brake light Seat Ibiza ST 2012 Owner's Guide

[x] Cancel search | Manufacturer: SEAT, Model Year: 2012, Model line: Ibiza ST, Model: Seat Ibiza ST 2012Pages: 282, PDF Size: 3.77 MB

Page 226 of 282

224If and when

If you have a puncture on one of the front wheels when using snow chains,

fit the compact temporary spare wheel in place of one of the rear wheels.

You can then attach the snow chains to the wheel taken from the rear and

use this wheel to replace the punctured front wheel.

WARNING

● The tyre pressures must be checked and corrected as soon as possi-

ble after fitting the temporary spare wheel.

● Do not drive faster than 80 km/h (50 mph). Higher speeds can cause

an accident.

● Avoid heavy acceleration, hard braking and fast cornering. Risk of ac-

cident.

● Never use more than one temporary spare wheel at the same time,

risk of accident.

● No other type of tyre (normal summer or winter tyre) may be fitted on

the compact temporary spare wheel rim.

Tyre repair kit*

The tyre repair kit (for vehicles not including a temporary

spare wheel) is stored under the floor panel in the luggage

compartment. Your vehicle is equipped with the Tyre Mobility System “Tyre repair kit”.

The tyre repair kit consists of a container with sealing product to repair the

puncture and a compressor to generate the required tyre pressure. The kit

will reliably seal punctures up to a size of about 4 mm caused by the pene-

tration of a foreign body into the tyre.

Note

● Seek professional assistance if the repair of a tyre puncture is not possi-

ble with the sealing product.

Wheel change Preparation work

What you must do before changing a wheel.

– If you have a flat tyre or puncture, park the vehicle as far away

from the flow of traffic as possible. Choose a location that is as

level as possible.

– All vehicle occupants should leave the vehicle. They should

wait in a safe area (for instance behind the roadside crash barri-

er).

– Switch the engine off. Switch the hazard warning lights on and

place the warning triangles in position.

– Apply the handbrake firmly.

– Engage the first gear , or put the selector lever to position P for

those vehicles with an automatic gearbox.

– If you are towing a trailer, unhitch it from your vehicle.

– Take the vehicle tools and the spare wheel out of the luggage

compartment.

Page 232 of 282

230If and when

What to do first

Certain steps must be taken before repairing a tyre.

–If you have a flat tyre or puncture, park the vehicle as far away

from the flow of traffic as possible.

– Apply the handbrake firmly.

– Engage first gear , or put the selector lever to position P.

– All occupants should leave the vehicle. They should wait in a

safe area (for instance behind the roadside crash barrier).

– Check whether a repair is possible using the Tyre Mobility Sys-

tem “General information and safety notes.”

– Unscrew inflation cap from the affected wheel.

– Take the tyre repair kit out of the luggage compartment.

WARNING

Switch on the hazard warning lights and place the warning triangles in

position. This is for your own safety and also warns other road users.

CAUTION

Take special care if you have to repair a tyre on a slope.

Note

● Please observe legal requirements when doing so.

● Remember to replace the sealing product as soon as possible. Tyre repair

The following sections describe the procedures for repairing

a tyre.

Using the sealing product

– The instructions on the container give detailed information on

how to use the sealing product.

Inflating the tyre.

– Remove the air compressor and hose from the container.

– Screw the retaining nut onto the valve.

– Plug the compressor cable into a 12 volt power socket.

– Turn on compressor and monitor the pressure shown on the

pressure gauge.

Completing the repair

– Remove the compressor hose from the valve.

– Fit the valve cap.

– Unplug the compressor from the socket.

– Return all tools to their proper storing location.

Note

The compressor should never be allowed to run for longer than 6 minutes.

Page 234 of 282

232If and when

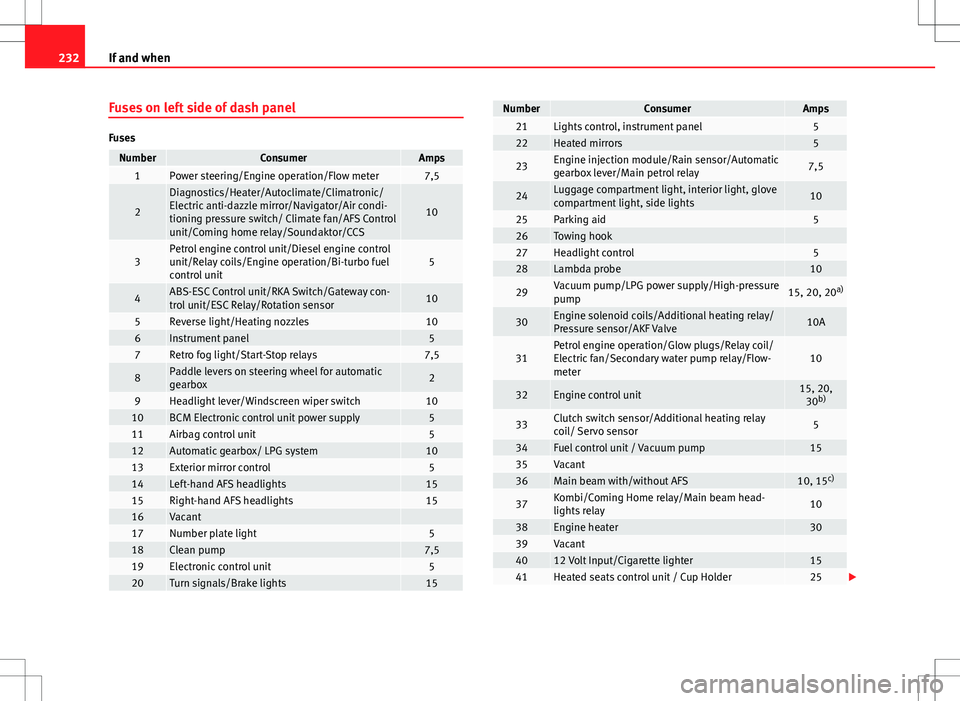

Fuses on left side of dash panel

Fuses

NumberConsumerAmps1Power steering/Engine operation/Flow meter7,5

2

Diagnostics/Heater/Autoclimate/Climatronic/

Electric anti-dazzle mirror/Navigator/Air condi-

tioning pressure switch/ Climate fan/AFS Control

unit/Coming home relay/Soundaktor/CCS

10

3Petrol engine control unit/Diesel engine control

unit/Relay coils/Engine operation/Bi-turbo fuel

control unit5

4ABS-ESC Control unit/RKA Switch/Gateway con-

trol unit/ESC Relay/Rotation sensor10

5Reverse light/Heating nozzles106Instrument panel57Retro fog light/Start-Stop relays7,5

8Paddle levers on steering wheel for automatic

gearbox2

9Headlight lever/Windscreen wiper switch1010BCM Electronic control unit power supply511Airbag control unit512Automatic gearbox/ LPG system1013Exterior mirror control514Left-hand AFS headlights1515Right-hand AFS headlights1516Vacant 17Number plate light518Clean pump7,519Electronic control unit520Turn signals/Brake lights15

NumberConsumerAmps21Lights control, instrument panel522Heated mirrors5

23Engine injection module/Rain sensor/Automatic

gearbox lever/Main petrol relay7,5

24Luggage compartment light, interior light, glove

compartment light, side lights10

25Parking aid526Towing hook 27Headlight control528Lambda probe10

29Vacuum pump/LPG power supply/High-pressure

pump15, 20, 20a)

30Engine solenoid coils/Additional heating relay/

Pressure sensor/AKF Valve10A

31Petrol engine operation/Glow plugs/Relay coil/

Electric fan/Secondary water pump relay/Flow-

meter10

32Engine control unit15, 20,

30 b)

33Clutch switch sensor/Additional heating relay

coil/ Servo sensor5

34Fuel control unit / Vacuum pump1535Vacant 36Main beam with/without AFS10, 15 c)

37Kombi/Coming Home relay/Main beam head-

lights relay10

38Engine heater3039Vacant 4012 Volt Input/Cigarette lighter1541Heated seats control unit / Cup Holder25

Page 246 of 282

244If and when

–Installation involves the above steps in reverse sequence.

– Check that the bulb works properly.

Changing the rear lights (on the wing) Overview of tail lights

Tail lights on side panel Bulb lamps

● Brake lights

● Side lights

● Turn signal

Tail lights on side panel LED lamps

● Brake lights (LEDS)

● Side lights (LEDS)

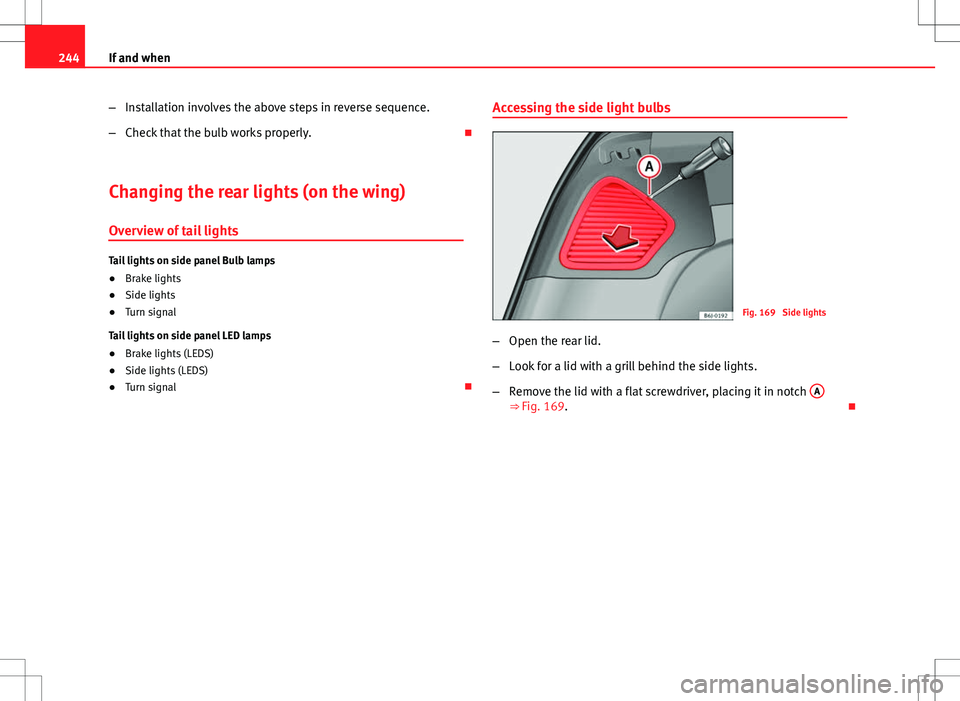

● Turn signal Accessing the side light bulbs

Fig. 169 Side lights

– Open the rear lid.

– Look for a lid with a grill behind the side lights.

– Remove the lid with a flat screwdriver, placing it in notch A

⇒ Fig. 169.

Page 247 of 282

245

If and when

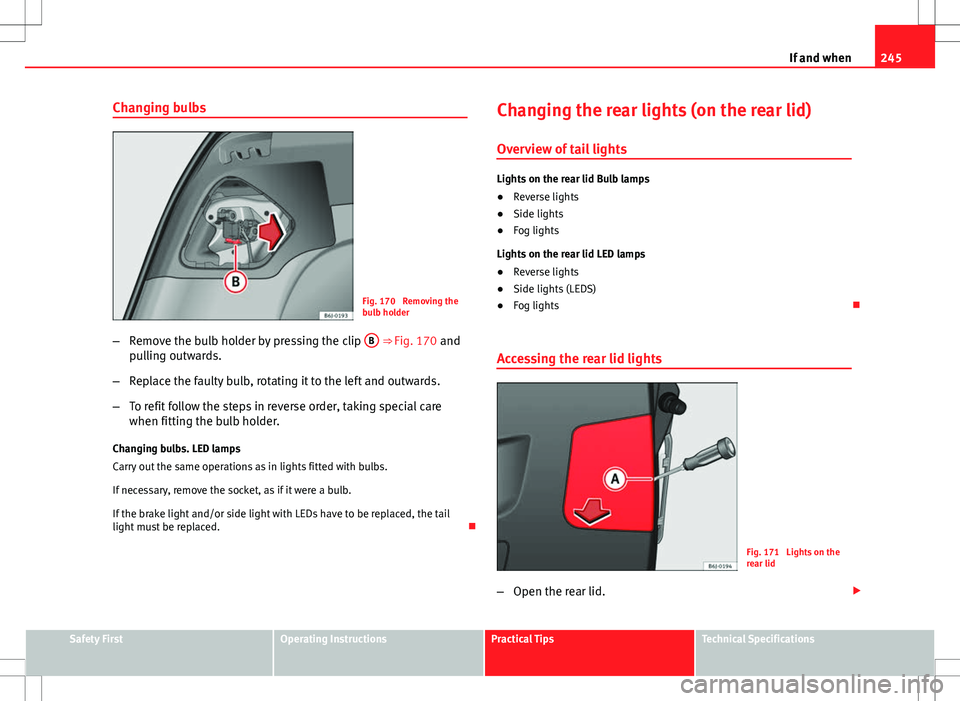

Changing bulbs

Fig. 170 Removing the

bulb holder

– Remove the bulb holder by pressing the clip B

⇒ Fig. 170 and

pulling outwards.

– Replace the faulty bulb, rotating it to the left and outwards.

– To refit follow the steps in reverse order, taking special care

when fitting the bulb holder.

Changing bulbs. LED lamps

Carry out the same operations as in lights fitted with bulbs.

If necessary, remove the socket, as if it were a bulb.

If the brake light and/or side light with LEDs have to be replaced, the tail

light must be replaced. Changing the rear lights (on the rear lid)

Overview of tail lights

Lights on the rear lid Bulb lamps

●

Reverse lights

● Side lights

● Fog lights

Lights on the rear lid LED lamps

● Reverse lights

● Side lights (LEDS)

● Fog lights

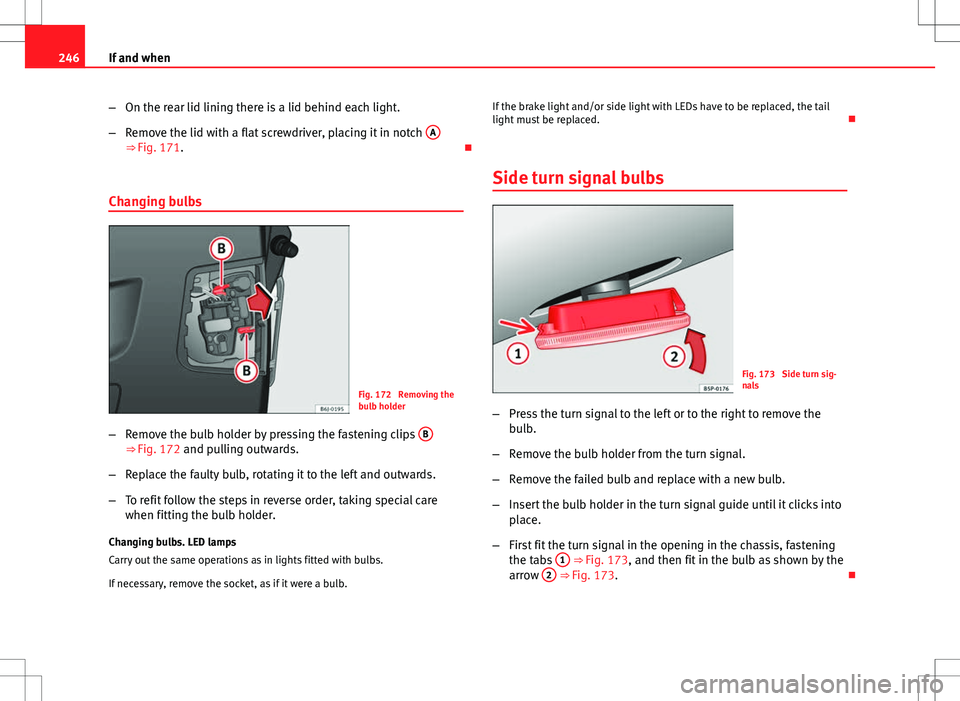

Accessing the rear lid lights

Fig. 171 Lights on the

rear lid

– Open the rear lid.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 248 of 282

246If and when

–On the rear lid lining there is a lid behind each light.

– Remove the lid with a flat screwdriver, placing it in notch A

⇒ Fig. 171.

Changing bulbs

Fig. 172 Removing the

bulb holder

– Remove the bulb holder by pressing the fastening clips B

⇒ Fig. 172 and pulling outwards.

– Replace the faulty bulb, rotating it to the left and outwards.

– To refit follow the steps in reverse order, taking special care

when fitting the bulb holder.

Changing bulbs. LED lamps

Carry out the same operations as in lights fitted with bulbs.

If necessary, remove the socket, as if it were a bulb. If the brake light and/or side light with LEDs have to be replaced, the tail

light must be replaced.

Side turn signal bulbs

Fig. 173 Side turn sig-

nals

– Press the turn signal to the left or to the right to remove the

bulb.

– Remove the bulb holder from the turn signal.

– Remove the failed bulb and replace with a new bulb.

– Insert the bulb holder in the turn signal guide until it clicks into

place.

– First fit the turn signal in the opening in the chassis, fastening

the tabs 1

⇒ Fig. 173, and then fit in the bulb as shown by the

arrow 2 ⇒ Fig. 173.

Page 250 of 282

248If and when

–First fit the glass with the fastening tabs over the frame of the

switch. Next press the front part until the two long tabs click on

the support.

Additional brake lights*

Given the difficulty involved in the replacement of this light it should be

done by the Technical Service.

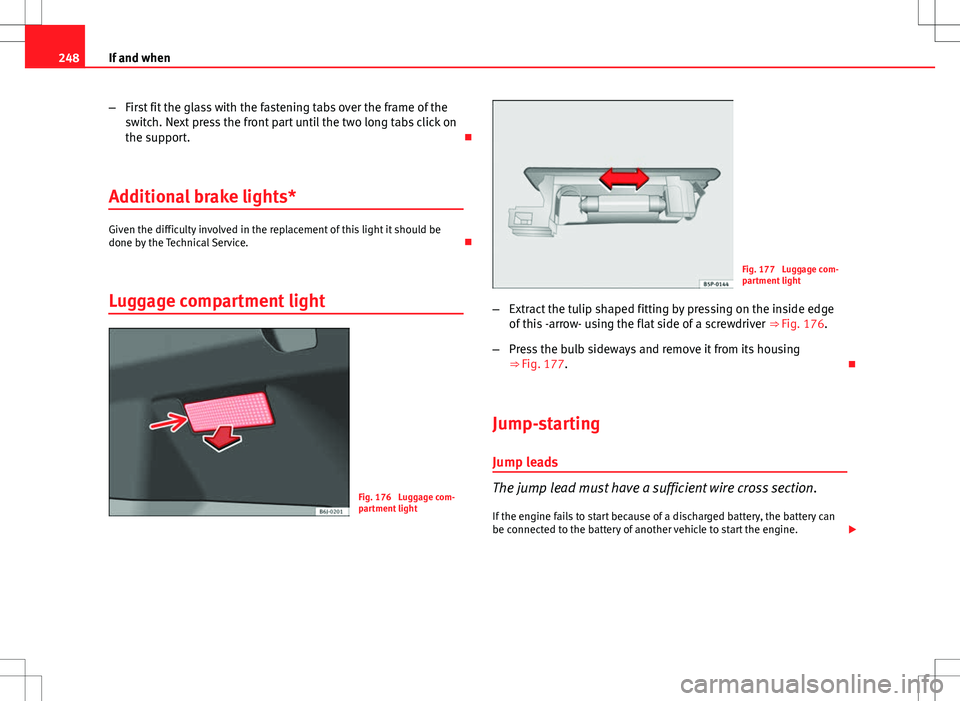

Luggage compartment light

Fig. 176 Luggage com-

partment light

Fig. 177 Luggage com-

partment light

– Extract the tulip shaped fitting by pressing on the inside edge

of this -arrow- using the flat side of a screwdriver ⇒ Fig. 176.

– Press the bulb sideways and remove it from its housing

⇒ Fig. 177.

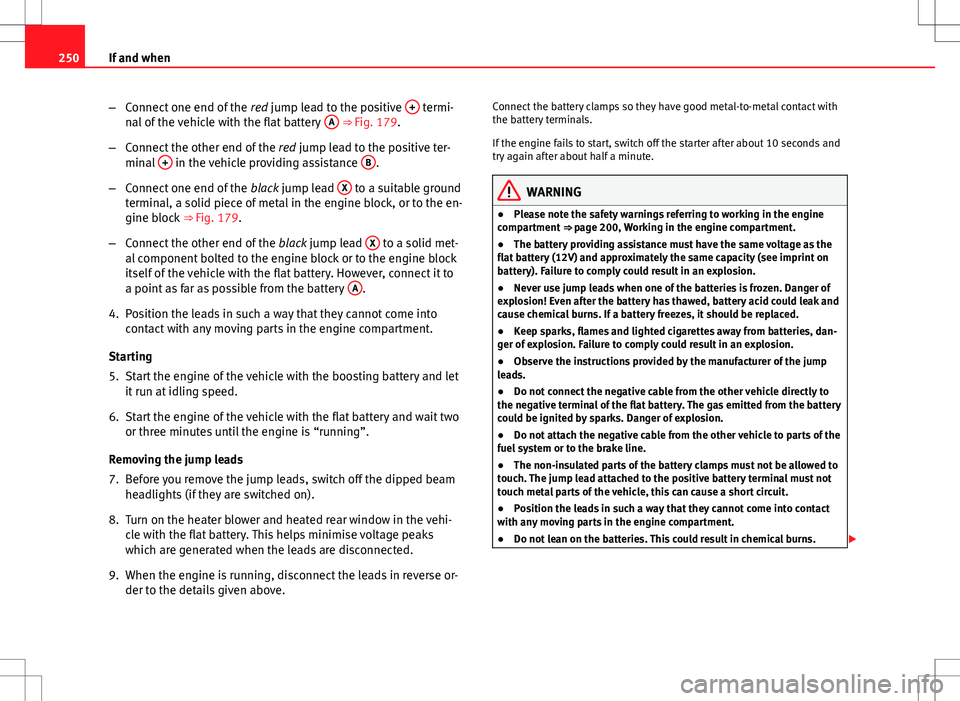

Jump-starting

Jump leads

The jump lead must have a sufficient wire cross section. If the engine fails to start because of a discharged battery, the battery can

be connected to the battery of another vehicle to start the engine.

Page 252 of 282

250If and when

–Connect one end of the red jump lead to the positive +

termi-

nal of the vehicle with the flat battery A ⇒ Fig. 179.

– Connect the other end of the red jump lead to the positive ter-

minal +

in the vehicle providing assistance B.

– Connect one end of the black jump lead X

to a suitable ground

terminal, a solid piece of metal in the engine block, or to the en-

gine block ⇒ Fig. 179.

– Connect the other end of the black jump lead X

to a solid met-

al component bolted to the engine block or to the engine block

itself of the vehicle with the flat battery. However, connect it to

a point as far as possible from the battery A

.

4. Position the leads in such a way that they cannot come into contact with any moving parts in the engine compartment.

Starting

5. Start the engine of the vehicle with the boosting battery and let it run at idling speed.

6. Start the engine of the vehicle with the flat battery and wait two or three minutes until the engine is “running”.

Removing the jump leads

7. Before you remove the jump leads, switch off the dipped beam headlights (if they are switched on).

8. Turn on the heater blower and heated rear window in the vehi- cle with the flat battery. This helps minimise voltage peaks

which are generated when the leads are disconnected.

9. When the engine is running, disconnect the leads in reverse or- der to the details given above. Connect the battery clamps so they have good metal-to-metal contact with

the battery terminals.

If the engine fails to start, switch off the starter after about 10 seconds and

try again after about half a minute.

WARNING

● Please note the safety warnings referring to working in the engine

compartment ⇒ page 200, Working in the engine compartment.

● The battery providing assistance must have the same voltage as the

flat battery (12V) and approximately the same capacity (see imprint on

battery). Failure to comply could result in an explosion.

● Never use jump leads when one of the batteries is frozen. Danger of

explosion! Even after the battery has thawed, battery acid could leak and

cause chemical burns. If a battery freezes, it should be replaced.

● Keep sparks, flames and lighted cigarettes away from batteries, dan-

ger of explosion. Failure to comply could result in an explosion.

● Observe the instructions provided by the manufacturer of the jump

leads.

● Do not connect the negative cable from the other vehicle directly to

the negative terminal of the flat battery. The gas emitted from the battery

could be ignited by sparks. Danger of explosion.

● Do not attach the negative cable from the other vehicle to parts of the

fuel system or to the brake line.

● The non-insulated parts of the battery clamps must not be allowed to

touch. The jump lead attached to the positive battery terminal must not

touch metal parts of the vehicle, this can cause a short circuit.

● Position the leads in such a way that they cannot come into contact

with any moving parts in the engine compartment.

● Do not lean on the batteries. This could result in chemical burns.

Page 254 of 282

252If and when

Towing and tow-starting

Tow-starting*

The use of jump leads is preferable to tow-starting.

We recommend that you do not tow-start your vehicle. Jump-start-

ing is preferable ⇒ page 248.

However, if your vehicle has to be tow-started:

– Engage the 2nd or the 3rd gear.

– Keep the clutch pressed down.

– Switch the ignition on.

– Once both vehicles are moving, release the clutch.

– As soon as the engine starts, press the clutch and move the

gear lever into neutral. This helps to prevent driving into the

towing vehicle.

WARNING

The risk of accidents is high when tow-starting. The vehicle being towed

can easily collide with the towing vehicle.

CAUTION

When tow-starting, fuel could enter the catalytic converter and damage it. Comments

Please observe the following points if you use a tow rope:

Notes for the driver of the towing vehicle

–

Drive slowly at first until the tow rope is taut. Then accelerate

gradually.

– Begin and change gears cautiously. If you are driving an auto-

matic vehicle, accelerate gently.

– Remember that the brake servo and power steering are not

working in the vehicle you are towing. Brake sooner than nor-

mal and pressing the pedal gently.

Notes for the driver of the towed vehicle

– Ensure that the tow rope remains taut at all times when towing.

Tow rope or tow bar

It is easier and safer to tow a vehicle with a tow bar. You should only use a

tow rope if you do not have a tow bar.

A tow rope should be slightly elastic to reduce the loading on both vehicles.

It is advisable to use a tow rope made of synthetic fibre or similarly elastic

material.

Attach the tow rope or the tow bar only to the towline anchorages provided

or a towing bracket.

Driving style

Towing requires some experience, especially when using a tow rope. Both

drivers should be familiar with the technique required for towing. Inexper-

ienced drivers should not attempt to tow.

Page 255 of 282

253

If and when

Do not pull too hard with the towing vehicle and take care to avoid jerking

the tow rope. When towing on an unpaved road, there is always a risk of

overloading and damaging the anchorage points.

The ignition of the vehicle being towed must be switched on to prevent the

steering wheel from locking and also to allow the use of the turn signals,

horn, windscreen wipers and washers.

As the brake servo does not work if the engine is not running, you must ap-

ply considerably more pressure to the brake pedal than you normally would.

As the power assisted steering does not work if the engine is not running,

you will need more strength to steer than you normally would.

Towing vehicles with an automatic gearbox

● Put the selector lever into position “N”.

● Do not drive faster than 50 km/h (30 mph).

● Do not tow further than 50 km (30 miles).

● If a breakdown vehicle is used, the vehicle must be towed with the front

wheels raised.

Note

● Observe legal requirements when towing or tow-starting.

● Switch on the hazard warning lights of both vehicles. However, observe

any regulations to the contrary.

● For technical reasons, vehicles with an automatic gearbox must not be

tow-started.

● If damage to your vehicle means that there is no lubricant in the gear-

box, you must raise the driven wheels while the vehicle is being towed.

● If the vehicle has to be towed more than 50 km (30 miles), the front

wheels should be raised during towing, and towing should be carried out by

a qualified person. ●

The steering wheel is locked when the vehicle has no electrical power.

The vehicle must then be towed with the front wheels raised. Towing should

be carried out by a qualified person.

● The towline anchorage should always be kept in the vehicle.

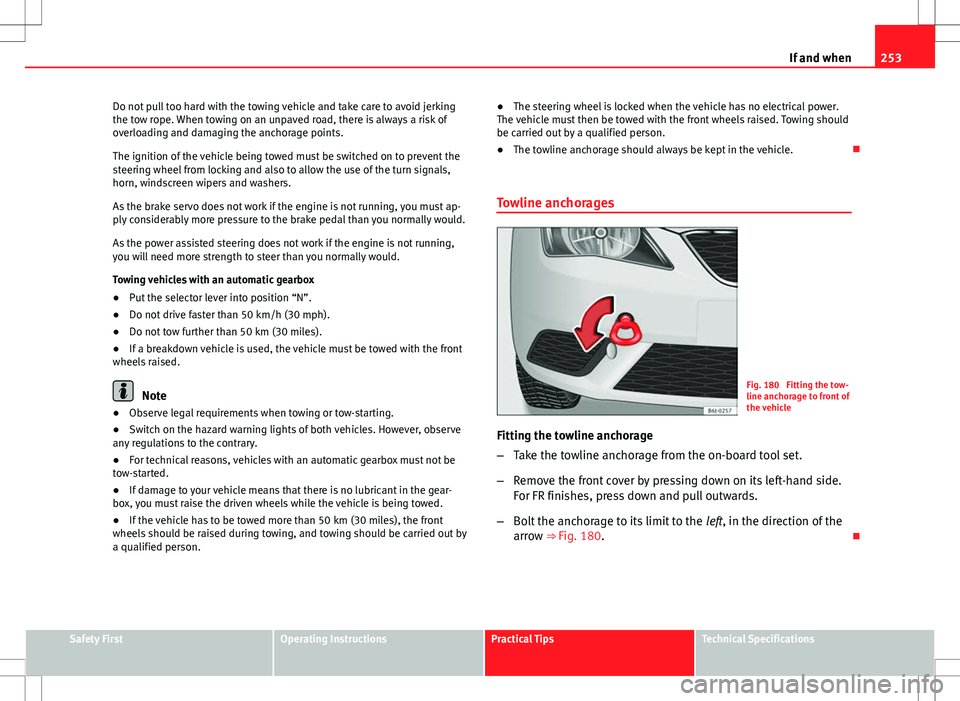

Towline anchoragesFig. 180 Fitting the tow-

line anchorage to front of

the vehicle

Fitting the towline anchorage

– Take the towline anchorage from the on-board tool set.

– Remove the front cover by pressing down on its left-hand side.

For FR finishes, press down and pull outwards.

– Bolt the anchorage to its limit to the left, in the direction of the

arrow ⇒ Fig. 180.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications