torque Seat Ibiza 2020 Directive 2014/53/EU Bluetooth

[x] Cancel search | Manufacturer: SEAT, Model Year: 2020, Model line: Ibiza, Model: Seat Ibiza 2020Pages: 406, PDF Size: 9.22 MB

Page 21 of 406

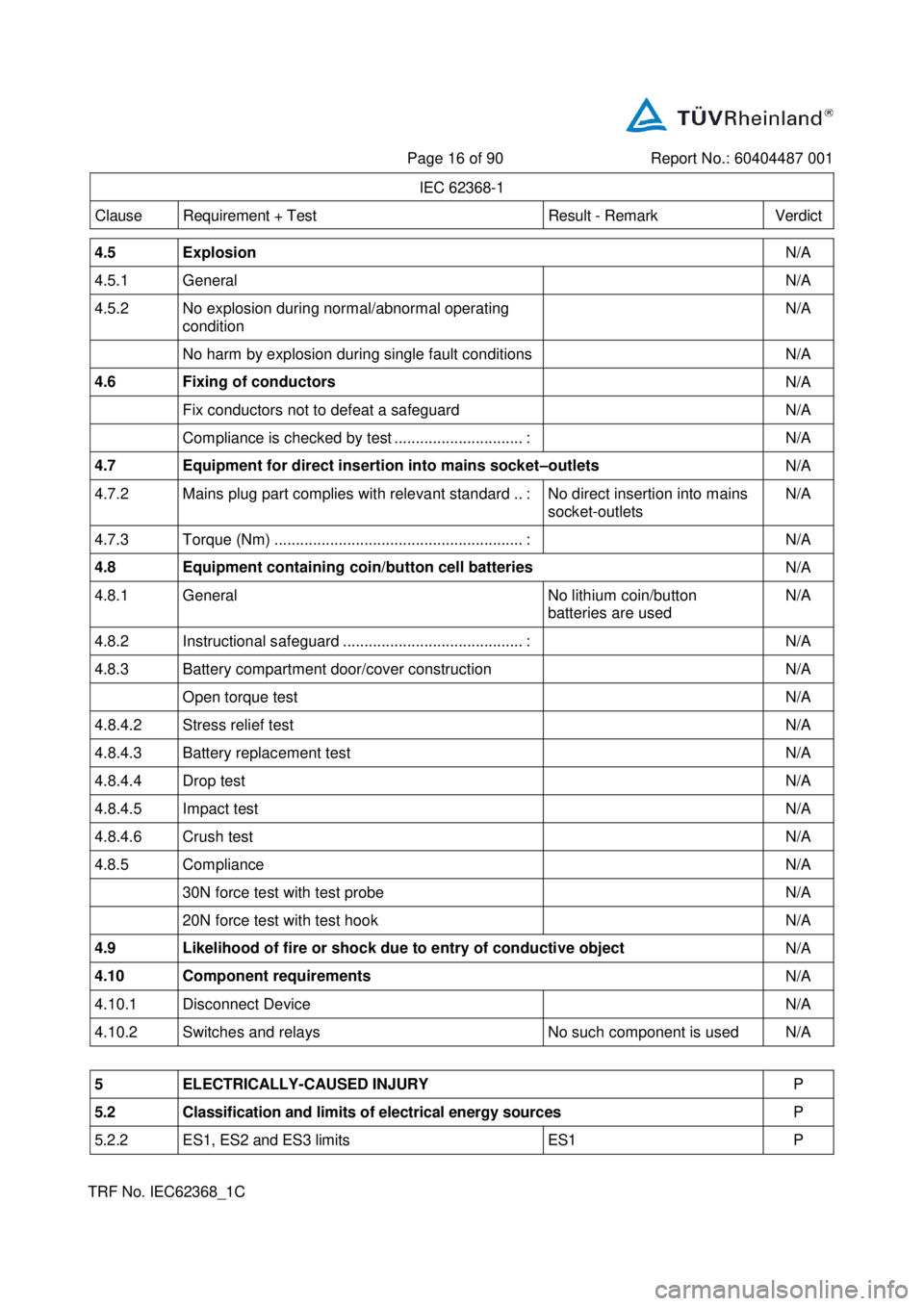

Page 16 of 90 Report No. : 60404487 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

4.5 Explosion

N/A

4.5.1 General N/A

4.5.2 No explosion during normal/abnormal operating

condition N/A

No harm by explosion during single fault conditions N/A

4.6 Fixing of conductors

N/A

Fix conductors not to defeat a safeguard N/A

Compliance is checked by test .............................. : N/A

4.7 Equipment for direct insertion into mains socket – outlets

N/A

4.7.2 Mains plug part complies with relevant standard .. : No direct insertion into m ains

socket - outlets N/A

4.7.3 Torque (Nm) ................................ .......................... : N/A

4.8 Equipment containing coin/button cell batteries

N/A

4.8.1 General No lithium coin/button

batteries are used N/A

4.8.2 Instructional safeguard ................................ .......... : N/A

4.8.3 Battery compartment door/cover construction N/A

Open torque test N/A

4.8.4.2 Stress relief test N/A

4.8.4.3 Battery replacement test N/A

4.8.4.4 Drop test N/A

4.8.4.5 Impact test N/A

4.8.4.6 Crush test N/A

4.8.5 Compliance N/A

30N force test with test probe N/A

20N force test w ith test hook N/A

4.9 Likelihood of fire or shock due to entry of conductive object

N/A

4.10 Component requirements

N/A

4.10.1 Disconnect Device N/A

4.10.2 Switches and relays No such component is used N/A

5 ELECTRICALLY - CAUSED INJURY

P

5.2 Classi fication and limits of electrical energy sources

P

5.2.2 ES1, ES2 and ES3 limits ES1 P

Page 31 of 406

Page 26 of 90 Report No. : 60404487 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

8.6.1 General Buil t - in equipment N/A

Instructional safeguard ................................ .............. : N/A

8.6.2 Static stability N/A

8.6.2.2 Static stability test ................................ ..................... : N/A

8.6.2.3 Downward force test N/A

8.6.3 Relocation stability N/A

Wheels diameter (mm) ................................ ............. :

Tilt test N/A

8.6.4 Glass slide tes t N/A

8.6.5 Horizontal force test ................................ .................. : N/A

8.7 Equipment mounted to wall, ceiling or other structure

N/A

8.7.1 Mount means type ................................ .................... : Built - in equipment N/A

8.7.2 Test methods N/A

Test 1, additional downwards force (N) .................... : N/A

Test 2, number of attachme nt points and test force

(N) ................................ ................................ .............. : N/A

Test 3 Nominal diameter (mm) and applied torque

(Nm) ................................ ................................ ........... : N/A

8.8 Handles strength

N/A

8.8.1 General No such part N/A

8.8.2 Handle strength test N/A

Number of handles ................................ .................... :

Force applied (N) ................................ ...................... :

8.9 Wheels or casters attachment requirements

N/A

8.9.2 Pull test No wheels or casters N/A

8.10 Carts, stands and similar carriers

N/A

8.10.1 General Built - in equipment N/A

8.10.2 Marking and instructions ................................ ........... : N/A

8.10.3 Cart, stand or carrier loading test N/A

Loading force applied (N) ................................ ......... : N/A

8.10.4 Cart, stand or carrier impact test N/A

8.10.5 Mechanical stability N/A

Force applied (N) ................................ ...................... :

Page 49 of 406

Page 44 of 90 Report No. : 60404487 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

Mounting of samples ................................ ............ :

Wall thickness (mm) ................................ .............. :

S.4 Flammability classification of materials

N/A

S.5 Flammability test for fire enclosures and fire barrier materials o f equipment

where the steady state power exceeding 4 000 W N/A

Samples, material ................................ .................. :

Wall thickness (mm) ................................ .............. :

Conditioning ( C) ................................ ................... :

T MECHANICAL STRENGTH TESTS

P

T.1 General

P

T.2 Steady force test, 10 N ................................ ....... :

N/A

T.3 Steady force test, 30 N ................................ ....... :

N/A

T.4 Steady force test, 100 N ................................ ..... :

N/A

T.5 Steady force test, 250 N ................................ ..... :

N/A

T.6 Enclosure impact test

P

Fall test P

Swing test N/A

T.7 Drop test ................................ .............................. :

N/A

T.8 Stress relief test ................................ ................... :

(See appended table T.8) P

T.9 Glass Impact Test ................................ ................... :

N/A

T.1 0 Glass fragmentation test

N/A

Number of particles counted ................................ .... : N/A

T.11 Test for telescoping or rod antennas

N/A

Torque value (Nm) ................................ ................ : N/A

U MECHANICAL STRENGTH OF CATHODE RAY TUBES (CRT) AND

PROTECTION AGAINST THE EFFECTS OF IMPLOSION N/A

U.1 Genera l

N/A

Instructional safeguard :

No CRT provided within the

equipment N/A

U.2 Test method and compliance for non - intrinsically protected CRTs

N/A

U.3 Protective screen

N/A

V DETERMINATION OF ACCESSIBLE PARTS

N/A

V.1 Accessible parts of equipment

N/A

Page 68 of 406

Page 63 of 90 Report No. : 60404487 001

IEC 62368 - 1 – ATTACHMENT 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

ZB ANNEX ZB, SPECIAL NATIONAL CONDITIONS (EN)

N/A

4.1.15 Denmark, Finland, Norway and Sweden

To the end of the subclause the following is added:

Class I pluggable equipment type A intended for

connection to other equipment or a network shall, if

safety relies on connection to reliable earthing or if

surge suppressors are connected between the network

terminals and accessible parts, have a marking stating

that the equipment shall be connected to an earthed

mains socket - outlet.

The marking text in the app licable countries shall be as

follows:

In Denmark : “Apparatets stikprop skal tilsluttes en

stikkontakt med jord som giver forbindelse til

stikproppens jord.”

In Finland : "Laite on liitettä vä suojakoskettimilla

varustettuun pistorasiaan"

In Norway : “Apparat et må tilkoples jordet stikkontakt”

In Sweden : “Apparaten skall anslutas till jordat uttag” N/A

4.7.3 United Kingdom

To the end of the subclause the following is added:

The torque test is performed using a socket - outlet

complying with BS 1363, and the pl ug part shall be

assessed to the relevant clauses of BS 1363. Also see

Annex G.4.2 of this annex N/A

5.2.2.2 Denmark

After the 2nd paragraph add the following:

A warning (marking safeguard ) for high touch current

is required if the touch current exceeds the limits of 3,5

mA a.c. or 10 mA d.c. N/A

Page 88 of 406

Page 83 of 90 Report No. : 60404487 001

IEC 62368 - 1_ATTACHMENT 2

Clause Requirement + Test Result - Remark Verdict

TRF No. IEC62368_1 C

4.7.3 United Kingdom

To the end of the subclause the following is added:

The torque test is performed using a socket - outlet

complying with BS 1363, and the plug part shall be

assessed to the relevant clauses of BS 1363. Also

see Annex G.4.2 of thi s annex N/A

5.2.2.2 Denmark

After the 2nd paragraph add the following:

A warning (marking safeguard) for high touch

current is required if the touch current exceeds the

limits of 3,5 mA a.c. or 10 mA d.c. N/A

5.4.11.1

and

Annex G Finland and Sweden

To the end of the subclause the following is added:

For separation of the telecommunication network

from earth the following is applicable:

If this insulation is solid, including insulation forming

part of a component, it shall at least

consist of either

• two layers of thin sheet material, each of which

shall pass the electric strength test below, or

• one layer having a distance through insulation of

at least 0,4 mm, which shall pass the electric

strength test below.

If this insulation forms part of a semiconductor

component (e.g. an optocoupler), there is no

distance through insulation requirement for the

insulation consisting of an insulating compound

completely filling the casing, so that clearances and

creepage distances do not exist, if the co mponent

passes the electric strength test in accordance with

the compliance clause below and in addition

• passes the tests and inspection criteria of 5.4.8

with an electric strength test of 1,5 kV multiplied

by 1,6 (the electric strength test of 5.4.9 sh all be

performed using 1,5 kV),

and

• is subject to routine testing for electric strength

during manufacturing, using a test voltage of 1,5

kV.

It is permitted to bridge this insulation with a

capacitor complying with EN 60384 - 14:2005,

subclass Y2. N/A

Page 125 of 406

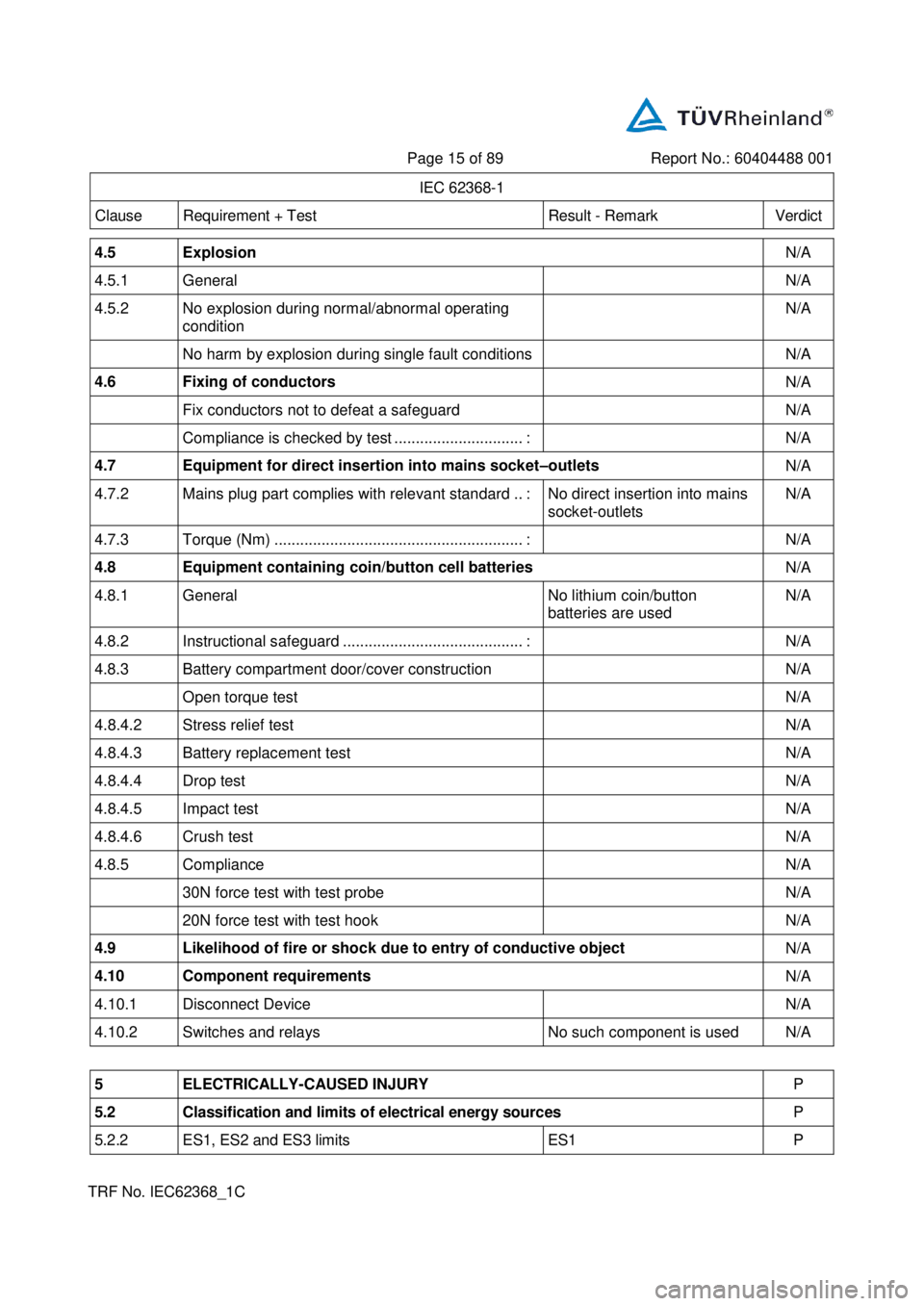

Page 15 of 89 Report No. : 60404488 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

4.5 Explosion

N/A

4.5.1 General N/A

4.5.2 No explosion during normal/abnormal operating

condition N/A

No harm by explosion during single fault conditions N/A

4.6 Fixing of conductors

N/A

Fix conductors not to defeat a safeguard N/A

Compliance is checked by test .............................. : N/A

4.7 Equipment for direct insertion into mains socket – outlets

N/A

4.7.2 Mains plug part complies with relevant standard .. : No direct insertion into mains

socket - outlets N/A

4.7.3 Torque (Nm) ................................ .......................... : N/A

4.8 Equipment containing coin/button cell batteries

N/A

4.8.1 General No lithium coin/button

batteries are used N/A

4.8.2 Instructional safeguard ................................ .......... : N/A

4.8.3 Battery compartment door/cover construction N/A

Open torque test N/A

4.8.4.2 Stress reli ef test N/A

4.8.4.3 Battery replacement test N/A

4.8.4.4 Drop test N/A

4.8.4.5 Impact test N/A

4.8.4.6 Crush test N/A

4.8.5 Compliance N/A

30N force test with test probe N/A

20N force test with test hook N/A

4.9 Likelihood of fire or shoc k due to entry of conductive object

N/A

4.10 Component requirements

N/A

4.10.1 Disconnect Device N/A

4.10.2 Switches and relays No such component is used N/A

5 ELECTRICALLY - CAUSED INJURY

P

5.2 Classification and limits of electrical energy sources

P

5.2.2 ES1, ES2 and ES3 limits ES1 P

Page 135 of 406

Page 25 of 89 Report No. : 60404488 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

8.6.1 General Built - in equipment N/A

Instructional safeguard ................................ .............. : N/ A

8.6.2 Static stability N/A

8.6.2.2 Static stability test ................................ ..................... : N/A

8.6.2.3 Downward force test N/A

8.6.3 Relocation stability N/A

Wheels diameter (mm) ................................ ............. :

Tilt test N/A

8.6.4 Glass slide test N/A

8.6.5 Horizontal force test ................................ .................. : N/A

8.7 Eq uipment mounted to wall, ceiling or other structure

N/A

8.7.1 Mount means type ................................ .................... : Built - in equipment N/A

8.7.2 Test methods N/A

Test 1, additional downwards force (N) .................... : N/A

Test 2, number of attachment points and test force

(N) ................................ ................................ .............. : N/A

Test 3 Nomin al diameter (mm) and applied torque

(Nm) ................................ ................................ ........... : N/A

8.8 Handles strength

N/A

8.8.1 General No such part N/A

8.8.2 Handle strength test N/A

Number of handles ................................ .................... :

Force applied (N) ................................ ...................... :

8.9 Wheels or casters attachment requirements

N/A

8.9.2 Pull t est No wheels or casters N/A

8.10 Carts, stands and similar carriers

N/A

8.10.1 General Built - in equipment N/A

8.10.2 Marking and instructions ................................ ........... : N/A

8.10.3 Cart, stand or carrier loading test N/A

Loading force applied (N) ................................ ......... : N/A

8.10.4 Cart, sta nd or carrier impact test N/A

8.10.5 Mechanical stability N/A

Force applied (N) ................................ ...................... :

Page 153 of 406

Page 43 of 89 Report No. : 60404488 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

Mounting of samples ................................ ............ :

Wall thickness (mm) ................................ .............. :

S.4 Flammability classification of materials

N/A

S.5 Flammability test for fire enclosures and fire barrier materials of equipment

where the steady state power exceedi ng 4 000 W N/A

Samples, material ................................ .................. :

Wall thickness (mm) ................................ .............. :

Conditioning ( C) ................................ ................... :

T MECHANICAL STRENGTH TESTS

P

T.1 General

P

T.2 Steady force test, 10 N ................................ ....... :

N/A

T.3 Steady force test, 30 N ................................ ....... :

N/A

T.4 Steady force test, 100 N ................................ ..... :

N/A

T.5 Steady force test, 250 N ................................ ..... :

N/A

T.6 Enclosure impact test

P

Fall test P

Swing test N/A

T.7 Drop test ................................ .............................. :

N/A

T.8 Stress relief test ................................ ................... :

(See appended table T.8) P

T.9 Glass Impact Test ................................ ................... :

N/A

T.10 Glass fragmentation test

N/A

Number of parti cles counted ................................ .... : N/A

T.11 Test for telescoping or rod antennas

N/A

Torque value (Nm) ................................ ................ : N/A

U MECHANICAL STRENGTH OF CATHODE RAY TUBES (CRT) AND

PROTECTION AGAINST THE EFFECTS OF IMPLOSION N/A

U.1 General

N/A

Instructional safeguard :

No CRT provid ed within the

equipment N/A

U.2 Test method and compliance for non - intrinsically protected CRTs

N/A

U.3 Protective screen

N/A

V DETERMINATION OF ACCESSIBLE PARTS

N/A

V.1 Accessible parts of equipment

N/A

Page 172 of 406

Page 62 of 89 Report No. : 60404488 001

IEC 62368 - 1 – ATTACHMENT 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

ZB ANN EX ZB, SPECIAL NATIONAL CONDITIONS (EN)

N/A

4.1.15 Denmark, Finland, Norway and Sweden

To the end of the subclause the following is added:

Class I pluggable equipment type A intended for

connection to other equipment or a network shall, if

safety relies o n connection to reliable earthing or if

surge suppressors are connected between the network

terminals and accessible parts, have a marking stating

that the equipment shall be connected to an earthed

mains socket - outlet.

The marking text in the applicable c ountries shall be as

follows:

In Denmark : “Apparatets stikprop skal tilsluttes en

stikkontakt med jord som giver forbindelse til

stikproppens jord.”

In Finland : "Laite on liitettä vä suojakoskettimilla

varustettuun pistorasiaan"

In Norway : “Apparatet må til koples jordet stikkontakt”

In Sweden : “Apparaten skall anslutas till jordat uttag” N/A

4.7.3 United Kingdom

To the end of the subclause the following is added:

The torque test is performed using a socket - outlet

complying with BS 1363, and the plug part s hall be

assessed to the relevant clauses of BS 1363. Also see

Annex G.4.2 of this annex N/A

5.2.2.2 Denmark

After the 2nd paragraph add the following:

A warning (marking safeguard ) for high touch current

is required if the touch current exceeds the limit s of 3,5

mA a.c. or 10 mA d.c. N/A

Page 192 of 406

Page 82 of 89 Report No. : 60404488 001

IEC 62368 - 1_ATTACHMENT 2

Clause Requirement + Test Result - Remark Verdict

TRF No. IEC62368_1 C

4.7.3 United Kingdom

To the end of the subclause the following is added:

The torque test is performed using a socket - outlet

complying with BS 1363, and the plug part shall be

assessed to the relevant clauses of BS 1363. Also

see Annex G.4.2 of thi s annex N/A

5.2.2.2 Denmark

After the 2nd paragraph add the following:

A warning (marking safeguard) for high touch

current is required if the touch current exceeds the

limits of 3,5 mA a.c. or 10 mA d.c. N/A

5.4.11.1

and

Annex G Finland and Sweden

To the end of the subclause the following is added:

For separation of the telecommunication network

from earth the following is applicable:

If this insulation is solid, including insulation forming

part of a component, it shall at least

consist of either

• two layers of thin sheet material, each of which

shall pass the electric strength test below, or

• one layer having a distance through insulation of

at least 0,4 mm, which shall pass the electric

strength test below.

If this insulation forms part of a semiconductor

component (e.g. an optocoupler), there is no

distance through insulation requirement for the

insulation consisting of an insulating compound

completely filling the casing, so that clearances and

creepage distances do not exist, if the co mponent

passes the electric strength test in accordance with

the compliance clause below and in addition

• passes the tests and inspection criteria of 5.4.8

with an electric strength test of 1,5 kV multiplied

by 1,6 (the electric strength test of 5.4.9 sh all be

performed using 1,5 kV),

and

• is subject to routine testing for electric strength

during manufacturing, using a test voltage of 1,5

kV.

It is permitted to bridge this insulation with a

capacitor complying with EN 60384 - 14:2005,

subclass Y2. N/A