ABS Seat Ibiza ST 2011 User Guide

[x] Cancel search | Manufacturer: SEAT, Model Year: 2011, Model line: Ibiza ST, Model: Seat Ibiza ST 2011Pages: 280, PDF Size: 4.01 MB

Page 169 of 280

167

Intelligent technology

Practical Tips Intelligent technology

Brakes Brake servo

The brake servo increases the pressure you apply to the brake pedal. It

works only when the engine is running .

If the brake servo is not functioning due to a malfunction, or if the vehicle

has to be towed, you will have to press the brake pedal considerably harder

to make up for the lack of servo assistance.

WARNING

The braking distance can also be affected by external factors.

● Never let the vehicle coast with the engine switched off. Failure to do

so could result in an accident. The braking distance is increased consid-

erably when the brake servo is not active.

● If the brake servo is not working, for example when the vehicle is be-

ing towed, you will have to press the brake pedal considerably harder

than normal.

Hydraulic Brake Assist (HBA)*

The Hydraulic Brake Assist function (HBA) is only included in

vehicles with ESP.

In an emergency, most drivers brake in time, but not with maximum force.

This results in unnecessarily long braking distances.

This is when the brake assist system comes into action. When pressing the

brake pedal rapidly, the assistant interprets it as an emergency. It then very

quickly builds up the full brake pressure so that the ABS can be activated

more quickly and efficiently, thus reducing the braking distance.

Do not reduce the pressure on the brake pedal. The brake assist system

switches off automatically as soon as you release the brake.

Automatic hazard warning lights activation

The brake lights flash automatically to indicate that the vehicle is braking

suddenly or in an emergency situation. If the emergency braking continues

until the vehicle comes to a standstill, the hazard warning lights will then

come on and the brake lights will remain on permanently from that moment.

The warning lights will automatically switch off when the vehicle begins to

move again or when the "warning" light button is pressed.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 170 of 280

168Intelligent technology

WARNING

● The risk of accident is higher if you drive too fast, if you do not keep

your distance to the vehicle in front, and when the road surface is slip-

pery or wet. The increased accident risk cannot be reduced by the brake

assist system.

● The brake assist system cannot defy the laws of physics. Slippery

and wet roads are dangerous even with the brake assist system! There-

fore, it is essential that you adjust your speed to suit the road and traffic

conditions. Do not let the extra safety features tempt you into taking any

risks when driving.

Anti-lock brake system and traction control

ABS Anti-lock brake system (ABS)

The anti-lock brake system prevents the wheels locking dur-

ing braking.

The anti-lock brake system (ABS) is an important part of the vehicle's active

safety system.

How the ABS works

If one of the wheels is turns too slowly in relation to the road speed, and is

close to locking, the system will reduce the braking pressure for this wheel.

The driver is made aware of this control process by a pulsating of the brake

pedal and audible noise. This is a deliberate warning to the driver that one

or more of the wheels is tending to lock and the ABS control function has

intervened. In this situation it is important to keep the brake pedal fully de-

pressed so the ABS can regulate the brake application. Do not “pump”. If you brake hard on a slippery road surface, the best possible control is re-

tained as the wheels do not lock.

However, ABS will not necessarily guarantee shorter braking distances in

all

conditions. The braking distance could even be longer if you brake on gravel

or on fresh snow covering a slippery surface.

WARNING

● The anti-lock brake system cannot defy the laws of physics. Slippery

and wet roads are dangerous even with ABS! If you notice that the ABS is

working (to counteract locked wheels under braking), you should reduce

speed immediately to suit the road and traffic conditions. Do not let the

extra safety features tempt you into taking any risks when driving.

● The effectiveness of ABS is also determined by the tyres fitted

⇒ page 215.

● If the running gear or brakes are modified, the effectiveness of the

ABS could be severely limited.

Traction control system (TCS)*

The traction control system prevents the drive wheels from

spinning when the vehicle is accelerating. The system al-

ways includes ABS

Description and operation of the traction control system during

acceleration (TCS)

TCS reduces engine power to help prevent the drive wheels of front-wheel

drive vehicles losing traction during acceleration. The system works in the

entire speed range in conjunction with ABS. If a malfunction occurs in the

ABS, the TCS will also be inoperative.

Page 171 of 280

169

Intelligent technology

TCS helps the vehicle to start moving, accelerate and climb a gradient in

slippery conditions where this may otherwise be difficult or even impossi-

ble.

The TCS is switched on automatically when the engine is started. If necessa-

ry, it may be turned on or off by briefly pushing the ESP button on the centre

console.

When the TCS is off, the warning lamp is lit. The TCS should normally be

left on. Only in exceptional circumstances, when the slipping of the wheels

is required, can they be disconnected using the ESP button, for example.

● With compact temporary spare wheel.

● When using the snow chains.

● When driving in deep snow or on loose surfaces

● When the vehicle is bogged-down, to free it by rocking.

The TCS should be switched on again as soon as possible.

WARNING

● It must be remembered that TCS cannot defy the laws of physics. This

should be kept in mind, particularly on slippery and wet roads and when

towing a trailer.

● Always adapt your driving style to suit the condition of the roads and

the traffic situation. Do not let the extra safety afforded by TCS tempt you

into taking any risks when driving, this can cause accidents.

CAUTION

● In order to ensure that TCS function correctly, all four wheels must be fit-

ted with the same tyres. Any differences in the rolling radius of the tyres can

cause the system to reduce engine power when this is not desired.

● Modifications to the vehicle (e.g. to the engine, the brake system, run-

ning gear or any components affecting the wheels and tyres) could affect

the efficiency of the ABS and TCS. XDS*

Driveshaft differential

When taking a bend, the driveshaft differential mechanism allows the outer

wheel to turn at a higher speed than the inner wheel. In this way, the wheel

that is turning faster (outer wheel) receives less drive torque than the inner

wheel. This may mean that in certain situations the torque delivered to the

inner wheel is too high, causing the wheels to spin. On the other hand, the

outer wheel is receiving a lower drive torque than it could transmit. This

causes an overall loss of lateral grip on the front axle, resulting in under-

steer or “lengthening” of the trajectory.

By using the ESP sensors and signals, the XDS system is able to detect and

correct this effect.

Through the ESP, the XDS brakes the inner wheel, thereby counteracting the

excess drive torque in this wheel. This means that the driver's desired tra-

jectory is much more precise,

The XDS system operates in combination with the ESP and is always active,

even when the traction control, TCS, is disconnected.

Electronic Stability Programme (ESP)* General notes

The Electronic Stability Programme increases the vehicle's

stability on the road.

The Electronic Stability Programme helps reduce the danger of skidding.

The Electronic Stability Programme (ESP) consists of ABS, EDL and TCS.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 172 of 280

170Intelligent technology

Electronic Stability Programme (ESP)*

ESP reduces the danger of skidding by braking the wheels individually.

The system uses the steering wheel angle and road speed to calculate the

changes of direction desired by the driver, and constantly compares them

with the actual behaviour of the vehicle. If the desired course is not being

maintained (for instance, if the vehicle is starting to skid), then the ESP

compensates automatically by braking the appropriate wheel.

The forces acting on the braked wheel bring the vehicle back to a stable

condition. If the vehicle tends to oversteer, the system will act on the front

wheel on the outside of the turn.

WARNING

● It must be remembered that ESP cannot defy the laws of physics. This

should be kept in mind, particularly on slippery and wet roads and when

towing a trailer.

● Always adapt your driving style to suit the condition of the roads and

the traffic situation. Do not let the extra safety afforded by ESP tempt you

into taking any risks when driving, as this can cause accidents.

CAUTION

● In order to ensure that ESP functions correctly, all four wheels must be

fitted with the same tyres. Any differences in the rolling radius of the tyres

can cause the system to reduce engine power when this is not desired.

● Modifications to the vehicle (e.g. to the engine, the brake system, run-

ning gear or any components affecting the wheels and tyres) could affect

the efficiency of the ABS, EDL, ESP and TCS. Anti-lock brake system (ABS)

The anti-lock brake system prevents the wheels locking during braking

⇒ page 168.

Electronic differential lock (EDL)*

The electronic differential lock helps prevent the loss of trac-

tion caused if one of the driven wheels starts spinning.

EDL helps the vehicle to start moving, accelerate and climb a gradient in

slippery conditions where this may otherwise be difficult or even impossi-

ble.

The system will control the revolutions of the drive wheels using the ABS

sensors (in case of an EDL fault the warning lamp for ABS lights up)

⇒ page 69.

At speeds of up to approximately 80 km/h, it is able to balance out differen-

ces in the speed of the driven wheels of approximately 100 rpm caused by a

slippery road surface on one side of the vehicle. It does this by braking the

wheel which has lost traction and distributing more driving force to the oth-

er driven wheel via the differential.

To prevent the disc brake of the braking wheel from overheating, the EDL

cuts out automatically if subjected to excessive loads. The vehicle will con-

tinue to function normally without EDL. For this reason, the driver is not in-

formed that the EDL has been switched off.

The EDL will switch on again automatically when the brake has cooled

down.

Page 198 of 280

196Checking and refilling levels

The LPG tank ⇒ fig. 129 in the spare wheel well has a capacity of 52.8 litres.

If the outside temperatures are very low, it may not be possible to complete-

ly fill the LPG tank.

Pump attachments

There are a variety of types of LPG pump, and the methods of use may vary.

Therefore, let the pump operator fill the tank when refuelling for the first

time or fill from another pump.

Noises when refuelling with LPG

When refuelling with LPG, noises may be heard. These noises are insignifi-

cant.

WARNING

Failure to refuel or handle LPG in the correct way could result in a fire,

cause an explosion or lead to injuries.

● LPG is a highly explosive and inflammable substance. It may cause

severe burns and other injury.

● Switch off the engine before refuelling.

● Always disconnect mobile phones and any other radiophony applian-

ces, as electromagnetic waves may produce sparks and cause a fire.

● Do not remain in the vehicle while refuelling. If it is absolutely neces-

sary to enter the vehicle, close the door and touch a metal surface before

touching the attachment again. This will prevent the generation of static

electricity and any possible fires while refuelling.

● Small quantities of LPG may leak out after refuelling. If LPG comes in-

to contact with skin, there is a risk of freezing.

● Do not smoke and always keep bare flames away from the tank during

refuelling. Failure to do so may lead to an explosion.

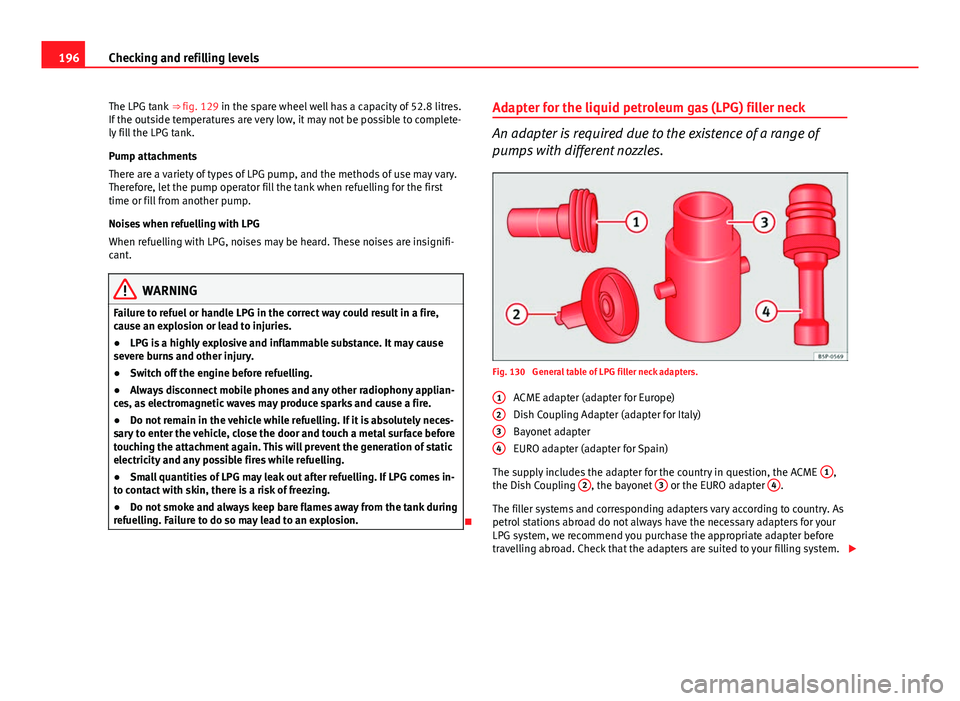

Adapter for the liquid petroleum gas (LPG) filler neck

An adapter is required due to the existence of a range of

pumps with different nozzles.

Fig. 130 General table of LPG filler neck adapters.

ACME adapter (adapter for Europe)

Dish Coupling Adapter (adapter for Italy)

Bayonet adapter

EURO adapter (adapter for Spain)

The supply includes the adapter for the country in question, the ACME 1

,

the Dish Coupling 2, the bayonet 3 or the EURO adapter 4.

The filler systems and corresponding adapters vary according to country. As

petrol stations abroad do not always have the necessary adapters for your

LPG system, we recommend you purchase the appropriate adapter before

travelling abroad. Check that the adapters are suited to your filling system.

1

234

Page 214 of 280

212Checking and refilling levels

WARNING

Before opening the bonnet to check the brake fluid level, read and ob-

serve the warnings ⇒ page 199.

Changing the brake fluid

The Maintenance Programme indicates the brake fluid

change intervals. We recommend that you have the brake fluid changed by an Authorised

Service Centre.

Before opening the bonnet, please read and follow the warnings ⇒

in

Safety instructions on working in the engine compartment on page 199 in

section “Safety notes for working in the engine compartment”.

Brake fluid absorbs moisture. In the course of time, it will absorb water from

the ambient air. If the water content in the brake fluid is too high, the brake

system could corrode. This also considerably reduces the boiling point of

the brake fluid. Heavy use of the brakes may then cause a vapour lock

which could impair the braking effect.

It is important that you use only brake fluid compliant with US standard

FMVSS 116 DOT 4. We recommend the use of Genuine SEAT brake fluid.

WARNING

Brake fluid is poisonous. Old brake fluid impairs the braking effect.

● Before opening the bonnet to check the brake fluid level, read and ob-

serve the warnings ⇒ page 199.

WARNING (Continued)

● Brake fluid should be stored in the closed original container in a safe

place out of reach of children. There is a toxic risk.

● Complete the brake fluid change according to the Maintenance Pro-

gramme. Heavy use of the brakes may cause a vapour lock if the brake

fluid is left in the system for too long. This would seriously affect the effi-

ciency of the brakes and the safety of the vehicle. This may cause an ac-

cident.

CAUTION

Brake fluid could damage the paintwork. Wipe off any brake fluid from the

paintwork immediately.

For the sake of the environment

The brake pads and fluid must be collected and disposed of according the

applicable regulations. The SEAT Technical Service network has the neces-

sary equipment and qualified personnel for collecting and disposing of this

waste material.

Page 232 of 280

230If and when

Note

● If a newly replaced fuse blows again after a short time, the electrical sys-

tem must be checked by a specialised workshop as soon as possible.

● If you replace a fuse with higher-rating fuse, you could cause damage to

another location in the electrical system.

● Always keep some spare fuses in the vehicle. These are available from

SEAT dealers.

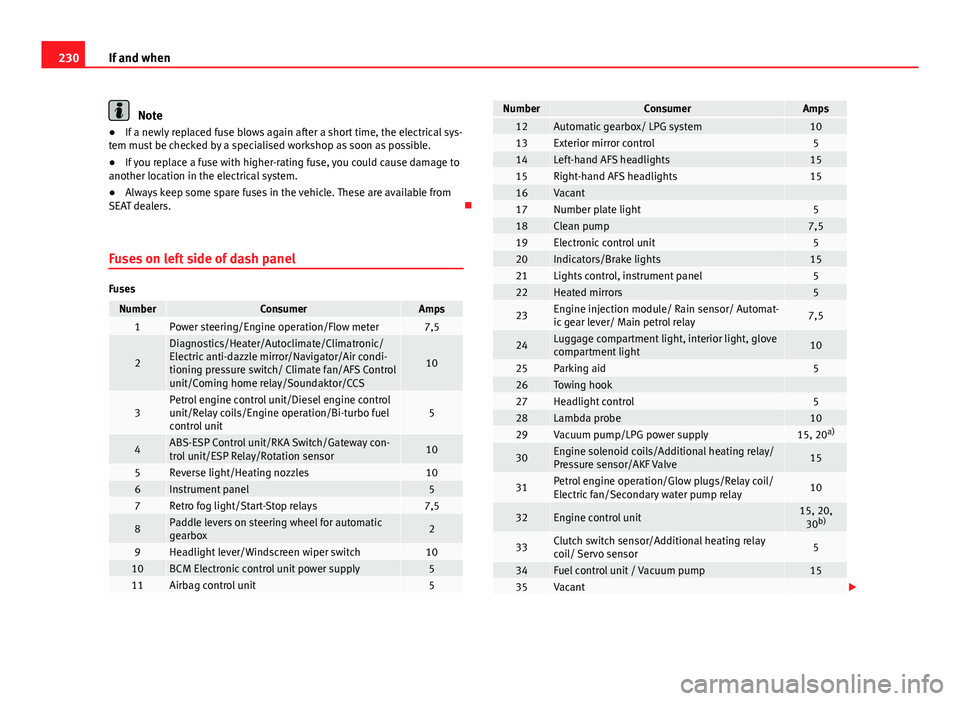

Fuses on left side of dash panel

Fuses

NumberConsumerAmps1Power steering/Engine operation/Flow meter7,5

2

Diagnostics/Heater/Autoclimate/Climatronic/

Electric anti-dazzle mirror/Navigator/Air condi-

tioning pressure switch/ Climate fan/AFS Control

unit/Coming home relay/Soundaktor/CCS

10

3Petrol engine control unit/Diesel engine control

unit/Relay coils/Engine operation/Bi-turbo fuel

control unit5

4ABS-ESP Control unit/RKA Switch/Gateway con-

trol unit/ESP Relay/Rotation sensor10

5Reverse light/Heating nozzles106Instrument panel57Retro fog light/Start-Stop relays7,5

8Paddle levers on steering wheel for automatic

gearbox2

9Headlight lever/Windscreen wiper switch1010BCM Electronic control unit power supply511Airbag control unit5

NumberConsumerAmps12Automatic gearbox/ LPG system1013Exterior mirror control514Left-hand AFS headlights1515Right-hand AFS headlights1516Vacant 17Number plate light518Clean pump7,519Electronic control unit520Indicators/Brake lights1521Lights control, instrument panel522Heated mirrors5

23Engine injection module/ Rain sensor/ Automat-

ic gear lever/ Main petrol relay7,5

24Luggage compartment light, interior light, glove

compartment light10

25Parking aid526Towing hook 27Headlight control528Lambda probe1029Vacuum pump/LPG power supply15, 20 a)

30Engine solenoid coils/Additional heating relay/

Pressure sensor/AKF Valve15

31Petrol engine operation/Glow plugs/Relay coil/

Electric fan/Secondary water pump relay10

32Engine control unit15, 20,

30 b)

33Clutch switch sensor/Additional heating relay

coil/ Servo sensor5

34Fuel control unit / Vacuum pump1535Vacant

Page 234 of 280

232If and when

Fuses in engine compartment above battery

Fig. 150 Fuses in engine

compartment

Non-metal fuses

NumberConsumerAmpsS1ABS ESP Control unit25S2Electroblower climate heater/fan30S3Automatic gearbox control unit30S4ABS ESP Control unit10S5Electronic control unit5S6Injection module30

Some of the electrical items listed in the table are only fitted on certain

models or are optional extras.

Please note that the above list contains all data at the time of going to

press, so it is subject to modifications. Bulb change

General notes

Before changing any bulb, first turn off the failed component.

Do not touch the bulb glass. Fingerprints vaporise in the heat, causing a re-

duction in the bulb life and condensation on the mirror surface, thus reduc-

ing efficiency.

A bulb should only be replaced by one of the same type. The type is inscri-

bed on the bulb, either on the glass part or on the base.

Below, the light source used for all functions is detailed.

Double headlights - H7 Long Life

- H7

- W5W Long Life - PY 21W

Single headlight - H4 Long Life

- W5W Long Life - PY 21W

Dipped beam

Main beam

Position

Turn signal

Dipped/Main

Position

Turn signal

Page 246 of 280

244If and when

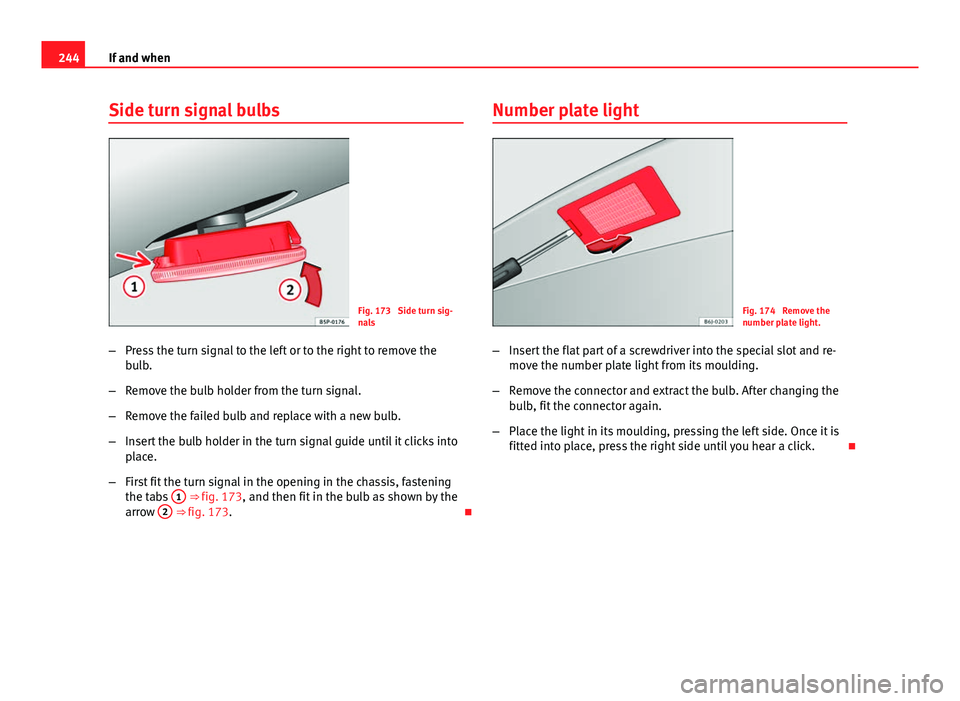

Side turn signal bulbs

Fig. 173 Side turn sig-

nals

– Press the turn signal to the left or to the right to remove the

bulb.

– Remove the bulb holder from the turn signal.

– Remove the failed bulb and replace with a new bulb.

– Insert the bulb holder in the turn signal guide until it clicks into

place.

– First fit the turn signal in the opening in the chassis, fastening

the tabs 1

⇒ fig. 173, and then fit in the bulb as shown by the

arrow 2 ⇒ fig. 173. Number plate light

Fig. 174 Remove the

number plate light.

– Insert the flat part of a screwdriver into the special slot and re-

move the number plate light from its moulding.

– Remove the connector and extract the bulb. After changing the

bulb, fit the connector again.

– Place the light in its moulding, pressing the left side. Once it is

fitted into place, press the right side until you hear a click.

Page 247 of 280

245

If and when

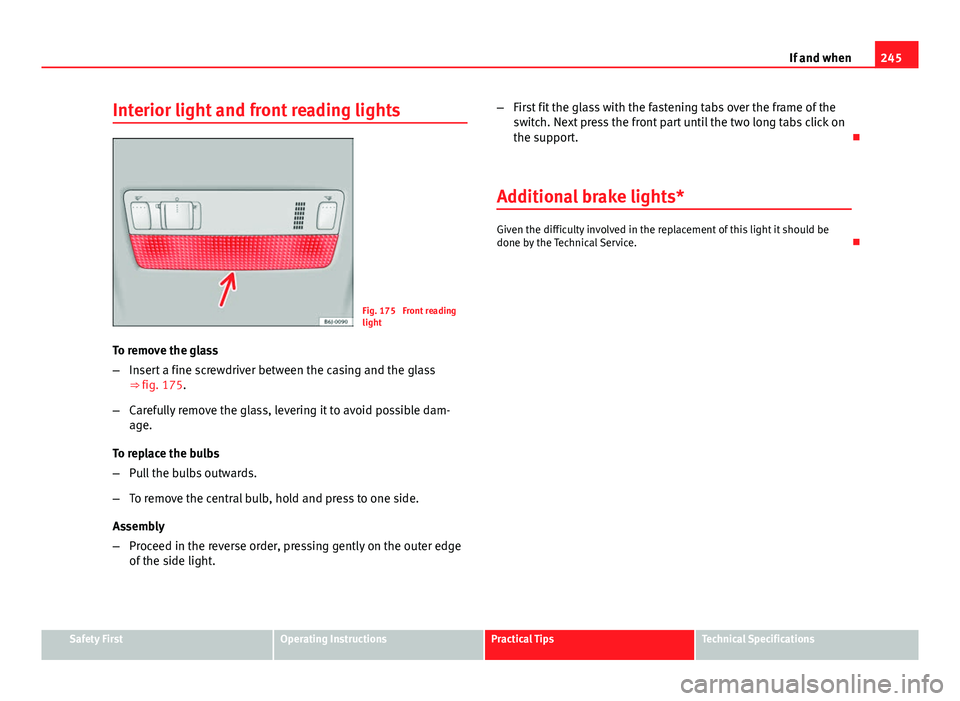

Interior light and front reading lights

Fig. 175 Front reading

light

To remove the glass

– Insert a fine screwdriver between the casing and the glass

⇒ fig. 175.

– Carefully remove the glass, levering it to avoid possible dam-

age.

To replace the bulbs

– Pull the bulbs outwards.

– To remove the central bulb, hold and press to one side.

Assembly

– Proceed in the reverse order, pressing gently on the outer edge

of the side light. –

First fit the glass with the fastening tabs over the frame of the

switch. Next press the front part until the two long tabs click on

the support.

Additional brake lights*

Given the difficulty involved in the replacement of this light it should be

done by the Technical Service.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications