Seat Exeo ST 2013 Owner's manual

Manufacturer: SEAT, Model Year: 2013, Model line: Exeo ST, Model: Seat Exeo ST 2013Pages: 327, PDF Size: 5.07 MB

Page 291 of 327

289

If and when

– Position the bulb holder on the tail light and align it so that it is

securely seated.

– Press the bulb holder into the tail light until it engages.

– Check that all four retaining tabs ⇒ Fig. 229 -arrows- have en-

gaged.

– Re-install the tail light unit ⇒ page 289.

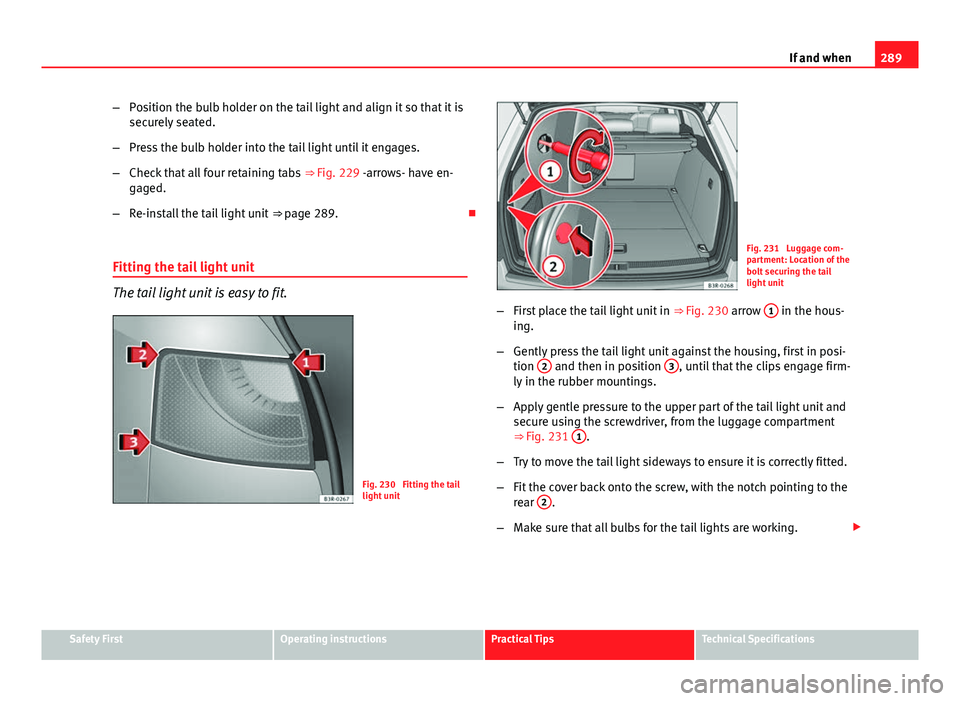

Fitting the tail light unit

The tail light unit is easy to fit.

Fig. 230 Fitting the tail

light unit

Fig. 231 Luggage com-

partment: Location of the

bolt securing the tail

light unit

– First place the tail light unit in ⇒ Fig. 230 arrow 1

in the hous-

ing.

– Gently press the tail light unit against the housing, first in posi-

tion 2

and then in position 3, until that the clips engage firm-

ly in the rubber mountings.

– Apply gentle pressure to the upper part of the tail light unit and

secure using the screwdriver, from the luggage compartment

⇒ Fig. 231 1

.

– Try to move the tail light sideways to ensure it is correctly fitted.

– Fit the cover back onto the screw, with the notch pointing to the

rear 2

.

– Make sure that all bulbs for the tail lights are working.

Safety FirstOperating instructionsPractical TipsTechnical Specifications

Page 292 of 327

290If and when

CAUTION

Take care when fitting the tail light unit to make sure there is no damage to

the paintwork or any of its components.

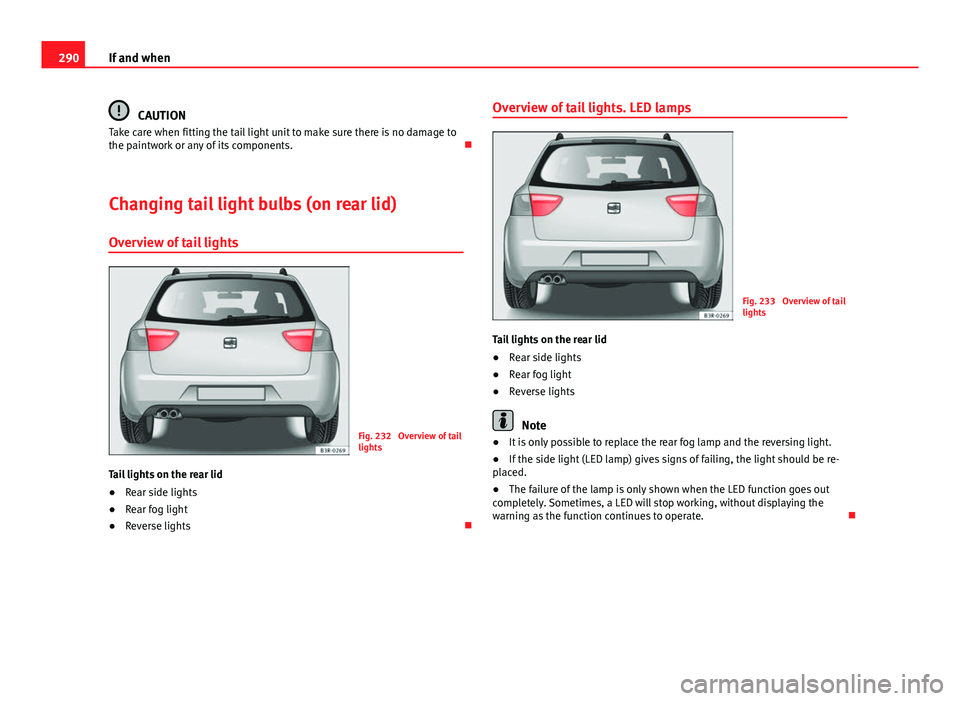

Changing tail light bulbs (on rear lid)

Overview of tail lights

Fig. 232 Overview of tail

lights

Tail lights on the rear lid

● Rear side lights

● Rear fog light

● Reverse lights Overview of tail lights. LED lamps

Fig. 233 Overview of tail

lights

Tail lights on the rear lid

● Rear side lights

● Rear fog light

● Reverse lights

Note

● It is only possible to replace the rear fog lamp and the reversing light.

● If the side light (LED lamp) gives signs of failing, the light should be re-

placed.

● The failure of the lamp is only shown when the LED function goes out

completely. Sometimes, a LED will stop working, without displaying the

warning as the function continues to operate.

Page 293 of 327

291

If and when

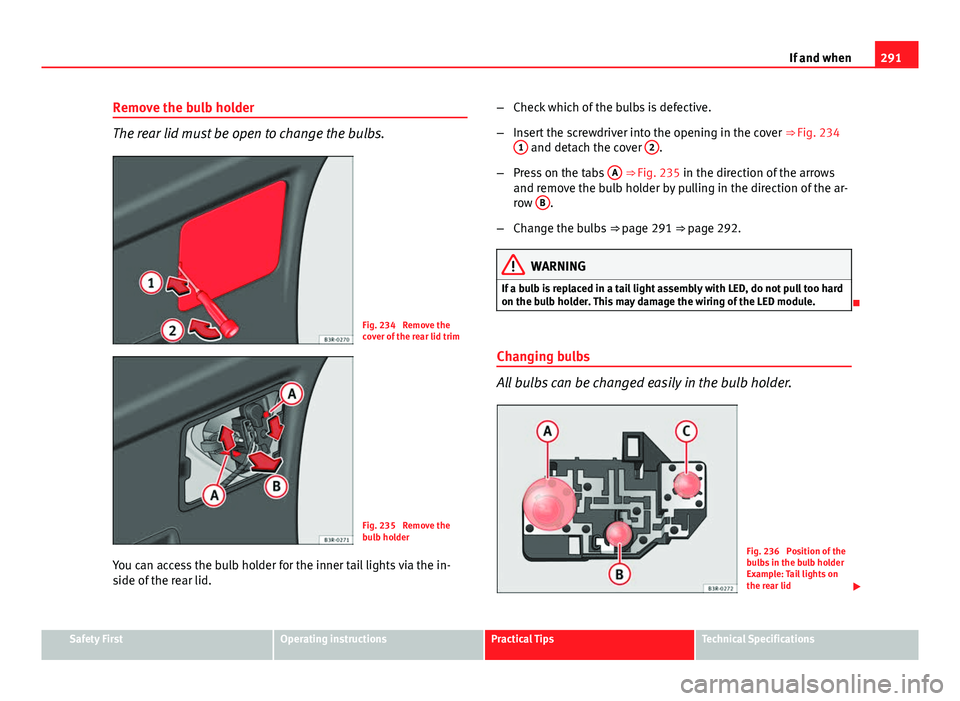

Remove the bulb holder

The rear lid must be open to change the bulbs.

Fig. 234 Remove the

cover of the rear lid trim

Fig. 235 Remove the

bulb holder

You can access the bulb holder for the inner tail lights via the in-

side of the rear lid. –

Check which of the bulbs is defective.

– Insert the screwdriver into the opening in the cover ⇒ Fig. 234

1

and detach the cover 2.

– Press on the tabs A

⇒ Fig. 235 in the direction of the arrows

and remove the bulb holder by pulling in the direction of the ar-

row B

.

– Change the bulbs ⇒ page 291 ⇒ page 292.

WARNING

If a bulb is replaced in a tail light assembly with LED, do not pull too hard

on the bulb holder. This may damage the wiring of the LED module.

Changing bulbs

All bulbs can be changed easily in the bulb holder.

Fig. 236 Position of the

bulbs in the bulb holder

Example: Tail lights on

the rear lid

Safety FirstOperating instructionsPractical TipsTechnical Specifications

Page 294 of 327

292If and when

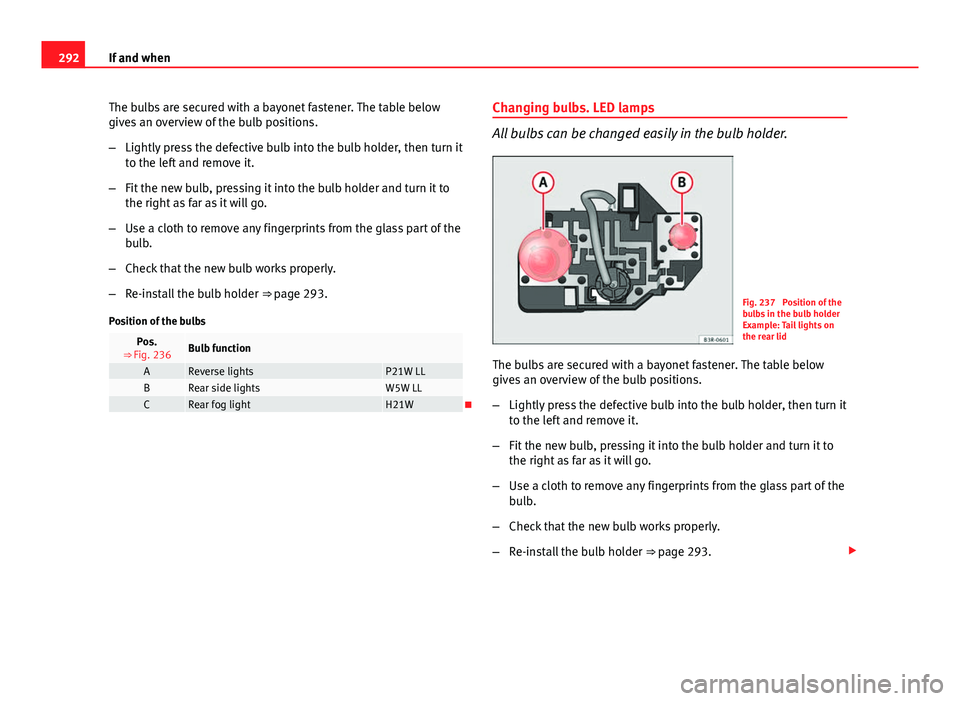

The bulbs are secured with a bayonet fastener. The table below

gives an overview of the bulb positions.

–Lightly press the defective bulb into the bulb holder, then turn it

to the left and remove it.

– Fit the new bulb, pressing it into the bulb holder and turn it to

the right as far as it will go.

– Use a cloth to remove any fingerprints from the glass part of the

bulb.

– Check that the new bulb works properly.

– Re-install the bulb holder ⇒ page 293.

Position of the bulbs

Pos.

⇒ Fig. 236Bulb function

AReverse lightsP21W LLBRear side lightsW5W LLCRear fog lightH21W Changing bulbs. LED lamps

All bulbs can be changed easily in the bulb holder.

Fig. 237 Position of the

bulbs in the bulb holder

Example: Tail lights on

the rear lid

The bulbs are secured with a bayonet fastener. The table below

gives an overview of the bulb positions.

– Lightly press the defective bulb into the bulb holder, then turn it

to the left and remove it.

– Fit the new bulb, pressing it into the bulb holder and turn it to

the right as far as it will go.

– Use a cloth to remove any fingerprints from the glass part of the

bulb.

– Check that the new bulb works properly.

– Re-install the bulb holder ⇒ page 293.

Page 295 of 327

293

If and when

Position of the bulbs

Pos.

⇒ Fig. 236Bulb function

AReverse lightsP21W LLBRear fog lightH21W

Fitting the bulb holder

The bulb holder is easy to fit. – Position the bulb holder on the tail light and align it so that it is

securely seated.

– Press the bulb holder into the tail light until it engages.

– Fit the cover back in the interior trim so that it engages.

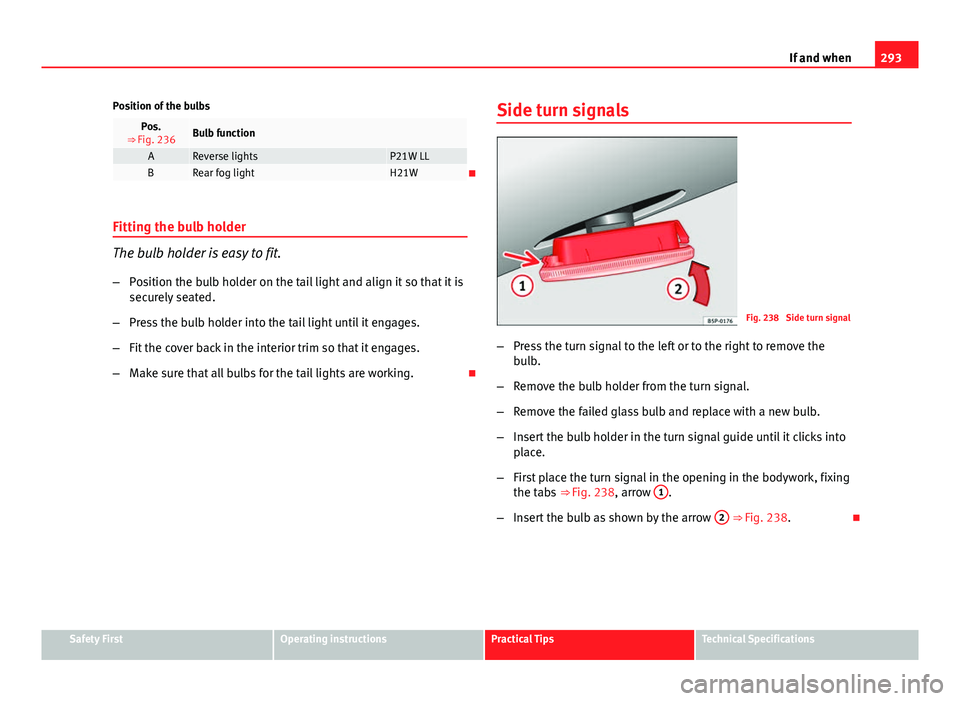

– Make sure that all bulbs for the tail lights are working. Side turn signals

Fig. 238 Side turn signal

– Press the turn signal to the left or to the right to remove the

bulb.

– Remove the bulb holder from the turn signal.

– Remove the failed glass bulb and replace with a new bulb.

– Insert the bulb holder in the turn signal guide until it clicks into

place.

– First place the turn signal in the opening in the bodywork, fixing

the tabs ⇒ Fig. 238, arrow 1

.

– Insert the bulb as shown by the arrow 2

⇒ Fig. 238.

Safety FirstOperating instructionsPractical TipsTechnical Specifications

Page 296 of 327

294If and when

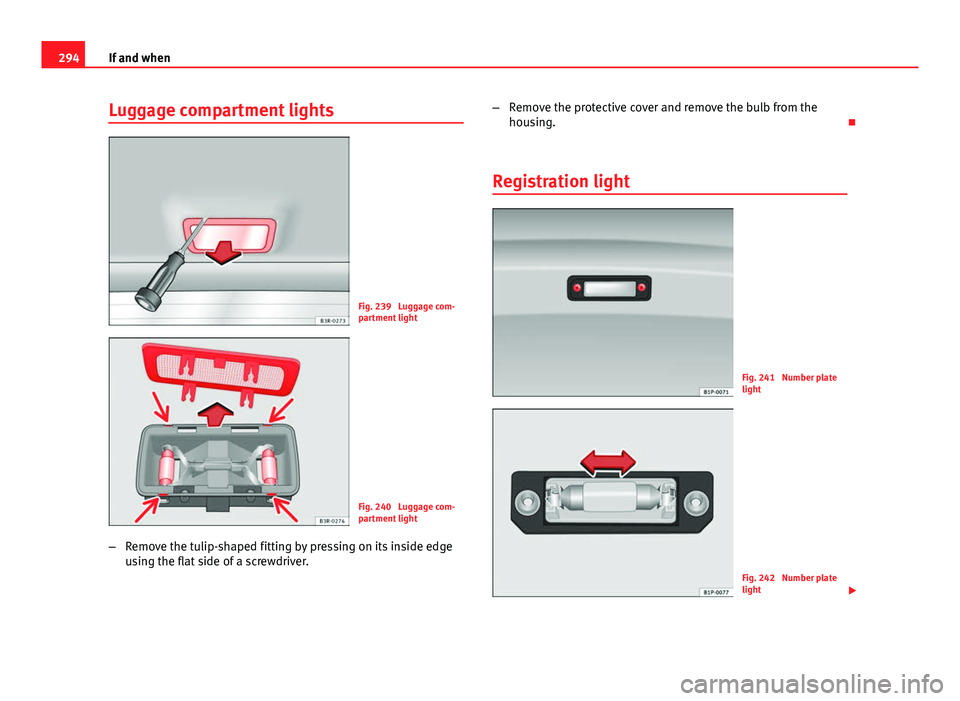

Luggage compartment lights

Fig. 239 Luggage com-

partment light

Fig. 240 Luggage com-

partment light

– Remove the tulip-shaped fitting by pressing on its inside edge

using the flat side of a screwdriver. –

Remove the protective cover and remove the bulb from the

housing.

Registration light

Fig. 241 Number plate

light

Fig. 242 Number plate

light

Page 297 of 327

295

If and when

– Unscrew the screws to remove the bulb ⇒ Fig. 241.

– Remove the bulb, moving it in the direction of the arrow and

outwards ⇒ Fig. 242.

– Installation involves all of the above steps in reverse sequence.

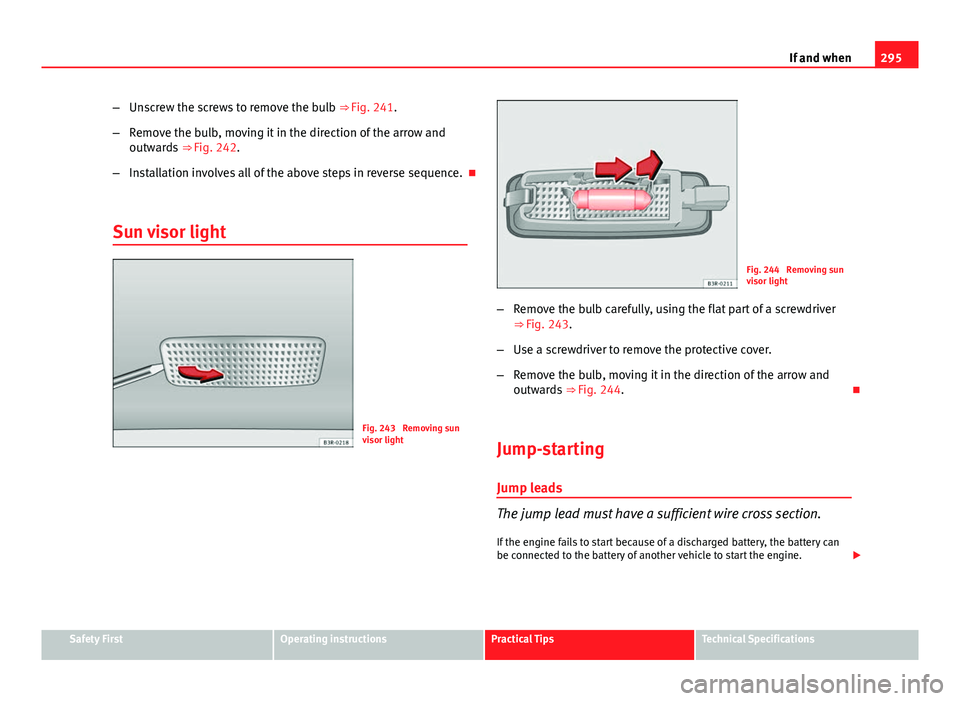

Sun visor light

Fig. 243 Removing sun

visor light

Fig. 244 Removing sun

visor light

– Remove the bulb carefully, using the flat part of a screwdriver

⇒ Fig. 243.

– Use a screwdriver to remove the protective cover.

– Remove the bulb, moving it in the direction of the arrow and

outwards ⇒ Fig. 244.

Jump-starting

Jump leads

The jump lead must have a sufficient wire cross section. If the engine fails to start because of a discharged battery, the battery can

be connected to the battery of another vehicle to start the engine.

Safety FirstOperating instructionsPractical TipsTechnical Specifications

Page 298 of 327

296If and when

Jump leads

Jump leads must comply with standard DIN 72553 (see cable manufactur-

er's instructions). The wire cross section must be at least 25 mm 2

for petrol

engines and at least 35 mm 2

for diesel engines.

Note

● The vehicles must not touch each other, otherwise electricity could flow

as soon as the positive terminals are connected.

● The discharged battery must be properly connected to the on-board net-

work.

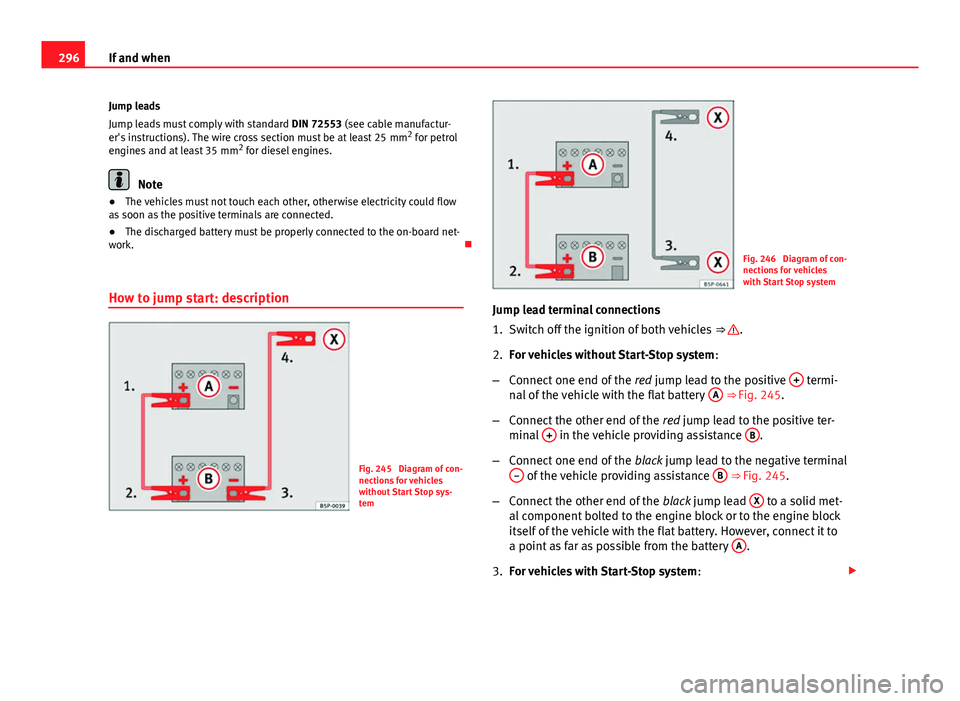

How to jump start: description

Fig. 245 Diagram of con-

nections for vehicles

without Start Stop sys-

tem

Fig. 246 Diagram of con-

nections for vehicles

with Start Stop system

Jump lead terminal connections

1. Switch off the ignition of both vehicles ⇒

.

2. For vehicles without Start-Stop system :

– Connect one end of the red jump lead to the positive +

termi-

nal of the vehicle with the flat battery A ⇒ Fig. 245.

– Connect the other end of the red jump lead to the positive ter-

minal +

in the vehicle providing assistance B.

– Connect one end of the black jump lead to the negative terminal

–

of the vehicle providing assistance B ⇒ Fig. 245.

– Connect the other end of the black jump lead X

to a solid met-

al component bolted to the engine block or to the engine block

itself of the vehicle with the flat battery. However, connect it to

a point as far as possible from the battery A

.

3. For vehicles with Start-Stop system :

Page 299 of 327

297

If and when

– Connect one end of the red jump lead to the positive +

termi-

nal of the vehicle with the flat battery A ⇒ Fig. 246.

– Connect the other end of the red jump lead to the positive ter-

minal +

in the vehicle providing assistance B.

– Connect one end of the black jump lead X

to a suitable ground

terminal, a solid piece of metal in the engine block, or to the en-

gine block ⇒ Fig. 246.

– Connect the other end of the black jump lead X

to a solid met-

al component bolted to the engine block or to the engine block

itself of the vehicle with the flat battery. However, connect it to

a point as far as possible from the battery A

.

4. Position the leads in such a way that they cannot come into contact with any moving parts in the engine compartment.

Starting

5. Start the engine of the vehicle with the boosting battery and let it run at idling speed.

6. Start the engine of the vehicle with the flat battery and wait two or three minutes until the engine is “running”.

Removing the jump leads

7. Before you remove the jump leads, switch off the dipped beam headlights (if they are switched on).

8. Turn on the heater blower and heated rear window in the vehi- cle with the flat battery. This helps minimise voltage peaks

which are generated when the leads are disconnected.

9. When the engine is running, disconnect the leads in reverse or- der to the details given above. Connect the battery clamps so they have good metal-to-metal contact with

the battery terminals.

If the engine fails to start, switch off the starter after about 10 seconds and

try again after about half a minute.

WARNING

● Please note the safety warnings referring to working in the engine

compartment ⇒ page 235.

● The battery providing assistance must have the same voltage as the

flat battery (12V) and approximately the same capacity (see imprint on

battery). Failure to comply could result in an explosion.

● Never use jump leads when one of the batteries is frozen. Danger of

explosion! Even after the battery has thawed, battery acid could leak and

cause chemical burns. If a battery freezes, it should be replaced.

● Keep sparks, flames and lighted cigarettes away from batteries, dan-

ger of explosion. Failure to comply could result in an explosion.

● Observe the instructions provided by the manufacturer of the jump

leads.

● Do not connect the negative cable from the other vehicle directly to

the negative terminal of the flat battery. The gas emitted from the battery

could be ignited by sparks. Danger of explosion.

● Do not attach the negative cable from the other vehicle to parts of the

fuel system or to the brake line.

● The non-insulated parts of the battery clamps must not be allowed to

touch. The jump lead attached to the positive battery terminal must not

touch metal parts of the vehicle, this can cause a short circuit.

● Position the leads in such a way that they cannot come into contact

with any moving parts in the engine compartment.

● Do not lean on the batteries. This could result in chemical burns.

Safety FirstOperating instructionsPractical TipsTechnical Specifications

Page 300 of 327

298If and when

Note

The vehicles must not touch each other, otherwise electricity could flow as

soon as the positive terminals are connected.