tow Seat Exeo ST 2009 Repair Manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2009, Model line: Exeo ST, Model: Seat Exeo ST 2009Pages: 316, PDF Size: 8.83 MB

Page 207 of 316

Trailer towing205

Safety First

Controls and equipment

Practical tips

Technical Data

Make sure the ball joint is clean and undamaged

– Check the locking pin , release pin , shaft section and

knob ⇒page 204, fig. 164 on the ball joint to make sure they

are clean and undamaged.

The spring mechanism inside the ball joint must be in the ready

position

– Check that the red marking ⇒page 204, fig. 165 on the knob

is inside the black zone marked on the ball joint.

– Check that the locking pin is inside the holes in the shaft section of the ball joint.

– Check that the knob protrudes visibly from the ball joint, so that there is a clear gap between the knob and the ball joint.The ball joint can only be installed if the internal spring mechanism is in the

ready position.

Cont ⇒page 205, “Fitting the ball joint (step 3)”.

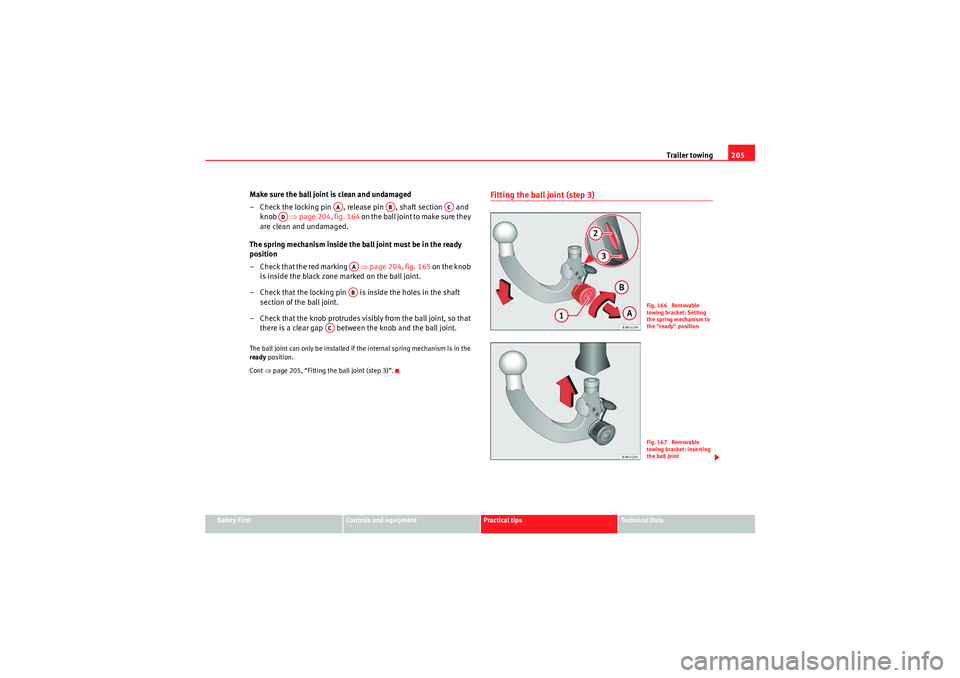

Fitting the ball joint (step 3)

AA

AB

AC

AD

AAAB

AC

Fig. 166 Removable

towing bracket: Setting

the spring mechanism to

the "ready" positionFig. 167 Removable

towing bracket: inserting

the ball joint

ExeoST_EN.book Seite 205 Donnerstag, 3. September 2009 12:24 12

Page 208 of 316

Trailer towing

206

Setting the spring mechanism to the ready position (if required)

– Insert the key ⇒page 205, fig. 166 in the lock on the knob

and turn it towards the red marking.

– Pull out the knob in direction , hold and turn in direction

until the locking pin engages and the release pin moves

out visibly ⇒.

inserting the ball joint

– With the spring mechanism in the ready position, insert the ball joint into the mounting fixture and push it upwards ⇒page 205,

fig. 167 in the direction indicated (arrow) ⇒. It should lock

into position automatically. You should now clearly hear it click

into place.

– Lock the ball joint by turning the key to the green marking.

– Remove the key.Cont ⇒page 206, “Fitting the ball joint (step 4)”.

WARNING

•If it is not possible to set the spring mechanism to the ready position as

described above, do not use the ball joint. Please contact a specialist

garage.•To avoid injury, keep your hands away from the knob or cover piece

when inserting the ball joint in the mounting fixture. Otherwise, you could

be injured.

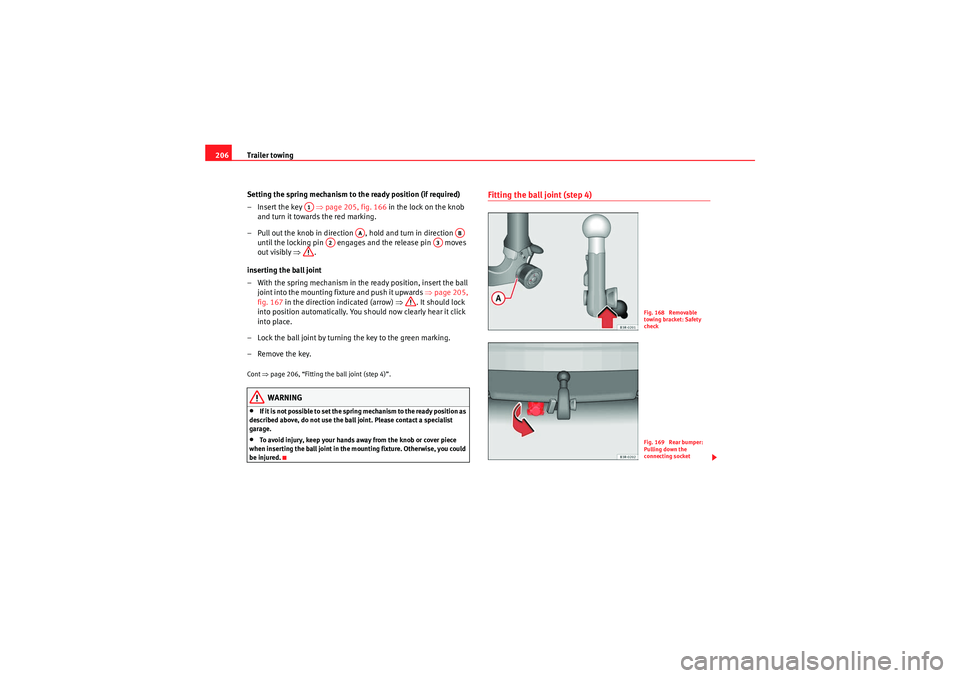

Fitting the ball joint (step 4)

A1

AA

AB

A2

A3

Fig. 168 Removable

towing bracket: Safety

checkFig. 169 Rear bumper:

Pulling down the

connecting socket

ExeoST_EN.book Seite 206 Donnerstag, 3. September 2009 12:24 12

Page 209 of 316

Trailer towing207

Safety First

Controls and equipment

Practical tips

Technical Data

Safety check

– Check that the green marking ⇒page 206, fig. 168 on the

knob is inside the black zone marked on the ball joint.

– Check that the knob is directly against the ball joint, so that there is no gap between the knob and the ball joint -arrow-.

– Check that the ball joint is locked and the key is removed so that the knob cannot be pulled out ⇒.

– Check that the ball joint fits tightly in the mounting fixture (try moving it about to check).

To w i n g s o c k e t

– To plug in the electrical connection for the trailer, pull down the socket below the bumper ⇒page 206, fig. 169 .If the safety check is not satisfactory, the ball joint must be fitted again prop-

erly.

WARNING

To avoid accidents, the ball joint must meet all the safety requirements

listed in the safety check. The towing bracket must not be used if any one

of these requirements is not met. If this is the case, you should contact a

specialist garage.

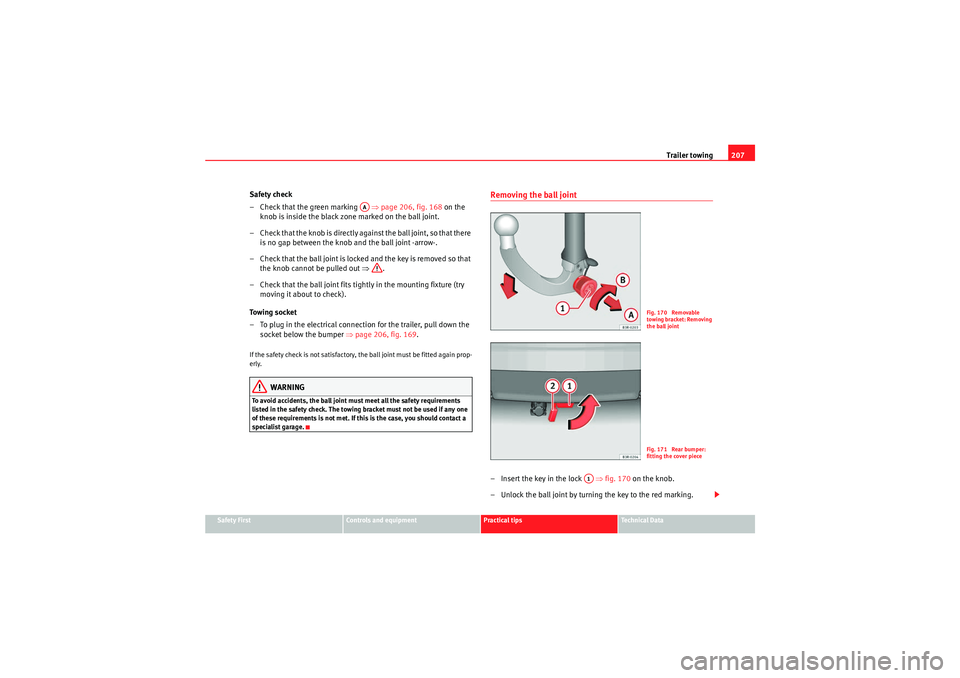

Removing the ball joint– Insert the key in the lock ⇒fig. 170 on the knob.

– Unlock the ball joint by turning the key to the red marking.

AA

Fig. 170 Removable

towing bracket: Removing

the ball jointFig. 171 Rear bumper:

fitting the cover piece

A1

ExeoST_EN.book Seite 207 Donnerstag, 3. September 2009 12:24 12

Page 210 of 316

Trailer towing

208

– Take hold of the ball joint and pull out the knob in direction .

– Keep hold of the knob and turn it as far as it will go in direction

.

– Release the knob. The spring mechanism will remain in the ready position ⇒.

– Pull the ball joint down out of the mounting fixture ⇒page 207, fig. 171. The cover piece will cover the mounting

fixture automatically .

– Put away the ball joint attachment under the floor panel in the luggage compartment.

– Move the socket back up to its original position.

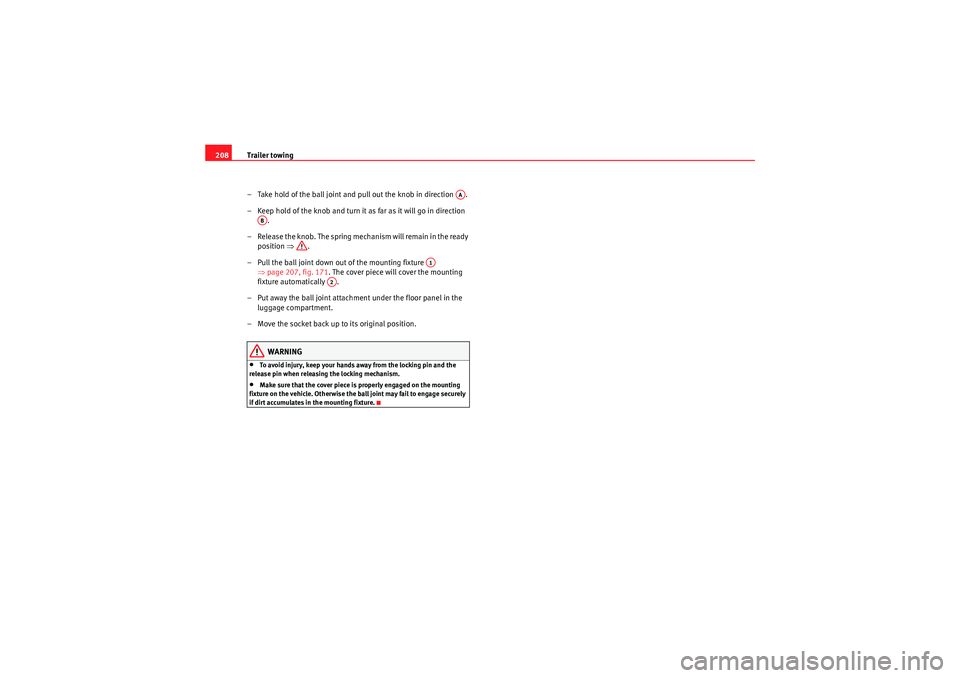

WARNING

•To avoid injury, keep your hands away from the locking pin and the

release pin when releasing the locking mechanism.•Make sure that the cover piece is properly engaged on the mounting

fixture on the vehicle. Otherwise the ball joint may fail to engage securely

if dirt accumulates in the mounting fixture.

AA

AB

A1

A2

ExeoST_EN.book Seite 208 Donnerstag, 3. September 2009 12:24 12

Page 211 of 316

Trailer towing209

Safety First

Controls and equipment

Practical tips

Technical Data

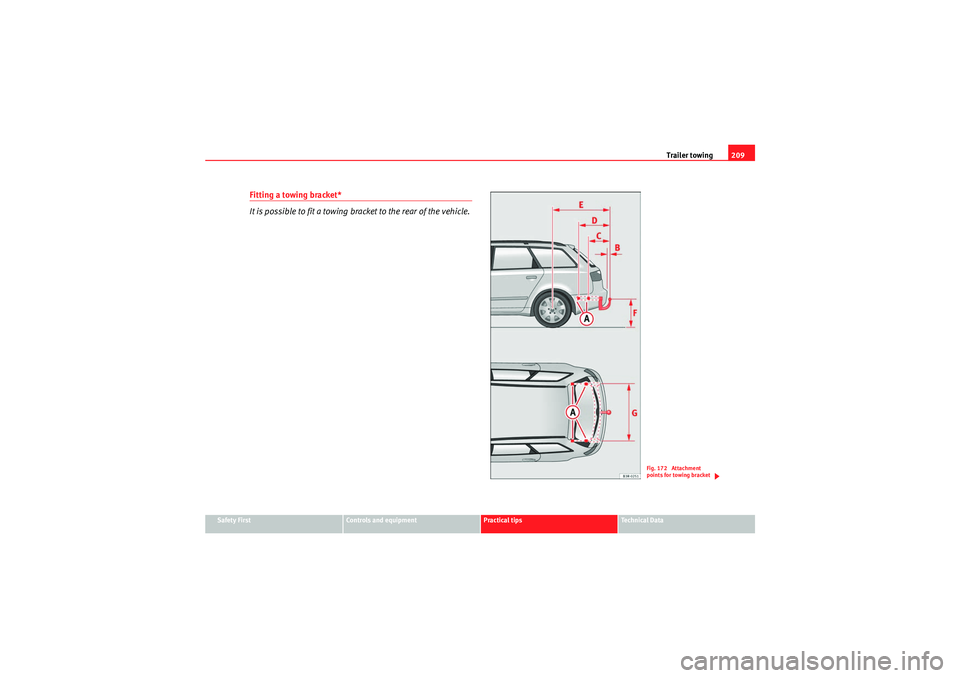

Fitting a towing bracket*

It is possible to fit a towing bracket to the rear of the vehicle.

Fig. 172 Attachment

points for towing bracket

ExeoST_EN.book Seite 209 Donnerstag, 3. September 2009 12:24 12

Page 212 of 316

Trailer towing

210If a towing bracket is to be fitted after the vehicle is purchased, this must be

completed according to the instructions of the towing bracket manufacturer.

The attachment points for the towing bracket are on the lower part of the

vehicle.

The distance between the centre of the ball coupling and the ground should

never be lower than the indicated value, even with a fully loaded vehicle and

including the maximum resting weight.

Elevation values for securing the towing bracket:

65 mm (minimum)

403

629 mm

1112 mm (vehicle with max. load)

from 350 to 420 mm (fully loaded vehicle)

1,000 mm

Fitting a towing bracket•Driving with a trailer involves an extra effort for the vehicle. Therefore,

before fitting a towing bracket, please contact an Authorised Service Centre

to check whether your cooling system needs modification.•Submit to the legal requirements in your country (e.g. the fitting of a sepa-

rate warning lamp).•Certain vehicle components, e.g. the rear bumper, must be removed and

reinstalled. The towing bracket securing bolts must be tightened using a

torque wrench, and an electrical socket must be connected to the vehicle's

electrical system. The above-mentioned require specialized knowledge and

tools.•Figures in the illustration show the elevation value and the attachment

points which must be considered if you are retrofitting a towing bracket.WARNING

Towing brackets should be fitted by specialists.

•If the towing bracket is incorrectly installed, there is serious danger of

accident.•For your own safety, please observe the instructions provided by the

manufacturer of the towing bracket.Caution

•If the electrical socket is incorrectly installed, this could cause damage to

the vehicle's electrical system.Note

For the Sport finish, fitting a trailer bracket is not recommended due to the

design of the bumpers.

AA

ABACADAEAFAG

WARNING (continued)

ExeoST_EN.book Seite 210 Donnerstag, 3. September 2009 12:24 12

Page 254 of 316

If and when

252•A hook for removing wheel covers* or hub caps•Box spanner for wheel bolts•A screwdriver with reversible blade•Towi ng e ye•An adapter for the anti-theft wheel bolts*

Before replacing the jack in the storage bin, wind down the arm of the jack as

far as it will go.

Some of the tools listed are only provided in certain models or are optional

extras.WARNING

•Do not use the hexagonal socket in the screwdriver handle to tighten

the wheel bolts, as with this it is not possible to tighten the bolts to the

required torque. Risk of accident.•The jack supplied by the factory is only designed for changing wheels

on this model. On no account attempt to use it for lifting heavier vehicles

or other loads. Risk of injury.•Never start the engine when the vehicle is raised. Failure to do so could

result in an accident.•If work is to be carried out underneath the vehicle, this must be secured

by suitable stands. Otherwise, there is a risk of injury.

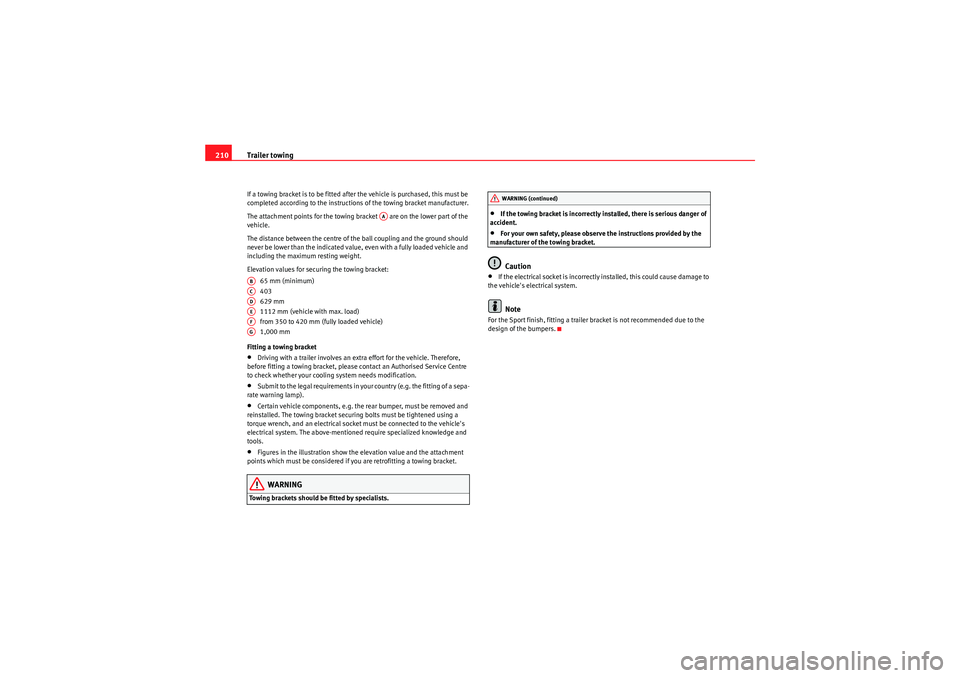

Tyre mobility system

The tyre mobility system is stor ed under the floor panel in the

luggage compartment.– Take hold of the handle and fold back the floor panel in the

luggage compartment.

– Take out the tyre mobility system.Your vehicle is equipped with a Tyre Mobility System in case of a puncture.

The tyre mobility system consists of a container with sealing compound and

a compressor to generate the required tyre pressure.

Instructions for using the sealant compound and the compressor are

included with the sealant can.

Fig. 193 Tyre Mobility

System under floor panel

in luggage compartment

ExeoST_EN.book Seite 252 Donnerstag, 3. September 2009 12:24 12

Page 256 of 316

If and when

254Changing a wheelPreparation work

What you must do before changing a wheel.– If you have a flat tyre or puncture, park the car as far away from

the flow of traffic as possible. Choose a location that is as level

as possible.

– All passengers should leave the vehicle. They should wait in a

safe place (e.g. behind the roadside crash barrier).

–Apply the handbrake firmly.

–Engage 1st gear.

– When towing a trailer: Unhitch the trailer from your vehicle.

–Take the tools and the spare wheel ⇒ page 251 out of the

luggage compartment.

WARNING

If you have a puncture in heavy traffic, switch on the hazard warning lights

and place the warning triangle in a visible location. This is for your own

safety and also warns other road users.

Caution

If you have to change the tyre on a gradient, block the wheel opposite the

wheel being changed by placing a stone or similar object under it to prevent

the vehicle from rolling away.

Note

Please observe legal requirements when doing so.Changing a wheel

Change the wheel as described below.– Remove the wheel cover.

–Loosen the wheel bolts ⇒ page 255.

– Raise the car with the jack ⇒page 256.

– Ta k e o f f the wheel with the flat tyre and then put on the spare

wheel ⇒page 257.

– Lower the vehicle.

– Tighten the wheel bolts firmly in diagonal sequence with the box

spanner ⇒page 255.

–Replace the cover .After changing a wheel

After changing the wheel, there are still tasks to complete.– Place the wheel with the defective tyre in the spare wheel well

and secure it.

– Put the tools and jack back in the luggage compartment.

ExeoST_EN.book Seite 254 Donnerstag, 3. September 2009 12:24 12

Page 265 of 316

If and when263

Safety First

Controls and equipment

Practical tips

Technical Data

Caution

Never “repair” damaged fuses and never replace them with fuses with a

higher rating. Failure to comply could result in fire. It could also cause

damage to other parts of the electrical system.

Note

If a newly replaced fuse blows again after a short time, the electrical system

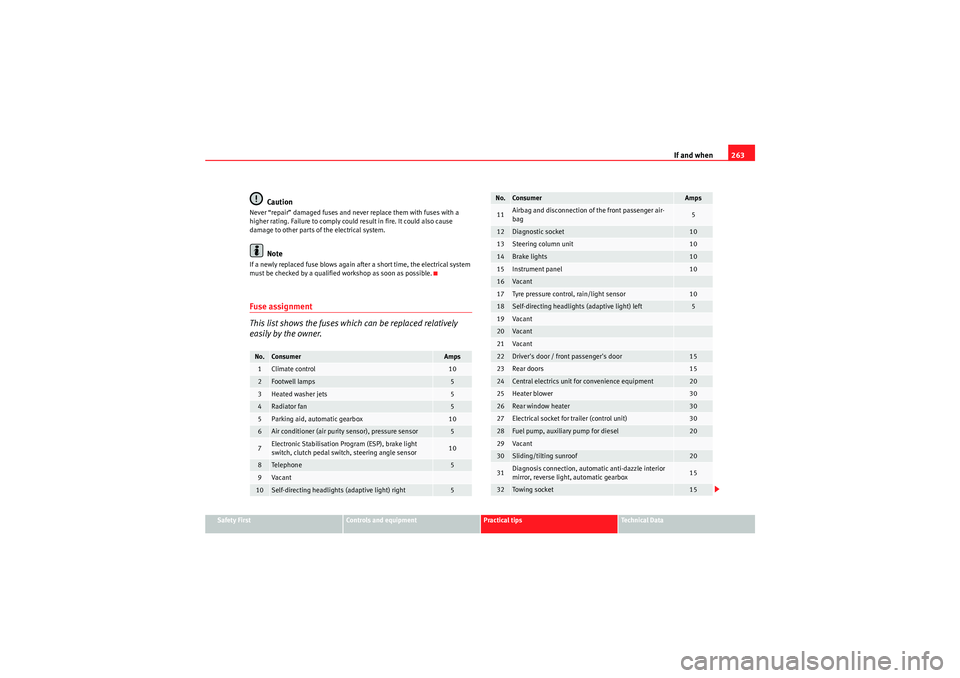

must be checked by a qualified workshop as soon as possible.Fuse assignment

This list shows the fuses which can be replaced relatively

easily by the owner.No.

Consumer

Amps

1

Climate control

10

2

Footwell lamps

5

3

Heated washer jets

5

4

Radiator fan

5

5

Parking aid, automatic gearbox

10

6

Air conditioner (air purity sensor), pressure sensor

5

7

Electronic Stabilisation Program (ESP), brake light

switch, clutch pedal switch, steering angle sensor

10

8

Te le p hon e

5

9

Va can t

10

Self-directing headlights (adaptive light) right

5

11

Airbag and disconnection of the front passenger air-

bag

5

12

Diagnostic socket

10

13

Steering column unit

10

14

Brake lights

10

15

Instrument panel

10

16

Va can t

17

Tyre pressure control, rain/light sensor

10

18

Self-directing headlights (adaptive light) left

5

19

Va can t

20

Va can t

21

Va can t

22

Driver's door / front passenger's door

15

23

Rear doors

15

24

Central electrics unit for convenience equipment

20

25

Heater blower

30

26

Rear window heater

30

27

Electrical socket for trailer (control unit)

30

28

Fuel pump, auxiliary pump for diesel

20

29

Va can t

30

Sliding/tilting sunroof

20

31

Diagnosis connection, automatic anti-dazzle interior

mirror, reverse light, automatic gearbox

15

32

Towi ng s ocke t

15

No.

Consumer

Amps

ExeoST_EN.book Seite 263 Donnerstag, 3. September 2009 12:24 12

Page 267 of 316

If and when265

Safety First

Controls and equipment

Practical tips

Technical Data

WARNING

•Take particular care when working on components in the engine

compartment if the engine is warm - risk of burns!•Bulbs are highly sensitive to pressure. The glass can break when you

touch the bulb, causing injury.•The high voltage element of gas discharge lamps* (xenon light) must

be handled correctly. Otherwise, there is a risk of death.•When changing bulbs, please take care not to injure yourself on sharp

parts in the headlight housing.Caution

•Remove the ignition key before working on the electric system. If not, a

short circuit could occur.•Switch off the lights or parking lights before you change a bulb.For the sake of the environment

Please ask your specialist retailer how to dispose of used bulbs in the proper

manner.

Note

•Depending on weather conditions (cold or wet), the front lights, the fog

lights, the rear lights and the indicators may be temporarily misted. This does not affect the useful life of the lighting system. By switching on the lights, the

area through which the beam of light is projected will quickly be demisted.

However, the edges may continue to be misted.

•Please check at regular intervals that all lighting (especially the exterior

lighting) on your vehicle is functioning pr operly. This is not only in the interest

of your own safety, but also in that of all other road users.•Before changing a bulb, make sure you have the correct new bulb.•Do not touch the glass part of the bulb with your bare hands, use a cloth

or paper towel instead. Otherwise, the fingerprints left on the glass will

vaporise as a result of the heat generated by the bulb, be deposited on the

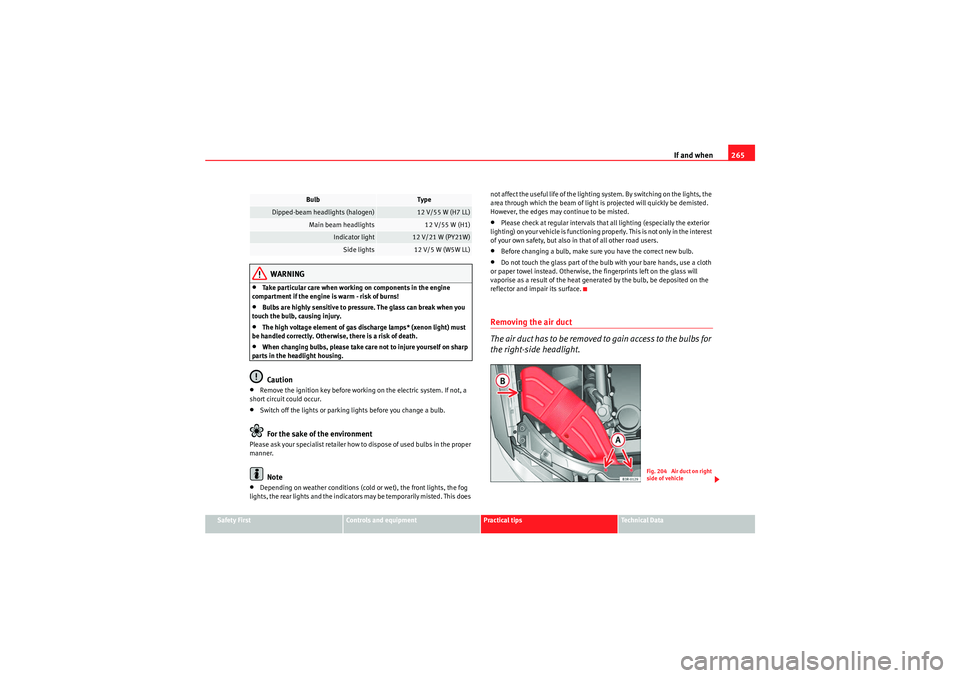

reflector and impair its surface.Removing the air duct

The air duct has to be removed to gain access to the bulbs for

the right-side headlight.

Bulb

Type

Dipped-beam headlights (halogen)

12 V/55 W (H7 LL)

Main beam headlights

12 V/55 W (H1)

Indicator light

12 V/21 W (PY21W)

Side lights

12 V/5 W (W5W LL)

Fig. 204 Air duct on right

side of vehicle

ExeoST_EN.book Seite 265 Donnerstag, 3. September 2009 12:24 12