maintenance Seat Leon 5D 2005 Owner's manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2005, Model line: Leon 5D, Model: Seat Leon 5D 2005Pages: 280, PDF Size: 8.46 MB

Page 221 of 280

If and when219

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

Wheel covers*

The wheel covers must be removed for access to the wheel

boltsRemoving

– Remove the wheel cover using the spanner and the hook*.

– Hook this into one of the cut-outs of the wheel cover.

– Put the box spanner over the wheel cover hook and lever gently and carefully to avoid damage to the paintwork.

Fitting

– Fit the wheel cover onto the wheel rim by pressing it firmly. Put pressure initially on the point of the cut-out for the valve. Then

press the wheel cover onto the steel rim so that it engages all

round.

Loosening the wheel bolts

The wheel bolts must be loosened before raising the vehicle.Loosening

–Fit the box spanner as far as it will go over the wheel bolt.

– Grasp the box spanner by the end turn it about one full turn to the left ⇒ fig. 147 .

Tightening

– Fit the box spanner as far as it will go over the wheel bolt.

– Grasp the box spanner close to the end and turn the bolt to the right until it is secured.

– An adapter is required to unscrew or tighten the anti-theft wheel bolts.

Fig. 147 Changing the

wheel: Loosening the

wheel bolts

leon_ingles Seite 219 Donnerstag, 20. Oktober 2005 12:14 12

Page 223 of 280

If and when221

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

a large and stable base, if necessary. On a hard, slippery surface (such as

tiles) use a rubber mat or similar to prevent the jack from slipping.

WARNING

•

Take all precautions so that the base of the jack does not slip. Failure to

do so could result in an accident.

•

The vehicle can be damaged if the jack is not applied at the correct

jacking points. There is also a risk of injury since the jack can slip off

suddenly if it is not properly engaged.

Removing and fitting the wheel

For removal and fitting the wheel, the following tasks must be

completed.Change the wheel as described below after loosening the wheel

bolts and raising the vehicle with the jack. Removing a wheel

– Unscrew the bolts using the

hexagonal tool in the handle of the

screwdriver (vehicle tool) and place them on a clean surface

⇒ fig. 150.

Fitting a wheel

– Screw in the wheel bolts and tighten them lightly using the hexagonal socket in the screwdriver handle.

The wheel bolts should be clean and turn easily. Before fitting the spare

wheel, inspect the condition of the wheel and hub mounting surfaces. These

surfaces must be clean before fitting the wheel.

The hexagonal socket in the screwdriver handle makes it easier to turn the

wheel bolts when they are loose. The reversible screwdriver blade should be

removed when the tool is used for this purpose.

If tyres with a specific direction of ro tation are fitted, note the direction of

rotation.

Note

Do not use the hexagonal socket in the screwdriver handle to loosen or

tighten the wheel bolts.

Fig. 150 Wheel change:

Hexagon socket in screw-

driver handle to turn the

wheel bolts after they

have been loosened

leon_ingles Seite 221 Donnerstag, 20. Oktober 2005 12:14 12

Page 225 of 280

If and when223

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

Notes for the proper use of the air compressor are included in an additional

instruction leaflet.

WARNING

•

Do not attempt to repair a puncture with the sealing compound if the

tyre has been damaged by driving the car after the tyre has lost its air.

•

Always observe warnings and follow instructions concerning

compressor and sealing compound carefully.

•

Do not drive faster than 80 km/h, avoid heavy acceleration, hard

braking and fast cornering.

•

Tyres which have been repaired with sealing compound are only suit-

able for temporary use over a short period. Therefore, please drive carefully

to the next available qualified workshop.For the sake of the environment

Used sealing compound containers should be disposed of at a proper facility.

Note

Seek professional assistance if the repair of a tyre puncture is not possible

with the sealing compound.Preparation work

Certain steps must be taken before repairing a tyre.– If you have a flat tyre or puncture, park the vehicle as far away

from the flow of traffic as possible.

–Apply the handbrake firmly. – Engage the first gear

, of put the selector lever to position P.

– All passengers should leave the vehicle. They should wait in a

safe area (for instance behind the roadside crash barrier).

– C h e ck w h e t h e r a r e p a i r i s p o s s i b l e u s i n g t h e Ty r e M o b i l i t y S y s t e m “General info rmation and safety notes”.

– Unscrew inflation cap from the affected wheel.

– Take the tyre repair kit out of the luggage compartment.

WARNING

Put the hazard warning lights on and place the warning triangle in position.

This is for your own safety and also warns other road users.

Caution

Take special care if you have to repair a tyre on a gradient.

Note

Please observe legal requirements when doing so.Tyre repair

The following sections describe the procedures for repairing

a tyre.Using the sealing compound

– The instructions on the container give detailed information on

how to use the sealing compound.

leon_ingles Seite 223 Donnerstag, 20. Oktober 2005 12:14 12

Page 227 of 280

If and when225

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

Fuse cover underneath the steering wheel

– Switch off the ignition and the component concerned.

– Identify the fuse for the failed component ⇒page 226.

– Take the plastic clip from inside the fuse cover, fit it onto the blown fuse and pull the fuse out.

– Replace the blown fuse (which will have a melted metal strip) with a new fuse of the same ampere rating.

Fuse cover in engine compartment

– Switch off the ignition and the component concerned.

– Prise off the fuse cover in the engine compartment by pressing the tabs towards the centre of the cover ⇒page 224, fig. 153 .

– Identify the fuse for the failed component ⇒page 226.

– Take the plastic clip from inside the fuse cover (at left-hand end of the dash panel), fit it onto the blown fuse and pull the fuse out.

– Replace the blown fuse (which will have a melted metal strip) with a new fuse of the same ampere rating.

– Carefully fit the fuse cover back on to ensure no water can enter the fuse box.The individual electrical circuits are pr otected by fuses. The fuses are located

behind a cover at the left-hand end of the dash panel and on the left-hand

side of the engine compartment.

The electric windows are protected by circuit breakers. These reset automat-

ically after a few seconds when the overload (caused for example by frozen

windows) has been corrected. Colour coding of fuses

WARNING

Never “repair” damaged fuses and never replace them with fuses with a

higher rating. Failure to comply could re

sult in fire. This could also cause

damage to other parts of the electrical system.

Note

•

If a newly replaced fuse blows again after a short time, the electrical

system must be checked by a qualified workshop as soon as possible.

•

If you replace a fuse with a stronger fuse, you could cause damage to

another location in the electrical system.

•

Always keep some spare fuses in the vehicle. These are available from

official Service. Colour

Amperes

light brown 5

red 10

blue 15

yellow 20

natural (white) 25

green 30

orange 40

red 50

white 80

blue 100

grey 150

violet 200

leon_ingles Seite 225 Donnerstag, 20. Oktober 2005 12:14 12

Page 229 of 280

If and when227

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

22

Heater 40

23 Door control unit 30

24 Cigarette lighter 25

25 Cable control unit 25

26 12 V power sockets 30

27 FSI capacity gauge control unit, fuel relay, EKP 1.6 relay 15

28 Comfort system control unit (without autolock 4F8) 25

29 Flowmeter, engine 10

30 Prewired 20

31 Vacuum pump 20

32 Door control unit 30

33 Sunroof 30

34 Comfort system control unit (autolock 4 K3) 25

35 Alarm sensor, horn 5

36 Headlight washer system 20

37 Seats 30

38 Engine 10

39 Automatic gearbox 20

40 Heater 40

41 Tailgate, power 15

42 Cable control unit 15

43 Trailer control unit 15

44 Trailer control unit 20

45 Trailer control unit 15

Number

Electrical equipment Amperes

leon_ingles Seite 227 Donnerstag, 20. Oktober 2005 12:14 12

Page 231 of 280

If and when229

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

11

Vacant

12 Gateway 5

13 Petrol injection module supply

25

Diesel injection module supply 30

14 Coil 20

15 Engine T71 / 20 FSI

5

Pump relay 10

16 ADS pump 30

17 Horn 15

18 Vacant

19 Clean 30

20 Vacant

21 Lambda probe 15

22 Brake pedal, speed sensor 5

23 Engine 1.6, main relay (relay n° 100)

5

T 71 diesel EGR 10

2.0 D2L High-pressure fuel pump 15

24 ARF, change valve 10

25 Right lighting 40

26 Left lighting 40

1.6 SLP engine 40

1.9 TDI Glow plug relay 50

28 KL15 40

Number

Electrical equipment Amperes

leon_ingles Seite 229 Donnerstag, 20. Oktober 2005 12:14 12

Page 233 of 280

If and when231

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

Bulb changeGeneral notesBefore changing any bulb first turn off the equipment concerned.

Do not touch the bulb glass. Fingerprints vaporise in the heat, causing a

reduction in the bulb life and condensation on the mirror surface, thus

reducing efficiency.

A bulb should only be replaced by one of the same type. The type is inscribed

on the bulb, either on the glass part or on the base.

It is highly recommended to keep a box of spare bulbs in the vehicle. At the

very least, the bulbs that most affect road safety should have spares in the

vehicle.

Main headlights

Dipped beam - H7

Full lights - H1

Front side ligths - W5W

Indicator - PY21W

Xenon headlights

19)

Dipped beam and full lights - D1S

20)

Light burst and additional full lights - H1

Front side lights - W5W

Indicators - PY21W Fog lights

Fog lights - H3

Fixed rear light

Stop/Rear side lights - P21W

21)

Indicator - P21W

Rear tailgate light

Fog light (driver side) - P21W

Reverse gear light (passenger side) - P21W

Rear side lights - W5W

Indicator

Side indicator - W5W

Registration plate light

Registration plate light - C5W

Note

•

Due to the difficulty in accessing the lamps, these must be changed by an

Authorised Service Centre. However, the following is a description of how to

change the bulbs except for the fog lights and interior bulbs.

19)For these type of headlights, the bulbs must be changed by an Authorised Service

Centre, given that complex elements of the vehicle must be removed and that the au-

tomatic control system must be reset.20)Xenon bulbs discharge emit 2.5 times as much light flux and have a useful life five

times greater than halogen bulbs.

21)Electronically controlled single filament bulb for Stop/Side bulbs. If the bulb blows

it will not work or Stop position.

leon_ingles Seite 231 Donnerstag, 20. Oktober 2005 12:14 12

Page 235 of 280

If and when233

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

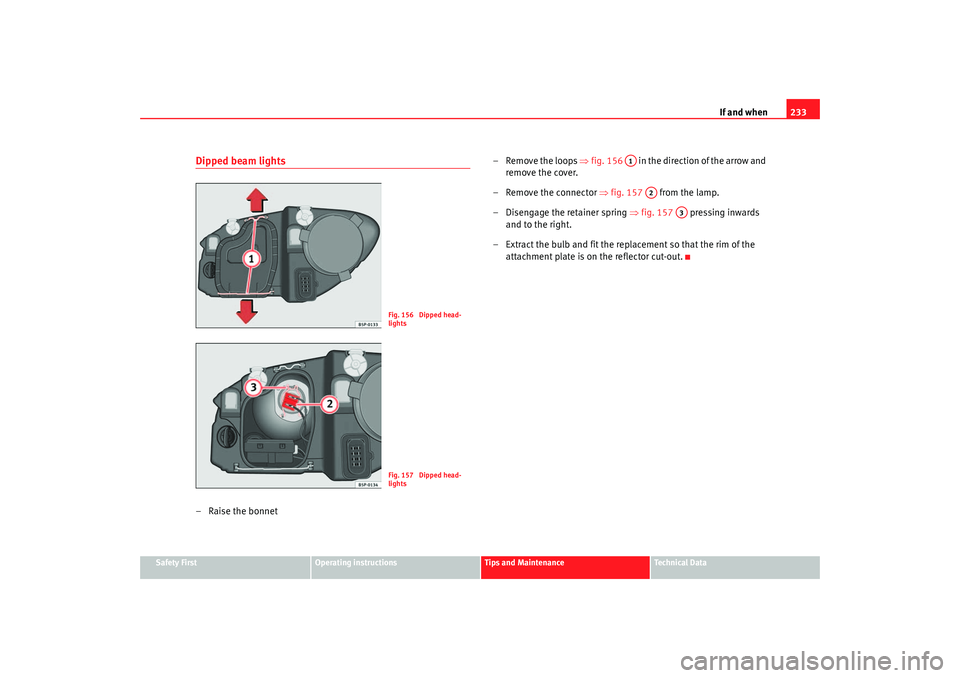

Dipped beam lights–Raise the bonnet – Remove the loops

⇒fig. 156 in the direction of the arrow and

remove the cover.

– Remove the connector ⇒fig. 157 from the lamp.

– Disengage the retainer spring ⇒fig. 157 pressing inwards

and to the right.

– Extract the bulb and fit the repl acement so that the rim of the

attachment plate is on the reflector cut-out.

Fig. 156 Dipped head-

lightsFig. 157 Dipped head-

lights

A1

A2

A3

leon_ingles Seite 233 Donnerstag, 20. Oktober 2005 12:14 12

Page 237 of 280

If and when235

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

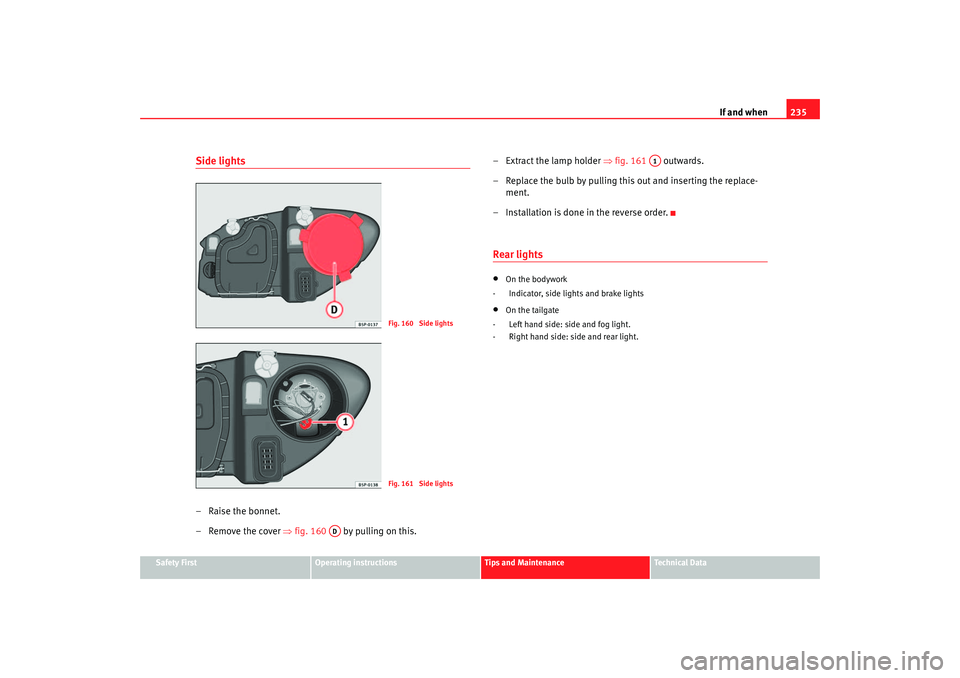

Side lights–Raise the bonnet.

– Remove the cover ⇒fig. 160 by pulling on this. – Extract the lamp holder

⇒fig. 161 outwards.

– Replace the bulb by pulling this out and inserting the replace- ment.

– Installation is done in the reverse order.

Rear lights•

On the bodywork

- Indicator, side lights and brake lights

•

On the tailgate

- Left hand side: side and fog light.

- Right hand side: side and rear light.

Fig. 160 Side lightsFig. 161 Side lights

AD

A1

leon_ingles Seite 235 Donnerstag, 20. Oktober 2005 12:14 12

Page 239 of 280

If and when237

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

– Take the lampholder out pressing on the securing pins and

extract it outwards ⇒ page 236, fig. 164.

– Replace the faulty lamp, rotating it to the left and outwards.

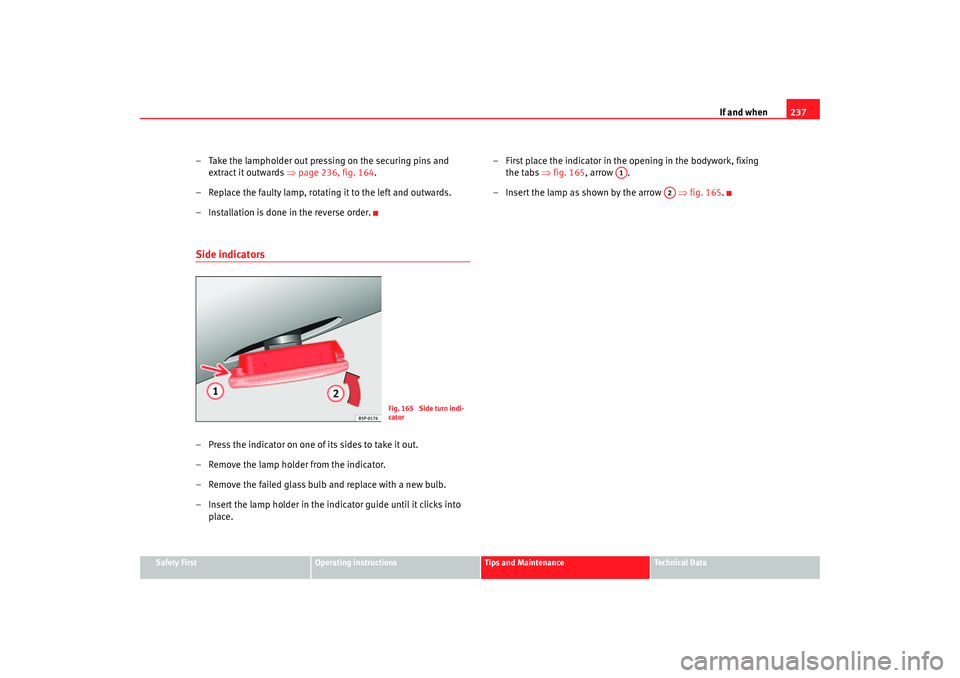

– Installation is done in the reverse order.Side indicators– Press the indicator on one of its sides to take it out.

– Remove the lamp holder from the indicator.

– Remove the failed glass bulb and replace with a new bulb.

– Insert the lamp holder in the indicator guide until it clicks into place. – First place the indicator in the opening in the bodywork, fixing

the tabs ⇒fig. 165, arrow .

– Insert the lamp as shown by the arrow ⇒fig. 165 .

Fig. 165 Side turn indi-

cator

A1

A2

leon_ingles Seite 237 Donnerstag, 20. Oktober 2005 12:14 12