dimensions Seat Ibiza 2020 Directive 2014/53/EU Bluetooth

[x] Cancel search | Manufacturer: SEAT, Model Year: 2020, Model line: Ibiza, Model: Seat Ibiza 2020Pages: 406, PDF Size: 9.22 MB

Page 167 of 406

Page 57 of 89 Report No. : 60404488 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

4.1.2 TABLE: Critical components information

P

Object / part No. Manufacturer/

trademark Type / model Technical data Standard Mark(s) of

conformity 1)

Plastic

Enclosure LG C HEM LTD LUPOY GN -

5007F(#) V - 0 UL 94 UL ( E67171 )

Alternate Interchangeable Interchangeable Min. HB UL 94 UL

- Description: Interchangeability based on specified ratings

Metal Enclosure Interchangeable Interchangeable AL or EGI(SECC)

or GI(SGCC) or

NI or ALDC or

MG or SUS or

STS or NSP or

STEEL, Min. 0.4

thickness IEC 62368 - 1 Tested in

equipment

- Description: Interchangeability based on specified ratings and dimensions

PCB ZHEJIANG

HUABANG

ELECTRONICS

CO LTD H - 01 V - 0 UL 796 UL ( E251053 )

Alternate HYUN WOO

INDUSTRIAL

CO LTD 3 V - 0 UL 796 UL (E131308)

Alternate Interchangeable Interchangeable Min. V - 1 UL 796 UL

- Description: Interchangeability based on specified ratings

LCD Panel LG Display Co.,

Ltd. LA065WV1 6.5 inch ,

( 800 x 480 ) IEC 62368 - 1 Tested in

equipment

Alternate LG Display

(Paju) Co., Ltd. LA065WV3 6.5 inch ,

( 800 x 480 ) IEC 60065 T Ü V - Rh

(JPTUV -

080511)

Alternate Giantplus

Technology Co.,

LTD. GPM1696A0 6.5 inch ,

( 800 x 480 ) IEC 60065 SGS F imko

(FI - 37636)

Mains connector

materia l KURARAY CO

LTD GN2330(#) V - 0 UL 94 UL (E90350)

Alternate Interchangeable Interchangeable Min. V - 1 UL 94 UL

- Description: Interchangeability based on specified ratings

Fuse ST VN5E 010MHTR -

E 13A Switch off ISO/TS

16949:2009 9136.STM2

Supplementary information:

1)

Provided evidence ensures the agreed level of compliance. See OD - 2039.

Page 228 of 406

Page 15 of 88 Report No. : 60404489 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

5.2.2 .2 Steady - state voltage and current limits .................... : (See appended table 5.2) P

5.2.2.3 Capacitance limits ................................ ..................... : N/A

5.2.2.4 Single pulse limits ................................ ..................... : No such single pulse with the

e quipment N/A

5.2.2.5 Limits for repetitive pulses ................................ ........ : No such repetitive pulses with

the e quipment N/A

5.2.2.6 Ringing signals No Ringing signals N/A

5.2.2.7 Audio signals P

5.3 Protection against electrical energy sources

N/A

5.3.1 General Requirements for accessible parts to

ordinary, instructed and skilled persons Only ES1 N/A

5.3. 1 a) Accessible ES1/ES2 derived from ES2/ES3 circuits N/A

5.3.1 b) Skilled persons not unintentional contact ES3 bare

conductors N/A

5.3.2.1 Accessibility to electrical energy sources and

safeguards N/A

Accessibility to outdoor equipment bare parts N/A

5.3.2.2 Contact requirements N/A

Test with test probe from Annex V -

5.3.2.2 a) Air gap – electric strength test potential (V) ............. : N/A

5.3.2.2 b) Air gap – distance (mm) ................................ ........... : N/A

5.3.2.3 Compliance N/A

5.3.2.4 Terminals for connecting strippe d wire N/A

5.4 Insulation materials and requirements

N/A

5.4.1.2 Properties of insulating material N/A

5.4.1.3 Material is non - hygroscopic N/A

5.4.1.4 Maximum operating temperature for insulating

materials ................................ ................................ .... : N/A

5.4.1.5 Pollution degrees ................................ ...................... : N/A

5.4.1.5.2 Test for pollution degree 1 environment and for an

insulating compound N/A

5.4.1.5.3 Thermal cycling test N/A

5.4.1.6 Insulation in transformers with varying dimensions N/A

5.4.1.7 Insulation in circuits generating starting pulses N/A

5. 4.1.8 Determination of working voltage ............................. : N/A

Page 234 of 406

Page 21 of 88 Report No. : 60404489 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

6.4.3 Reduction of the likelihood of ignition under single

fault conditions in PS2 and PS3 circuits N/A

6.4.3.1 Supplementary safeguards N/A

6.4.3.2 Single Fault Conditions ................................ .......... : N/A

Special conditions for temperature limited by fuse N/A

6.4.4 Control of fire spread in PS1 circuits P

6.4.5 Control of fire spread in PS2 circuits P

6.4.5.2 Supplementa ry safeguards For conductor and devices are

mounted on printed board

made of Min. V - 1.

Other components in PS2 are

mounted on printed board

made of Min. V - 1 and PVC

wire used .

Not ignite during single fault

condition . P

6.4.6 Control of fire spread in PS3 circuits Provided Metallic enclosure P

6.4.7 Separation of combustible materials from a PIS P

6.4.7.2 Separation by distance N/A

6.4.7.3 Separation by a fire barrier P

6.4.8 Fire enclosures and fire barriers P

6.4.8.2 Fire enclosure and fire bar rier material properties P

6.4.8.2.1 Requirements for a fire barrier V - 0 class material or metal,

Printed board made of V - 0 P

6.4.8.2.2 Requirements for a fire enclosure Metallic enclosure provided P

6.4.8.3 Constructional requirements fo r a fire enclosure

and a fire barrier P

6.4.8.3.1 Fire enclosure and fire barrier openings P

6.4.8.3.2 Fire barrier dimensions P

6.4.8.3.3 Top openings and properties E quipment for building - in ,

e valuation shall be considered

in the end product N/A

Openings dimensions (mm) ................................ ... : N/A

6.4.8.3.4 Bottom openings and properties E quipment for building - in ,

e valuation shall be considered

in the end product N/A

Openings dimensions (mm) ................................ ... : N/A

Flammability tests for the bottom of a fire enclosure N/A

Page 235 of 406

Page 22 of 88 Report No. : 60404489 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

Inst ructional Safeguard ................................ ............. : N/A

6.4.8.3.5 Side openings and properties E quipment for building - in ,

e valuation shall be considered

in the end product N/A

Openings dimensions (mm) ................................ ... : N/A

6.4.8.3.6 Integrity of a fire enclosure, condition met: a), b) or

c) ................................ ................................ ............ : N ot such fire enclosure N/A

6.4.8.4 Separation of a PIS from a fire enclosure and a fire

barrier distance (mm) or flammability rating .......... : Not such fire enclosure P

6.4.9 Flammability of insulating liquid ............................... : N/A

6.5 Internal and external wiring

P

6.5.1 Ge neral requirements P

6.5.2 Requirements for interconnection to building wiring

................................ ................................ ............... : No such interconnection to

building wiring N/A

6.5.3 Internal wiring size (mm 2

) for socket - outlets .......... : N/A

6.6 Safeguards against fire due to the connection to additional equipment

P

7 INJURY CAUSED BY HAZARDOUS SUBSTANCES

N/A

7.2 Reduction of exposure to hazardous substances

N/A

7.3 Ozone exposure

N/A

7.4 Use of personal safeguards or personal protective equipment (PPE)

N/A

Personal safeguards and instructions ................... :

7.5 Use of instructional safeguards and instructions

N/A

Instructional safeguard (ISO 7010) ........................ :

7.6 Batteries and their protection circuits

N/A

8 MECHANICALLY - CAUSED INJURY

P

8.2 Mechanical energy source classifications

P

8.3 Safeguards against mechanical energy sources

P

8.4 Safeguards against parts with sharp edges and corners

P

8.4.1 Safeguards All edges and corners are

rounded or smoothed P

Instructional Safeguard ................................ ............. : MS1 N/A

8.4.2 Sharp edges or corners P

8.5 Safeguards against moving parts

N/A

Page 236 of 406

Page 23 of 88 Report No. : 60404489 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

8.5.1 Fingers, jewellery, clothing, hair, etc., contact with

MS2 or MS3 parts N/A

MS2 or MS3 part required to be accessible for the

function of the equipment N/A

Moving MS3 parts only accessible to skilled person N/A

8.5.2 Instruction al safeguard ................................ .............. : N/A

8.5.4 Special categories of equipment containing moving

parts N/A

8.5.4.1 General N/A

8.5.4.2 Equipment containing work cells with MS3 parts N/A

8.5.4.2.1 Protection of persons in the work cell N/A

8.5.4.2.2 Access protection o verride N/A

8.5.4.2.2.1 Override system

N/A

8.5.4.2.2.2 Visual indicator

N/A

8.5.4.2.3 Emergency stop system

N/A

Maximum stopping distance from the point of

activation (m) ................................ ............................. : N/A

Space between end point and nearest fixed

mechanical part (mm) ................................ ............... : N/A

8.5.4.2.4 Endurance requirements N/A

Mechanical system subjected to 100 000 cycles of

operation N/A

- Mechanical function check and visual inspection N/A

- Cable assembly ................................ ...................... : N/A

8.5.4.3 Equipment having electromechanical device for

destruct ion of media N/A

8.5.4.3.1 Equipment safeguards N/A

8.5.4.3.2 Instructional safeguards against moving parts ........ : N/A

8.5.4.3.3 Disconnection from the supply N/A

8.5.4.3.4 Cut type and test force (N) ................................ ........ : N/A

8.5.4.3.5 Compliance N/A

8.5.5 High press ure lamps No High pressure lamps N/A

Explosion test ................................ ............................ : N/A

8.5.5.3 Glass particles dimensions (mm) ............................. : N/A

8.6 Stability of equipment

N/A

Page 253 of 406

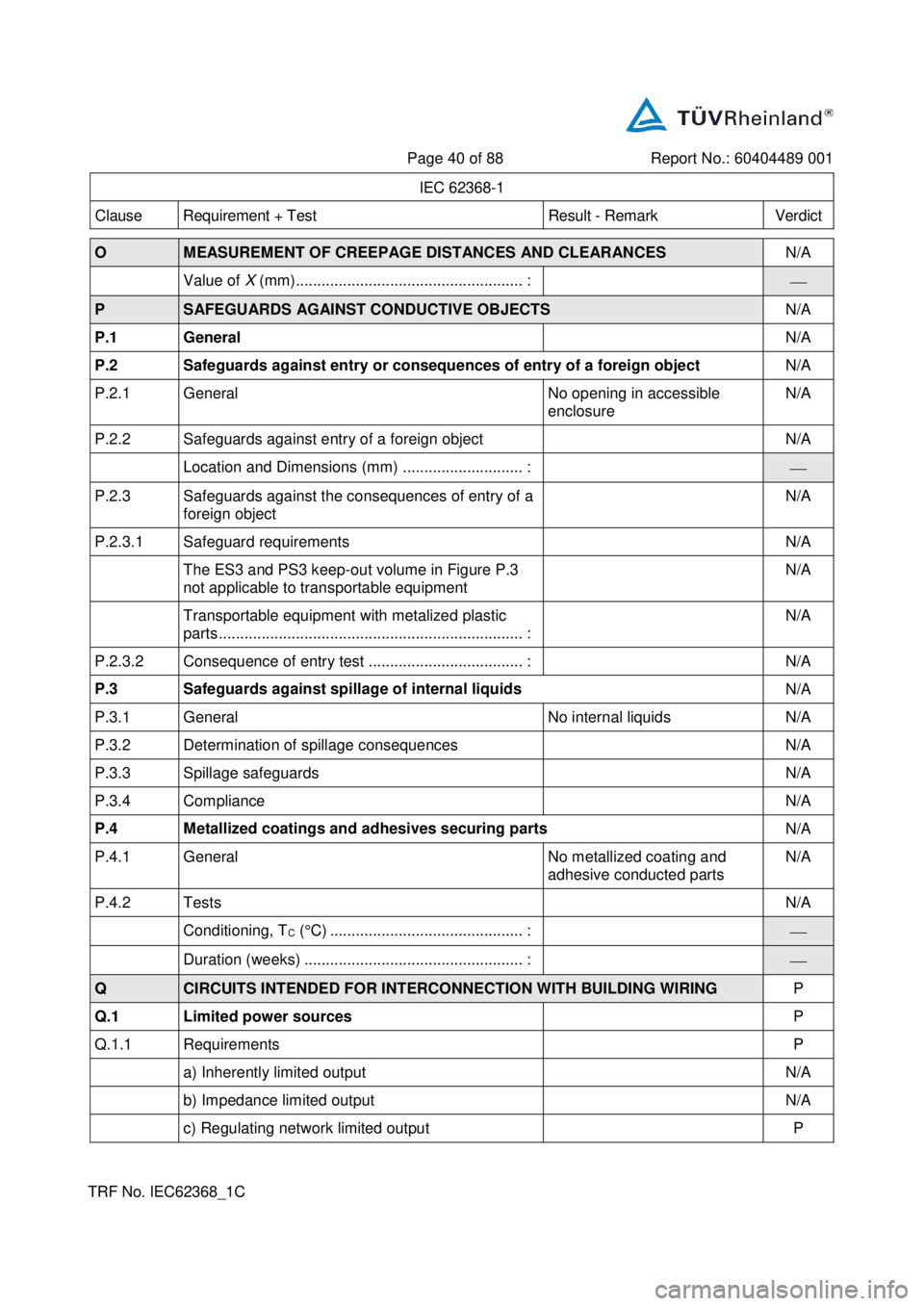

Page 40 of 88 Report No. : 60404489 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

O MEASUREMENT OF CREEPAGE DISTANCES AND CLEARANCES

N/A

Value of X (mm) ................................ ..................... :

P SAFEGUARDS AGAINST CONDUCTIVE OBJECTS

N/A

P.1 General

N/A

P.2 Safeguards against entry or consequences of entry of a foreign object

N/A

P.2.1 General No opening in accessible

enclosure N/A

P.2.2 Safeguards agai nst entry of a foreign object N/A

Location and Dimensions (mm) ............................ :

P.2.3 Safeguards against the consequences of entry of a

foreign object N/A

P.2.3.1 Safeguard requirements N/A

The ES3 and PS3 keep - out volume in Figure P.3

not applicable to tran sportable equipment N/A

Transportable equipment with metalized plastic

parts ................................ ................................ ....... : N/A

P.2.3.2 Consequence of entry test ................................ .... : N/A

P.3 Safeguards against spillage of internal liquids

N/A

P.3.1 General No internal liquids N/A

P.3.2 Determination of spilla ge consequences N/A

P.3.3 Spillage safeguards N/A

P.3.4 Compliance N/A

P.4 Metallized coatings and adhesives securing parts

N/A

P.4.1 General No meta l lized coating and

adhesive conducted parts N/A

P.4.2 Tests N/A

Conditioning, T

C (°C) ................................ ............. :

Du ration (weeks) ................................ ................... :

Q CIRCUITS INTENDED FOR INTERCONNECTION WITH BUILDING WIRING

P

Q.1 Limited power sources

P

Q.1.1 Requirements P

a) Inherently limited output N/A

b) Impedance limited output N/A

c) Regulating network limited output P

Page 269 of 406

Page 56 of 88 Report No. : 60404489 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

4.1.2 TABLE: Critical components information

P

Object / part No. Manufacturer/

trademark Type / model Technical data Standard Mark(s) of

conformity 1)

Plastic

Enclosure LG CHEM LTD LUPOY GN -

5007F(#) V - 0 UL 94 UL ( E67171 )

Alternate Interchangeable Interchangeable Min. HB UL 94 UL

- Description: Interchangeability based on specified ratings

Metal Enclosure Interchangeable Interchangeable AL or EGI(SECC)

or GI(SGCC) or

NI or ALDC or

MG or SUS or

STS or NSP or

STEEL, Min. 0.4

thickness IEC 62368 - 1 Tested in

equipment

- Description: Interchangeability based on specified ratings and dimensions

PCB ZHEJIANG

HUABANG

ELECTRONICS

CO LTD H - 01 V - 0 UL 796 UL ( E251053 )

Alternate HYUN WOO

INDUST RIAL

CO LTD 3 V - 0 UL 796 UL (E131308)

Alternate Interchangeable Interchangeable Min. V - 1 UL 796 UL

- Description: Interchangeability based on specified ratings

LCD Panel LG Display Co.,

Ltd. LA065WV1 6.5 inch ,

( 800 x 480 ) IEC 62368 - 1 Tested in

equipm ent

Alternate LG Display

(Paju) Co., Ltd. LA065WV3 6.5 inch ,

( 800 x 480 ) IEC 60065 T Ü V - Rh

(JPTUV -

080511)

Alternate Giantplus

Technology Co.,

LTD. GPM1696A0 6.5 inch ,

( 800 x 480 ) IEC 60065 SGS F imko

(FI - 37636)

Mains connector

material KURARAY CO

LTD GN2330(#) V - 0 UL 94 UL (E90350)

Alternate Interchangeable Interchangeable Min. V - 1 UL 94 UL

- Description: Interchangeability based on specified ratings

Fuse ST VN5E010MHTR -

E 13A Sw itch off ISO/TS

16949:2009 9136.STM2

Supplementary information:

1)

Provided evidence ensures the agreed level of compliance. See OD - 2039.

Page 326 of 406

Page 15 of 88 Report No. : 60404490 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

5.2.2 .2 Steady - state voltage and current limits .................... : (See appended table 5.2) P

5.2.2.3 Capacitance limits ................................ ..................... : N/A

5.2.2.4 Single pulse limits ................................ ..................... : No such single pulse with the

e quipment N/A

5.2.2.5 Limits for repetitive pulses ................................ ........ : No such repetitive pulses with

the e quipment N/A

5.2.2.6 Ringing signals No Ringing signals N/A

5.2.2.7 Audio signals P

5.3 Protection against electrical energy sources

N/A

5.3.1 General Requirements for accessible parts to

ordinary, instructed and skilled persons Only ES1 N/A

5.3. 1 a) Accessible ES1/ES2 derived from ES2/ES3 circuits N/A

5.3.1 b) Skilled persons not unintentional contact ES3 bare

conductors N/A

5.3.2.1 Accessibility to electrical energy sources and

safeguards N/A

Accessibility to outdoor equipment bare parts N/A

5.3.2.2 Contact requirements N/A

Test with test probe from Annex V -

5.3.2.2 a) Air gap – electric strength test potential (V) ............. : N/A

5.3.2.2 b) Air gap – distance (mm) ................................ ........... : N/A

5.3.2.3 Compliance N/A

5.3.2.4 Terminals for connecting strippe d wire N/A

5.4 Insulation materials and requirements

N/A

5.4.1.2 Properties of insulating material N/A

5.4.1.3 Material is non - hygroscopic N/A

5.4.1.4 Maximum operating temperature for insulating

materials ................................ ................................ .... : N/A

5.4.1.5 Pollution degrees ................................ ...................... : N/A

5.4.1.5.2 Test for pollution degree 1 environment and for an

insulating compound N/A

5.4.1.5.3 Thermal cycling test N/A

5.4.1.6 Insulation in transformers with varying dimensions N/A

5.4.1.7 Insulation in circuits generating starting pulses N/A

5. 4.1.8 Determination of working voltage ............................. : N/A

Page 332 of 406

Page 21 of 88 Report No. : 60404490 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

6.4.3 Reduction of the likelihood of ignition under single

fault conditions in PS2 and PS3 circuits N/A

6.4.3.1 Supplementary safeguards N/A

6.4.3.2 Single Fault Conditions ................................ .......... : N/A

Special conditions for temperature limited by fuse N/A

6.4.4 Control of fire spread in PS1 circuits P

6.4.5 Control of fire spread in PS2 circuits P

6.4.5.2 Supplementa ry safeguards For conductor and devices are

mounted on printed board

made of Min. V - 1.

Other components in PS2 are

mounted on printed board

made of Min. V - 1 and PVC

wire used .

Not ignite during single fault

condition . P

6.4.6 Control of fire spread in PS3 circuits Provided Metallic enclosure P

6.4.7 Separation of combustible materials from a PIS P

6.4.7.2 Separation by distance N/A

6.4.7.3 Separation by a fire barrier P

6.4.8 Fire enclosures and fire barriers P

6.4.8.2 Fire enclosure and fire bar rier material properties P

6.4.8.2.1 Requirements for a fire barrier V - 0 class material or metal,

Printed board made of V - 0 P

6.4.8.2.2 Requirements for a fire enclosure Metallic enclosure provided P

6.4.8.3 Constructional requirements fo r a fire enclosure

and a fire barrier P

6.4.8.3.1 Fire enclosure and fire barrier openings P

6.4.8.3.2 Fire barrier dimensions P

6.4.8.3.3 Top openings and properties E quipment for building - in ,

e valuation shall be considered

in the end product N/A

Openings dimensions (mm) ................................ ... : N/A

6.4.8.3.4 Bottom openings and properties E quipment for building - in ,

e valuation shall be considered

in the end product N/A

Openings dimensions (mm) ................................ ... : N/A

Flammability tests for the bottom of a fire enclosure N/A

Page 333 of 406

Page 22 of 88 Report No. : 60404490 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

Inst ructional Safeguard ................................ ............. : N/A

6.4.8.3.5 Side openings and properties E quipment for building - in ,

e valuation shall be considered

in the end product N/A

Openings dimensions (mm) ................................ ... : N/A

6.4.8.3.6 Integrity of a fire enclosure, condition met: a), b) or

c) ................................ ................................ ............ : N ot such fire enclosure N/A

6.4.8.4 Separation of a PIS from a fire enclosure and a fire

barrier distance (mm) or flammability rating .......... : Not such fire enclosure P

6.4.9 Flammability of insulating liquid ............................... : N/A

6.5 Internal and external wiring

P

6.5.1 Ge neral requirements P

6.5.2 Requirements for interconnection to building wiring

................................ ................................ ............... : No such interconnection to

building wiring N/A

6.5.3 Internal wiring size (mm 2

) for socket - outlets .......... : N/A

6.6 Safeguards against fire due to the connection to additional equipment

P

7 INJURY CAUSED BY HAZARDOUS SUBSTANCES

N/A

7.2 Reduction of exposure to hazardous substances

N/A

7.3 Ozone exposure

N/A

7.4 Use of personal safeguards or personal protective equipment (PPE)

N/A

Personal safeguards and instructions ................... :

7.5 Use of instructional safeguards and instructions

N/A

Instructional safeguard (ISO 7010) ........................ :

7.6 Batteries and their protection circuits

N/A

8 MECHANICALLY - CAUSED INJURY

P

8.2 Mechanical energy source classifications

P

8.3 Safeguards against mechanical energy sources

P

8.4 Safeguards against parts with sharp edges and corners

P

8.4.1 Safeguards All edges and corners are

rounded or smoothed P

Instructional Safeguard ................................ ............. : MS1 N/A

8.4.2 Sharp edges or corners P

8.5 Safeguards against moving parts

N/A