lock Seat Leon 5D 2005 Repair Manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2005, Model line: Leon 5D, Model: Seat Leon 5D 2005Pages: 280, PDF Size: 8.46 MB

Page 196 of 280

Checking and refilling levels

194

WARNING

All work on the engine or in the engine compartment, e.g. checking and

refilling fluids, involves the danger of injury and scalding as well as the risk

of accident or fire.•

Never open the bonnet if you see steam, smoke or coolant escaping

from the engine compartment. Otherwise, there is a risk of sustaining

burns. Wait until no more steam or coolant is emitted, then allow the

engine to cool before carefully opening the bonnet.

•

Switch off the engine and remove the key from the ignition.

•

Apply the handbrake and move the gea r stick to neutral or selector

lever to position P.

•

Keep children away from the vehicle.

•

Never touch hot engine parts. There is a risk of burns.

•

Never spill liquids on a hot engine or on a hot exhaust gas system. This

is a fire hazard.

•

Avoid causing short-circuits in the electrical system, particularly at the

points where the jump leads are attached ⇒page 241. The battery could

explode.

•

Never touch the radiator fan. It is temperature controlled and could

start automatically, even when the engine has been switched off and the

key removed from the ignition!

•

Do not unscrew the cap on the expansion tank when the engine is hot.

If the coolant is hot, the cooling system will be pressurised!

•

Protect face, hands and arms by covering the cap with a large, thick

cloth to protect against escaping coolant and steam.

•

Always make sure you have not left any objects, such as cleaning cloths

and tools, in the engine compartment.

•

If you have to work underneath the vehicle, you must use suitable

stands additionally to support the vehicl e, there is a risk of accident! A

hydraulic jack is insufficient for securing the vehicle and there is a risk of

injury.

•

If any work has to be performed when the engine is started or with the

engine running, there is an additional, potentially fatal, safety risk from the

rotating parts, such as the drive belt s, alternator, radiator fan, etc., and

from the high-voltage ignition system. You should also observe the

following points:

−Never touch the electrical wiring of the ignition system.

− Ensure that jewellery, loose clothing and long hair do not get

trapped in rotating engine parts. Danger of death. Before starting any

work remove jewellery, tie back and cover hair, and wear tight-fitting

clothes.

− Always think carefully about pressing the accelerator if a gear is

engaged in either an automatic or manual gearbox. The vehicle could

move, even if the handbrake is applied. Danger of death.

•

If work has to be carried out on the fuel system or on electrical compo-

nents, you must observe the following safety notes in addition to the above

warnings:

−Always disconnect the battery. The vehicle must be unlocked when

this is done, otherwise the alarm will be triggered.

− Do not smoke.

− Never work near naked flames.

− Always have a fire extinguisher on hand.Caution

When changing or topping up service fluids, make absolutely certain that you

fill the fluids into the correct reservoirs. Failure to observe this point will result

in serious malfunctions and engine damage!

WARNING (continued)

leon_ingles Seite 194 Donnerstag, 20. Oktober 2005 12:14 12

Page 198 of 280

Checking and refilling levels

196•

Wait until no more steam, smoke or coolant is emitted from the bonnet,

then carefully open the bonnet.

•

When working in the engine compartment, always observe the safety

warnings ⇒ page 193.

Closing the bonnet– Raise the bonnet slightly

– Release the bonnet stay and replace it in its support.

– At a height of about 30 cm let it fall so it is locked.If the bonnet does not close, do not press downwards. Open it once more and

let it fall as before.

WARNING

If the bonnet is not closed properly, it could open while you are driving and

completely obscure your view of the road. Risk of accident.•

After closing the bonnet, always check that it is properly secured. The

bonnet must be flush with the surrounding body panels.

•

If you notice that the bonnet latch is not secured when the vehicle is

moving, stop the vehicle immediately and close the bonnet properly. Risk

of accident.

Engine oilEngine oil specifications

The engine oil used must conform to exact specifications.Specifications

The engine comes with a special, high quality, multi grade oil that can be

used in all seasons of the year except for those regions affected by extreme

cold.

As the use of high quality oil is essential for the correct operation of the

engine and its long useful life, when topping up or replacement is necessary

use only those oils that conform to the requirements of the VW standards.

If it is not possible to find oil conforming to the VW standards then oil

conforming to the ACEA or API standards with an appropriate viscosity at

atmospheric temperature should be used in stead. The use of this type of oil

may have some repercussions on the performance of the engine for example,

long starting time, increased consumption and a higher emission level.

If a top up is required then different oils may be mixed as long as they all

conform to the VW standards.

The specifications (VW standards) set out in the following page should

appear on the container of the service oil; the container will display together

the different standards for petrol and diesel engines, the oil can be used for

both types of engines.

WARNING (continued)

leon_ingles Seite 196 Donnerstag, 20. Oktober 2005 12:14 12

Page 205 of 280

Checking and refilling levels203

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

Washer fluid and windscreen wiper bladesTopping up washer fluid

The water for cleaning the windscreen should always be

mixed with washer fluid.The windscreen washer and the headlight washing system are supplied with

fluid from the windscreen washer flui d container in the engine compartment.

The reservoir is located on the right-hand side of the engine compartment.

Plain water is not enough to clean the windscreen and headlights. We recom-

mend that you always add a product to the windscreen washer fluid.

Approved windscreen cleaning products exist on the market with high deter-

gent and anti-freeze properties, these may be added all-year-round. Please

follow the dilution instructions on the packaging.

WARNING

Any work carried out in the engine compartment or on the engine must be

carried out cautiously.•

When working in the engine compartm ent, always observe the safety

warnings ⇒page 193.Caution

•

Never put radiator anti-freeze or other additives into the windscreen

washer fluid.

•

Always use approved windscreen cleansing products diluted as per

instructions. If you use other washer fl uids or soap solutions, the tiny holes

in the fan-shaped nozzles could become blocked.

Fig. 139 In the engine

compartment: Cap of

windscreen washer fluid

reservoir.

leon_ingles Seite 203 Donnerstag, 20. Oktober 2005 12:14 12

Page 208 of 280

Checking and refilling levels

206Brake fluidChecking the brake fluid level

The brake fluid is checked at the intervals given in the service

schedule.– Read off the fluid level at the transparent brake fluid reservoir. It

should always be between the “MIN” and “MAX” marks.The position of the brake fluid reservoir is shown in the corresponding engine

compartment diagram ⇒ page 252. The brake fluid reservoir has a black and

yellow cap.

The brake fluid level drops slightly when the vehicle is being used as the

brake pads are automatically adjusted as they wear. However, if the level goes down noticeab

ly in a short time, or drops below the

“MIN” mark, there may be a leak in the brake system. A display on the instru-

ment panel will warn you if the brake fluid level is too low ⇒page 71.

WARNING

Before opening the bonnet to check the brake fluid level, read and observe

the warnings ⇒page 193.Changing the brake fluid

The brake fluid must be renewed every two years.We recommend that you have the brake fluid changed by an Authorised

Service Centre.

Before opening the bonnet, please read and follow the warnings ⇒ in

“Safety instructions on working in the engine compartment” on page 193 in

“Working in the engine compartment”.

Brake fluid absorbs moisture. In the cour se of time, it will absorb water from

the ambient air. If the water content in the brake fluid is too high, the brake

system could corrode. This also consider ably reduces the boiling point of the

brake fluid. Heavy use of the brakes may then cause a vapour lock which

could impair the braking effect.

For this reason the brake fluid must be renewed every two years.

It is important that you use only use brake fluid compliant with the US

standard FMVSS 116 DOT 4. We recommend the use of Genuine SEAT brake

fluid.

WARNING

Brake fluid is poisonous. Old brake fluid impairs the braking effect.

Fig. 142 In the engine

compartment: Brake fluid

reservoir cover

leon_ingles Seite 206 Donnerstag, 20. Oktober 2005 12:14 12

Page 209 of 280

Checking and refilling levels207

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

•

Before opening the bonnet to check the brake fluid level, read and

observe the warnings ⇒page 193.

•

Brake fluid should be stored in the closed original container in a safe

place out of reach of children. This represents a toxic danger.

•

Have the brake fluid changed every two years at the latest. Heavy use

of the brakes may cause a vapour lock if the brake fluid is left in the system

for too long. This would seriously affect the efficiency of the brakes and the

safety of the vehicle. This may be an accident risk.Caution

Brake fluid could damage the paintwork. Wipe off any brake fluid from the

paintwork immediately.

For the sake of the environment

Brake fluid must be drained and disposed of in the proper manner observing

environmental regulations.

BatteryWarnings on handling the battery

WARNING

Always be aware of the danger of injury and chemical burns as well as the

risk of accident or fire when working on the battery and the electrical

system:•

Wear eye protection. Protect your eyes , skin and clothing from acid and

particles containing lead.

•

Battery acid is very corrosive and caustic. Wear protective gloves and

eye protection. Do not tilt the batter ies. This could spill acid through the

vents. Rinse battery acid from eyes immediately for several minutes with

clear water. Then seek medical care immediately. Neutralize any acid

splashes on the skin or clothing with a soapy solution, and rinse off with

plenty of water. If acid is swallowed by mistake, consult a doctor immedi-

ately.

•

Fires, sparks, naked lights and smoki ng are prohibited. When handling

cables and electrical equipment, avoid causing sparks and electrostatic

WARNING (continued)

Wear eye protection

Battery acid is very corrosive and caustic. Wear protec-

tive gloves and eye protection!

Fires, sparks, naked lights and smoking are prohibited!

A highly explosive mixture of gases is released when the

battery is under charge.

Keep children away from acid and batteries!

leon_ingles Seite 207 Donnerstag, 20. Oktober 2005 12:14 12

Page 210 of 280

Checking and refilling levels

208charge. Never short the battery terminals. High-energy sparks can cause

injury.•

A highly explosive mixture of gases is released when the battery is

under charge. The batteries should be charged in a well-ventilated room

only.

•

Keep children away from acid and batteries.

•

Before working on the electrical system, you must switch off the

engine, the ignition and all consumers. The negative cable on the battery

must be disconnected. When a light bulb is changed, you need only switch

off the light.

•

Deactivate the anti-theft alarm by unlocking the vehicle before you

disconnect the battery! The alarm will otherwise be triggered.

•

When disconnecting the battery from the vehicle electrical system,

disconnect first the negative cable and then the positive cable.

•

Switch off all electrical consumers before reconnecting the battery.

Reconnect first the positive cable and then the negative cable. Never

reverse the polarity of the connections. This could cause an electrical fire.

•

Never charge a frozen battery, or one which has thawed. This could

result in explosions and chemical burns. Always replace a battery which

has frozen. A flat battery can freeze at temperatures around 0

°C.

•

Ensure that the vent hose is always connected to the battery.

•

Never use a defective battery. This may be fatally explosive. Replace a

damaged battery immediately.Caution

•

Never disconnect the battery if the ignition is switched on or if the engine

is running. This could damage the electrical system or electronic compo-

nents.

•

Do not expose the battery to direct sunlight over a long period of time, as

the intense ultraviolet radiation can damage the battery housing.

•

If the vehicle is left standing in cold conditions for a long period, protect

the battery from frost. If it “freezes” it will be damaged.

Checking the electrolyte level

The electrolyte level should be checked regularly in high-

mileage vehicles, in hot countries and in older batteries.– Open the bonnet and open the battery cover at the front ⇒ in

“Safety instructions on working in the engine compartment” on

page 193 ⇒ in “Warnings on handling the battery” on

page 207.

– Check the colour display in the “magic eye” on the top of the battery.

– If there are air bubbles in the window, tap the window gently until they disperse.The position of the battery is show n in the corresponding engine compart-

ment diagram ⇒page 252.

The round window (“magic eye”) on the top of the battery changes colour,

depending on the charge level and electrolyte level of the battery.

If the colour in the window is colourless or bright yellow, the electrolyte level

of the battery is too low. Have the battery checked by a qualified workshop.

The colours green and black are used by the workshops for diagnostic

purposes.

WARNING (continued)

leon_ingles Seite 208 Donnerstag, 20. Oktober 2005 12:14 12

Page 219 of 280

If and when217

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

Note

•

Seek professional assistance if the repair of a tyre puncture is not

possible with the sealing compound.

Wheel changePreparation work

What you must do before changing a wheel.– If you have a flat tyre or puncture, park the vehicle as far away from the flow of traffic as possible. Choose a location that is as

level as possible.

– All passengers should leave the vehicle. They should wait in a safe area (for instance behind the roadside crash barrier).

– Switch off the engine. Switch on the hazard warning lights.

–Apply the handbrake firmly.

–Engage the first gear, or put the selector lever to position P for

those vehicles with an automatic gearbox.

– If you are towing a trailer, unhitch it from your vehicle.

–Take the vehicle tools and the spare wheel out of the luggage

compartment.

WARNING

Put the hazard warning lights on and place the warning triangle in position.

This is for your own safety and also warns other road users.

Caution

If you have to change the wheel on a gradient, block the wheel opposite the

wheel being changed by placing a stone or similar object under it to prevent

the vehicle from rolling away.

Note

Please observe legal requirements when doing so.Changing a wheelChange the wheel as described below

– Remove the wheel cover. See ⇒page 218, fig. 146 .

–Slacken the wheel bolts.

– Raise the car wi th the jack in the corresponding zone.

– Take off the wheel and then put on the spare wheel.

– Lower the vehicle.

– Tighten the wheel bolts firmly i n d i a go na l s e q u e n ce wi t h t h e b ox

spanner.

–Replace the cover.

leon_ingles Seite 217 Donnerstag, 20. Oktober 2005 12:14 12

Page 228 of 280

If and when

226Fuses on left side of dash panelFuses

Number Electrical equipment Amperes

1 Diesel and petrol engine control unit 10

2 ABS/ESP control unit 5

3 Airbag control unit 5

4 Heating controls, pressure sensor, heated seats, ESP switch, reverse gear 5

5 Left and right headlamp motor, dimmer, GDL control unit 5

6 Gateway, Automatic gearbox lever 5

7 Windscreen relay, heated mirrors, VDA telephone 5

8 Trailer control unit 5

9 Vacant

10 Vacant

11 Vacant

12 Door control unit (autolock K3) 10

13 Diagnosis, light switch, brake 10

14 Automatic gearbox 5

15 Cable control unit 7,5

16 Heating controls / Air and air conditioning 10

17 Rain sensor 5

18 Automatic gearbox selector lever, parking aid control unit 5

19 Vacant

20 ESP control unit 5

21 D2L engine (20 147 kW) 10

leon_ingles Seite 226 Donnerstag, 20. Oktober 2005 12:14 12

Page 229 of 280

If and when227

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

22

Heater 40

23 Door control unit 30

24 Cigarette lighter 25

25 Cable control unit 25

26 12 V power sockets 30

27 FSI capacity gauge control unit, fuel relay, EKP 1.6 relay 15

28 Comfort system control unit (without autolock 4F8) 25

29 Flowmeter, engine 10

30 Prewired 20

31 Vacuum pump 20

32 Door control unit 30

33 Sunroof 30

34 Comfort system control unit (autolock 4 K3) 25

35 Alarm sensor, horn 5

36 Headlight washer system 20

37 Seats 30

38 Engine 10

39 Automatic gearbox 20

40 Heater 40

41 Tailgate, power 15

42 Cable control unit 15

43 Trailer control unit 15

44 Trailer control unit 20

45 Trailer control unit 15

Number

Electrical equipment Amperes

leon_ingles Seite 227 Donnerstag, 20. Oktober 2005 12:14 12

Page 232 of 280

If and when

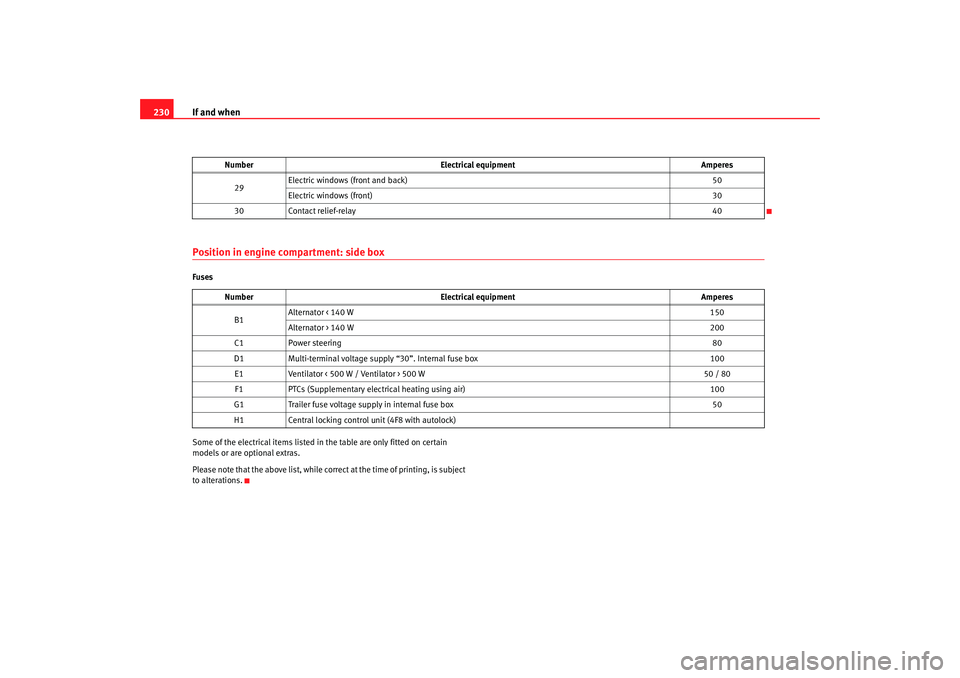

230Position in engine compartment: side boxFuses

Some of the electrical items listed in the table are only fitted on certain

models or are optional extras.

Please note that the above list, while corr ect at the time of printing, is subject

to alterations. 29

Electric windows (front and back)

50

Electric windows (front) 30

30 Contact relief-relay 40

Number Electrical equipment Amperes

B1 Alternator < 140 W

150

Alternator > 140 W 200

C1 Power steering 80

D1 Multi-terminal voltage supply “30”. Internal fuse box 100

E1 Ventilator < 500 W / Ventilator > 500 W 50 / 80

F1 PTCs (Supplementary electrical heating using air) 100

G1 Trailer fuse voltage supply in internal fuse box 50

H1 Central locking control unit (4F8 with autolock)

Number

Electrical equipment Amperes

leon_ingles Seite 230 Donnerstag, 20. Oktober 2005 12:14 12