ECU Seat Exeo 2011 Owner's Guide

[x] Cancel search | Manufacturer: SEAT, Model Year: 2011, Model line: Exeo, Model: Seat Exeo 2011Pages: 313, PDF Size: 5.02 MB

Page 149 of 313

147

Seats and storage compartments

Drink holder in the rear armrest*

Fig. 121 Drink holder in

the rear armrest

Opening the drink holder

– Press the symbol A

⇒ fig. 121.

Adjusting the retainer arm

– To adjust one of the retainer arms B

, release it by pressing in

the direction indicated (arrow) and move it as required.

The retainer arm should be positioned against the drink holder so that it is

held securely.

One or two drink holders can be held in the centre console.

WARNING

● Do not put any hot drinks in the drink holder while the vehicle is mov-

ing. You can be scalded if the hot liquid is spilt.

● Do not use hard china cups or glasses. These could cause injury in the

event of an accident.

Ashtray*, cigarette lighter* and electric

sockets* Front ashtray*

Fig. 122 Centre console:

Open ashtray

Opening the ashtray

– Lightly press the front part of the ashtray A

⇒ fig. 122.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 153 of 313

151

Seats and storage compartments

WARNING

● Heavy appliances or connectors (for example, adapters) which hang

down directly from the Europlug socket may damage the socket with the

resultant risk of injury.

● Ensure that appliances connected to the socket are secure to prevent

them from being thrown around the vehicle in the event of sharp braking

or an accident. This could result in severe injury or loss of life ⇒ page 16,

Storing objects.

● Never spill liquid over the socket – there is a risk of death. If any

moisture enters the socket, ensure that it is thoroughly dry before using.

● Improper use of the sockets or electrical accessories can lead to seri-

ous injuries or cause a fire, with the resultant risk of injury.

● Children must never be left alone in the vehicle with the engine run-

ning. They could cause an accident.

● Appliances connected to the socket do not behave in the same way as

when they are connected to the mains power supply. They may overheat

during use and cause injury.

● When using adapters and extension leads, the childproof safety de-

vice on the 230 volt socket is disconnected and the socket is live. Risk of

injury!.

● Never insert objects which conduct electricity, such as a needle, in

the pins of the 230 volt socket. There is a risk of death.

● Always switch off electrical appliances connected to the socket if the

inverter goes off as a result of overheating. Failure to comply could result

in injuries.

CAUTION

● The instructions for handling appliances connected to the socket must

be observed.

● If the power consumption of the appliances connected exceeds 150

watts, the socket inverter will overheat. If the temperature exceeds a certain

value, the inverter will switch off. It may also switch off if the outside tem- perature is very high, even if the power consumption is normal. The inverter

will switch on again automatically after it has cooled down. Appliances con-

nected to the socket, and which have been left switched on, will automati-

cally come back on

⇒

.

● Do not connect neon lamps to the socket. For technical reasons, these

could break down.

● Do not connect 115 volt appliances to the 230 volt power socket, as

they could be damaged. If you have any queries, please check the manufac-

turer's label for details of the power supply accepted by the appliance.

● With some adapters, for example for laptops, their built-in overload dis-

connection system prevents the equipment from switching on in the event

of an excessive start-up current. In this case, disconnect the adapter from

the power supply and try to reconnect after ten seconds.

Note

● Non-insulated equipment may cause interference to the radio or vehicle

electronics.

● The Europlug socket has a built-in childproof device and only carries live

current when the Europlug is correctly plugged in.

● Some appliances may not operate correctly in the absence of adequate

power (watts).

● In some countries this socket is 115 volts. Therefore the socket should

have a different inverter installed at the factory. You can obtain retrofit kits

from your Authorised Technical Service. Do not connect 115 Volt appliances

to the 230 Volt socket.

● The use of electrical equipment in the vicinity of the aerial in the rear

window may cause interference to the reception of stations broadcasting in

AM.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 167 of 313

165

Driving

Driving SteeringAdjusting the steering wheel position

The height and reach of the steering wheel can be freely ad-

justed to suit the driver

Fig. 134 Lever beneath

steering column

– Push the lever ⇒ fig. 134 down ⇒

.

– Move the steering wheel to the desired position.

– Then push the lever back up against the steering column until it

engages in position.

WARNING

● Never adjust the position of the steering wheel when the vehicle is

moving, as this could cause an accident.

● For safety reasons, the lever must always be securely engaged when

the vehicle is moving, so that the position of the steering wheel cannot

shift unexpectedly. Otherwise this could cause an accident.

Safety Electronic Stability Programme (ESP)

ESP helps make driving safer in certain situations.

Fig. 135 Detailed view of

the centre console: ESP

button

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 198 of 313

196Trailer towing

Trailer towing

Trailer towing

Technical requirements

The towing bracket must meet certain technical require-

ments.

Your vehicle is intended mainly for transporting passengers and luggage.

However, if suitably equipped, it can also be used to tow a trailer or cara-

van.

If your vehicle has been factory-supplied with a towing bracket, all of the

necessary technical and legal aspects for trailing towing have been taking

into account during manufacturing.

Your vehicle is fitted with a 13-pole socket for the electrical connection be-

tween the trailer and the vehicle. If the trailer has a 7-pole connector you

can use an adapter cable. This can be purchased at an Authorised Service.

If a towing bracket is to be fitted after the vehicle is purchased, this must be

done according to the instructions of the towing bracket manufacturer

⇒ page 204.

WARNING

If a towing bracket is retrofitted, the installation should be carried out by

a qualified workshop.

● Particularly in high outdoor temperatures, it is not possible to drive

up long steep gradients without a suitable cooling system. The engine

would heat up.

● Incorrect installation can result in a safety risk!

Notes on towing

There are a number of points which need to be checked be-

fore towing a trailer or caravan.

– Observe the maximum permitted trailer weights ⇒ page 290.

Trailer weight

Never exceed the maximum permitted trailer weight.

If you do not load the trailer up to the maximum permitted trailer weight,

you can then climb correspondingly steeper gradients.

The maximum trailer weights listed are only applicable for altitudes up to

1000 m above sea level. With increasing altitude the engine power and

therefore the vehicle's climbing ability are impaired because of the reduced

air density. The maximum trailer weight has to be reduced accordingly. The

weight of the vehicle and trailer must be reduced by about 10% for every

subsequent 1000 m (or part thereof). This figure refers to the combined

weight of the (loaded) vehicle and (loaded) trailer.

The figures for the drawbar load that appear on the identification plate of

the towing bracket are for certification purposes only. The correct figures for

your specific model, which may be lower than these figures for the towing

bracket, are given in the registration documents and on ⇒ page 283. Also

refer to ⇒ page 290.

Distributing the load

Distribute loads in the trailer so that heavy objects are as near to the axle as

possible. Loads carried in the trailer must be secured to prevent them mov-

ing.

Page 201 of 313

199

Trailer towing

Removable towing bracket Introduction

Special care is required when fitting and removing the tow-

ing bracket.

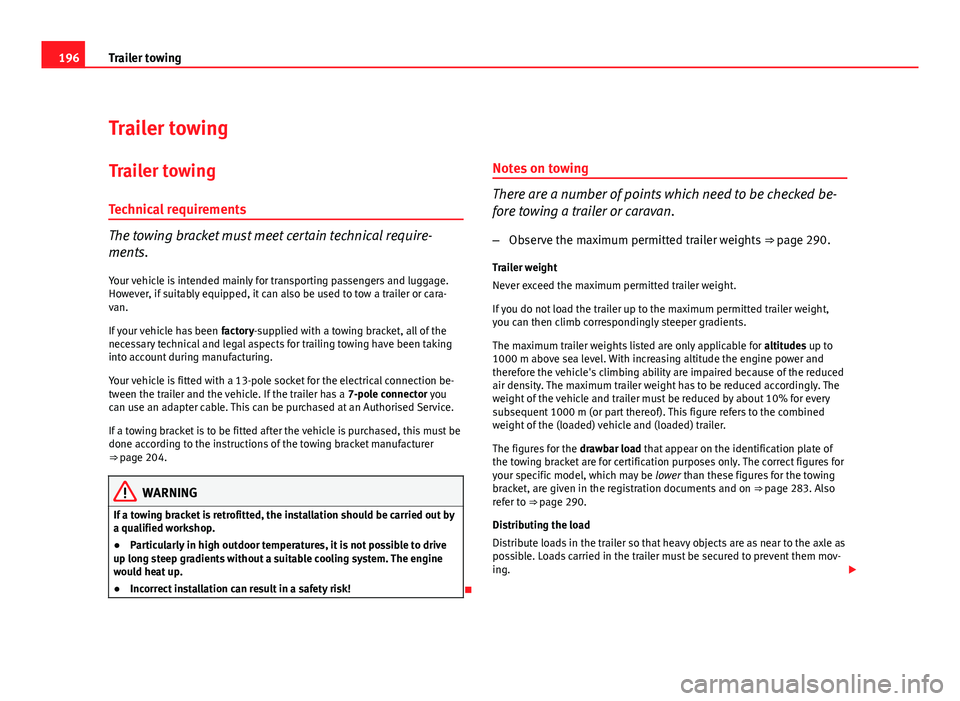

Fig. 151 Luggage com-

partment: Spare wheel

with towing bracket

The removable ball joint attachment for the towing bracket is stored under

the floor panel in the luggage compartment.

● Vehicles with a spare wheel ⇒ fig. 151.

The ball joint can be fitted and removed by hand.

Accessories mounted on the towing bracket

Please note that the ball joint attachment can be damaged by using unsuit-

able equipment that is mounted onto the towing bracket (e.g. bicycle rack).

Due to the material construction, such damage to the towing bracket dra-

matically increases safety risks and in extreme cases could lead to breakage

of the towing bracket while towing ⇒

. Therefore, before buying such equipment, ensure that it is suitable for

mounting onto the vehicle's towing bracket and that it is approved for this

purpose. To prevent damage to the ball joint from unsuitable equipment, we

recommend that equipment for the towing bracket be purchased through

your SEAT Dealer. Also see

⇒ page 215.

WARNING

● Only mount equipment on the towing bracket of your vehicle if you

are certain it will not damage the bracket. Use of unsuitable equipment

can result in severe damage to the towing bracket. The towing bracket

could then break while pulling a trailer and cause an accident.

● Never use tools of any kind when fitting and removing the ball joint.

This would damage the locking device, no longer guaranteeing the cor-

rect working order of the bracket. This could lead to an accident.

Note

● Do not attempt to modify or repair the ball joint or other towing bracket

components.

● Should you have any difficulties when using the towing bracket, or sus-

pect that it is not fitted properly, contact a qualified workshop.

● Before setting off, always check that the ball joint is secured properly

⇒ page 202.

● Never disengage the ball joint with the caravan / trailer still hitched or

with a bicycle rack or similar accessory still attached.

● It is advisable to remove the ball joint when you are not towing a trailer.

Make sure that the cover piece is properly fitted on the mounting fixture on

the vehicle.

● Remove the ball joint before washing the vehicle with pressurised steam

equipment. Make sure the cover piece is fitted correctly onto the mounting

fixture.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 202 of 313

200Trailer towing

Fitting the ball joint (step 1)

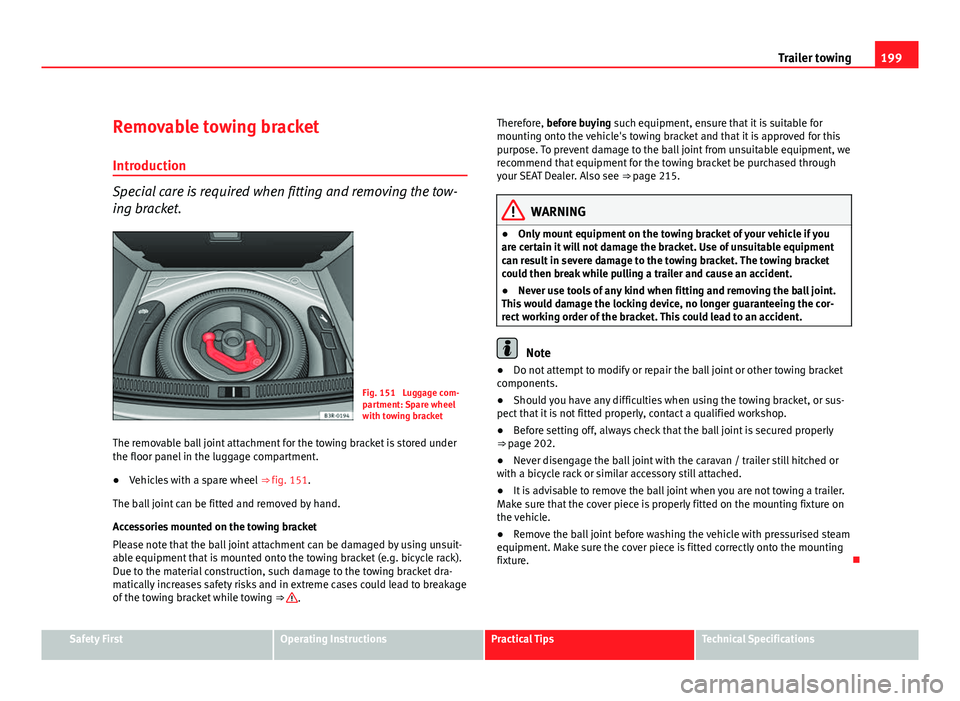

Fig. 152 Rear bumper:

Open the cover piece

– Remove the cover piece 2

⇒ fig. 152 on the mounting fixture

1 below the bumper as far as it will go. The cover piece is held

automatically in the open position.

– Make sure the mounting fixture is clean. If not, clean it ⇒

.

Cont ⇒ page 200, Fitting the ball joint (step 2).

WARNING

It is important to keep the mounting fixture clean. Otherwise the ball

joint may fail to engage safely and securely. This could lead to an acci-

dent.

Fitting the ball joint (step 2)

Fig. 153 Removable tow-

ing bracket: Ball joint

Fig. 154 Removable tow-

ing bracket: Ball joint

Page 206 of 313

204Trailer towing

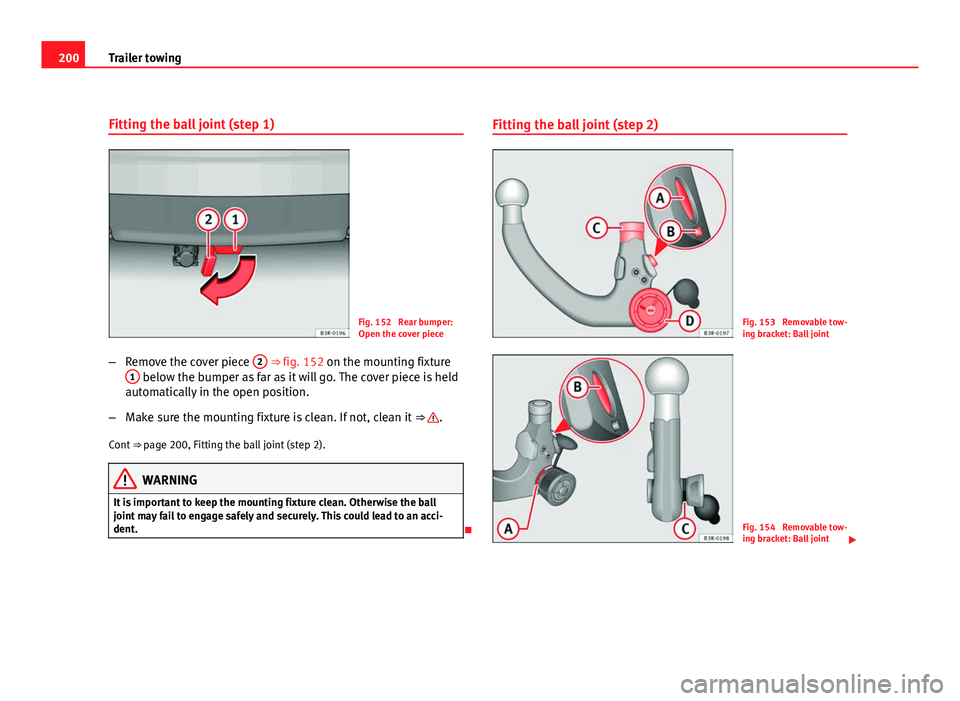

–Take hold of the ball joint and pull out the knob in direction A

.

– Keep hold of the knob and turn it as far as it will go in direction

B

.

– Release the knob. The spring mechanism will remain in the

ready position ⇒

.

– Pull the ball joint down out of the mounting fixture 1

⇒ fig. 160. The cover piece will cover the mounting fixture auto-

matically 2.

– Put away the ball joint attachment under the floor panel in the

luggage compartment.

– Move the socket back up to its original position.

WARNING

● To avoid injury, keep your hands away from the locking pin and the

release pin when releasing the locking mechanism.

● Make sure that the cover piece is properly engaged on the mounting

fixture on the vehicle. Otherwise the ball joint may fail to engage secure-

ly if dirt accumulates in the mounting fixture.

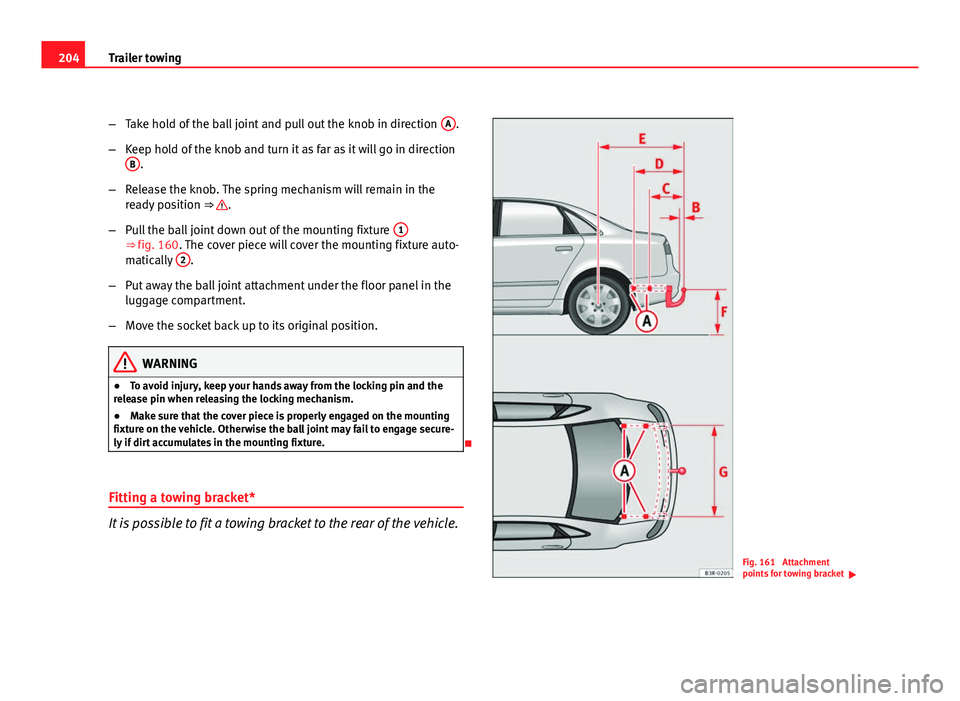

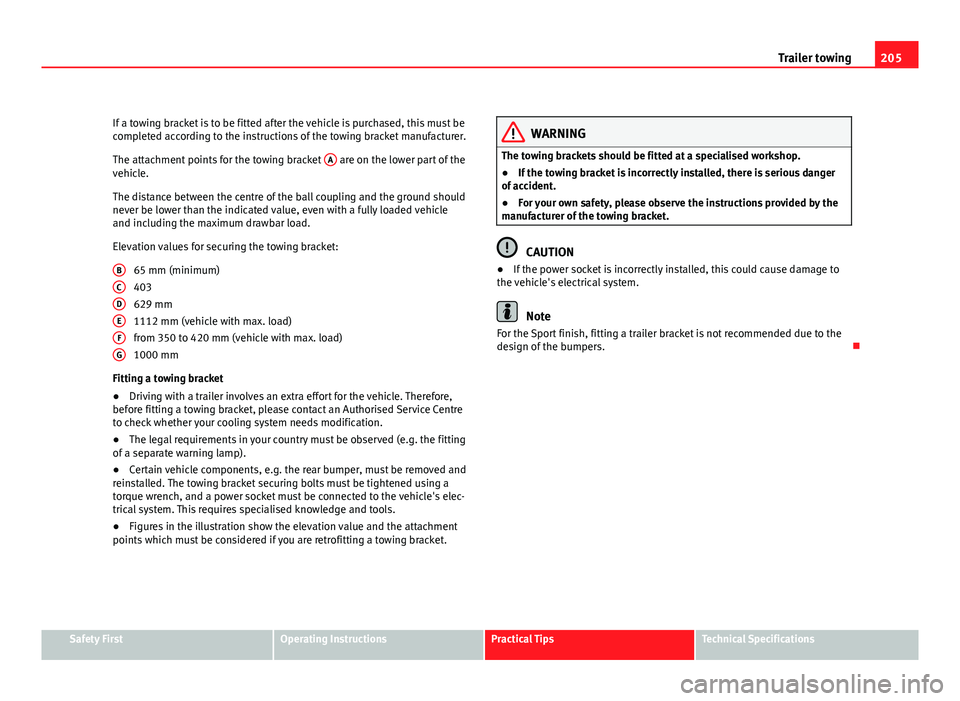

Fitting a towing bracket*

It is possible to fit a towing bracket to the rear of the vehicle.

Fig. 161 Attachment

points for towing bracket

Page 207 of 313

205

Trailer towing

If a towing bracket is to be fitted after the vehicle is purchased, this must be

completed according to the instructions of the towing bracket manufacturer.

The attachment points for the towing bracket A

are on the lower part of the

vehicle.

The distance between the centre of the ball coupling and the ground should

never be lower than the indicated value, even with a fully loaded vehicle

and including the maximum drawbar load.

Elevation values for securing the towing bracket:

65 mm (minimum)

403

629 mm

1112 mm (vehicle with max. load)

from 350 to 420 mm (vehicle with max. load)

1000 mm

Fitting a towing bracket

● Driving with a trailer involves an extra effort for the vehicle. Therefore,

before fitting a towing bracket, please contact an Authorised Service Centre

to check whether your cooling system needs modification.

● The legal requirements in your country must be observed (e.g. the fitting

of a separate warning lamp).

● Certain vehicle components, e.g. the rear bumper, must be removed and

reinstalled. The towing bracket securing bolts must be tightened using a

torque wrench, and a power socket must be connected to the vehicle's elec-

trical system. This requires specialised knowledge and tools.

● Figures in the illustration show the elevation value and the attachment

points which must be considered if you are retrofitting a towing bracket. B

CDEFG

WARNING

The towing brackets should be fitted at a specialised workshop.

● If the towing bracket is incorrectly installed, there is serious danger

of accident.

● For your own safety, please observe the instructions provided by the

manufacturer of the towing bracket.

CAUTION

● If the power socket is incorrectly installed, this could cause damage to

the vehicle's electrical system.

Note

For the Sport finish, fitting a trailer bracket is not recommended due to the

design of the bumpers.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 224 of 313

222Checking and refilling levels

WARNING (Continued)

● If any tests have to be performed with the engine running, there is an

added safety risk from the rotating parts (e.g. drive belts, alternator, ra-

diator fan, etc.) and from the high-voltage ignition system.

● Observe the following additional warnings if work on the fuel system

or the electrical system is necessary:

–Always disconnect the battery.

– Do not smoke.

– Never work near open flames.

– Always keep an approved fire extinguisher immediately available.

CAUTION

When topping up fluids, make sure the correct fluid is put into the correct

filler opening. This can otherwise cause serious malfunctions or engine

damage.

For the sake of the environment

Inspect the ground underneath your vehicle regularly so that any leaks are

detected at an early stage. If you find spots of oil or other fluids, have your

vehicle inspected at the workshop.

● When the external temperature and level of humidity are high or when

the engine stops, it is possible for water to drop from the air conditioning

system evaporator potentially forming a small puddle on the ground. This is

normal and does not indicate a leak.

Note

On right-hand drive vehicles some of the reservoirs mentioned below are lo-

cated on the other side of the engine compartment. Closing the bonnet

–

To close the bonnet, push it down until it overcomes the spring

pressure.

– Let the bonnet engage in the locking part. Do not force it ⇒

.

WARNING

● For safety reasons the bonnet must always be completely closed

when the vehicle is moving. After closing it always check that it is proper-

ly secured. The bonnet must be flush with the adjacent body panels.

● Should you notice that the bonnet is not safely secured when the ve-

hicle is moving, stop the vehicle immediately and close the bonnet. Fail-

ure to do so could result in an accident.

Engine oil General notes

The engine comes with a special, high quality, multi grade oil that can be

used in all seasons of the year except for those regions affected by extreme

cold.

As the use of good quality oil is necessary for the correct operation and long

service life of the engine, when it becomes necessary to replenish or

change the oil, always use an oil that complies to the VW standards.

The specifications (VW standards) set out in the following page should ap-

pear on the container of the service oil; when the container displays the

specific standards for petrol and diesel engines together, it means that the

oil can be used for both types of engines.

Page 234 of 313

232Checking and refilling levels

Winter operation

The battery is drained more in cold weather, which means that the starting

power is reduced. For this reason, have the battery checked and charged if

necessary before the start of winter.

Replacing the battery

A replacement battery must have the same capacity, voltage and current rat-

ing. It must also have the same dimensions as the original, factory-fitted

battery and have sealed caps. The SEAT batteries which have been specially

developed fulfil the maintenance, performance and safety specifications for

your vehicle.

We recommend you use maintenance-free batteries.

WARNING

● All work on batteries requires specialist knowledge. If work is re-

quired on the battery, this should be performed by a Technical Service or

qualified workshop. Danger of caustic burns and explosion!

● The battery must not be opened. Never try to change the battery's liq-

uid level. Explosive gas is released from the battery that could cause an

explosion.

CAUTION

● The battery holder and clamps must always be correctly secured.

● Before starting any work on the battery, always observe the warnings

listed under ⇒

.

For the sake of the environment

Batteries contain toxic substances including sulphuric acid and lead.

Therefore, they must be disposed of in line with environmental regulations

and must not be disposed of with ordinary household waste. Make sure dis-

connected batteries cannot tip over. Sulphuric acid could be spilt! Important safety warnings for handling a vehicle battery

The battery is located at the back of the engine compartment

⇒ page 290.

Wear eye protection

Battery acid is very corrosive and caustic. Wear protective

gloves and eye protection!

Fires, sparks, open flames and smoking are prohibited!

A highly explosive mixture of gases is released when the bat-

tery is under charge.

Keep children away from acid and batteries!

WARNING

Always be aware of the danger of injury and chemical burns as well as

the risk of accident or fire when working on the battery and the electrical

system:

● Wear eye protection. Protect your eyes, skin and clothing from acid

and particles containing lead.

● Battery acid is very corrosive and caustic. Wear protective gloves and

eye protection. Do not tilt the batteries. This could spill acid through the

vents. Rinse battery acid from eyes immediately for several minutes with

clear water. Then seek medical care immediately. Neutralise any acid

splashes on the skin or clothing with a soapy solution, and rinse off with

plenty of water. If acid is swallowed by mistake, consult a doctor immedi-

ately.

● Fires, sparks, open flames and smoking are prohibited. When han-

dling cables and electrical equipment, avoid causing sparks and electro-

static charge. Never short the battery terminals. High-energy sparks can

cause injury.