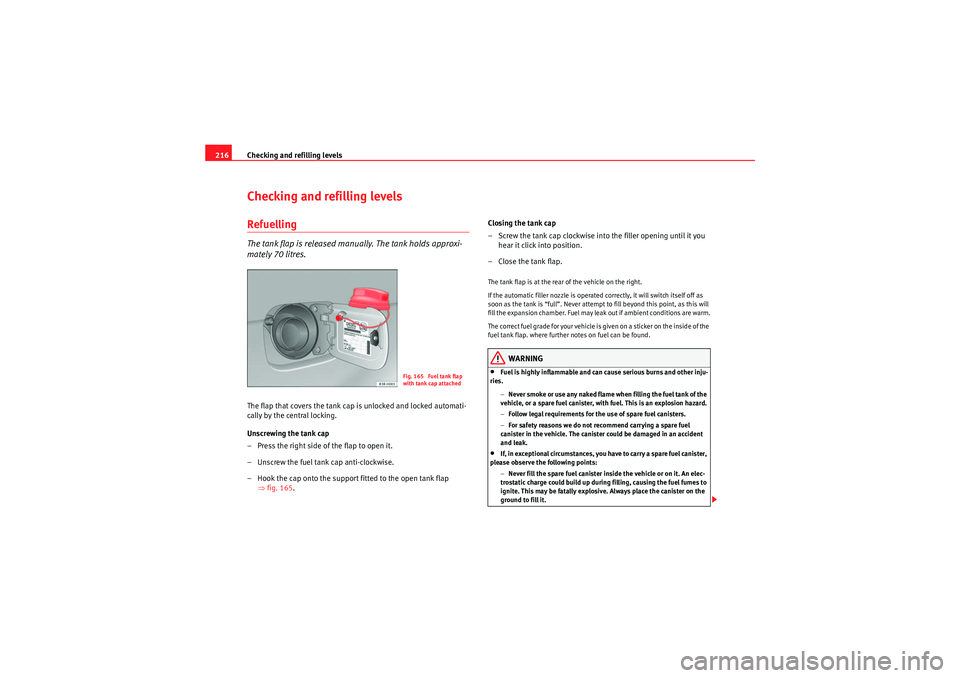

216Checking and refilling levelsRefuellingThe tank flap is released manually. The tank holds approxi-

mately 70 litres.The flap that covers the tank cap is unlocked and locked automati-

cally by the central locking.

Unscrewing the tank cap

– Press the right side of the flap to open it.

– Unscrew the fuel tank cap anti-clockwise.

– Hook the cap onto the support fitted to the open tank flap

⇒fig. 165 . Closing the tank cap

– Screw the tank cap clockwise into the filler opening until it you

hear it click into position.

– Close the tank flap.

The tank flap is at the rear of the vehicle on the right.

If the automatic filler nozzle is operated correctly, it will switch itself off as

soon as the tank is “full”. Never attempt to fill beyond this point, as this will

fill the expansion chamber. Fuel may leak out if ambient conditions are warm.

T he co rr ec t fu el g rad e fo r you r v eh icle is giv en on a sti cker o n th e i nsid e of the

fuel tank flap. where further notes on fuel can be found.

WARNING

•Fuel is highly inflammable and can cause serious burns and other inju-

ries.

−Never smoke or use any naked flame when filling the fuel tank of the

vehicle, or a spare fuel canister, with fuel. This is an explosion hazard.

− Follow legal requirements for the use of spare fuel canisters.

− For safety reasons we do not recommend carrying a spare fuel

canister in the vehicle. The canister could be damaged in an accident

and leak.•If, in exceptional circumstances, you have to carry a spare fuel canister,

please observe the following points:

−Never fill the spare fuel canister inside the vehicle or on it. An elec-

trostatic charge could build up during filling, causing the fuel fumes to

ignite. This may be fatally explosive. Always place the canister on the

ground to fill it.

Fig. 165 Fuel tank flap

with tank cap attached

Exeo_EN.book Seite 216 Freitag, 28. August 2009 10:14 10

Page 219 of 310

Checking and refilling levels217

Safety First

Controls and equipment

Practical tips

Technical Data

−

Insert the fuel nozzle into the mouth of the canister as far as

possible.

− If the spare fuel canister is made of metal, the filling nozzle must be

in contact with the canister during filling. This helps prevent an electro-

static charge building up.

− Never spill fuel in the vehicle or in the luggage compartment. Fuel

vapours are explosive. Danger of death.

Caution

•Fuel spills should be removed from the paintwork immediately.•Never run the tank completely dry. An irregular fuel supply could cause

misfiring. As a result, unburnt fuel could enter the catalytic converter and

cause damage.•When filling the fuel tank after having run it completely dry on a vehicle

with a diesel engine the ignition must be switched on for at least 30 seconds

without starting the engine. When you then start the engine it may take

longer than normal (up to one minute) for the engine to start firing. This is due

to the fact that the fuel system has to purge itself of air before starting.For the sake of the environment

Do not try to put in more fuel after the automatic filler nozzle has switched off;

this may cause the fuel to overflow if it becomes warm.

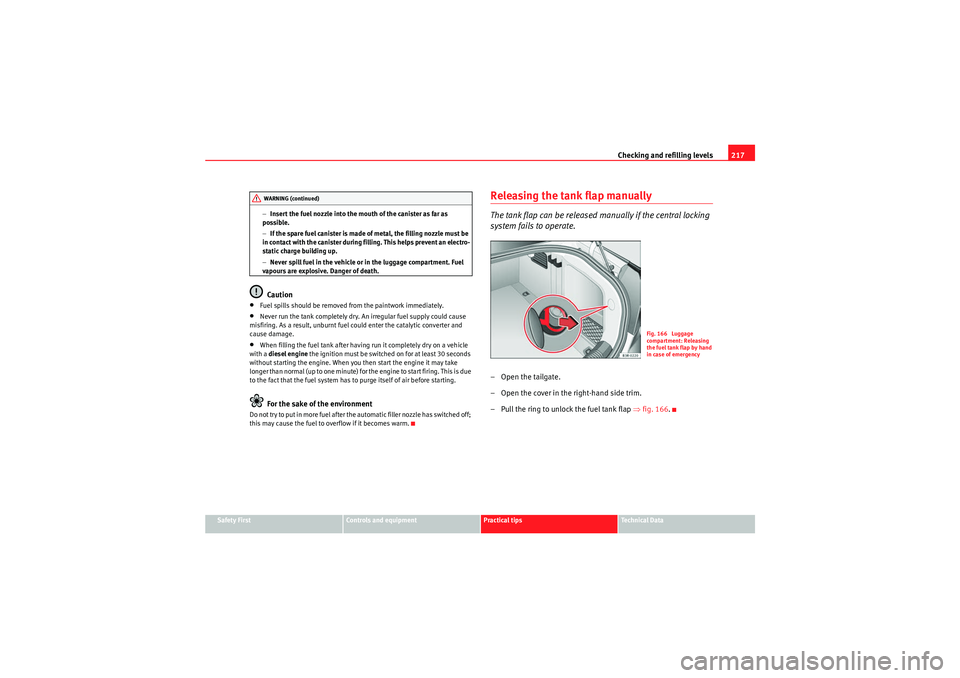

Releasing the tank flap manuallyThe tank flap can be released manually if the central locking

system fails to operate.–Open the tailgate.

– Open the cover in the right-hand side trim.

– Pull the ring to unlock the fuel tank flap ⇒fig. 166 .

WARNING (continued)

Fig. 166 Luggage

compartment: Releasing

the fuel tank flap by hand

in case of emergency

Exeo_EN.book Seite 217 Freitag, 28. August 2009 10:14 10

Page 222 of 310

Checking and refilling levels

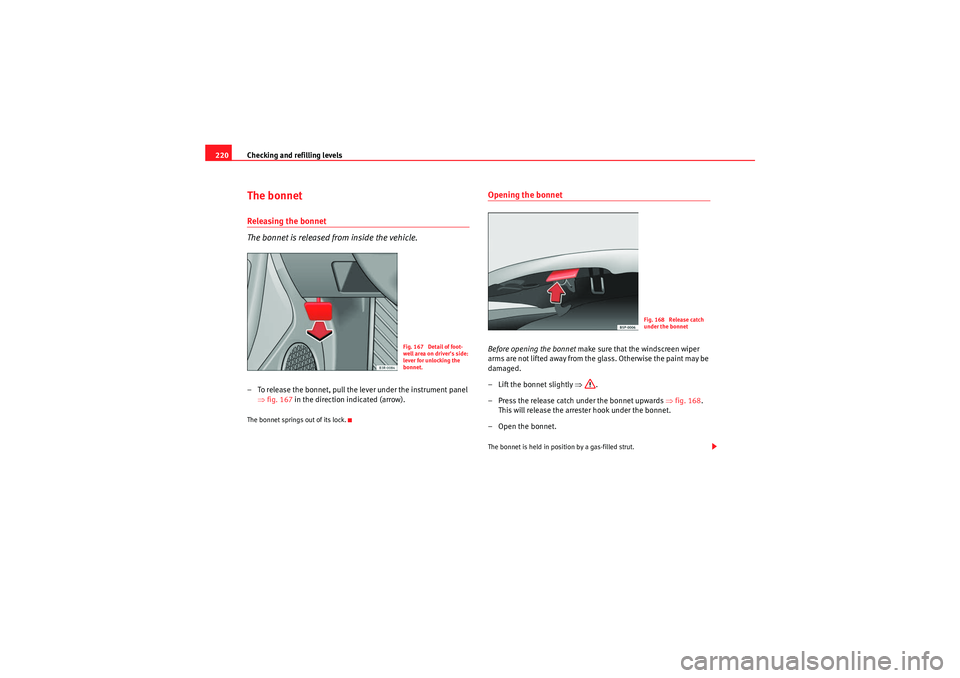

220The bonnetReleasing the bonnet

The bonnet is released from inside the vehicle.– To release the bonnet, pull the lever under the instrument panel

⇒fig. 167 in the direction indicated (arrow).The bonnet springs out of its lock.

Opening the bonnetBefore opening the bonnet make sure that the windscreen wiper

arms are not lifted away from the glass. Otherwise the paint may be

damaged.

– Lift the bonnet slightly ⇒.

– Press the release catch under the bonnet upwards ⇒fig. 168 .

This will release the arrester hook under the bonnet.

– Open the bonnet.The bonnet is held in position by a gas-filled strut.

Fig. 167 Detail of foot-

well area on driver's side:

lever for unlocking the

bonnet.

Fig. 168 Release catch

under the bonnet

Exeo_EN.book Seite 220 Freitag, 28. August 2009 10:14 10

Page 224 of 310

Checking and refilling levels

222

NoteOn right-hand drive vehicles some of the containers/ reservoirs mentioned

below are located on the other side of the engine compartment.Closing the bonnet– To close the bonnet, pull it down to overcome the spring pres- sure.

– Leave the bonnet secured in the locking part. Do not tighten

⇒ .

WARNING

•For safety reasons the bonnet must always be completely closed when

the vehicle is moving. After closing it always check that it is properly

secured. The bonnet must be flush with the adjacent body panels.•Should you notice that the bonnet is not safely secured when the

vehicle is moving, stop the vehicle immediately and close the bonnet.

Failure to do so could result in an accident.

Engine oilGeneral notesWe recommend that the oil change should be performed by an Authorised

Service Centre or a qualified workshop, according to the Maintenance

Program. The correct oil specifications for your engine are listed in the

⇒page 223,

“Oil properties”.

Check that the specifications quoted (VW standards) appear on the container

either singly or in combination with other specifications.

Flexible maintenance intervals (Extended Service Intervals*)

Special lubricating oils ⇒page 223 have been developed in the framework

of the SEAT “Extended Service Intervals” ⇒Booklet “Maintenance Program”

This type of oil must be used if you intend to take advantage of the prolonga-

tion of the maintenance intervals in the framework of the “Extended Service

Intervals” program.

•Do not mix the LongLife oil with oil intended for fixed service intervals, as

the requirements for the extended service intervals are then no longer guar-

anteed.•Only in exceptional circumstances, if the engine oil level is too low

⇒ page 224 and LongLife oil is not available, it is permitted to top up (once)

with oil for fixed service intervals ⇒ page 223 (up to a maximum of 0.5

litres).

Fixed service intervals*

If “Extended Service Intervals” are not applied to your vehicle, you can use

oils for fixed service intervals ⇒ page 223. In this case, your vehicle must be

serviced after a fixed interval of 1 year / 15,000 km (10,000 miles) (see the

Maintenance Program).•In exceptional circumstances, if the engine oil level is too low

⇒ page 224 and you cannot obtain the oil specified for your vehicle, you can

put in a small quantity of oil conforming to the specification ACEA A2 or

ACEA A3 (petrol engines) or ACEA B3 or ACEA B4 (diesel engines) (up to 0.5l).

Vehicles with diesel particulate filter*

The Maintenance Program states whether your vehicle is fitted with a diesel

particulate filter.

Exeo_EN.book Seite 222 Freitag, 28. August 2009 10:14 10

Page 229 of 310

Checking and refilling levels227

Safety First

Controls and equipment

Practical tips

Technical Data

Liquid coolant losses

Any loss of liquid coolant normally indicates a

leak in the cooling system. In

this case the cooling system should be inspected by a specialist garage

without delay. It is not sufficient merely to top up the liquid coolant.

If there are no leaks in the system, a loss of liquid coolant can only occur if

the coolant boils and is forced out of the system as a result of overheating.

Caution

Radiator sealants must not be added to the liquid coolant. Such additives

could seriously impair the function of the cooling system.Topping up the liquid coolant

Be careful when topping up with liquid coolant.– Switch the engine off.

– Wait for the engine to cool down.

– Cover the cap on the expansion tank ⇒page 226, fig. 172 with a

cloth, and carefully unscrew the cap anti-clockwise ⇒.

– Add liquid coolant.

– Screw on the cap tightly.Make sure that the liquid coolant meets the required specifications

⇒page 225, “Liquid coolant”. Do not use a different type of anti-freeze if

anti-freeze G12++ is not available. In this case, use only water and bring the

anti-freeze concentration back up to the correct level as soon as possible.

Always top up with new liquid coolant. Do not fill above the “max” mark. Excess liquid coolant is forced out of the

system through the valve in the filler cap when the engine gets hot.

If a lot of liquid coolant has been lost, wait for the engine to

cool down before

putting in cold coolant. Failure to do so could result in serious engine

damage.

WARNING

•The cooling system is under pressure. Do not unscrew the cap on the

expansion tank when the engine is hot. Failure to comply could result in

burns.•The anti-freeze and liquid coolant can be a health hazard. Therefore,

the anti-freeze should be stored in the original container in a safe place out

of reach of children. Failure to comply could result in poisoning.For the sake of the environment

Drained off coolant should not be used again. Drain off the used coolant into

a suitable container and dispose of it in the proper manner (observe environ-

mental regulations).Radiator fan

The radiator fan can start running spontaneously.The auxiliary fan can continue to run for as long as 10 minutes after stopping

the engine – even after the ignition is switched off. It may also start running

suddenly ⇒ after some while if•stored heat raises the coolant temperature, or•the hot engine compartment is additionally heated up by the sun.

Exeo_EN.book Seite 227 Freitag, 28. August 2009 10:14 10

Page 233 of 310

Checking and refilling levels231

Safety First

Controls and equipment

Practical tips

Technical Data

Topping up and changing the brake fluid

It is best to have the brake fluid changed by a professional.Brake fluid absorbs damp. Therefore, in the course of time it will absorb water

from the ambient air. If the water content in the brake fluid is too high, the

brake system could corrode. In addition, the boiling point of the brake fluid

will be considerably reduced. This could adversely affect the braking ability in

certain circumstances.

For this reason the brake fluid must be changed periodically.

Your vehicle's Service Schedule will tell you when the brake fluid has to be

renewed.

We recommend you have the brake fluid changed as part of a regular Inspec-

tion Service at your garage. They are familiar with the procedure and have the

necessary special tools and spare parts as well as the proper facilities for

disposing of the old fluid.

Use only the genuine brake fluid specified by the factory Specialist garages

know that the brake fluid -DOT 4- is factory approved. The brake fluid must be

new.

WARNING

•Therefore, it must always be kept closed in its original container. Keep

out of the reach of children. Failure to comply could result in poisoning.•Heavy use of the brakes may cause a vapour lock if the brake fluid is left

in the system for too long. This would seriously affect the efficiency of the

brakes and the safety of the car, leading to the risk of accident.Caution

Please note that brake fluid will attack the paintwork on contact.

For the sake of the environment

If the fluid has to be drained out of the brake system, use an appropriate

container to catch the used brake fluid and dispose of it in the proper

manner.BatteryGeneral notes

All work on batteries requires specialist knowledge.The battery is virtually maintenance-free and is checked in the Inspection

Services.

We recommend that you replace a battery once it is older than 5 years.

Disconnecting the battery

If the battery is disconnected, some of the vehicle's functions will become

inoperative (e.g. electric windows). These functions will require resetting

after the battery is reconnected. For this reason, the battery should only be

disconnected from the vehicle's electrical system when absolutely necessary.

Long periods of non-use

The battery will gradually lose its charge because certain electrical equip-

ment continues to draw current even when the ignition is off. If you park the

vehicle for long periods of time in winter you should take the battery out of

the vehicle and keep it in a frost-proof room. Store the battery in a place

where it cannot “freeze up” and become damaged. At warm outside temper-

atures it is sufficient to disconnect the negative terminal of the battery. Even

when the battery is not connected you should charge it from time to time.

Exeo_EN.book Seite 231 Freitag, 28. August 2009 10:14 10

Page 235 of 310

Checking and refilling levels233

Safety First

Controls and equipment

Practical tips

Technical Data

•A highly explosive mixture of gases is released when the battery is

under charge. The batteries should be charged in a well-ventilated room

only.•Keep children away from acid and batteries.•Before working on the electrical system, you must switch off the

engine, the ignition and all consumers. The negative cable on the battery

must be disconnected. When a light bulb is changed, you need only switch

off the light.•Deactivate the anti-theft alarm by unlocking the vehicle before you

disconnect the battery! The alarm will otherwise be triggered.•When disconnecting the battery from the vehicle electrical system,

disconnect first the negative cable and then the positive cable.•Switch off all electrical consumers before reconnecting the battery.

Reconnect first the positive cable and then the negative cable. Never

reverse the polarity of the connections. This could cause an electrical fire.•Never charge a frozen battery, or one which has thawed. This could

result in explosions and chemical burns. Always replace a battery which

has frozen. A flat battery can freeze at temperatures around 0°.•Ensure that the vent hose is always connected to the battery.•Never use a defective battery. This may be fatally explosive. Replace a

damaged battery immediately.Caution

•Never disconnect the battery if the ignition is switched on or if the engine

is running. This could damage the electrical system or electronic compo-

nents.•Do not expose the battery to direct sunlight over a long period of time, as

the intense ultraviolet radiation can damage the battery housing.•If the vehicle is left standing in cold conditions for a long period, protect

the battery from frost. If it “freezes” it will be damaged.

Charging the battery

A fully-charged battery is important for reliable starting.–Note the warnings ⇒ in “Important safety warnings for

handling a car battery” on page 232 and ⇒.

– Switch off the ignition and all electrical equipment.

– Only if “fast-charging”: both battery cables must be discon- nected (first the “negative” cable, then the “positive” cable).

– Connect the charger cables to the battery terminals, noting the colour code (red is used for “positive”, black or brown for “nega-

tive”).

– Now connect the battery charger to the power point and switch on.

– After charging the battery: switch off the battery charger and disconnect the power point cable.

– Finally disconnect the charger cables from the battery.

– If necessary, reconnect both battery cables to the battery (first the “positive” cable, then the “negative” cable).When charging with a low current (for instance with a small battery charger)

the battery does not normally have to be disconnected. However, both

battery cables must be disconnected before “ fast-charging” the battery with

a high current. However, always follow the instructions given by the manufac-

turer of the battery charger.

The fast-charging procedure for a battery is dangerous ⇒ in “Important

safety warnings for handling a car battery” on page 232, as it requires a

WARNING (continued)

Exeo_EN.book Seite 233 Freitag, 28. August 2009 10:14 10

Page 247 of 310

If and when245

Safety First

Controls and equipment

Practical tips

Technical Data

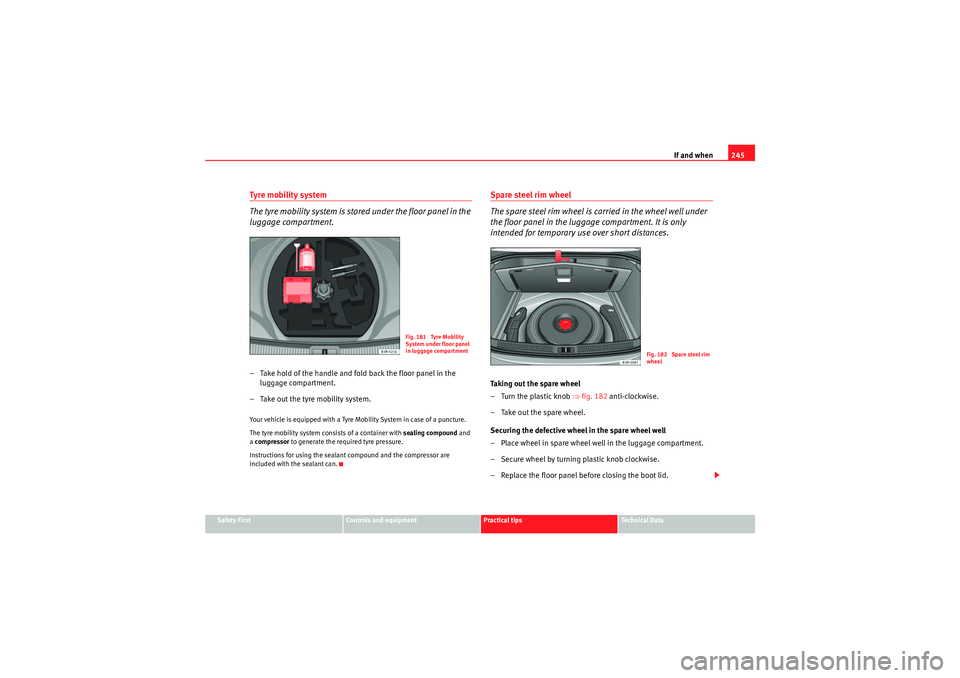

Tyre mobility system

The tyre mobility system is stored under the floor panel in the

luggage compartment.– Take hold of the handle and fold back the floor panel in the

luggage compartment.

– Take out the tyre mobility system.Your vehicle is equipped with a Tyre Mobility System in case of a puncture.

The tyre mobility system consists of a container with sealing compound and

a compressor to generate the required tyre pressure.

Instructions for using the sealant compound and the compressor are

included with the sealant can.

Spare steel rim wheel

The spare steel rim wheel is carried in the wheel well under

the floor panel in the luggage compartment. It is only

intended for temporary use over short distances.Taking out the spare wheel

–Turn the plastic knob ⇒ fig. 182 anti-clockwise.

– Take out the spare wheel.

Securing the defective wheel in the spare wheel well

– Place wheel in spare wheel well in the luggage compartment.

– Secure wheel by turning plastic knob clockwise.

– Replace the floor panel before closing the boot lid.

Fig. 181 Tyre Mobility

System under floor panel

in luggage compartment

Fig. 182 Spare steel rim

wheel

Exeo_EN.book Seite 245 Freitag, 28. August 2009 10:14 10

Page 248 of 310

If and when

246Your vehicle can be equipped with a steel spare wheel at the factory. The

spare wheel does not usually meet the same performance standards as the

wheels fitted on the vehicle because of the wheel/tyre dimensions, rubber

composition, tread pattern, etc. Therefore, note the following restrictions:•The spare steel rim wheel is designed only for your vehicle model. Do not

attempt to mount the wheel on any vehicle but your own.•Your vehicle will have different driving characteristics when the spare

steel rim wheel is mounted ⇒.•The spare wheel is only intended for temporary use after having a flat tyre.

Replace the spare wheel with a normal wheel that has the proper tyre dimen-

sions as soon as possible.•If the size of the spare steel rim wheel is different to that of the other

wheels, it is unlikely that snow chains suitable for the other wheels will fit it.WARNING

•After mounting the spare steel rim wheel, the tyre pressure must be

checked and corrected as soon as possible. The inflating pressure must

adapt to the vehicle load (consult the table containing the inflation pres-

sures). Otherwise there is danger of causing an accident. Use the highest

tyre pressure as indicated in the table.•Do not drive faster than 80 km/h, as higher speeds can cause an acci-

dent.•Avoid heavy acceleration, hard braking and fast cornering, as this could

cause an accident.

Changing a wheelPreparation work

What you must do before changing a wheel.– If you have a flat tyre or puncture, park the car as far away from the flow of traffic as possible. Choose a location that is as level

as possible.

– All passengers should leave the vehicle. They should wait in a

safe place (e.g. behind the roadside crash barrier).

–Apply the handbrake firmly.

–Engage 1st gear.

– When towing a trailer: Unhitch the trailer from your vehicle.

–Take the tools and the spare wheel ⇒ page 244 out of the

luggage compartment.

WARNING

If you have a puncture in heavy traffic, switch on the hazard warning lights

and place the warning triangle in a visible location. This is for your own

safety and also warns other road users.

Caution

If you have to change the tyre on a gradient, block the wheel opposite the

wheel being changed by placing a stone or similar object under it to prevent

the vehicle from rolling away.

Exeo_EN.book Seite 246 Freitag, 28. August 2009 10:14 10

Page 250 of 310

If and when

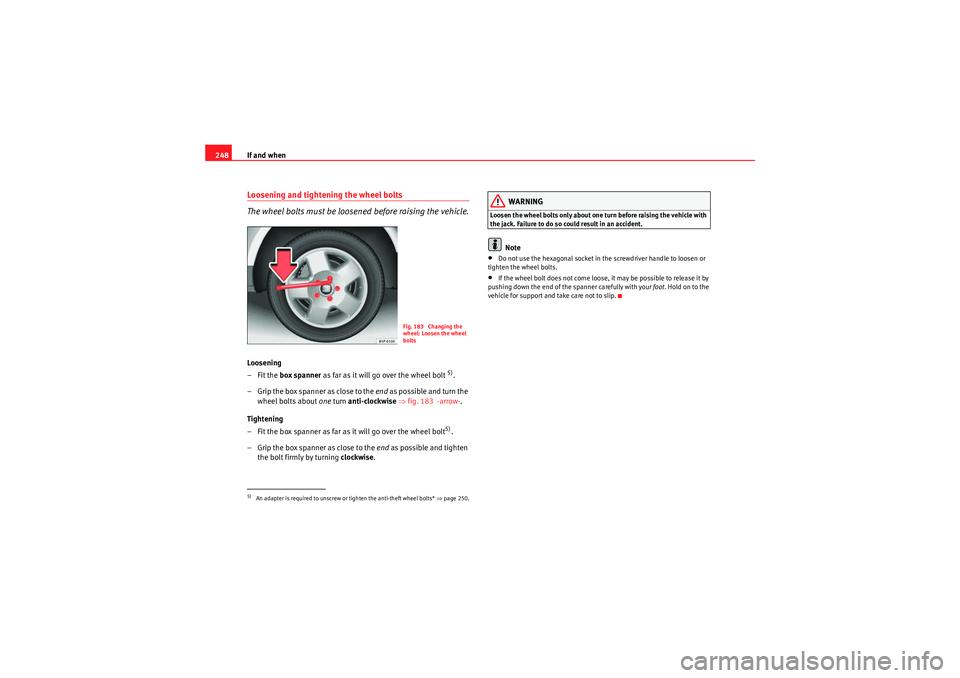

248Loosening and tightening the wheel bolts

The wheel bolts must be loosened before raising the vehicle.Loosening

–Fit the box spanner as far as it will go over the wheel bolt

5).

– Grip the box spanner as close to the end as po ssible an d turn t he

wheel bolts about one turn anti-clockwise ⇒ fig. 183 -arrow- .

Tightening

– Fit the box spanner as far as it will go over the wheel bolt5).

– Grip the box spanner as close to the end as possible and tighten

the bolt firmly by turning clockwise.

WARNING

Loosen the wheel bolts only about one turn before raising the vehicle with

the jack. Failure to do so could result in an accident.

Note

•Do not use the hexagonal socket in the screwdriver handle to loosen or

tighten the wheel bolts.•If the wheel bolt does not come loose, it may be possible to release it by

pushing down the end of the spanner carefully with your foot. Hold on to the

vehicle for support and take care not to slip.

5)An adapter is required to unscrew or tighten the anti-theft wheel bolts* ⇒page 250.

Fig. 183 Changing the

wheel: Loosen the wheel

bolts

Exeo_EN.book Seite 248 Freitag, 28. August 2009 10:14 10