engine Seat Leon 5D 2005 Manual PDF

[x] Cancel search | Manufacturer: SEAT, Model Year: 2005, Model line: Leon 5D, Model: Seat Leon 5D 2005Pages: 280, PDF Size: 8.46 MB

Page 228 of 280

If and when

226Fuses on left side of dash panelFuses

Number Electrical equipment Amperes

1 Diesel and petrol engine control unit 10

2 ABS/ESP control unit 5

3 Airbag control unit 5

4 Heating controls, pressure sensor, heated seats, ESP switch, reverse gear 5

5 Left and right headlamp motor, dimmer, GDL control unit 5

6 Gateway, Automatic gearbox lever 5

7 Windscreen relay, heated mirrors, VDA telephone 5

8 Trailer control unit 5

9 Vacant

10 Vacant

11 Vacant

12 Door control unit (autolock K3) 10

13 Diagnosis, light switch, brake 10

14 Automatic gearbox 5

15 Cable control unit 7,5

16 Heating controls / Air and air conditioning 10

17 Rain sensor 5

18 Automatic gearbox selector lever, parking aid control unit 5

19 Vacant

20 ESP control unit 5

21 D2L engine (20 147 kW) 10

leon_ingles Seite 226 Donnerstag, 20. Oktober 2005 12:14 12

Page 229 of 280

If and when227

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

22

Heater 40

23 Door control unit 30

24 Cigarette lighter 25

25 Cable control unit 25

26 12 V power sockets 30

27 FSI capacity gauge control unit, fuel relay, EKP 1.6 relay 15

28 Comfort system control unit (without autolock 4F8) 25

29 Flowmeter, engine 10

30 Prewired 20

31 Vacuum pump 20

32 Door control unit 30

33 Sunroof 30

34 Comfort system control unit (autolock 4 K3) 25

35 Alarm sensor, horn 5

36 Headlight washer system 20

37 Seats 30

38 Engine 10

39 Automatic gearbox 20

40 Heater 40

41 Tailgate, power 15

42 Cable control unit 15

43 Trailer control unit 15

44 Trailer control unit 20

45 Trailer control unit 15

Number

Electrical equipment Amperes

leon_ingles Seite 227 Donnerstag, 20. Oktober 2005 12:14 12

Page 230 of 280

If and when

228Some of the electrical items listed in the table are only fitted on certain

models or are optional extras. Please note that the above list, while correct at the time of printing, is subject

to alterations. If discrepancies should

occur, please refer to the sticker on the

inside of the fuse cover for the correct information for your model.Fuses layout, engine compartment, left partFuses46

Heating jets, heating controls, air, air conditioning 5

47 Lambda probe 10

48 Lambda probe 10

49 Light switch 7,5

Number

Electrical equipment Amperes

NumberElectrical equipment Amperes

1 Wiper 30

2 Steering column 5

3 Cable control unit 5

4A BS 30

5 AQ gearbox 15

6I nstr u m en t p an el 5

7 Vacant

8R ad io 15

9 Telephone 5

10 Main relay in the FSI / diesel engine compartment / injection module supply

5

Main relay in the engine compartment D2L (2.0 FSI 147 kW) 10

leon_ingles Seite 228 Donnerstag, 20. Oktober 2005 12:14 12

Page 231 of 280

If and when229

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

11

Vacant

12 Gateway 5

13 Petrol injection module supply

25

Diesel injection module supply 30

14 Coil 20

15 Engine T71 / 20 FSI

5

Pump relay 10

16 ADS pump 30

17 Horn 15

18 Vacant

19 Clean 30

20 Vacant

21 Lambda probe 15

22 Brake pedal, speed sensor 5

23 Engine 1.6, main relay (relay n° 100)

5

T 71 diesel EGR 10

2.0 D2L High-pressure fuel pump 15

24 ARF, change valve 10

25 Right lighting 40

26 Left lighting 40

1.6 SLP engine 40

1.9 TDI Glow plug relay 50

28 KL15 40

Number

Electrical equipment Amperes

leon_ingles Seite 229 Donnerstag, 20. Oktober 2005 12:14 12

Page 232 of 280

If and when

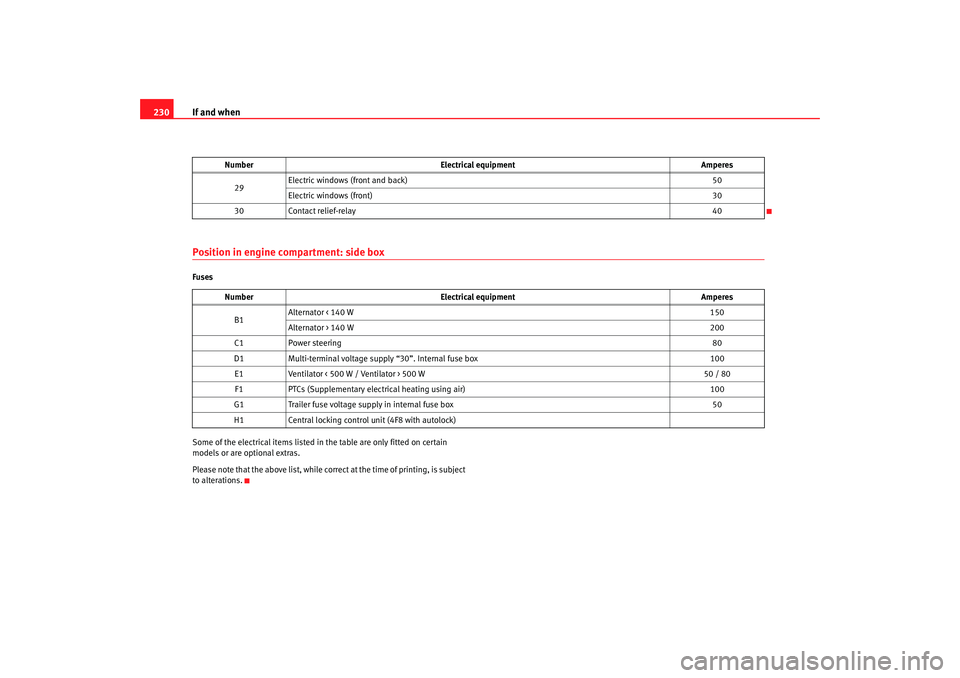

230Position in engine compartment: side boxFuses

Some of the electrical items listed in the table are only fitted on certain

models or are optional extras.

Please note that the above list, while corr ect at the time of printing, is subject

to alterations. 29

Electric windows (front and back)

50

Electric windows (front) 30

30 Contact relief-relay 40

Number Electrical equipment Amperes

B1 Alternator < 140 W

150

Alternator > 140 W 200

C1 Power steering 80

D1 Multi-terminal voltage supply “30”. Internal fuse box 100

E1 Ventilator < 500 W / Ventilator > 500 W 50 / 80

F1 PTCs (Supplementary electrical heating using air) 100

G1 Trailer fuse voltage supply in internal fuse box 50

H1 Central locking control unit (4F8 with autolock)

Number

Electrical equipment Amperes

leon_ingles Seite 230 Donnerstag, 20. Oktober 2005 12:14 12

Page 242 of 280

If and when

240Sunroof light– Carefully remove the lamp, using the flat side of the screwdriver,

as shown in the figure ⇒fig. 170 . – Remove the lamp, moving it in the direction of the arrow and

outwards ⇒ fig. 171.

– Installation is done in the reverse order.

Jump-startingJump leads

The jump lead must have a sufficient wire cross section.If the engine fails to start because of a discharged battery, the battery can be

connected to the battery of anot her vehicle to start the engine.

Jump leads

Jump leads must comply with the standard DIN 72553 (see manufacturer's

documentation). The wire cross section must be at least 25 mm

2 for petrol

engines and at least 35 mm

2 for diesel engines.

Note

•

The vehicles must not touch each other, otherwise electricity could flow as

soon as the positive terminals are connected.

•

The discharged battery must be properly connected to the vehicles elec-

trical system.

Fig. 170 Removing

sunroof lightFig. 171 Removing

sunroof light

leon_ingles Seite 240 Donnerstag, 20. Oktober 2005 12:14 12

Page 243 of 280

If and when241

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

How to jump startIn ⇒ fig. 172, the flat battery is A and the charged battery B.

Jump lead terminal connections

– Switch off the ignition on both vehicles ⇒.

1. Connect one end of the red jump lead to the positive ⇒fig. 172

terminal of the vehicle with the flat battery ⇒.

2. Connect the other end of the red jump lead to the positive terminal in the vehicle providing assistance.

3. Connect one end of the black jump lead to the negative terminal on the battery of the vehicle providing assistance. 4. Connect the other end of the black jump lead to a solid metal

component which is bolted on to the engine block, or onto the

engine block itself of the vehicle with the flat battery. Do not

connect it to a point near the battery ⇒.

5. Position the leads in such a way that they cannot come into contact with any moving parts in the engine compartment.

Starting

6. Start the engine of the vehicle with the boosting battery and let

it run at idling speed.

7. Start the engine of the car with the flat battery and wait one or two minutes until the engine is “running”.

Removing the jump leads

8. Before you remove the jump leads, switch off the headlights (if they are switched on).

9. Turn on the heater blower and rear window heater in the vehicle with the flat battery. This helps minimise voltage peaks which are

generated when the leads are disconnected.

10. When the engine is running, disconnect the leads in reverse order to the details given above.

Connect the battery clamps so they ha ve good metal-to-metal contact with

the battery terminals.

If the engine fails to start, switch off the starter after about 10 seconds and

try again after about half a minute.

Fig. 172 How to connect

the jump leads

A+

A+

A-

AX

leon_ingles Seite 241 Donnerstag, 20. Oktober 2005 12:14 12

Page 244 of 280

If and when

242

WARNING

•

Please note the safety warnings referring to working in the engine

compartment ⇒page 193, “Working in the engine compartment”.

•

The battery providing assistance must have the same voltage as the flat

battery (12V) and approximately the same capacity (see imprint on

battery). Failure to comply could result in an explosion.

•

Never use jump leads when one of the batteries is frozen. Danger of

explosion! Even after the battery has thawed, battery acid could leak and

cause chemical burns. If a battery freezes, it should be replaced.

•

Keep sparks, flames and lighted cigarettes away from batteries, danger

of explosion. Failure to comply could result in an explosion.

•

Observe the instructions provided by the manufacturer of the jump

leads.

•

Do not connect the negative cable from the other vehicle directly to the

negative terminal of the flat battery. The gas emitted from the battery could

be ignited by sparks. Danger of explosion.

•

Do not attach the negative cable from the other vehicle to parts of the

fuel system or to the brake line.

•

The non-insulated parts of the battery clamps must not be allowed to

touch. The jump lead atta ched to the positive battery terminal must not

touch metal parts of the vehicle, this can cause a short circuit.

•

Position the leads in such a way that they cannot come into contact

with any moving parts in the engine compartment.

•

Do not bend over the batteries. This could result in chemical burns.Note

The vehicles must not touch each other, otherwise electricity could flow as

soon as the positive terminals are connected.

leon_ingles Seite 242 Donnerstag, 20. Oktober 2005 12:14 12

Page 245 of 280

If and when243

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

Towing and tow-startingTo w - s t a r t i n g *

The use of jump leads is preferable to tow-starting.We recommend that you do not tow-start your vehicle. Jump-starting

is preferable ⇒page 240.

However, if your vehicle has to be tow-started:

–Engage the 2

nd or the 3

rd gear.

– Keep the clutch pressed down.

– Switch on the ignition.

– Once both vehicles are mo ving, release the clutch.

– As soon as the engine starts, press the clutch and move the gear lever into neutral. This helps to prevent driving into the towing

vehicle.

WARNING

The risk of accidents is high when tow-starting. The vehicle being towed

can easily collide with the towing vehicle.

Caution

When tow-starting, fuel could enter the catalytic converter and damage it.

Towing eyesPlease observe the following points if you use a tow-rope:

Fig. 173 The front right

section of the vehicle:

Fitting the front towing

eyeFig. 174 Fitting the

towing eye to the rear of

the vehicle

leon_ingles Seite 243 Donnerstag, 20. Oktober 2005 12:14 12

Page 246 of 280

If and when

244

Notes for the driver of the towing vehicle

– Drive slowly at first until the to w-rope is taut. Then accelerate

gradually.

– Begin and change gears cautiously. If you are driving an auto- matic vehicle, accelerate gently.

– Remember that the brake servo and power steering are not working in the vehicle you are towing. Brake earlier than you

would normally, but with a more gentle pressure on the brake.

Notes for the driver of the towed vehicle

– Ensure that the tow-rope remains taut at all times when towing.

Fitting the towing eye

– Take the towing ring and the wheel spanner out of the vehicle tool kit.

– Pull the lower front cover down and leave the cover hanging on the vehicle.

– Remove the cover of the screw hole, insert a screwdriver into the lower slot and lever gently.

– Screw the towing eye as shown by arrow anti-clockwise to the

limit position in the front ⇒page 243, fig. 173 or rear

⇒ page 243, fig. 174 threaded hole.

– Use the wrench for leverage to tighten the towing eye.Tow-rope or tow-bar

It is easier and safer to tow a vehicle with a tow-bar. You should only use a

tow-rope if you do not have a tow-bar. A tow-rope should be slightly elastic to reduce the loading on both vehicles.

It is advisable to use a tow-rope made of synthetic fibre or similarly elastic

material.

Attach the tow-rope or the tow-bar only to the towing eyes provided or a

towing bracket.

Driving style

Towing requires some experience, espec

ially when using a tow-rope. Both

drivers should be familiar with the te chnique required for towing. Inexperi-

enced drivers should not attempt to tow-start or tow away another vehicle.

Do not pull too hard with the towing vehicle and take care to avoid jerking the

tow-rope. When towing on an unpaved road, there is always a risk of over-

loading and damaging the anchorage points.

The ignition of the vehicle being towed must be switched on to prevent the

steering wheel from locking and also to allow the use of the turn signals,

horn, windscreen wipers and washers.

As the brake servo does not work if the engine is not running, you must apply

considerably more pressure to the brake pedal than you normally would.

As the power assisted steering does not work if the engine is not running, you

will need more strength to steer than you normally would.

Towing vehicles with an automatic gearbox

•

Put the selector lever into position “N”.

•

Do not drive faster than 50 km/h when towing a vehicle.

•

Do not tow further than 50 km.

•

If a breakdown vehicle is used, the vehicle must be towed with the front

wheels raised.Note

•

Observe legal requirements when towing or tow-starting.

leon_ingles Seite 244 Donnerstag, 20. Oktober 2005 12:14 12