lock Seat Exeo 2012 Repair Manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2012, Model line: Exeo, Model: Seat Exeo 2012Pages: 317, PDF Size: 5.29 MB

Page 204 of 317

202Trailer towing

Removable towing bracket

Introduction

Special care is required when fitting and removing the tow-

ing bracket.

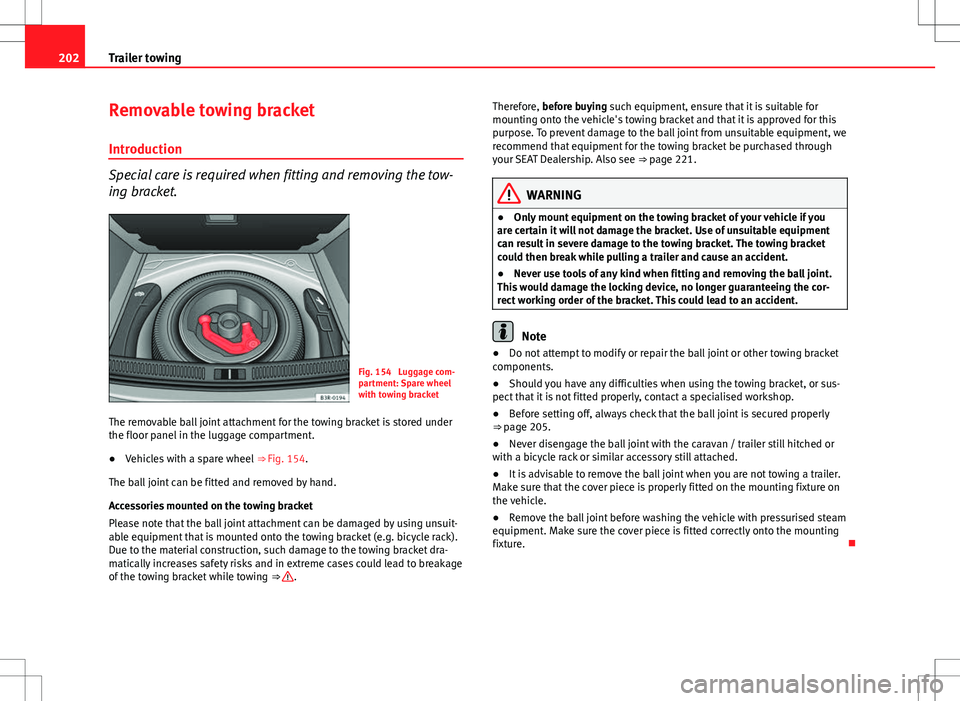

Fig. 154 Luggage com-

partment: Spare wheel

with towing bracket

The removable ball joint attachment for the towing bracket is stored under

the floor panel in the luggage compartment.

● Vehicles with a spare wheel

⇒ Fig. 154.

The ball joint can be fitted and removed by hand.

Accessories mounted on the towing bracket

Please note that the ball joint attachment can be damaged by using unsuit-

able equipment that is mounted onto the towing bracket (e.g. bicycle rack).

Due to the material construction, such damage to the towing bracket dra-

matically increases safety risks and in extreme cases could lead to breakage

of the towing bracket while towing ⇒

. Therefore, before buying such equipment, ensure that it is suitable for

mounting onto the vehicle's towing bracket and that it is approved for this

purpose. To prevent damage to the ball joint from unsuitable equipment, we

recommend that equipment for the towing bracket be purchased through

your SEAT Dealership. Also see

⇒ page 221.

WARNING

● Only mount equipment on the towing bracket of your vehicle if you

are certain it will not damage the bracket. Use of unsuitable equipment

can result in severe damage to the towing bracket. The towing bracket

could then break while pulling a trailer and cause an accident.

● Never use tools of any kind when fitting and removing the ball joint.

This would damage the locking device, no longer guaranteeing the cor-

rect working order of the bracket. This could lead to an accident.

Note

● Do not attempt to modify or repair the ball joint or other towing bracket

components.

● Should you have any difficulties when using the towing bracket, or sus-

pect that it is not fitted properly, contact a specialised workshop.

● Before setting off, always check that the ball joint is secured properly

⇒ page 205.

● Never disengage the ball joint with the caravan / trailer still hitched or

with a bicycle rack or similar accessory still attached.

● It is advisable to remove the ball joint when you are not towing a trailer.

Make sure that the cover piece is properly fitted on the mounting fixture on

the vehicle.

● Remove the ball joint before washing the vehicle with pressurised steam

equipment. Make sure the cover piece is fitted correctly onto the mounting

fixture.

Page 205 of 317

203

Trailer towing

Fitting the ball joint (step 1)

Fig. 155 Rear bumper:

Open the cover piece

– Remove the cover piece 2

⇒ Fig. 155 on the mounting fixture

1 below the bumper as far as it will go. The cover piece is held

automatically in the open position.

– Make sure the mounting fixture is clean. If not, clean it ⇒

.

Cont ⇒ page 203, Fitting the ball joint (step 2).

WARNING

It is important to keep the mounting fixture clean. Otherwise the ball

joint may fail to engage safely and securely. This could lead to an acci-

dent.

Fitting the ball joint (step 2)

Fig. 156 Removable tow-

ing bracket: Ball joint

Fig. 157 Removable tow-

ing bracket: Ball joint

Make sure the ball joint is clean and undamaged

– Check the locking pin A

, release pin B, shaft section C and

knob D ⇒ Fig. 156 on the ball joint to make sure they are clean

and undamaged.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 206 of 317

204Trailer towing

The spring mechanism inside the ball joint must be in the ready

position

–Check that the red marking A

⇒ Fig. 157 on the knob is inside

the black zone marked on the ball joint.

– Check that the locking pin B

is inside the holes in the shaft

section of the ball joint.

– Check that the knob protrudes visibly from the ball joint, so that

there is a clear gap C

between the knob and the ball joint.

The ball joint can only be installed if the internal spring mechanism is in the

ready position.

Cont ⇒ page 204, Fitting the ball joint (step 3).

Fitting the ball joint (step 3)

Fig. 158 Removable tow-

ing bracket: Setting the

spring mechanism to the

"ready" position

Fig. 159 Removable tow-

ing bracket: Inserting the

ball joint

Setting the spring mechanism to the ready position (if required)

– Insert the key 1

⇒ Fig. 158 in the lock on the knob and turn it

towards the red marking.

– Pull out the knob in direction A

, hold and turn in direction Buntil the locking pin 2 engages and the release pin 3 moves

out visibly ⇒ .

Inserting the ball joint

– With the spring mechanism in the ready position, insert the ball

joint into the mounting fixture and push it upwards ⇒ Fig. 159

in the direction indicated (arrow) ⇒

. It should lock into posi-

tion automatically. You should now clearly hear it click into

place.

– Lock the ball joint by turning the key to the green marking.

– Remove the key.

Cont ⇒ page 205, Fitting the ball joint (step 4).

Page 207 of 317

205

Trailer towing

WARNING

● If it is not possible to set the spring mechanism to the ready position

as described above, do not use the ball joint. Please contact a special-

ised workshop.

● To avoid injury, keep your hands away from the knob or cover piece

when inserting the ball joint in the mounting fixture. Otherwise, you

could be injured.

Fitting the ball joint (step 4)

Fig. 160 Removable tow-

ing bracket: Safety check

Fig. 161 Rear bumper:

Pulling down the power

socket

Safety check

– Check that the green marking A

⇒ Fig. 160 on the knob is in-

side the black zone marked on the ball joint.

– Check that the knob is directly against the ball joint, so that

there is no gap between the knob and the ball joint (arrow).

– Check that the ball joint is locked and the key is removed so

that the knob cannot be pulled out ⇒

.

– Check that the ball joint fits tightly in the mounting fixture (try

moving it about to check).

Towing socket

– To plug in the electrical connection for the trailer, pull down the

socket below the bumper ⇒ Fig. 161.

If the safety check is not satisfactory, the ball joint must be fitted again

properly.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 208 of 317

206Trailer towing

WARNING

To avoid accidents, the ball joint must meet all the safety requirements

listed in the safety check. The towing bracket must not be used if any one

of these requirements is not met. If this is the case, you should contact a

specialised workshop.

Removing the ball joint

Fig. 162 Removable tow-

ing bracket: Removing

the ball joint

Fig. 163 Rear bumper:

fitting the cover piece

– Insert the key in the lock 1

⇒ Fig. 162 on the knob.

– Unlock the ball joint by turning the key to the red marking.

– Take hold of the ball joint and pull out the knob in direction A

.

– Keep hold of the knob and turn it as far as it will go in direction

B

.

– Release the knob. The spring mechanism will remain in the

ready position ⇒

.

– Pull the ball joint down out of the mounting fixture 1

⇒ Fig. 163. The cover piece will cover the mounting fixture auto-

matically 2.

– Put away the ball joint attachment under the floor panel in the

luggage compartment.

– Move the socket back up to its original position.

Page 209 of 317

207

Trailer towing

WARNING

● To avoid injury, keep your hands away from the locking pin and the

release pin when releasing the locking mechanism.

● Make sure that the cover piece is properly engaged on the mounting

fixture on the vehicle. Otherwise the ball joint may fail to engage secure-

ly if dirt accumulates in the mounting fixture.

Fitting a towing bracket*

It is possible to fit a towing bracket to the rear of the vehicle.

Fig. 164 Attachment

points for towing bracket

If a towing bracket is to be fitted after the vehicle is purchased, this must be

completed according to the instructions of the towing bracket manufacturer.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 213 of 317

211

Vehicle maintenance and cleaning

CAUTION

● Never remove dirt, mud or dust if the vehicle surface is dry. Never use a

dry cloth or sponge for cleaning purposes. This could scratch the paintwork

or glass on your vehicle.

● Washing the vehicle in low temperatures: when washing the vehicle

with a hose, do not direct water into the lock cylinders or the gaps around

the doors, rear lid, or sunroof. Risk of freezing.

For the sake of the environment

To protect environment, the vehicle should be washed only in specially pro-

vided wash bays. This prevents toxic, oil-laden waste water entering the

sewerage system. In some places, washing vehicles outside wash bays is

prohibited.

Note

Do not wash the vehicle in direct sunlight.

Washing the vehicle with a high pressure cleaner

Be particularly careful when using a high pressure cleaner!

– Always observe the instructions for the high-pressure cleaner,

particularly those concerning the pressure and the spraying

distance.

– Increase the spraying distance for soft materials and painted

bumpers.

– Do not use a high pressure cleaner to remove ice or snow from

windows ⇒ page 212.

– Never use concentrated jet nozzles (“rotating jets”) ⇒

. –

After washing, avoid sudden and sharp braking. “Dry” the

brakes by braking several times ⇒ page 194.

WARNING

● Never wash tyres with a concentrated jet (“rotating nozzle”). Even at

large spraying distances and short cleaning times, visible and invisible

damage can occur to the tyres. This may cause an accident.

● Water, ice and salt on the brakes can reduce braking efficiency. Risk

of accident.

CAUTION

● Do not use water hotter than 60 °C. This could damage the car.

● To avoid damage to the vehicle, keep a sufficient distance from sensitive

materials such as flexible hoses, plastic, soundproofing material, etc. This

is also important for bumpers painted in the colour of the bodywork. The

closer the nozzle is to the surface, the greater the wear on the material.

Vehicle paint maintenance

Regular waxing protects the paintwork. You need to apply wax to your vehicle if water does not form small drops

and run off the paintwork when it is clean.

Good quality hard wax products are available at your Technical Service.

Regular wax applications help to protect the paintwork from environmental

contaminants ⇒ page 209. It is also effective in protecting against minor

scratches.

Even if a wax solution is used regularly in the vehicle washing tunnel, it is

advisable to protect the paint with a hard wax coating at least twice a year.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 215 of 317

213

Vehicle maintenance and cleaning

CAUTION

● Never use warm or hot water to remove snow and ice from windows and

mirrors. This could cause the glass to crack!

● The heating element for the rear window is located on the inner side of

the window. To prevent damage, do not put stickers over the heating ele-

ments on the inside of the window.

Cleaning windscreen wiper blades

Clean wiper blades improve visibility.

1. Use a soft cloth to remove dust and dirt from the windscreen wiper blades.

2. Use window cleaner to clean the windscreen wiper blades. Use a sponge or a cloth to remove stubborn dirt.

Rubber seals maintenance

If rubber seals are well looked after, they will not freeze so

quickly. 1. Use a soft cloth to remove dust and dirt from the rubber seals.

2. Apply a specialist care product to the rubber seals.

The rubber strips on the doors, windows, bonnet and rear lid will remain

pliable and last longer if they are treated with a suitable care product (for

example silicone spray). Caring for rubber seals will also prevent premature ageing and leaks. The

doors will be easier to open. If rubber seals are well looked after, they will

not freeze so quickly in winter.

Door lock cylinders

The door lock cylinders can freeze up in winter.

To de-ice the lock cylinders you should only use spray with lubricating and

anti-corrosive properties.

Cleaning chrome parts

1. Clean chrome parts with a damp cloth.

2. Polish chrome parts with a soft, dry cloth. If this does not provide satisfying results, use a specialist chrome cleaning

product. Chrome cleaning products will remove stains from the surface.

CAUTION

To prevent scratching chrome surfaces:

● Never use an abrasive cleaning product on chrome.

● Do not clean or polish chrome parts in a sandy or dusty environment.

Steel wheel rims

– Clean steel wheel rims regularly using a separate sponge.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 225 of 317

223

Checking and refilling levels

Checking and refilling levels Refuelling

The tank flap is released manually. The tank holds approxi-

mately 70 litres.

Fig. 166 Fuel tank flap

with tank cap attached

The flap that covers the tank cap is unlocked and locked automati-

cally by the central locking.

Unscrewing the tank cap

– Press the right side of the flap to open it.

– Unscrew the fuel tank cap anticlockwise.

– Hook the cap onto the support fitted to the open tank flap

⇒ Fig. 166. Closing the tank cap

–

Screw the tank cap clockwise into the filler opening until it you

hear it click into position.

– Close the tank flap.

The tank flap is at the rear of the vehicle on the right.

If the automatic filler nozzle is operated correctly, it will switch itself off as

soon as the tank is “full”. Never attempt to fill beyond this point, as this will

fill the expansion chamber. Fuel may leak out if ambient conditions are

warm.

The correct fuel grade for your vehicle is given on a sticker on the inside of

the fuel tank flap. Here you will find further information on fuel.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 228 of 317

226Checking and refilling levels

Winter driving

Diesel can thicken in winter.

Winter-grade diesel

When using summer-grade diesel fuel, difficulties may be experienced at

sub-zero temperatures because the fuel thickens due to wax separation. For

this reason, winter-grade diesel fuel is available in some countries during

the cold months. It can be used at temperatures as low as -22 °C.

In countries with different climatic conditions the diesel fuel generally sold

has different temperature characteristics. Check with a Technical Service or

filling stations in the country concerned regarding the type of diesel fuels

available.

Filter pre-heater

Your vehicle is fitted with a fuel filter glow plug system, making it well

equipped for operation in winter. This ensures that the fuel system remains

operational to approx. -24 °C, provided you use winter-grade diesel that is

safe to -15 °C.

However, if the fuel has waxed to such an extent that the engine will not

start at temperatures of under -24 °C, simply place the vehicle in a warm

place for a while.

CAUTION

Do not mix fuel additives (thinners or similar products) with diesel fuel. Bonnet

Releasing the bonnet

The bonnet is released from inside the vehicle.

Fig. 167 Detail of foot-

well area on driver side:

lever for unlocking the

bonnet.

– To release the bonnet, pull the lever under the dash panel

⇒ Fig. 167 in the direction indicated (arrow).

The bonnet springs out of its lock.