lock Seat Ibiza 2020 Directive 2014/53/EU Bluetooth

[x] Cancel search | Manufacturer: SEAT, Model Year: 2020, Model line: Ibiza, Model: Seat Ibiza 2020Pages: 406, PDF Size: 9.22 MB

Page 124 of 406

Page 14 of 89 Report No. : 60404488 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

4 GENERAL REQUIREMENTS

P

4.1.1 Acceptance of materials, components and

subassemblies (See appended table 4.1.2) P

4.1.2 Use of components

The equipment is so de signed

and constructed that, under

normal operating conditions

(see Clause B.2), abnormal

operating conditions (see

Clause B.3), and single fault

conditions (see Clause B.4),

safeguards are provided to

reduce the likelihood of injury

or, in the case of fi re, property

damage P

4.1.3 Equipment design and construction

P

4.1.4 Specified ambient temperature for outdoor use ( o

C)

................................ ................................ .................... : Not intended for outdoor use N/A

4.1.5 Constructions and components not specifically

covered N/A

4.1.8 Liquids and liquid fille d components (LFC) N/A

4.1.15 Markings and instructions (See Annex F) P

4.4.3 Safeguard robustness P

4.4.3.1 General P

4.4.3.2 Steady force tests Building - in equipment N/A

4.4.3.3 Drop tests Building - in equipment N/A

4.4.3.4 Impact tests P

4.4. 3.5 Internal accessible safeguard tests No Internal accessible

safeguard is used N/A

4.4.3.6 Glass impact tests No glass in the equipment N/A

4.4.3.7 Glass fixation tests No laminated glass used N/A

Glass impact test (1J) N/A

Push/pull test (10 N) N/A

4.4.3.8 Thermoplastic material tests P

4.4.3.9 Air comprising a safeguard N/A

4.4.3.10 Accessibility, glass, safeguard effectiveness P

4.4.4 Displacement of a safeguard by an insulating liquid No insulating liquid used N/A

4.4.5 Safety interlo cks No Safety interlocks N/A

Page 139 of 406

Page 29 of 89 Report No. : 60404488 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

B.3.7 Audio amplifier abnormal operating conditions P

B.3.8 Safeguards functional during and after abnorm al

operating conditions ................................ .............. : (See appended table B.3) P

B.4 Simulated single fault conditions

P

B.4.1 General P

B.4.2 Temperature controlling device N/A

B.4.3 Blocked motor test (See appended table B. 4 ) N/A

B.4.4 Functional insulation P

B.4.4.1 Short circuit of clearances for functional insulation P

B.4.4.2 Short circuit of creepage distances for functional

insulation P

B.4.4.3 Short circuit of functional insulation on coated

printed boards N/A

B.4.5 Short - circuit and interruption o f electrodes in tubes

and semiconductors P

B.4.6 Short circuit or disconnection of passive

components P

B.4.7 Continuous operation of components N/A

B.4.8 Compliance during and after single fault conditions

................................ ................................ ............... : (See appended table B.4) P

B.4.9 Battery charging and discharging under single fault

conditions Battery is not provided N/A

C UV RADIATION

N/A

C.1 Protection of materials in equipment from UV radiation

N/A

C.1.2 Requirements N/A

C.1.3 Test method N/A

C.2 UV light conditioning test

N/A

C .2.1 Test apparatus ................................ ....................... : N/A

C.2.2 Mounting of test samples N/A

C.2.3 Carbon - arc light - exposure test N/A

C.2.4 Xenon - arc light - exposure test N/A

D TEST GENERATORS

N/A

D.1 Impulse test generators

N/A

D.2 Antenna interface test generator

N/A

D.3 Elec tronic pulse generator

N/A

Page 144 of 406

Page 34 of 8 9 Report No. : 60404488 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

G.5.3.4.3 Transformers with double insulation or reinforced

insulation ................................ ............................... : N/A

G.5.3.4.4 Transformers with FIW wound on metal or ferrite

core N/A

G.5.3.4.5 Thermal cycling test and compliance N/A

G.5.3.4.6 Partial discharge test N/A

G. 5.3.4.7 Routine test N/A

G.5.4 Motors (See appended table 4.1.2) N/A

G.5.4.1 General requirements N/A

G.5.4.2 Motor overload test conditions N/A

G.5.4.3 Running overload test N/A

G.5.4.4.2 Locked - rotor overload test N/A

Test duration (days) ................................ .............. :

G.5.4.5 Running overload test for DC motors N/A

G.5.4.5.2 Tested in the unit N/A

G.5.4.5.3 Alternative method N/A

G.5.4.6 Locked - rotor overload test for DC motors N/A

G.5.4.6.2 Tested in the unit N/A

Maximum Temperature ................................ ........ : (See ap pended table B.3, B.4) N/A

G.5.4.6.3 Alternative method N/A

G.5.4.7 Motors with capacitors N/A

G.5.4.8 Three - phase motors N/A

G.5.4.9 Series motors N/A

Operating voltage ................................ ................. :

G.6 Wire Insulation

N/A

G.6.1 General N/A

G.6.2 Enamel led winding wire insulation N/A

G.7 Mains supply cords

N/A

G.7.1 General requirements N/A

Type ................................ ................................ ....... :

G.7.2 Cross sectional area (mm 2

or AWG) ..................... : N/A

G.7.3 Cord anchorages and strain relief for non -

detachable power supply cords N/A

G.7.3.2 Cord stra in relief N/A

Page 148 of 406

Page 38 of 89 Report No. : 60404488 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

Solid square and rectangular (flatwise bending)

winding wire, cross - sectional area (mm 2

) .............. : N/A

J.2/J.3

Tests and Manufacturing (See separate test report)

K SAFETY INTERLOCK S

N/A

K.1 General requirements

N/A

Instructional safeguard ................................ .......... : N/A

K.2 Components of safety interlock safeguard mechanism

N/A

K.3 Inadvertent change of operating mode

N/A

K.4 Interlock safeguard override

N/A

K.5 Fail - safe

N/A

K.5.1 Under single fa ult condition N/A

K.6 Mechanically operated safety interlocks

N/A

K.6.1 Endurance requirement N/A

K.6.2 Test method and compliance ................................ : N/A

K.7 Interlock circuit isolation

N/A

K.7.1 Separation distance for contact gaps & interlock

circuit elements N/A

In circuit connected to mains, separation distance

for contact gaps (mm) ................................ ............ : N/A

In circuit isolated from mains, separation distance

for contact gaps (mm) ................................ ............ : N/A

Electric strength test before and after the test of

K.7.2 ................................ ................................ ...... : N/A

K.7.2 Overload test , Current (A) ................................ ..... : N/A

K.7.3 Endurance test N/A

K.7.4 Electric strength test N/A

L DISCONNECT DEVICES

N/A

L.1 General requirements

N/A

L.2 Permanently connected equipment

N/A

L.3 Parts that remain energized

N/A

L.4 Single - phase equipment

N/ A

L.5 Three - phase equipment

N/A

L.6 Switches as disconnect devices

N/A

L.7 Plugs as disconnect devices

N/A

L.8 Multiple power sources

N/A

Page 163 of 406

Page 53 of 89 Report No. : 60404488 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

B.3, B.4 TABLE: Ab normal operating and fault condition tests

P

Ambient temperature T

amb ( C) ................................ ..................... : 2 1 - 2 3

Power source for EUT: Manufacturer, model/type, outputrating .. : -

Component No. Condition Supply

voltage

(V) Test

time Fuse no. Fuse

current

(A) Observation

Ventilati on

openings Block ed 14.4 2 h - - FI : 1.89 A, NO,

CT (Monitor body : 3 8. 1 C,

Power key knob body : 2 6. 9

C, Enclosure near media

button : 29. 9 C, Ambient :

2 2 .6 C, NCD, NH

Speaker output Max. non -

clipped output 14.4 2 h - - FI : 3.14 A, NO,

CT ( Amp I C body (IC163) :

64.8 C , Monitor body : 3 8. 1

C, Power key knob body :

26. 7 C, Enclosure near

media button : 29. 6 C,

Ambient : 2 2.4 C, NCD, NH

Speaker output SC 14.4 1 h - - FI : 0.5 - 1. 27 A , IP , NCD,

NH

IC101(3,8) SC 14.4 1 h - - FI : 0.5 A , CD(IC1 01) , NH

IC902(1,6) SC 14.4 1 h - - FI : 0.5 A , CD(IC902) , NH

Supplementary information:

Abbreviation:

FI – Final Input Current; IP – Internal protection operated; NO – Normal Operated;

CD – Component Damaged (list damaged components); NCD – No Component Damaged;

NH – No Hazard ; CT – Constant temperatures were obtained (list components: temperature;);

NB – No indication of dielectric breakdown; YB – Dielectric breakdown (indicate time and location);

NC – Cheesecloth remained intact; YC – Cheesecloth char red or flamed;

Page 170 of 406

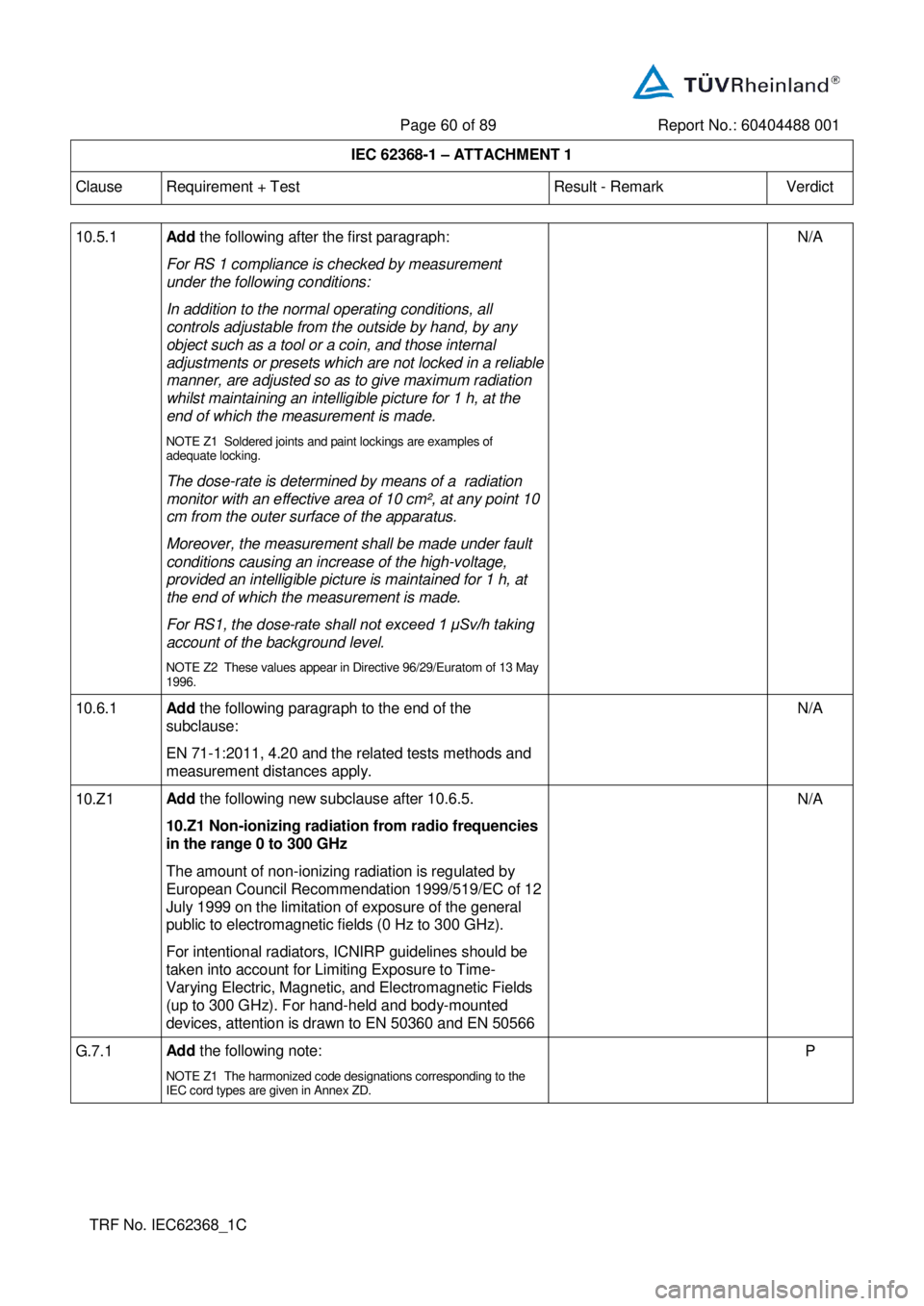

Page 60 of 89 Report No. : 60404488 001

IEC 62368 - 1 – ATTACHMENT 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

10.5.1 Add the following after the first paragraph:

For RS 1 compliance is checked by measurement

under the following conditions:

In addition to the normal operating conditions, all

controls adjustable from the outside by hand , by any

object such as a tool or a coin, and those internal

adjustments or presets which are not locked in a reliable

manner, are adjusted so as to give maximum radiation

whilst maintaining an intelligible picture for 1 h, at the

end of which the measurem ent is made.

NOTE Z1 Soldered joints and paint lockings are examples of

adequate locking.

The dose - rate is determined by means of a radiation

monitor with an effective area of 10 cm², at any point 10

cm from the outer surface of the apparatus.

Moreover, the measurement shall be made under fault

conditions causing an increase of the high - voltage,

provided an intelligible picture is maintained for 1 h, at

the end of which the measurement is made.

For RS1, the do se - rate shall not exceed 1 μSv/h taking

account of the background level.

NOTE Z2 These values appear in Directive 96/29/Euratom of 13 May

1996. N/A

10.6.1 Add the following paragraph to the end of the

subclause:

EN 71 - 1:2011, 4.20 and the related tests methods and

measurement distances apply. N/A

10.Z1 Add the following new subclause after 10.6.5.

10.Z1 Non - ionizing radiation from radio frequencies

in the range 0 to 300 GHz

The amount of non - ionizing radiation is regulated by

European Council Recommend ation 1999/519/EC of 12

July 1999 on the limitation of exposure of the general

public to electromagnetic fields (0 Hz to 300 GHz).

For intentional radiators, ICNIRP guidelines should be

taken into account for Limiting Exposure to Time -

Varying Electric, Mag netic, and Electromagnetic Fields

(up to 300 GHz). For hand - held and body - mounted

devices, attention is drawn to EN 50360 and EN 50566 N/A

G.7.1 Add the following note:

NOTE Z1 The harmonized code designations corresponding to the

IEC cord types are giv en in Annex ZD. P

Page 186 of 406

Page 76 of 89 Report No. : 60404488 001

IEC 62368 - 1_ATTACHMENT 2

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

are offered, an administrator (for example, parental

restrictions, business/educational administrators,

etc.) shall be able to lock any optional settings into a

specific configuration.

The personal music player shall be supplied with

easy to understand explanation to the user of the

dose management system, the risks involved, and

how to use the system safely. The user shall be

ma de aware that other sources may significantly

contribute to their sound exposure, for example

work, transportation, concerts, clubs, cinema, car

races, etc.

10.6.5.2 Dose - based warning and requirements

When a dose of 100 % CSD is reached, and at lea st

at every 100 % further increase of CSD , the device

shall warn the user and require an

acknowledgement. In case the user does not

acknowledge, the output level shall automatically

decrease to compliance with class RS1.

The warning shall at least clearly indicate that

listening above 100 % CSD leads to the risk of

hearing damage or loss. N/A

10.6.5.3 Exposure - based requirements

With only dose - based requirements, cause and

effect could be far separated in time, defying the

purpose of educating users abo ut safe listening

practice. In addition to dose - based requirements, a

PMP shall therefore also put a limit to the short - term

sound level a user can listen at.

The exposure - based limiter (EL) shall automatically

reduce the sound level not to exceed 100 dB (A) or

150 mV integrated over the past 180 s, based on

methodology defined in EN 50332 - 3.

The EL settling time (time from starting level

reduction to reaching target output) shall be 10 s or

faster.

Test of EL functionality is conducted according to

EN 50 332 - 3, using the limits from this clause. For

equipment provided as a package (player with its

listening device), the level integrated over 180 s

shall be 100 dB or lower. For equipment provided

with a standardized connector, the unweighted level

integrate d over 180 s shall be no more than 150 mV

for an analogue interface and no more than - 10

dBFS for a digital interface.

NOTE In case the source is known not to be music (or test

signal), the EL may be disabled. N/A

10.6.6

Requirements for listening devic es (headphones, earphones, etc.)

N/A

Page 190 of 406

Page 80 of 89 Report No. : 60404488 001

IEC 62368 - 1_ATTACHMENT 2

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

8

Modification to 10.5.1

N/A

10.5.1 Add the following after the first paragraph:

For RS 1 compliance is checked by measurement

under the fol lowing conditions:

In addition to the normal operating conditions, all

controls adjustable from the outside by hand, by any

object such as a tool or a coin, and those internal

adjustments or pre - sets which are not locked in a

reliable manner, are adjusted so as to give

maximum radiation whilst maintaining an intelligible

picture for 1 h, at the end of which the measurement

is made.

NOTE Z1 Soldered joints and paint lockings are examples of

adequate locking.

The dose - rate is determined by means of a radia tion

monitor with an effective area of 10 cm², at any point

10 cm from the outer surface of the apparatus.

Moreover, the measurement shall be made under

fault conditions causing an increase of the high

voltage, provided an intelligible picture is maintain ed

for 1 h, at the end of which the measurement is

made.

For RS1, the dose - rate shall not exceed 1 μSv/h

taking account of the background level.

NOTE Z2 These values appear in Directive 96/29/Euratom of 13

May 1996. N/A

9

Modification to G.7.1

N/A

G.7.1 Add the following note:

NOTE Z1 The harmonized code designations corresponding to

the IEC cord t ypes are given in Annex ZD. N/A

Page 225 of 406

Page 12 of 88 Report No. : 60404489 001

TR F No. IEC62368_1 C

E NERGY SOURCE DIAGRAM

Optional . Manufacturers are to provide the energy sources diagram identify declared energy sources and

identifying the demarcations are between power sources. Recommend diagram be provided included in

power supply and multipart system s.

Insert diagram below. Example diagram designs are; Block diagrams; image(s) with layered data; mechanical

drawings

■ ES ■ PS ■ MS ■ TS ■ RS

ES Classification:

ES1: All parts .

PS Classification:

PS3: Head unit .

PS2: LCD m odule and Keyboard circuits .

MS classification:

MS1 : There are no sharp edges or corners . Equipment mass is under 7 kg .

TS classification:

TS1: All accessible parts including monitor enclosure, screen surface and keyboard enclosure .

RS classification:

R S1: Indicating lights and low power devices.

Page 226 of 406

Page 13 of 88 Report No. : 60404489 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

4 GENERAL REQUIREMENTS

P

4.1.1 Acceptance of materials, components and

subassemblies (See appended table 4.1.2) P

4.1.2 Use of components

The equipment is so designed

and constructed that, under

normal ope rating conditions

(see Clause B.2), abnormal

operating conditions (see

Clause B.3), and single fault

conditions (see Clause B.4),

safeguards are provided to

reduce the likelihood of injury

or, in the case of fire, property

damage P

4.1.3 Equipment design and construction

P

4.1.4 Specified ambient temperature for outdoor use ( o

C)

................................ ................................ .................... : Not intended for outdoor use N/A

4.1.5 Constructions and components not specifically

covered N/A

4.1.8 Liquids and liquid filled components (LFC) N/A

4.1.15 Markings and instructions (See Annex F) P

4.4.3 Safeguard robustness P

4.4.3.1 General P

4.4.3.2 Steady force tests Building - in equipment N/A

4.4.3.3 Drop tests Building - in equipment N/A

4.4.3.4 Impact tests P

4.4.3.5 Internal accessible safeguard tests No In ternal accessible

safeguard is used N/A

4.4.3.6 Glass impact tests No glass in the equipment N/A

4.4.3.7 Glass fixation tests No laminated glass used N/A

Glass impact test (1J) N/A

Push/pull test (10 N) N/A

4.4.3.8 Thermoplastic material tests P

4.4.3.9 Air comprising a safeguard N/A

4.4.3.10 Accessibility, glass, safeguard effectiveness P

4.4.4 Displacement of a safeguard by an insulating liquid No insulating liquid used N/A

4.4.5 Safety interlocks No Safety interlocks N/A