technical data Seat Exeo ST 2009 Owner's manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2009, Model line: Exeo ST, Model: Seat Exeo ST 2009Pages: 316, PDF Size: 8.83 MB

Page 283 of 316

If and when281

Safety First

Controls and equipment

Practical tips

Technical Data

Caution

Take care when fitting the rear light unit to make sure there is no damage to

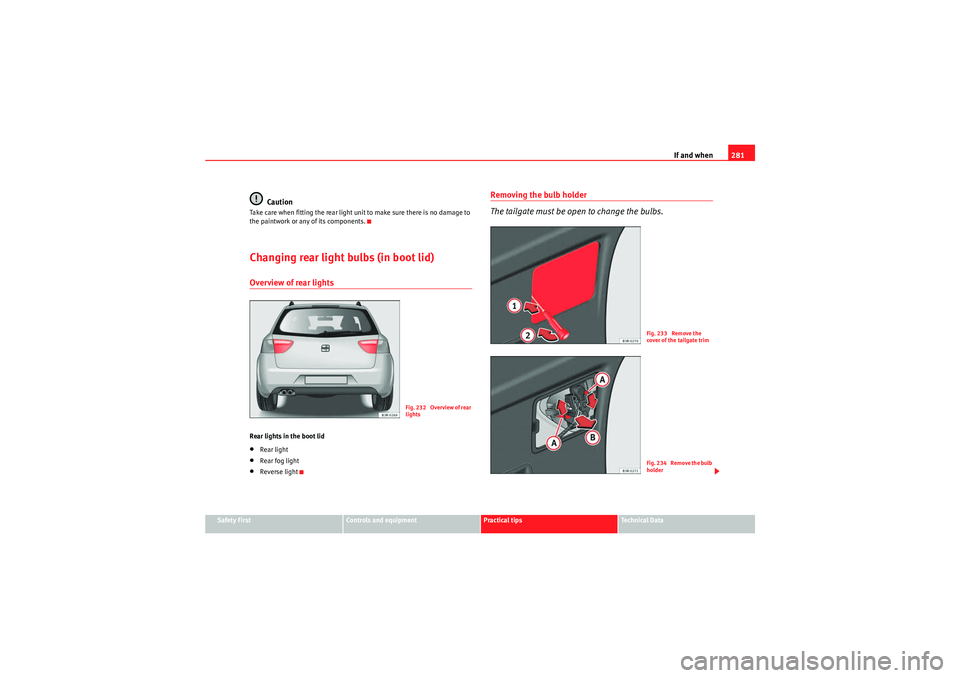

the paintwork or any of its components.Changing rear light bulbs (in boot lid)Overview of rear lightsRear lights in the boot lid•Rear light•Rear fog light•Reverse light

Removing the bulb holder

The tailgate must be open to change the bulbs.

F ig. 232 O ver vie w of rear

lights

Fig. 233 Remove the

cover of the tailgate trimFig. 234 Remove the bulb

holder

ExeoST_EN.book Seite 281 Donnerstag, 3. September 2009 12:24 12

Page 285 of 316

If and when283

Safety First

Controls and equipment

Practical tips

Technical Data

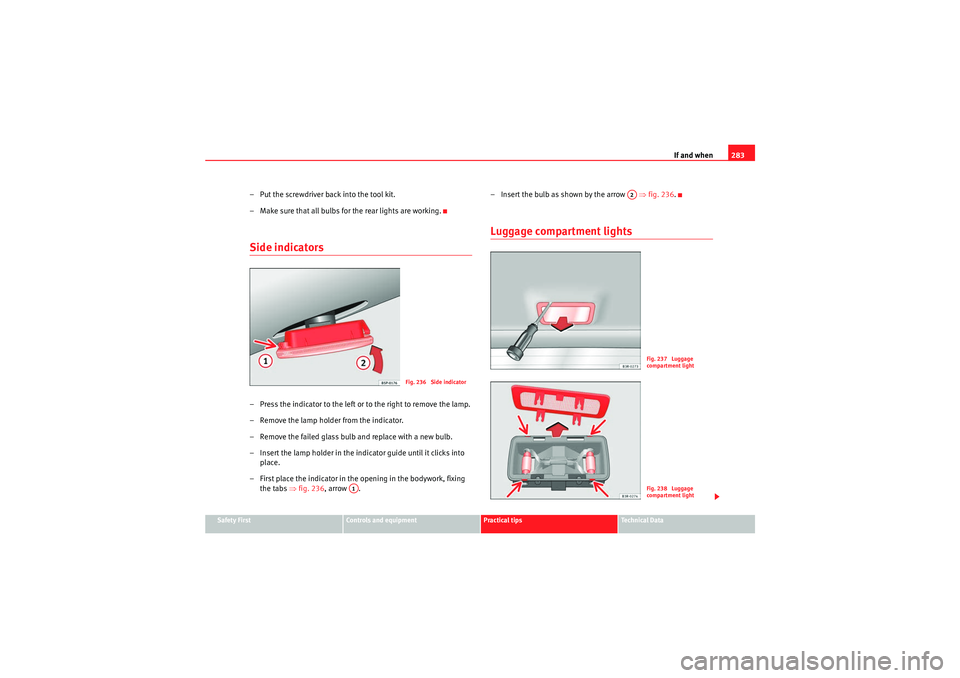

– Put the screwdriver back into the tool kit.

– Make sure that all bulbs for the rear lights are working.Side indicators– Press the indicator to the left or to the right to remove the lamp.

– Remove the lamp holder from the indicator.

– Remove the failed glass bulb and replace with a new bulb.

– Insert the lamp holder in the indicator guide until it clicks into

place.

– First place the indicator in th e opening in the bodywork, fixing

the tabs ⇒ fig. 236, arrow . – Insert the bulb as shown by the arrow

⇒fig. 236 .

Luggage compartment lights

Fig. 236 Side indicator

A1

A2

Fig. 237 Luggage

compartment lightFig. 238 Luggage

compartment light

ExeoST_EN.book Seite 283 Donnerstag, 3. September 2009 12:24 12

Page 287 of 316

If and when285

Safety First

Controls and equipment

Practical tips

Technical Data

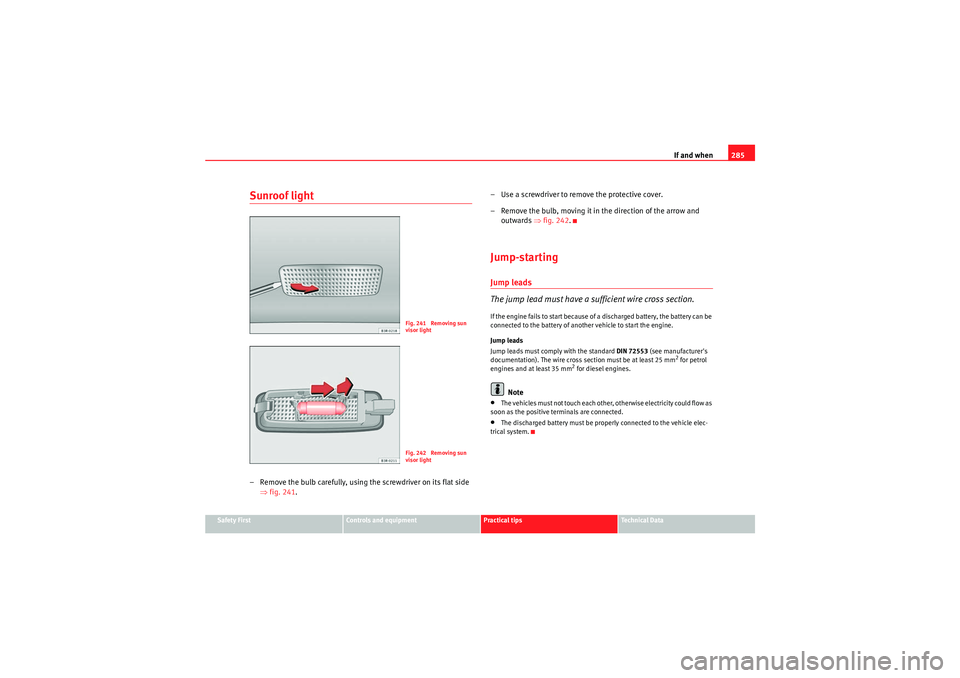

Sunroof light– Remove the bulb carefully, using the screwdriver on its flat side

⇒fig. 241 . – Use a screwdriver to remove the protective cover.

– Remove the bulb, moving it in the direction of the arrow and

outwards ⇒fig. 242 .

Jump-startingJump leads

The jump lead must have a su fficient wire cross section.If the engine fails to start because of a discharged battery, the battery can be

connected to the battery of another vehicle to start the engine.

Jump leads

Jump leads must comply with the standard DIN 72553 (see manufacturer's

documentation). The wire cross section must be at least 25 mm

2 for petrol

engines and at least 35 mm

2 for diesel engines.

Note

•The vehicles must not touch each other, otherwise electricity could flow as

soon as the positive terminals are connected.•The discharged battery must be properly connected to the vehicle elec-

trical system.

Fig. 241 Removing sun

visor lightFig. 242 Removing sun

visor light

ExeoST_EN.book Seite 285 Donnerstag, 3. September 2009 12:24 12

Page 289 of 316

If and when287

Safety First

Controls and equipment

Practical tips

Technical Data

WARNING

•Please note the safety warnings referring to working in the engine

compartment ⇒page 227.•The battery providing assistance must have the same voltage as the flat

battery (12V) and approximately the same capacity (see imprint on

battery). Failure to comply could result in an explosion.•Never use jump leads when one of the batteries is frozen. Danger of

explosion! Even after the battery has thawed, battery acid could leak and

cause chemical burns. If a battery freezes, it should be replaced.•Keep sparks, flames and lighted cigarettes away from batteries, danger

of explosion. Failure to comply could result in an explosion.•Observe the instructions provided by the manufacturer of the jump

leads.•Do not connect the negative cable from the other vehicle directly to the

negative terminal of the flat battery. The gas emitted from the battery could

be ignited by sparks. Danger of explosion.•Do not attach the negative cable from the other vehicle to parts of the

fuel system or to the brake line.•The non-insulated parts of the battery clamps must not be allowed to

touch. The jump lead attached to the positive battery terminal must not

touch metal parts of the vehicle, this can cause a short circuit.•Position the leads in such a way that they cannot come into contact

with any moving parts in the engine compartment.•Do not bend over the batteries. This could result in chemical burns.Note

The vehicles must not touch each other, otherwise electricity could flow as

soon as the positive terminals are connected.

ExeoST_EN.book Seite 287 Donnerstag, 3. September 2009 12:24 12

Page 291 of 316

If and when289

Safety First

Controls and equipment

Practical tips

Technical Data

Do not pull too hard with the towing vehicle and take care to avoid jerking the

tow-rope. When towing on an unpaved road, there is always a risk of over-

loading and damaging the anchorage points.

The ignition of the vehicle being towed must be switched on to prevent the

steering wheel from locking and also to allow the use of the indicators, horn,

windscreen wipers and washers.

As the brake servo does not work if the engine is not running, you must apply

considerably more pressure to the brake pedal than you normally would.

As the power assisted steering does not work if the engine is not running, you

will need more strength to steer than you normally would.

Towing vehicles with an automatic gearbox

•Put the selector lever into position “N”.•Do not drive faster than 50 km/h when towing a vehicle.•Do not tow further than 50 km.•If a breakdown vehicle is used, the vehicle must be towed with the front

wheels raised.Note

•Observe legal requirements when towing or tow-starting.•Switch on the hazard warning lights of both vehicles. However, observe

any regulations to the contrary.•For technical reasons, vehicles with an automatic gearbox must not be

tow-started.•If damage to your vehicle means that there is no lubricant in the gearbox,

you must raise the drive wheels while the vehicle is being towed.•If the vehicle has to be towed more than 50 km, the front wheels must be

raised during towing, and towing should be carried out by a qualified person.•The steering wheel is locked when the vehicle has no electrical power. The

vehicle must then be towed with the front wheels raised. Towing should be

carried out by a qualified person.

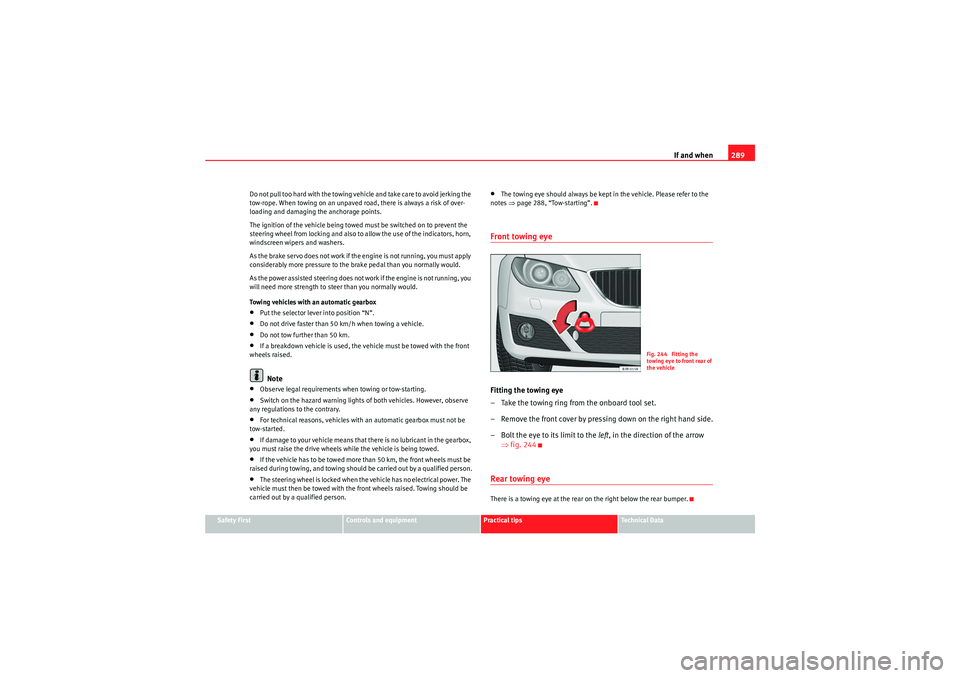

•The towing eye should always be kept in the vehicle. Please refer to the

notes ⇒page 288, “Tow-starting”.Front towing eyeFitting the towing eye

– Take the towing ring from the onboard tool set.

– Remove the front cover by pressing down on the right hand side.

– Bolt the eye to its limit to the left, in the direction of the arrow

⇒ fig. 244Rear towing eyeThere is a towing eye at the rear on the right below the rear bumper.

Fig. 244 Fitting the

towing eye to front rear of

the vehicle

ExeoST_EN.book Seite 289 Donnerstag, 3. September 2009 12:24 12

Page 293 of 316

General notes on the technical data291

Safety First

Controls and equipment

Practical tips

Technical Data

Te ch n i c a l D a t aGeneral notes on the technical dataOutstanding informationImportant considerations

All data in the official vehicle documents take precedence

over this data.All data provided in this manual are valid for the standard model in Spain. The

vehicle data card included in the Maintenance Programme or the vehicle

registration documents shows which engine is installed in the vehicle.

The figures may be different depending on if additional equipment is fitted,

for different models, for special vehicles and for other countries. Abbreviations used in this paragraph of the Technical Data

Abbrevia-

tion

Meaning

kW

Kilowatt, engine power measurement.

bhp

Brake horse power, formerly used to denote engine power

at rpm

Revolutions per minute - engine speed.

Nm

Newton metres, unit of engine torque.

l/100 km

Fuel consumption in litres per 100 km.

g/km

Carbon dioxide emissions in grams per km travelled.

CO2

Carbon dioxide

CN

Cetane number, indication of the diesel combustion power.

RON

Research octane number, indication of the knock resistance

of petrol.

ExeoST_EN.book Seite 291 Donnerstag, 3. September 2009 12:24 12

Page 294 of 316

General notes on the technical data

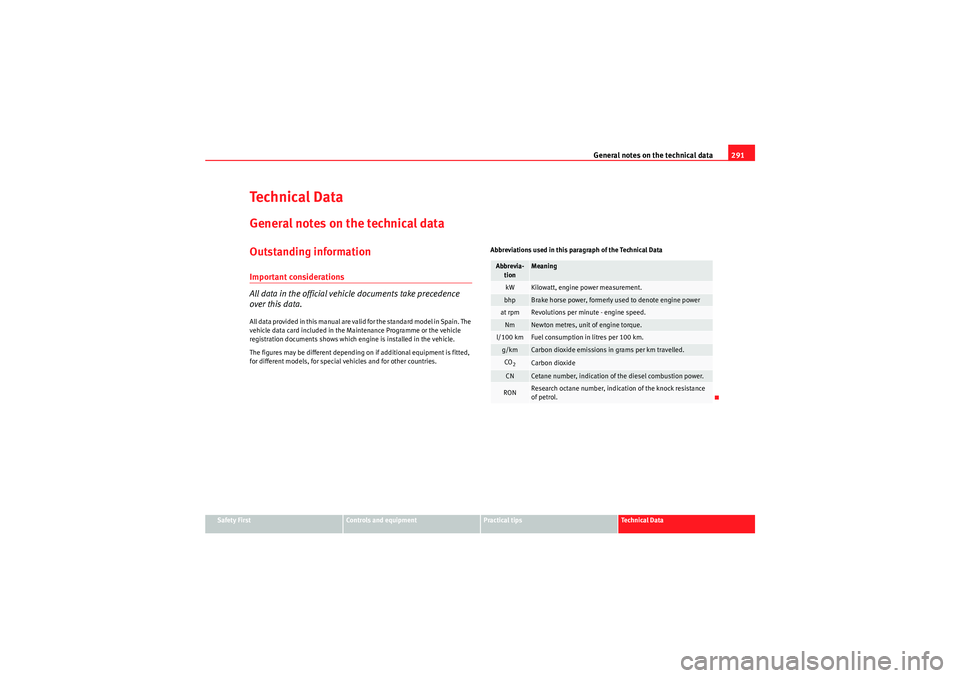

292Vehicle identification data

The most important data are given on the type plate and the

vehicle data sticker.Vehicles for certain export countries do not have a type plate.

Type plate

The type plate is located on the left rib inside the engine compartment.

Vehicle identification number

The vehicle identification number (chassis number) can be read from outside

the vehicle through a viewer in the windscreen. This is located on the left-

hand side of the vehicle in the lower area of the windscreen. It is also located

on the right hand side of the engine compartment. Vehicle data

The data sticker is placed on the inside of the spare wheel recess in the

luggage compartment.

The following information is provided on the vehicle data sticker:

⇒fig. 245 .

These data are also provided in the Maintenance Program. Production control number

Vehicle identification number (chassis number)

Model code number

Model designation / engine power output

Engine and gearbox code letters

Paintwork number / interior trim code

Optional equipment codes

Consumption values

CO

2 emissions values

Data from 2 to 9 are also provided in the Maintenance Program.

Consumption figures and CO

2

Consumption (litres/100 km) / CO

2 emissions (g/km) urban

Consumption (litres/100 km) / CO2 emissions (g/km) motorway

Consumption (l/100 km) / CO

2 Emissions (g/km) mixed

Fig. 245 Vehicle data

sticker – boot

A1A2A3A4A5A6A7A8A9AAABAC

ExeoST_EN.book Seite 292 Donnerstag, 3. September 2009 12:24 12

Page 295 of 316

General notes on the technical data293

Safety First

Controls and equipment

Practical tips

Technical Data

Data on fuel consumptionFuel consumption

The consumption and emission details shown on the vehicle

data sticker differ from one vehicle to another.The fuel consumption and CO

2 emissions of the vehicle can be found on the

vehicle data sticker.

The fuel consumption and emissions figures given are based on the vehicle

weight category, which is determined according to the engine/gearbox

combination and the equipment fitted.

The consumption and emission figures are calculated in accordance with the

EC test requirements 1999/100/EC. These test requirements specify a real-

istic test method based on normal everyday driving.

The following test conditions are applied:

Note

•Actual consumption may vary from quoted test values, depending on

personal driving style, road and traffic conditions, the weather and the

vehicle condition.WeightsKerb weight refers to the basic model with a fuel tank filled to 90% capacity

and without optional extras. The figure quoted includes 75 kg to allow for the

weight of the driver.

For special versions and optional equipment fittings or for the addition of

accessories, the weight of the vehicle will increase ⇒.

WARNING

•Please note that the centre of gravity may shift when transporting

heavy objects; this may affect the vehicle's handling and lead to an acci-

dent. Always adjust your speed and driving style to suit road conditions

and requirements.•Never exceed the gross axle weight rating or the gross vehicle weight

rating. If the allowed axle load or the allowed total weight is exceeded, the

driving characteristics of the vehicle may change, leading to accidents,

injuries and damage to the vehicle.

Urban cycle

The urban cycle starts with an engine cold start. City driving

is then simulated.

Extra urban

cycle

In the extra urban cycle simulation the vehicle frequently

accelerates and brakes in all gears, as in normal everyday

driving. The road speed ranges from 0 to 120 km/h.

To ta l co n-

sumption

The average total consumption is calculated with a weighting

of around 37% for the urban cycle and 63% for the extra

urban cycle.

CO2 emis-

sions

The exhaust gases are collected during both driving cycles to

calculate carbon dioxide emissions. The gas composition is

then analysed to evaluate the CO

2 content and other emis-

sions.

ExeoST_EN.book Seite 293 Donnerstag, 3. September 2009 12:24 12

Page 296 of 316

General notes on the technical data

294Towing a trailerTrailer weightsTrailer weights

The trailer weights and drawbar loads approved are selected in intensive

trials according to precisely defined criteria. The approved trailer weights are

valid for vehicles in the EU for maximum speeds of 80 km/h (in certain

circumstances up to 100 km/h). The figures may be different in other coun-

tries. All data in the official vehicle documents take precedence over these

data ⇒ .

Drawbar load

The maximum permitted weight exerted by the trailer drawbar on the ball joint

of the towing bracket must not exceed 75 kg.

In the interest of road safety, we recommend that you always tow

approaching the maximum drawbar load. The response of the trailer on the

road will be poor if the drawbar load is too small.

If the maximum permissible drawbar load cannot be met (e.g. with small,

empty and light-weight single axle trailers o r ta n d e m a x l e t r a i l e r s wi t h a n a x le

base of less than 1 metre), at least 4% of the actual trailer weight is a legal

stipulation for a drawbar load.

WARNING

•For safet y reas ons , d o not excee d the 8 0 k m/h limit . Th is is als o valid in

countries where higher speeds are permitted.•Never exceed the maximum trailer weights or the draw bar loading. If

the permissible axle load or the permissible total weight is exceeded, the

driving characteristics of the vehicle may change, leading to accidents,

injuries and damage to the vehicle.

WheelsTyre pressure, snow chains, wheel boltsTyre pressures

The sticker with the tyre pressure values can be found on the inside of the

tank flap. The tyre pressure values given there are for cold tyres. The slightly

raised pressures of warm tyres must not be reduced. ⇒

Snow chains

Snow chains may be fitted only to the front wheels.

Consult the chapter “wheels” of this manual.

Wheel bolts

After the wheels have been changed, the tightening torque of the wheel bolts

s ho uld b e che cke d as s o on as p ossible wit h a to rqu e w re nch ⇒ . The tight-

ening torque for steel and alloy wheels is 120 Nm.

WARNING

•Check the tyre pressure at least once per month. Checking tyre pressure

value is very important. If the tyre pressure is too high or too low, there is

an increased danger of accidents, particularly at high speeds.•If the torque of the wheel bolts is too low, they could loosen while the

vehicle is in motion. Risk of accident! If the tightening torque is too high,

the wheel bolts and threads can be damaged.Note

We recommend that you ask your Authorised Service Centre for information

about appropriate wheel, tyre and snow chain size.

ExeoST_EN.book Seite 294 Donnerstag, 3. September 2009 12:24 12

Page 297 of 316

Technical Data295

Safety First

Controls and equipment

Practical tips

Technical Data

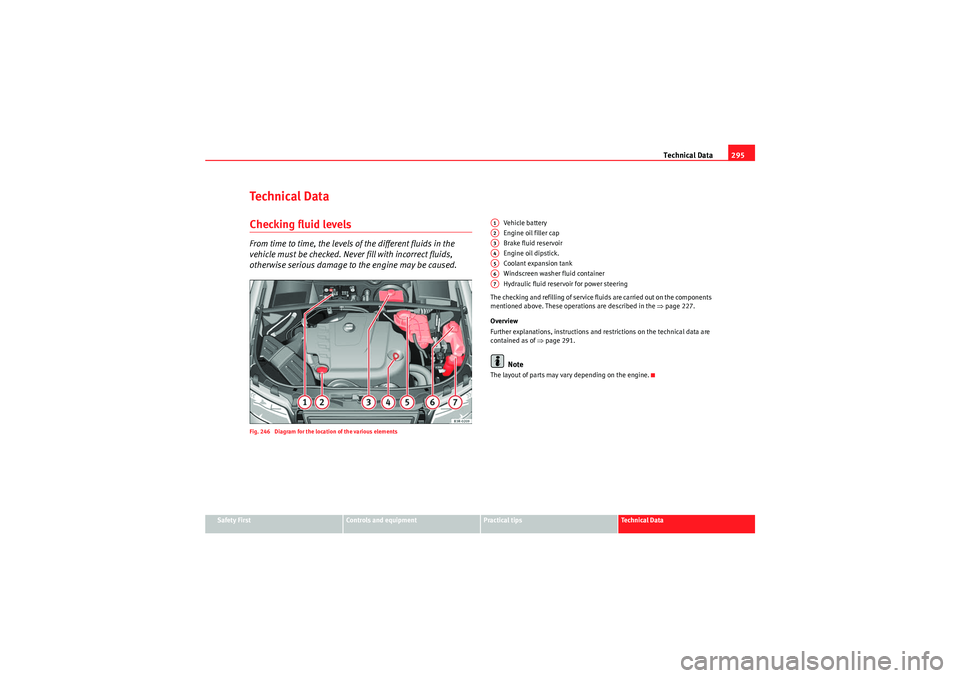

Te c h n i c a l D a t aChecking fluid levelsFrom time to time, the levels of the different fluids in the

vehicle must be checked. Never fill with incorrect fluids,

otherwise serious damage to the engine may be caused.Fig. 246 Diagram for the location of the various elements

Vehicle battery

Engine oil filler cap

Brake fluid reservoir

Engine oil dipstick.

Coolant expansion tank

Windscreen washer fluid container

Hydraulic fluid reservoir for power steering

The checking and refilling of service fluids are carried out on the components

mentioned above. These operations are described in the ⇒page 227.

Overview

Further explanations, instructions and restrictions on the technical data are

contained as of ⇒page 291.Note

The layout of parts may vary depending on the engine.A1A2A3A4A5A6A7

ExeoST_EN.book Seite 295 Donnerstag, 3. September 2009 12:24 12