battery Seat Exeo ST 2012 Owner's Guide

[x] Cancel search | Manufacturer: SEAT, Model Year: 2012, Model line: Exeo ST, Model: Seat Exeo ST 2012Pages: 325, PDF Size: 5.56 MB

Page 247 of 325

245

Checking and refilling levels

Topping up and changing the brake fluid

It is best to have the brake fluid changed by a professional. Brake fluid absorbs moisture. Therefore, in the course of time it will absorb

water from the air. If the water content in the brake fluid is too high, the

brake system could corrode. In addition, the boiling point of the brake fluid

will be considerably reduced. This could adversely affect the braking ability

in certain circumstances.

For this reason the brake fluid must be changed periodically.

Your vehicle's Service Plan will tell you when the brake fluid has to be re-

newed.

We recommend you have the brake fluid changed as part of a regular In-

spection Service at a Technical Service. They are familiar with the procedure

and have the necessary special tools and spare parts as well as the proper

facilities for disposing of the old fluid.

Be sure to always use the correct brake fluid. Only use brake fluid that ex-

pressly meets VW 501 14 standards.

You can buy VW 501 14 standard brake fluid in a SEAT dealership or SEAT

Official Service. If none is available, use only high quality brake fluid that

meets DIN ISO 4925 CLASS 4 standards, or USA Standards FMVSS 116 DOT

4.

Using any other kind of brake fluid or one that is not of a high quality may

affect operation of the brake system and reduce its effectiveness. Never use

a brake fluid if the container does not state that it complies with VW 501 14,

DIN ISO 4925 CLASS 4 standards, or USA standards FMVSS 116 DOT 4.WARNING

● Brake fluid must always be kept closed in its original container. Keep

out of the reach of children. Failure to comply could result in poisoning.

● If the brake fluid is left in the system for too long and the brakes are

subjected to heavy use, vapour bubbles may form in the brake system.

This would seriously affect the efficiency of the brakes and the safety of

the vehicle, leading to the risk of accident.

CAUTION

Please note that brake fluid will attack the paintwork on contact.

For the sake of the environment

The brake pads and fluid must be collected and disposed of according the

applicable regulations. The SEAT Technical Service network has the neces-

sary equipment and qualified personnel for collecting and disposing of this

waste material.

Vehicle battery General notes

All work on batteries requires specialist knowledge.

The battery is virtually maintenance-free and is checked in the Inspection

Services.

We recommend replacing the battery after 5 years.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 248 of 325

246Checking and refilling levels

Disconnecting the battery

If the battery is disconnected, some of the vehicle's functions will become

inoperative (e.g. electric windows). These functions will require resetting af-

ter the battery is reconnected. For this reason, the battery should only be

disconnected from the vehicle's electrical system when absolutely necessa-

ry.

Long periods of non-use

The battery will gradually lose its charge because certain electrical equip-

ment continues to draw current even when the ignition is off. If you park the

vehicle for long periods of time in winter you should take the battery out of

the vehicle and store it in a place protected from frost. This way it will not

freeze and become damaged. At warm outside temperatures it is sufficient

to disconnect the negative terminal of the battery. Even when the battery is

not connected you should charge it from time to time.

Winter operation

The battery is drained more in cold weather, which means that the starting

power is reduced. For this reason, have the battery checked and charged if

necessary before the start of winter.

Replacing the battery

A replacement battery must have the same capacity, voltage and current rat-

ing. It must also have the same dimensions as the original, factory-fitted

battery and have sealed caps. The SEAT batteries which have been specially

developed fulfil the maintenance, performance and safety specifications for

your vehicle.

We recommend you use maintenance-free batteries.

WARNING

● All work on batteries requires specialist knowledge. If work is re-

quired on the battery, this should be performed by a Technical Service or

specialised workshop. Danger of caustic burns and explosion!

● The battery must not be opened. Never try to change the battery's liq-

uid level. Explosive gas is released from the battery that could cause an

explosion.

CAUTION

● The battery holder and clamps must always be correctly secured.

● Before starting any work on the battery, always observe the warnings

listed under ⇒

.

For the sake of the environment

Batteries contain toxic substances including sulphuric acid and lead.

Therefore, they must be disposed of in line with environmental regulations

and must not be disposed of with ordinary household waste. Make sure dis-

connected batteries cannot tip over. Sulphuric acid could be spilt!

Important safety warnings for handling a vehicle battery

The battery is located at the back of the engine compartment ⇒ page 304.

Wear eye protection

Battery acid is very corrosive and caustic. Wear protective

gloves and eye protection!

Fires, sparks, open flames and smoking are prohibited!

Page 249 of 325

247

Checking and refilling levels

A highly explosive mixture of gases is released when the bat-

tery is under charge.

Keep children away from acid and batteries!

WARNING

Always be aware of the danger of injury and chemical burns as well as

the risk of accident or fire when working on the battery and the electrical

system:

● Wear eye protection. Protect your eyes, skin and clothing from acid

and particles containing lead.

● Battery acid is very corrosive and caustic. Wear protective gloves and

eye protection. Do not tilt the batteries. This could spill acid through the

vents. Rinse battery acid from eyes immediately for several minutes with

clear water. Then seek medical care immediately. Neutralise any acid

splashes on the skin or clothing with a soapy solution, and rinse off with

plenty of water. If acid is swallowed by mistake, consult a doctor immedi-

ately.

● Fires, sparks, open flames and smoking are prohibited. When han-

dling cables and electrical equipment, avoid causing sparks and electro-

static charge. Never short the battery terminals. High-energy sparks can

cause injury.

● A highly explosive mixture of gases is released when the battery is

under charge. The batteries should be charged in a well-ventilated room

only.

● Keep children away from acid and batteries.

● Before working on the electrical system, you must switch off the en-

gine, the ignition and all consumers. The negative cable on the battery

must be disconnected. When a light bulb is changed, you need only

switch off the light.

WARNING (Continued)

● Deactivate the anti-theft alarm by unlocking the vehicle before you

disconnect the battery! The alarm will otherwise be triggered.

● When disconnecting the battery from the vehicle electrical system,

disconnect first the negative cable and then the positive cable.

● Switch off all electrical consumers before reconnecting the battery.

Reconnect first the positive cable and then the negative cable. Never re-

verse the polarity of the connections. This could cause an electrical fire.

● Never charge a frozen battery, or one which has thawed. This could

result in explosions and chemical burns. Always replace a battery which

has frozen. A flat battery can also freeze at temperatures close to 0°C.

● Ensure that the vent hose is always connected to the battery.

● Never use a defective battery. This could cause an explosion. Replace

a damaged battery immediately.

CAUTION

● Never disconnect the battery if the ignition is switched on or if the en-

gine is running. This could damage the electrical system or electronic com-

ponents.

● Do not expose the battery to direct sunlight over a long period of time,

as the intense ultraviolet radiation can damage the battery housing.

● If the vehicle is left standing in cold conditions for a long period, protect

the battery from freezing. If it freezes it will be damaged.

Charging the battery

A fully-charged battery is important for reliable starting. – Note the warnings ⇒

in Important safety warnings for han-

dling a vehicle battery on page 247 and ⇒ .

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 250 of 325

248Checking and refilling levels

–Switch off the ignition and all electrical equipment.

– Only if fast-charging: both battery cables must be disconnected

(first the negative cable, then the positive cable).

– Connect the charger cables to the battery terminals, noting the

colour code (red = positive; black or brown = negative).

– Now connect the battery charger to the power socket and switch

on.

– After charging the battery: switch off the battery charger and

disconnect the power point cable.

– Finally disconnect the charger cables from the battery.

– If necessary, reconnect both battery cables to the battery (first

the positive cable, then the negative cable).

When charging with a low current (for instance with a small battery charger)

the battery does not normally have to be disconnected. However, both bat-

tery cables must be disconnected before fast-charging the battery with a

high current. However, always follow the instructions given by the manufac-

turer of the battery charger.

The fast-charging procedure for a battery is dangerous ⇒

in Important

safety warnings for handling a vehicle battery on page 247, as it requires a

special charger and the corresponding level of knowledge. We therefore rec-

ommend that this work should only be performed by a specialised work-

shop.

A flat battery can freeze at temperatures of around 0°C. The battery must be

defrosted before charging ⇒

. It is advisable to replace the battery if it has

frozen, because the ice can crack the battery casing and allow the battery

acid to escape.

The battery caps should not be opened while the battery is being charged.

WARNING

Never charge a frozen battery. Failure to comply could result in an explo-

sion.

Page 273 of 325

271

If and when

Fuse assignment

This list shows the fuses which can be replaced relatively

easily by the owner.

No.ConsumerAmps1Air conditioner102Footwell lamps53Heated washer jets54Radiator fan55Parking aid, automatic gearbox106Air conditioner (air purity sensor), pressure sensor5

7Electronic Stability Control (ESC), brake light switch,

clutch pedal switch, steering angle sensor10

8Telephone59Lambda probe heater1010Adaptive headlights right5

11Airbag and disconnection of the front passenger air-

bag5

12Diagnostic socket1013Steering column unit1014Brake lights1015Instrument panel1016Vacant 17Tyre pressure control, rain/light sensor1018Adaptive headlights left519Start-Stop control unit1020Engine management1521Start/Stop battery power management522Vacant 23Vacant

No.ConsumerAmps24Central electrics unit for convenience equipment2025Heater blower3026Rear window heater3027Power socket for trailer (control unit)3028Fuel pump, auxiliary pump for diesel2029Radio, amplifier (with Start-Stop)2030Sliding/tilting sunroof20

31Diagnosis connection, automatic anti-dazzle interior

mirror, reverse light, automatic gearbox15

32Towing socket1533Lighter2034Rear electric windows3035Luggage compartment power socket*2036Wiper system30

37Pump for windscreen washer and headlight washer

system30

38Luggage compartment illumination, alarm1539Radio, amplifier (without Start-Stop)2040Horn2541230 volt socket3042Electronic Stability Control (ESC)2543Front electric windows3044Seat heating35

Some of the electrical items listed in the table are only fitted on certain

models or are optional extras.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 295 of 325

293

If and when

– To remove the light cover, unscrew the bolts ⇒ Fig. 240.

– Remove the bulb, moving it in the direction of the arrow and

outwards ⇒ Fig. 241.

– Installation is done in the reverse order.

Sun visor light

Fig. 242 Removing sun

visor light

Fig. 243 Removing sun

visor light

– Remove the bulb carefully, using the flat part of a screwdriver

⇒ Fig. 242.

– Use a screwdriver to remove the protective cover.

– Remove the bulb, moving it in the direction of the arrow and

outwards ⇒ Fig. 243.

Jump-starting

Jump leads

The jump lead must have a sufficient wire cross section. If the engine fails to start because of a discharged battery, the battery can

be connected to the battery of another vehicle to start the engine.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 296 of 325

294If and when

Jump leads

Jump leads must comply with standard DIN 72553 (see manufacturer's doc-

umentation). The wire cross section must be at least 25 mm 2

for petrol en-

gines and at least 35 mm 2

for diesel engines.

Note

● The vehicles must not touch each other, otherwise electricity could flow

as soon as the positive terminals are connected.

● The discharged battery must be properly connected to the vehicle elec-

trical system.

How to jump start: description

Fig. 244 Diagram of con-

nections for vehicles

without Start-Stop sys-

tem

Fig. 245 Diagram of con-

nections for vehicles

with Start-Stop system

Jump lead terminal connections

1. Switch off the ignition of both vehicles ⇒

.

2. For vehicles without Start-Stop system :

– Connect one end of the red jump lead to the positive +

termi-

nal of the vehicle with the flat battery A ⇒ Fig. 244.

– Connect the other end of the red jump lead to the positive ter-

minal +

in the vehicle providing assistance B.

– Connect one end of the black jump lead to the negative terminal

–

of the vehicle providing assistance B ⇒ Fig. 244.

– Connect the other end of the black jump lead X

to a solid met-

al component bolted to the engine block or to the engine block

itself of the vehicle with the flat battery. However, connect it to

a point as far as possible from the battery A

.

3. For vehicles with Start-Stop system :

Page 297 of 325

295

If and when

– Connect one end of the red jump lead to the positive +

termi-

nal of the vehicle with the flat battery A ⇒ Fig. 245.

– Connect the other end of the red jump lead to the positive ter-

minal +

in the vehicle providing assistance B.

– Connect one end of the black jump lead X

to a suitable ground

terminal, a solid piece of metal in the engine block, or to the en-

gine block ⇒ Fig. 245.

– Connect the other end of the black jump lead X

to a solid met-

al component bolted to the engine block or to the engine block

itself of the vehicle with the flat battery. However, connect it to

a point as far as possible from the battery A

.

4. Position the leads in such a way that they cannot come into contact with any moving parts in the engine compartment.

Starting

5. Start the engine of the vehicle with the boosting battery and let it run at idling speed.

6. Start the engine of the vehicle with the flat battery and wait one or two minutes until the engine is running.

Removing the jump leads

7. Before you remove the jump leads, switch off the headlights (if they are switched on).

8. Turn on the heater blower and heated rear window in the vehi- cle with the flat battery. This helps minimise voltage peaks

which are generated when the leads are disconnected.

9. When the engine is running, disconnect the leads in reverse or- der to the details given above. Connect the battery clamps so they have good metal-to-metal contact with

the battery terminals.

If the engine fails to start, switch off the starter after about 10 seconds and

try again after about half a minute.

WARNING

● Please note the safety warnings referring to working in the engine

compartment ⇒ page 234.

● The battery providing assistance must have the same voltage as the

flat battery (12V) and approximately the same capacity (see imprint on

battery). Failure to comply could result in an explosion.

● Never use jump leads when one of the batteries is frozen. Danger of

explosion! Even after the battery has thawed, battery acid could leak and

cause chemical burns. If a battery freezes, it should be replaced.

● Keep sparks, flames and lighted cigarettes away from batteries, dan-

ger of explosion. Failure to comply could result in an explosion.

● Observe the instructions provided by the manufacturer of the jump

leads.

● Do not connect the negative cable from the other vehicle directly to

the negative terminal of the flat battery. The gas emitted from the battery

could be ignited by sparks. Danger of explosion.

● Do not attach the negative cable from the other vehicle to parts of the

fuel system or to the brake line.

● The non-insulated parts of the battery clamps must not be allowed to

touch. The jump lead attached to the positive battery terminal must not

touch metal parts of the vehicle, this can cause a short circuit.

● Position the leads in such a way that they cannot come into contact

with any moving parts in the engine compartment.

● Do not bend over the batteries. This could result in chemical burns.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 306 of 325

304Technical specifications

Technical specifications

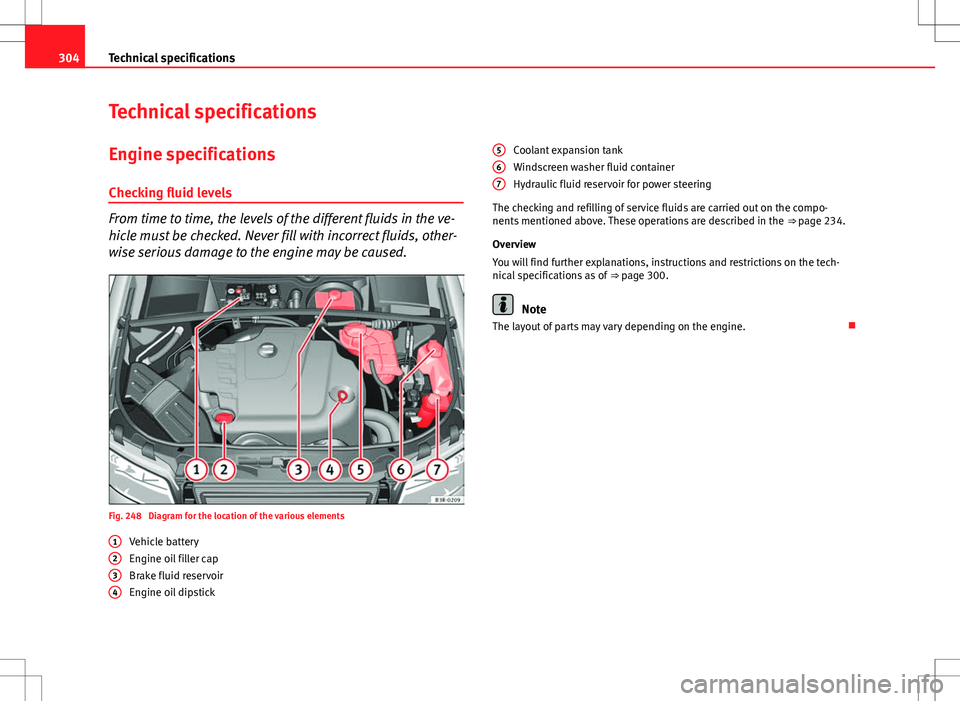

Engine specifications Checking fluid levels

From time to time, the levels of the different fluids in the ve-

hicle must be checked. Never fill with incorrect fluids, other-

wise serious damage to the engine may be caused.

Fig. 248 Diagram for the location of the various elements Vehicle battery

Engine oil filler cap

Brake fluid reservoir

Engine oil dipstick

1

234

Coolant expansion tank

Windscreen washer fluid container

Hydraulic fluid reservoir for power steering

The checking and refilling of service fluids are carried out on the compo-

nents mentioned above. These operations are described in the ⇒ page 234.

Overview

You will find further explanations, instructions and restrictions on the tech-

nical specifications as of ⇒ page 300.

Note

The layout of parts may vary depending on the engine.

567

Page 315 of 325

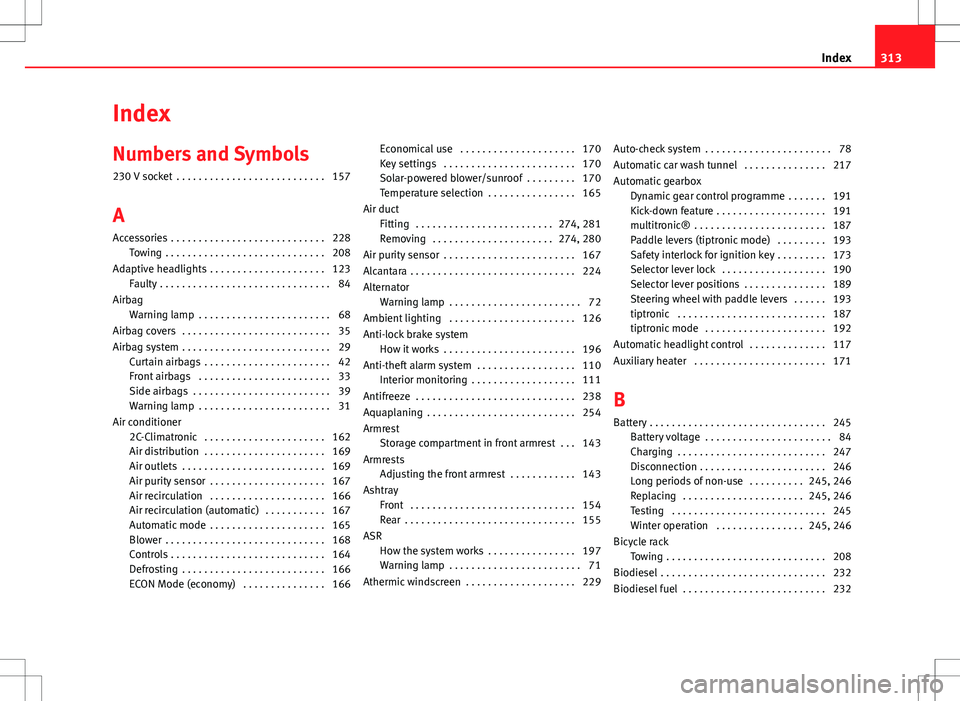

Index

Numbers and Symbols

230 V socket . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

A

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228 Towing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

Adaptive headlights . . . . . . . . . . . . . . . . . . . . . 123 Faulty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Airbag Warning lamp . . . . . . . . . . . . . . . . . . . . . . . . 68

Airbag covers . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Airbag system . . . . . . . . . . . . . . . . . . . . . . . . . . . 29 Curtain airbags . . . . . . . . . . . . . . . . . . . . . . . 42

Front airbags . . . . . . . . . . . . . . . . . . . . . . . . 33

Side airbags . . . . . . . . . . . . . . . . . . . . . . . . . 39

Warning lamp . . . . . . . . . . . . . . . . . . . . . . . . 31

Air conditioner 2C-Climatronic . . . . . . . . . . . . . . . . . . . . . . 162

Air distribution . . . . . . . . . . . . . . . . . . . . . . 169

Air outlets . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Air purity sensor . . . . . . . . . . . . . . . . . . . . . 167

Air recirculation . . . . . . . . . . . . . . . . . . . . . 166

Air recirculation (automatic) . . . . . . . . . . . 167

Automatic mode . . . . . . . . . . . . . . . . . . . . . 165

Blower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

Defrosting . . . . . . . . . . . . . . . . . . . . . . . . . . 166

ECON Mode (economy) . . . . . . . . . . . . . . . 166 Economical use . . . . . . . . . . . . . . . . . . . . . 170

Key settings . . . . . . . . . . . . . . . . . . . . . . . . 170

Solar-powered blower/sunroof . . . . . . . . . 170

Temperature selection . . . . . . . . . . . . . . . . 165

Air duct Fitting . . . . . . . . . . . . . . . . . . . . . . . . . 274, 281

Removing . . . . . . . . . . . . . . . . . . . . . . 274, 280

Air purity sensor . . . . . . . . . . . . . . . . . . . . . . . . 167

Alcantara . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

Alternator Warning lamp . . . . . . . . . . . . . . . . . . . . . . . . 72

Ambient lighting . . . . . . . . . . . . . . . . . . . . . . . 126

Anti-lock brake system How it works . . . . . . . . . . . . . . . . . . . . . . . . 196

Anti-theft alarm system . . . . . . . . . . . . . . . . . . 110 Interior monitoring . . . . . . . . . . . . . . . . . . . 111

Antifreeze . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

Aquaplaning . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

Armrest Storage compartment in front armrest . . . 143

Armrests Adjusting the front armrest . . . . . . . . . . . . 143

Ashtray Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

ASR How the system works . . . . . . . . . . . . . . . . 197

Warning lamp . . . . . . . . . . . . . . . . . . . . . . . . 71

Athermic windscreen . . . . . . . . . . . . . . . . . . . . 229 Auto-check system . . . . . . . . . . . . . . . . . . . . . . . 78

Automatic car wash tunnel . . . . . . . . . . . . . . . 217

Automatic gearbox

Dynamic gear control programme . . . . . . . 191

Kick-down feature . . . . . . . . . . . . . . . . . . . . 191

multitronic® . . . . . . . . . . . . . . . . . . . . . . . . 187

Paddle levers (tiptronic mode) . . . . . . . . . 193

Safety interlock for ignition key . . . . . . . . . 173

Selector lever lock . . . . . . . . . . . . . . . . . . . 190

Selector lever positions . . . . . . . . . . . . . . . 189

Steering wheel with paddle levers . . . . . . 193

tiptronic . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

tiptronic mode . . . . . . . . . . . . . . . . . . . . . . 192

Automatic headlight control . . . . . . . . . . . . . . 117

Auxiliary heater . . . . . . . . . . . . . . . . . . . . . . . . 171

B

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245 Battery voltage . . . . . . . . . . . . . . . . . . . . . . . 84

Charging . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

Disconnection . . . . . . . . . . . . . . . . . . . . . . . 246

Long periods of non-use . . . . . . . . . . 245, 246

Replacing . . . . . . . . . . . . . . . . . . . . . . 245, 246

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Winter operation . . . . . . . . . . . . . . . . 245, 246

Bicycle rack Towing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

Biodiesel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

Biodiesel fuel . . . . . . . . . . . . . . . . . . . . . . . . . . 232

313

Index