Seat Exeo 2011 Owner's manual

Manufacturer: SEAT, Model Year: 2011, Model line: Exeo, Model: Seat Exeo 2011Pages: 313, PDF Size: 5.02 MB

Page 251 of 313

249

If and when

Loosening and tightening the wheel bolts

The wheel bolts must be loosened before raising the vehicle.

Fig. 179 Changing the

wheel: Loosen the wheel

bolts

Loosening

– Fit the box spanner as far as it will go over the wheel bolt 1)

.

– Grip the box spanner as close to the end as possible and turn

the wheel bolts about one turn anti-clockwise

⇒ fig. 179 -arrow-.

Tightening

– Fit the box spanner as far as it will go over the wheel bolt 1)

.

– Grip the box spanner as close to the end as possible and tight-

en the bolt firmly by turning clockwise.

WARNING

Loosen the wheel bolts only about one turn before raising the vehicle

with the jack. Failure to do so could result in an accident.

Note

● If the wheel bolt does not come loose, it may be possible to release it by

pushing down the end of the spanner carefully with your foot. Hold on to the

vehicle for support and take care not to slip.

1)

An adapter is required to unscrew or tighten the anti-theft wheel bolts* ⇒ page 251.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 252 of 313

250If and when

Raising the vehicle

In order to remove the wheel, the vehicle must be raised

with a jack.

Fig. 180 Changing the

wheel: Jack position

points

Fig. 181 Changing the

wheel: Jack –

Position the vehicle jack under the door sill at the jacking point

closest to the wheel being changed ⇒ fig. 180 -arrows-.

– Wind up the jack under the jacking point until the claw of the

jack is directly below the vertical rib under the door sill.

– Align the jack so that the arm of the jack fits on the rib under

the door sill ⇒ fig. 181 A

and the movable base plate of the

jack B is flat on the ground.

– Raise the vehicle until the defective wheel is just clear of the

ground.

Recesses at the front and rear of the door sills mark the jacking points

⇒ fig. 180 -arrows-. There is only one jacking point for each wheel. Do not fit

the jack anywhere else.

The distance from the jacking points to the wheel arches is approximately

15 cm at the front and 25 cm at the rear.

An unstable surface under the jack may cause the vehicle to slip off the

jack. Therefore, the jack must be fitted on solid ground offering good sup-

port. Use a large, stable base if necessary. On a hard, slippery surface (such

as tiles) use a rubber mat or similar to prevent the jack from slipping.

WARNING

● Take all precautions so that the base of the jack does not slip. Failure

to do so could result in an accident.

● The vehicle can be damaged if the jack is not applied at the correct

jacking points. There is also a risk of injury since the jack can slip off

suddenly if it is not properly engaged.

Page 253 of 313

251

If and when

Removing and fitting the wheel

For removal and fitting the wheel, the following tasks must

be completed.

After loosening the wheel bolts and raising the vehicle with the

jack, change the wheel as described below:

Removing a wheel

– Unscrew the wheel bolts using the box spanner and place them

on a clean surface.

Fitting a wheel

– Screw on the wheel bolts in position and tighten them loosely

with a box spanner.

The wheel bolts should be clean and easily screwed. Before fitting the spare

wheel, inspect the wheel condition and hub mounting surfaces. These sur-

faces must be clean before fitting the wheel.

If tyres with a specific direction of rotation are fitted, note the direction of

rotation. Anti-theft wheel bolts*A special adapter is required to turn the anti-theft wheel

bolts.

Fig. 182 Anti-theft

wheel bolt

– Insert the adapter onto the wheel bolt and push it on as far as it

will go ⇒ fig. 182.

– Fit the box spanner as far as it will go over the adapter.

– Loosen or tighten the wheel bolt as appropriate.

Code

The code number of the anti-theft wheel bolt is stamped onto the front part

of the adaptor.

The code number should be noted and kept in a safe place, as it is only by

using the code number that a duplicate adaptor can be obtained from an

Authorised Service Centre.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 254 of 313

252If and when

Tyres with directional tread pattern

Tyres with directional tread pattern must be fitted so that

they rotate in the correct direction.

A directional tread pattern can be identified by arrows on the sidewall that

point in the direction of rotation. Always note the direction of rotation indi-

cated when fitting the wheel. This is important so that these tyres can give

maximum grip and avoid excessive noise, tread wear and aquaplaning.

If, in an emergency, you have to fit the spare wheel so it rotates in the wrong

direction, you must drive extremely carefully. The tyre will not give optimum

performance. This is particularly important when driving on wet roads.

To benefit from the advantages of tyres with this type of tread pattern, the

defective tyre should be replaced as soon as possible so that all tyres again

rotate in the correct direction. Tyre repair* (Tyre-Mobility-System)

General information and safety notes

Repaired tyres are only suitable for temporary use over a

short period.

Fig. 183 The Tyre Mobi-

lity System is not suita-

ble for repairing this type

of damage to tyres.

Your vehicle is equipped with a tyre repair kit: the Tyre Mobility System.

In the event of a puncture you will find the TMS, which consists of a sealing

compound and a compressor, located under the floor panel in the luggage

compartment.

The Tyre Mobility System will reliably seal tyres damaged by foreign bodies,

provided that the cuts or punctures are no larger than approx. 4 mm.

It is not necessary to remove the foreign body from the tyre.

Page 255 of 313

253

If and when

The sealing compound must not be used in the following cases:

● If the cuts and punctures on the tyre are longer than 4 mm ⇒ fig. 183 1

●

If the wheel rim has been damaged 2●

If you have been driving with very low pressure or a completely flat tyre

3

How to use the TMS (tyre mobility system) is described in the section Re-

pairing a tyre ⇒ page 254 and in the instructions supplied with the tyre

sealant can.

The TMS (tyre mobility system) can be used at outside temperatures down

to -20 °C.

WARNING

After repairing a tyre please note the following points:

● Do not drive faster than 80 km/h.

● Avoid heavy acceleration, hard braking and fast cornering.

● Vehicle handling could be impaired.

● Tyres which have been sealed using the Tyre Mobility System are only

suitable for temporary use over a short period.

● After using the tyre sealant the tyre pressure monitoring system* may

malfunction. Therefore, please drive carefully to the next available quali-

fied workshop.

● The Tyre Mobility System must NOT be used:

– If the cuts and punctures on the tyre are longer or wider than

4 mm.

– if the wheel rim has been damaged.

– if you have been driving with very low pressure or a completely flat

tyre.

● Seek professional assistance if the repair of a tyre puncture is not

possible with the sealing compound.

WARNING (Continued)

● Do not allow the sealant to come into contact with your eyes, skin or

clothing.

● If you do come into contact with the sealant immediately rinse the

eyes or skin affected with clean water.

● Change clothing immediately if it becomes soiled with the tyre seal-

ant.

● Make sure you do not breathe in the fumes!

● If any of the tyre sealant is accidentally ingested, immediately rinse

the mouth thoroughly and drink lots of water.

–Do not induce vomiting. Seek medical assistance if needed.

● If any allergic reactions should occur get medical help immediately.

● Keep the sealant away from children.

For the sake of the environment

If you have to dispose of a sealant can, go to a specialised waste service or

to a SEAT Technical Service, where the product can be recycled in an appro-

priate waste container.

Note

● If sealant should leak out, leave it to dry. This way you can pull it off like

a piece of foil.

● Observe the expiry date stated on the sealing compound can. Have the

sealing compound exchanged by a specialised workshop.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 256 of 313

254If and when

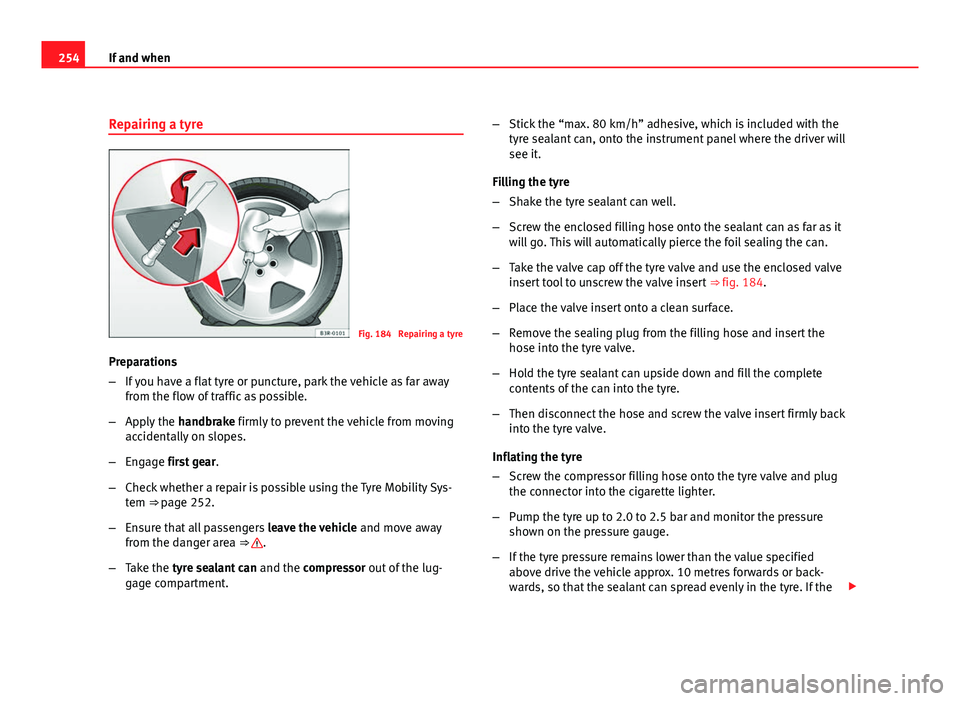

Repairing a tyre

Fig. 184 Repairing a tyre

Preparations

– If you have a flat tyre or puncture, park the vehicle as far away

from the flow of traffic as possible.

– Apply the handbrake firmly to prevent the vehicle from moving

accidentally on slopes.

– Engage first gear .

– Check whether a repair is possible using the Tyre Mobility Sys-

tem ⇒ page 252.

– Ensure that all passengers leave the vehicle and move away

from the danger area ⇒

.

– Take the tyre sealant can and the compressor out of the lug-

gage compartment. –

Stick the “max. 80 km/h” adhesive, which is included with the

tyre sealant can, onto the instrument panel where the driver will

see it.

Filling the tyre

– Shake the tyre sealant can well.

– Screw the enclosed filling hose onto the sealant can as far as it

will go. This will automatically pierce the foil sealing the can.

– Take the valve cap off the tyre valve and use the enclosed valve

insert tool to unscrew the valve insert ⇒ fig. 184.

– Place the valve insert onto a clean surface.

– Remove the sealing plug from the filling hose and insert the

hose into the tyre valve.

– Hold the tyre sealant can upside down and fill the complete

contents of the can into the tyre.

– Then disconnect the hose and screw the valve insert firmly back

into the tyre valve.

Inflating the tyre

– Screw the compressor filling hose onto the tyre valve and plug

the connector into the cigarette lighter.

– Pump the tyre up to 2.0 to 2.5 bar and monitor the pressure

shown on the pressure gauge.

– If the tyre pressure remains lower than the value specified

above drive the vehicle approx. 10 metres forwards or back-

wards, so that the sealant can spread evenly in the tyre. If the

Page 257 of 313

255

If and when

pressure is still lower than the specification the tyre is too badly

damaged and cannot be repaired using the tyre sealant.

Final check

– After about 10 minutes, stop to check the tyre pressure.

– If tyre pressure is less than 1.3 bar, the tyre is too badly dam-

aged. Do not drive on! You should obtain professional assis-

tance.

WARNING

● If you have a puncture in heavy traffic, switch on the hazard warning

lights and place the warning triangle in a visible location. This is for your

own safety and also warns other road users.

● Make sure your passengers wait in a safe place (for instance behind

the roadside crash barrier).

● Please observe the manufacturer's safety notes on the compressor

and the instructions supplied with the tyre sealant can.

● If it is not possible to build up a tyre pressure of 2.0 bar within 6 mi-

nutes this means that the tyre is too badly damaged. Do not drive on!

● Seek professional assistance if the repair of a tyre puncture is not

possible with the sealing compound.

● If tyre pressure is less than 1.3 bar after driving about 10 minutes,

the tyre is too badly damaged. Do not drive on! Obtain technical assis-

tance.

CAUTION

Take special care if you have to repair a tyre on a slope.

Note

● Do not use the compressor for longer than 6 minutes. Otherwise, it

might overheat. When the compressor has cooled down, you can use it

again.

● If tyre sealant should leak out, leave it to dry and then pull it off like foil.

● After carrying out a tyre repair remember to buy a new tyre sealant can at

a qualified workshop. This will ensure that the Tyre Mobility System is oper-

ative again.

● Please observe legal requirements when doing so.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 258 of 313

256If and when

Fuses

Changing fuses

If a fuse has blown, it must be replaced.

Fig. 185 Left side of

dash panel: Fuse box cov-

er

Fig. 186 Schematic

drawing of fuse box at

the left-hand end of dash

panel: Fuses (without

fuse cover) –

Switch off the ignition and its failed electrical component.

– Remove the fuse cover using a screwdriver ⇒ fig. 185.

– Identify the fuse corresponding to the damaged electric con-

sumer ⇒ page 257, Fuse assignment.

– Take the plastic clip from inside the fuse cover, fit it onto the

blown fuse, and pull the fuse out.

– Replace the blown fuse (which will have a melted metal strip)

with a new fuse of the same amp rating.

– Fit the fuse cover back on.

The individual electrical circuits are protected by fuses. The fuses are loca-

ted behind a cover at the left-hand end of the dash panel.

Two spare fuses and a sticker identifying the fuses are provided on the in-

side of the fuse cover. There is also a crank handle for operating the sun-

roof* by hand (if the electrical system fails).

CAUTION

Never “repair” damaged fuses and never replace them with fuses with a

higher rating. Failure to comply could result in fire. It could also cause dam-

age to other parts of the electrical system.

Note

If a newly replaced fuse blows again after a short time, the electrical system

must be checked by a qualified workshop as soon as possible.

Page 259 of 313

257

If and when

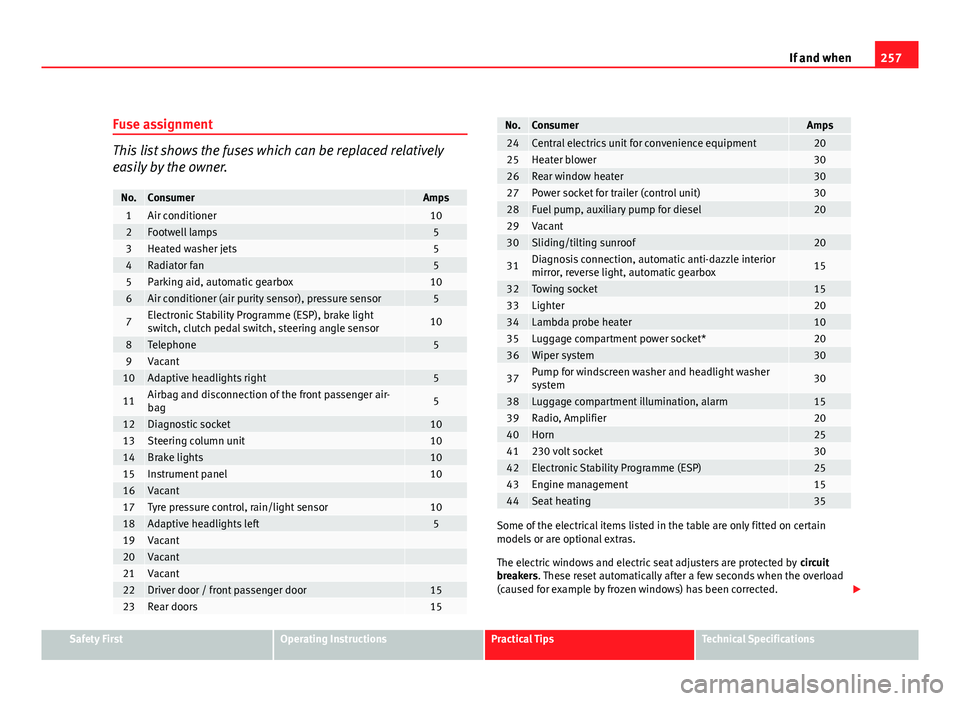

Fuse assignment

This list shows the fuses which can be replaced relatively

easily by the owner.

No.ConsumerAmps1Air conditioner102Footwell lamps53Heated washer jets54Radiator fan55Parking aid, automatic gearbox106Air conditioner (air purity sensor), pressure sensor5

7Electronic Stability Programme (ESP), brake light

switch, clutch pedal switch, steering angle sensor10

8Telephone59Vacant 10Adaptive headlights right5

11Airbag and disconnection of the front passenger air-

bag5

12Diagnostic socket1013Steering column unit1014Brake lights1015Instrument panel1016Vacant 17Tyre pressure control, rain/light sensor1018Adaptive headlights left519Vacant 20Vacant 21Vacant 22Driver door / front passenger door1523Rear doors15

No.ConsumerAmps24Central electrics unit for convenience equipment2025Heater blower3026Rear window heater3027Power socket for trailer (control unit)3028Fuel pump, auxiliary pump for diesel2029Vacant 30Sliding/tilting sunroof20

31Diagnosis connection, automatic anti-dazzle interior

mirror, reverse light, automatic gearbox15

32Towing socket1533Lighter2034Lambda probe heater1035Luggage compartment power socket*2036Wiper system30

37Pump for windscreen washer and headlight washer

system30

38Luggage compartment illumination, alarm1539Radio, Amplifier2040Horn2541230 volt socket3042Electronic Stability Programme (ESP)2543Engine management1544Seat heating35

Some of the electrical items listed in the table are only fitted on certain

models or are optional extras.

The electric windows and electric seat adjusters are protected by circuit

breakers. These reset automatically after a few seconds when the overload

(caused for example by frozen windows) has been corrected.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 260 of 313

258If and when

Note

Please note that the above list contains all data at the time of going to

press, so it is subject to modifications. If discrepancies should occur,

please refer to the sticker on the inside of the fuse cover for the correct in-

formation for your model.

Bulbs

General information

You can change the following bulbs for exterior lights yourself:

● Main headlights: all bulbs (except xenon headlights)

● Tail lights: all bulbs

● Side turn signal bulb

The following bulbs can only be changed by a qualified workshop:

● Main headlights: Xenon* bulb ⇒ page 265

● Front fog lights: Bulb

As a rule, you require a certain degree of practical skill to change defective

bulbs. This applies in particular to those bulbs which are only accessible

from the engine compartment.

If in doubt, we recommend that you have defective bulbs changed by a

qualified workshop or qualified mechanic.

If you do decide to change bulbs in the engine compartment yourself, be

aware of the safety risks involved ⇒ page 221 ⇒

in Types of bulbs on

page 259. The name of many of the lamps fitted by SEAT ends in "LL". This means Long

Life. These lamps are used for functions with a long service time (dipped

beam, side lights, daylight driving, etc.). This does not apply to lamps with

a shorter service time (turn signals, etc.). A lamp with the same name ex-

cept for the last two letters, "LL“ or “SLL”, is compatible, but will have a

service life of approximately half of the LongLife lamps.

When replacing lamp bulbs, the same type of bulb as originally fitted

should always be used where possible.