tyre pressure Seat Ibiza SC 2014 Owner's Guide

[x] Cancel search | Manufacturer: SEAT, Model Year: 2014, Model line: Ibiza SC, Model: Seat Ibiza SC 2014Pages: 240, PDF Size: 4.89 MB

Page 185 of 240

Emergencies

Wheel change Preparation work โ

If you have a flat tyre or puncture, park the

vehicle as far away from the flow of traffic

as possible. Choose a location that is as

level as possible.

โ All vehicle occupants should leave the ve-

hicle. They should wait in a safe area (for

instance behind the roadside crash barri-

er).

โ Switch the engine off. Switch the hazard

warning lights on and place the warning tri-

angles in position.

โ Apply the handbrake

firmly.

โ En g

age the first gear , or put

the selector

lever to position P for those vehicles with

an automatic gearbox.

โ If you are towing a trailer, unhitch it from

your vehicle.

โ Take the vehicle tools and the spare wheel

out of

the luggage compartment. WARNING

โ Switch on the hazard warning lights and

place the warning triangles in position. This

is for your own safety and also warns other

road users. โ

If you change the wheel on a slope, block

the wheel on the opposite side of the car with

a stone or similar to prevent the vehicle from

moving. Changing a wheel

Change the wheel as described below:

โ Remove the hub caps or the integral trim .

โ Sl ac

ken the wheel bolts .

โ Rai

se the vehicle with the jack at the corre-

s pondin

g area.

โ Remove the wheel and put on the spare

one.

โ Lower the vehicle.

โ Tighten the wheel

bolts firmly with the box

sp

anner.

โ Replace the hub cap.

Aft

er changing a wheel โ

Put the tools back in their storage location.

โ Place the wheel with the defective tyre in

the luggage compartment and secure it.

โ Check the tyre pressure of the newly fitted

tyre as soon as possible. โ

Have the tightening torque of the wheel

bolts checked as soon as possible with a

torque wrench. The prescribed torque must

be 120 Nm. Note

โ If you notice that the wheel bolts are corro-

ded and difficult to turn when changing a

wheel, they must be replaced before having

the wheel bolt tightening torque checked.

โ For safety reasons, drive at moderate

speeds until the wheel bolt tightening torque

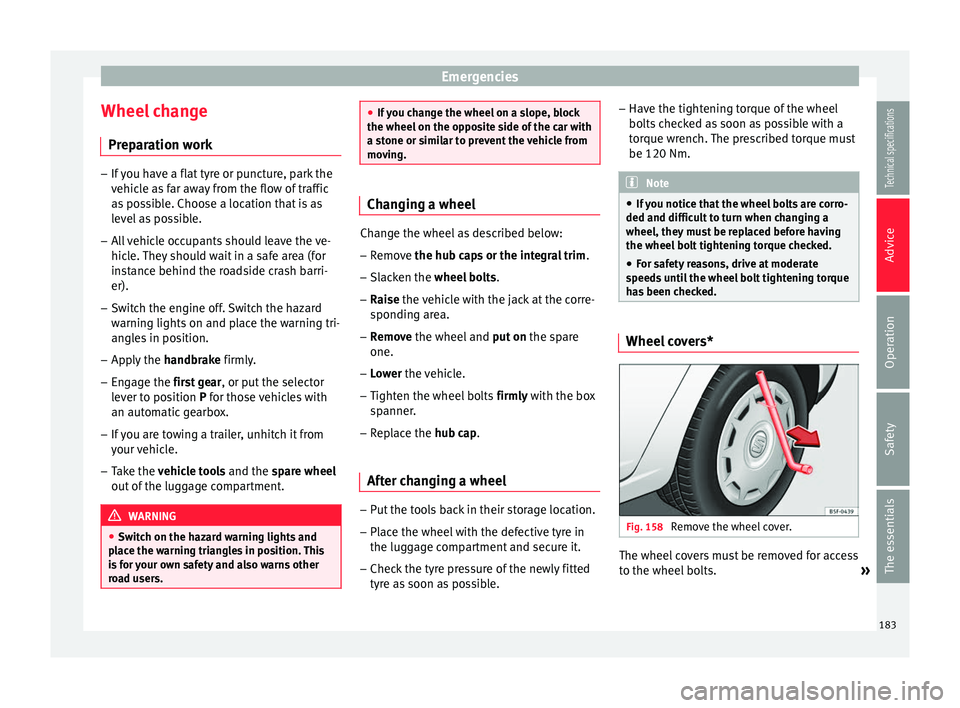

has been checked. Wheel covers*

Fig. 158

Remove the wheel cover. The wheel covers must be removed for access

to the wheel bolts.

ยป

183

Technical specifications

Advice

Operation

Safety

The essentials

Page 188 of 240

Advice

Tyres with directional tread pattern A directional tread pattern can be identified

by arrows on the sidewall that point in the di-

rection of rotation. Always note the direction

of rotation indicated when fitting the wheel.

This is important so that these tyres can give

maximum grip and avoid excessive noise,

tread wear and aquaplaning.

If, in an emergency, you have to mount the

spare wheel so it rotates in the wrong direc-

tion, you must drive extremely carefully. The

tyre will not give optimum performance. This

is particularly important when driving on wet

roads.

To benefit from the advantages of tyres with

this type of tread pattern, the defective tyre

should be replaced as soon as possible so

that all tyres again rotate in the correct direc-

tion.

Tyre repair TMS (Tyre Mobility System)* Read the additional information carefully

โบโบโบ ๏จ page 26

The Anti-puncture kit* (Tyre Mobility System)

will reliably seal punctures caused by the

penetration of a foreign body of up to about 4 mm in diameter. Do not remove foreign ob-

jects, e.g. screws or nails, from the tyre.

After inserting the sealant residue in the tyre,

you must again check the tyre pressure about

10 minutes after starting the engine.

You should only use the tire mobility set if

the vehicle is parked in a safe place, you are

familiar with the procedure and you have the

necessary tire mobility set! Otherwise, you

should seek professional assistance.

The tyre sealant must not be used in the

following cases:

โ If the wheel rim has been damaged.

โ In outside temperatures below -20 ยฐC

(-4 ยฐF).

โ In the event of cuts or perforations in the

tyre greater than 4 mm.

โ If you have been driving with very low pres-

sure or a completely flat tyre.

โ If the sealant bottle has passed its use by

date. WARNING

Using the tyre mobility system can be dan-

gerous, especially when filling the tyre at the

roadside. Please observe the following rules

to minimise the risk of injury:

โ Stop the vehicle safely as soon as possible.

Park it at a safe distance from surrounding

traffic to fill the tyre. โ

Ensure the ground on which you park is flat

and solid.

โ All passengers and particularly children

must keep a safe distance from the work area.

โ Turn on the hazard warning lights to warn

other road users.

โ Use the tyre mobility system only if you are

familiar with the necessary procedures. Oth-

erwise, you should seek professional assis-

tance.

โ The tyre mobility set is intended for tempo-

rary emergency use only until you can reach

the nearest specialised workshop.

โ Replace the repaired tyre with the tire mo-

bility set as soon as possible.

โ The sealant is a health hazard and must be

cleaned immediately if it comes into contact

with the skin.

โ Always keep the tire mobility set out of the

reach of small children.

โ Never use an equivalent jack, even if it has

been approved for your vehicle.

โ Always stop the engine, apply the hand-

brake lever firmly and engage gear if using a

manual gearbox, in order to reduce the risk of

vehicle involuntary movement. WARNING

A tyre filled with sealant does not have the

same performance properties as a conven-

tional tyre.

โ Never drive faster than 80 km/h (50 mph). 186

Page 189 of 240

Emergencies

โ

Avoid heavy acceleration, hard braking and

fast cornering.

โ Drive for only 10 minutes at a maximum

speed of 80 km/h (50 mph) and then check

the tyre. For the sake of the environment

Dispose of used or expired sealant observing

any legal requirements. Note

โ A new bottle of sealant can be purchased at

SEAT dealerships.

โ Take into account the separate instruction

manual of the tyre mobility set* manufactur-

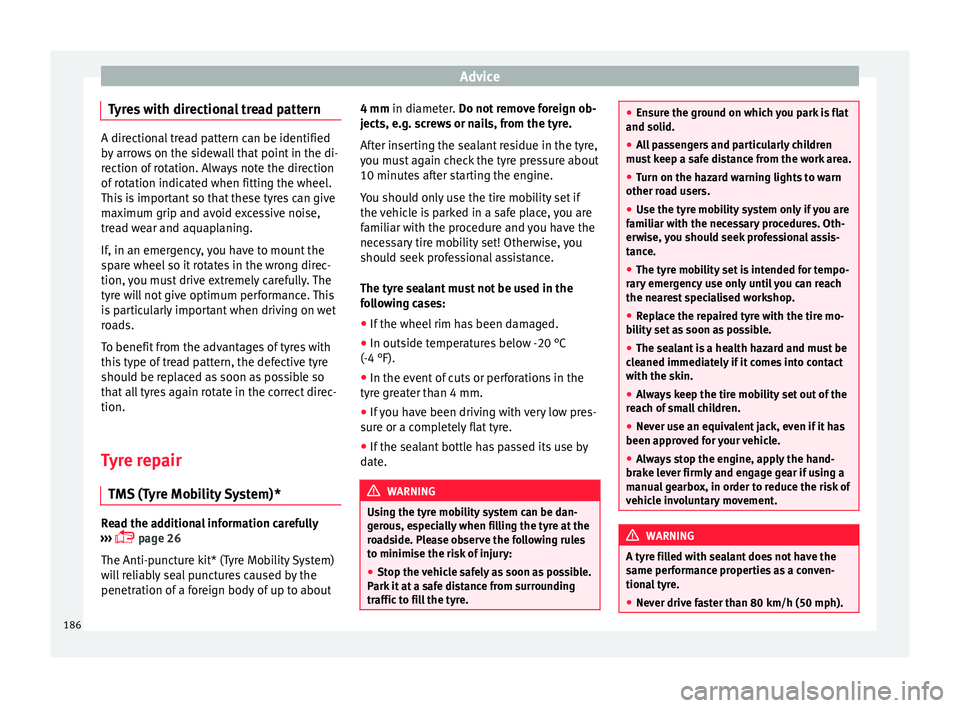

er. Contents of the tyre mobility system*

Fig. 163

Standard representation: Contents

of the tyre mobility system. The tyre mobility set is located underneath

the floor covering in the luggage compart-

ment. It includes the following components

โบโบโบ Fig. 163 :

T y

re valve remover

Sticker indicating maximum speed โmax.

80 km/hโ or โmax. 50 mphโ

Filler tube with cap

Air compressor

Tube for inflating tyres

Warning provided by tyre pressure moni-

toring system (it can also be integrated in

the compressor).

1 2

3

4

5

6 Air bleed screw (in its place, the compres-

sor may have a button).

ON/OFF switch

12 volt connector

Bottle of sealant

Spare tyre valve

The valve insert remover

1 has a gap at the

lower end for a valve insert. The valve insert

can only be screwed or unscrewed in this

way. This also applies to its replacement part 11 .

WARNING

When inflating the wheel, the air compressor

and the inflator tube may become hot.

โ Protect hands and skin from hot parts.

โ Do not place the hot flexible inflator tube or

hot air compressor on flammable material.

โ Allow them to cool before storing the de-

vice.

โ If it is not possible to inflate the tyre to at

least 2.0 bars (29 psi / 200 kPa), the tyre is

too badly damaged. The sealant is not in a

good condition to seal the tyre. Do not con-

tinue driving. Seek specialist assistance. CAUTION

Switch off the air compressor after a maxi-

mum of 8 operational minutes to avoid over-

heating! Before switching on the air compres-

sor again, let it cool for several minutes. 7

8

9

10

11

187

Technical specifications

Advice

Operation

Safety

The essentials

Page 190 of 240

Advice

Check after 10 minutes of driving Screw in the inflator tube

โบโบโบ Fig. 163 5 again and check the pressure on the gauge

6 .

1.3 bar (19 psi / 130 kPa) and lower:

โ Stop the vehicle! The tyre cannot be sealed

sufficiently with the tyre mobility set.

โ You should obtain professional assistance

โบโบโบ .

1.4 bar (20 psi / 140 kPa) and higher:

โ Set the tyre pressure to the correct value

again.

โ Carefully resume your journey until you

reach the nearest specialised workshop with-

out exceeding 80 km/h (50 mph).

โ Have the damaged tyre replaced. WARNING

Driving with an unsealed tyre is dangerous

and can cause accidents and serious injury.

โ Do not continue driving if the tyre pressure

is 1.3 bar (19 psi / 130 kPa) and lower.

โ Seek specialist assistance. Jump-starting

Jump leads The jump lead must have a sufficient wire

cross section.

If the engine fails to start because of a dis-

charged battery, the battery can be connec-

ted to the battery of another vehicle to start

the engine.

Jump leads

Jump leads must comply with standard

DIN

72553 (see cable manufacturer's instruc-

tion s).

The wire cross section must be at least

25 mm 2

for petrol engines and at least

35 mm 2

for diesel engines. Note

โ The vehicles must not touch each other,

otherwise electricity could flow as soon as

the positive terminals are connected.

โ The discharged battery must be properly

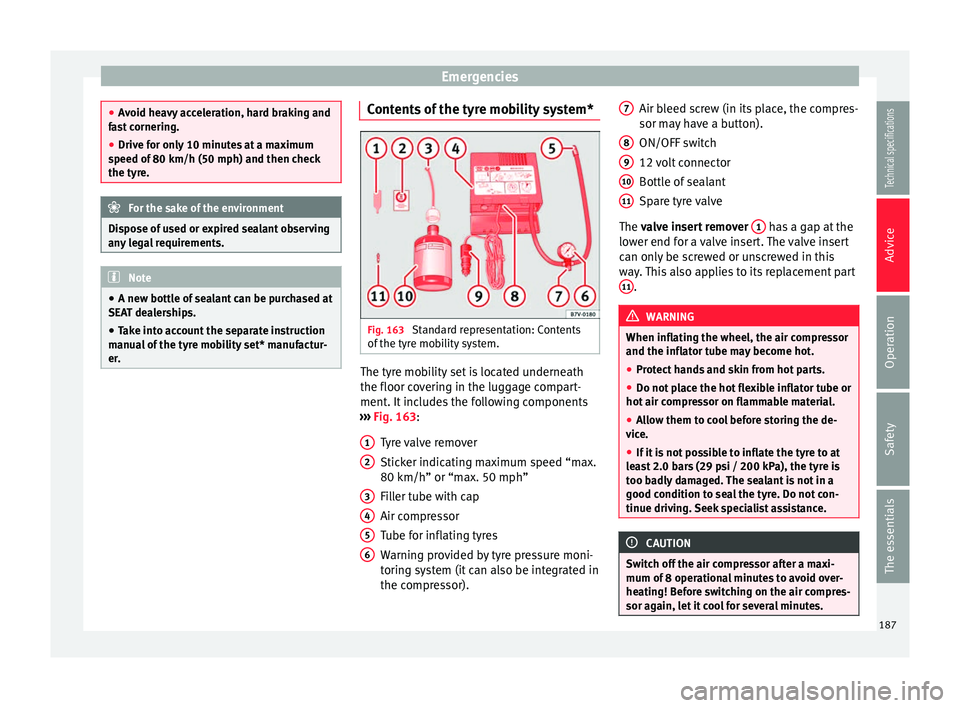

connected to the on-board network. How to jump start: description

Fig. 164

Diagram of connections for vehicles

without Start-Stop system. Fig. 165

Diagram of connections for vehicles

with Start-Stop system. Jump lead terminal connections

1. Switch off the ignition of both vehicles

โบโบโบ .

188

Page 212 of 240

Technical specifications

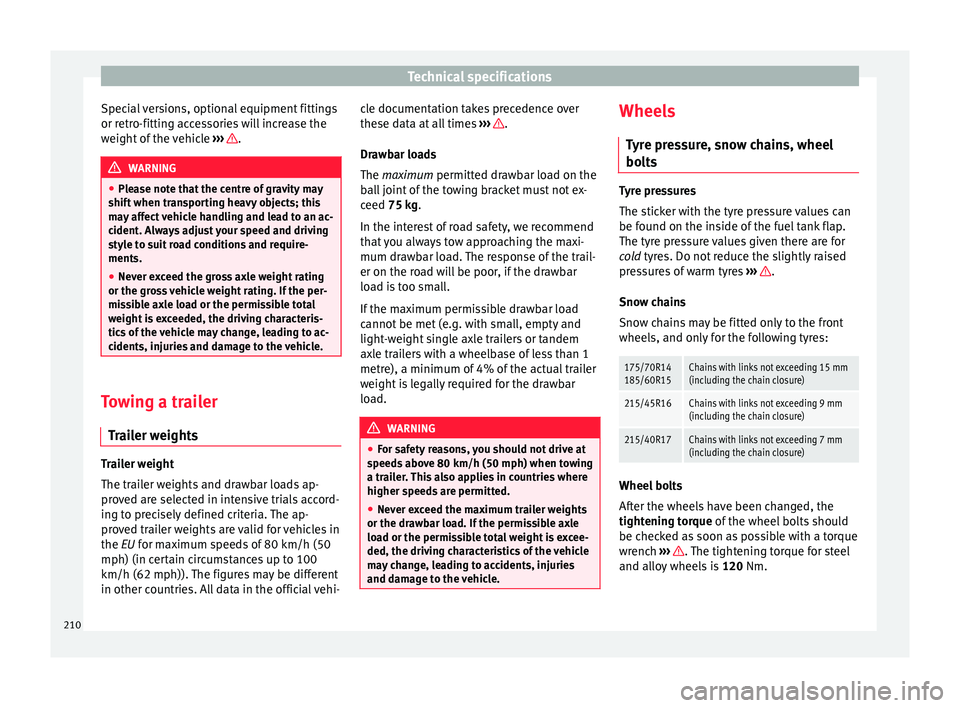

Special versions, optional equipment fittings

or retro-fitting accessories will increase the

weight of the vehicle โบโบโบ .

WARNING

โ Please note that the centre of gravity may

shift when transporting heavy objects; this

may affect vehicle handling and lead to an ac-

cident. Always adjust your speed and driving

style to suit road conditions and require-

ments.

โ Never exceed the gross axle weight rating

or the gross vehicle weight rating. If the per-

missible axle load or the permissible total

weight is exceeded, the driving characteris-

tics of the vehicle may change, leading to ac-

cidents, injuries and damage to the vehicle. Towing a trailer

Trailer weights Trailer weight

The trailer weights and drawbar loads ap-

proved are selected in intensive trials accord-

ing to precisely defined criteria. The ap-

proved trailer weights are valid for vehicles in

the

EU

for maximum speeds of 80 km/h (50

mph) (in c ertain circumstances up to 100

km/h (62 mph)). The figures may be different

in other countries. All data in the official vehi- cle documentation takes precedence over

these data at all times

โบโบโบ .

Drawbar loads

The maximum

permitted drawbar load on the

b

all joint of the towing bracket must not ex-

ceed

75 kg.

In the interest of road safety, we recommend

that you always tow approaching the maxi-

mum drawbar load. The response of the trail-

er on the road will be poor, if the drawbar

load is too small.

If the maximum permissible drawbar load

cannot be met (e.g. with small, empty and

light-weight single axle trailers or tandem

axle trailers with a wheelbase of less than 1

metre), a minimum of 4% of the actual trailer

weight is legally required for the drawbar

load. WARNING

โ For safety reasons, you should not drive at

speeds above 80 km/h (50 mph) when towing

a trailer. This also applies in countries where

higher speeds are permitted.

โ Never exceed the maximum trailer weights

or the drawbar load. If the permissible axle

load or the permissible total weight is excee-

ded, the driving characteristics of the vehicle

may change, leading to accidents, injuries

and damage to the vehicle. Wheels

Tyre pressure, snow chains, wheel

bolts Tyre pressures

The sticker with the tyre pressure values can

be found on the inside of the fuel tank flap.

The tyre pressure values given there are for

cold tyres. Do not reduce the slightly raised

pr

e

ssures of warm tyres โบโบโบ .

Snow chains

Snow chains may be fitted only to the front

wheels, and only for the following tyres:

175/70R14

185/60R15Chains with links not exceeding 15 mm

(including the chain closure)

215/45R16Chains with links not exceeding 9 mm

(including the chain closure)

215/40R17Chains with links not exceeding 7 mm

(including the chain closure) Wheel bolts

After the wheels have been changed, the

tightening torque

of the wheel bolts should

be c hec

ked as soon as possible with a torque

wrench โบโบโบ . The tightening torque for steel

and alloy wheels is 120 Nm.

210

Page 213 of 240

Technical features

WARNING

โ Check the tyre pressure at least once per

month. Checking the tyre pressure is very im-

portant. If the tyre pressure is too high or too

low, there is an increased danger of accidents

- particularly at high speeds.

โ If the tightening torque of the wheel bolts

is too low, they could loosen while the vehi-

cle is in motion. Risk of accident! If the tight-

ening torque is too high, the wheel bolts and

threads can be damaged. Note

We recommend that you ask your Technical

Service for information about appropriate

wheel, tyre and snow chain size. 211Technical specifications

Advice

Operation

Safety

The essentials

Page 229 of 240

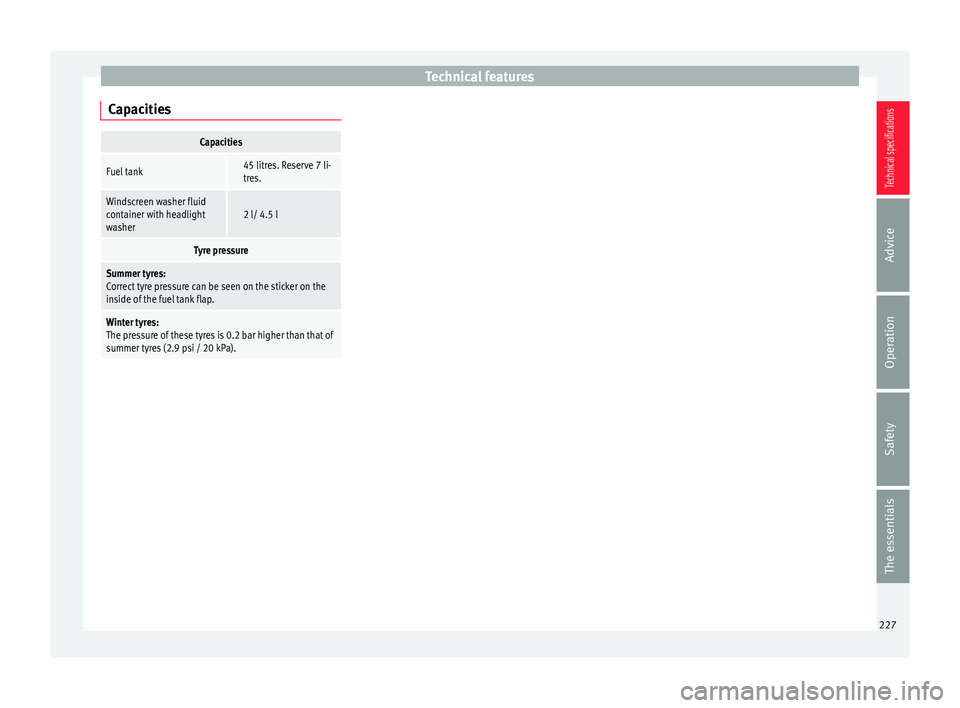

Technical features

CapacitiesCapacities

Fuel tank 45 litres. Reserve 7 li-

tres.

Windscreen washer fluid

container with headlight

washer 2 l/ 4.5 l

Tyre pressure

Summer tyres:

Correct tyre pressure can be seen on the sticker on the

inside of the fuel tank flap.

Winter tyres:

The pressure of these tyres is 0.2 bar higher than that of

summer tyres (2.9 psi / 20 kPa). 227

Technical specifications

Advice

Operation

Safety

The essentials

Page 237 of 240

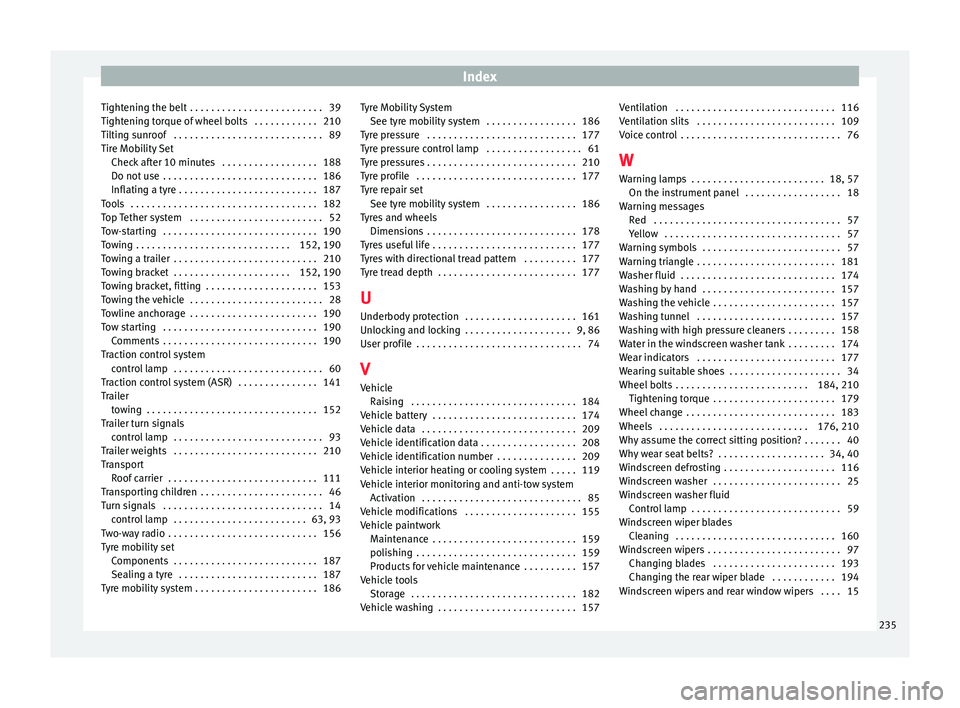

Index

Tightening the belt . . . . . . . . . . . . . . . . . . . . . . . . . 39

Tightening torque of wheel bolts . . . . . . . . . . . . 210

Tilting sunroof . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Tire Mobility Set Check after 10 minutes . . . . . . . . . . . . . . . . . . 188

Do not use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

Inflating a tyre . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Top Tether system . . . . . . . . . . . . . . . . . . . . . . . . . 52

Tow-starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

Towing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152, 190

Towing a trailer . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

Towing bracket . . . . . . . . . . . . . . . . . . . . . . 152, 190

Towing bracket, fitting . . . . . . . . . . . . . . . . . . . . . 153

Towing the vehicle . . . . . . . . . . . . . . . . . . . . . . . . . 28

Towline anchorage . . . . . . . . . . . . . . . . . . . . . . . . 190

Tow starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190 Comments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

Traction control system control lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Traction control system (ASR) . . . . . . . . . . . . . . . 141

Trailer towing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Trailer turn signals control lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Trailer weights . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

Transport Roof carrier . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Transporting children . . . . . . . . . . . . . . . . . . . . . . . 46

Turn signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 control lamp . . . . . . . . . . . . . . . . . . . . . . . . . 63, 93

Two-way radio . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Tyre mobility set Components . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Sealing a tyre . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Tyre mobility system . . . . . . . . . . . . . . . . . . . . . . . 186 Tyre Mobility System

See tyre mobility system . . . . . . . . . . . . . . . . . 186

Tyre pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Tyre pressure control lamp . . . . . . . . . . . . . . . . . . 61

Tyre pressures . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

Tyre profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Tyre repair set See tyre mobility system . . . . . . . . . . . . . . . . . 186

Tyres and wheels Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Tyres useful life . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Tyres with directional tread pattern . . . . . . . . . . 177

Tyre tread depth . . . . . . . . . . . . . . . . . . . . . . . . . . 177

U Underbody protection . . . . . . . . . . . . . . . . . . . . . 161

Unlocking and locking . . . . . . . . . . . . . . . . . . . . 9, 86

User profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

V Vehicle Raising . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Vehicle battery . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Vehicle data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Vehicle identification data . . . . . . . . . . . . . . . . . . 208

Vehicle identification number . . . . . . . . . . . . . . . 209

Vehicle interior heating or cooling system . . . . . 119

Vehicle interior monitoring and anti-tow system Activation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Vehicle modifications . . . . . . . . . . . . . . . . . . . . . 155

Vehicle paintwork Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

polishing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Products for vehicle maintenance . . . . . . . . . . 157

Vehicle tools Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Vehicle washing . . . . . . . . . . . . . . . . . . . . . . . . . . 157 Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Ventilation slits . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Voice control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

W Warning lamps . . . . . . . . . . . . . . . . . . . . . . . . . 18, 57 On the instrument panel . . . . . . . . . . . . . . . . . . 18

Warning messages Red . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Yellow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Warning symbols . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Warning triangle . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Washer fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Washing by hand . . . . . . . . . . . . . . . . . . . . . . . . . 157

Washing the vehicle . . . . . . . . . . . . . . . . . . . . . . . 157

Washing tunnel . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Washing with high pressure cleaners . . . . . . . . . 158

Water in the windscreen washer tank . . . . . . . . . 174

Wear indicators . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Wearing suitable shoes . . . . . . . . . . . . . . . . . . . . . 34

Wheel bolts . . . . . . . . . . . . . . . . . . . . . . . . . 184, 210 Tightening torque . . . . . . . . . . . . . . . . . . . . . . . 179

Wheel change . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176, 210

Why assume the correct sitting position? . . . . . . . 40

Why wear seat belts? . . . . . . . . . . . . . . . . . . . . 34, 40

Windscreen defrosting . . . . . . . . . . . . . . . . . . . . . 116

Windscreen washer . . . . . . . . . . . . . . . . . . . . . . . . 25

Windscreen washer fluid Control lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Windscreen wiper blades Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Windscreen wipers . . . . . . . . . . . . . . . . . . . . . . . . . 97 Changing blades . . . . . . . . . . . . . . . . . . . . . . . 193

Changing the rear wiper blade . . . . . . . . . . . . 194

Windscreen wipers and rear window wipers . . . . 15

235