warning Seat Leon 5D 2007 Owner's manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2007, Model line: Leon 5D, Model: Seat Leon 5D 2007Pages: 302, PDF Size: 9.14 MB

Page 231 of 302

If and when229

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

If and whenVehicle tools, tyre repa ir kit and spare wheelVeh icle To ols

The vehicle onboard tools are located under the floor panel in

the luggage compartment.– Lift the cover of the luggage compartment, by pulling it up with a

finger in the fitting.

– Take the onboard tools out of the vehicle.The tool kit includes:•

Jack*

•

Hook for removing wheel covers* or hub caps*

•

Box spanner for wheel bolts*

•

Reversible screwdriver with handle (i ncluding hexagonal interior) for the

wheel bolts. The screwdriver is a combination tool.

•

To wi ng e y e

•

Adapter for the anti-theft wheel bolts*

Some of the items listed are only provided in certain models / model years,

or are optional extras.

WARNING

•

Do not use the hexagonal socket in the screwdriver handle to tighten

the wheel bolts as with this it is not possible to tighten the bolts to the

required torque, risk of accident.

•

The jack* supplied by the factory is only designed for changing wheels

on this model. On no account attempt to use it for lifting heavier vehicles

or other loads, risk of injury.

•

Use the jack* only on firm, level ground.

•

Never start the engine when the vehicle is on the jack, risk of accident.

•

I f w o r k is t o b e ca r r i e d o ut un d e r n ea t h t h e v e h i cle , t h is m u st b e s e c ure d

by suitable stands. Otherwise, there is a risk of injury.WARNING (continued)

leon ingles.book Seite 229 Dienst ag, 11. September 2007 1:47 13

Page 232 of 302

If and when

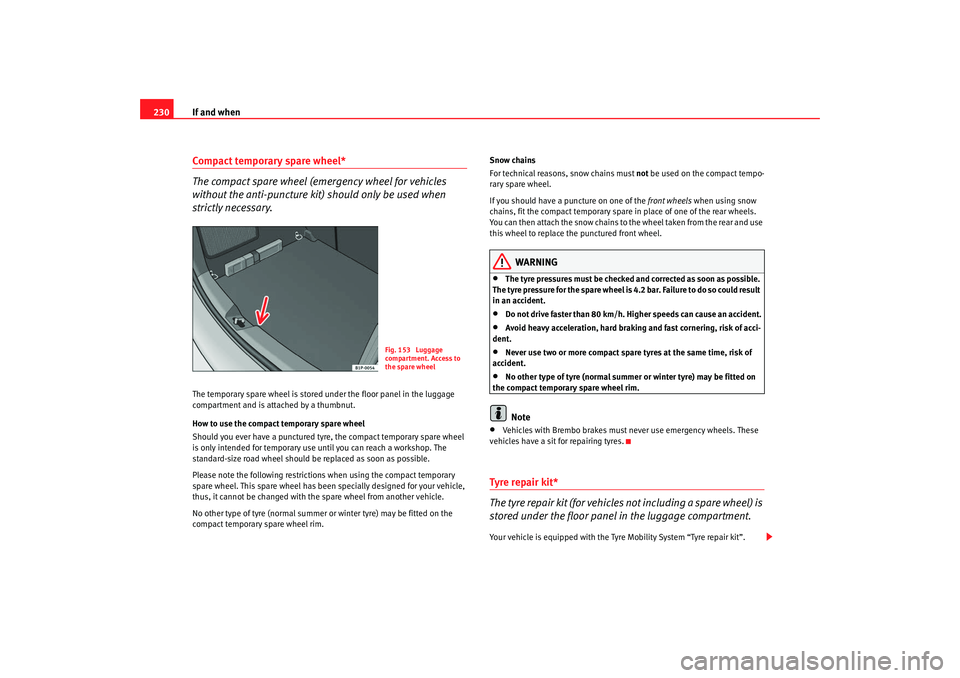

230Compact temporary spare wheel*

The compact spare wheel (emergency wheel for vehicles

without the anti-puncture kit) should only be used when

strictly necessary.The temporary spare wheel is stored under the floor panel in the luggage

compartment and is attached by a thumbnut.

How to use the compact temporary spare wheel

Should you ever have a punctured tyre, the compact temporary spare wheel

is only intended for temporary use until you can reach a workshop. The

standard-size road wheel should be replaced as soon as possible.

Please note the following restrictio ns when using the compact temporary

spare wheel. This spare wheel has been specially designed for your vehicle,

thus, it cannot be changed with th e spare wheel from another vehicle.

No other type of tyre (normal summer or winter tyre) may be fitted on the

compact temporary spare wheel rim. Snow chains

For technical reasons, snow chains must

not be used on the compact tempo-

rary spare wheel.

If you should have a puncture on one of the front wheels when using snow

chains, fit the compact temporary spare in place of one of the rear wheels.

You can then attach the snow chains to the wheel taken from the rear and use

this wheel to replace the punctured front wheel.

WARNING

•

The tyre pressures must be checked and corrected as soon as possible.

The tyre pressure for the spare wheel is 4.2 bar. Failure to do so could result

in an accident.

•

Do not drive faster than 80 km/h. Higher speeds can cause an accident.

•

Avoid heavy acceleration, hard braking and fast cornering, risk of acci-

dent.

•

Never use two or more compact spare tyres at the same time, risk of

accident.

•

No other type of tyre (normal summer or winter tyre) may be fitted on

the compact temporary spare wheel rim.Note

•

Vehicles with Brembo brakes must never use emergency wheels. These

vehicles have a sit for repairing tyres.

Tyre repair ki t*

The tyre repair kit (for vehicles not including a spare wheel) is

stored under the floor panel in the luggage compartment.Your vehicle is equipped with the Tyre Mobility System “Tyre repair kit”.

Fig. 153 Luggage

compartment. Access to

the spare wheel

leon ingles.book Seite 230 Dienst ag, 11. September 2007 1:47 13

Page 233 of 302

If and when231

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

The tyre repair kit consists of a contai

ner with sealing compound to repair the

puncture and a compressor to generate the required tyre pressure. The kit will

reliably seal punctures up to a size of about 4 mm caused by the penetration

of a foreign body into the tyre.

Note

•

Seek professional assistance if the repair of a tyre puncture is not

possible with the sealing compound.

Wheel changePreparation work

What you must do before changing a wheel.– If you have a flat tyre or puncture, park the vehicle as far away from the flow of traffic as possible. Choose a location that is as

level as possible.

– All passengers should leave the vehicle. They should wait in a safe area (for instance behind the roadside crash barrier).

– Switch off the engine. Switch on the hazard warning lights.

–Apply the handbrake firmly.

–Engage the first gear, or put the selector lever to position P for

those vehicles with an automatic gearbox.

– If you are towing a trailer, unhitch it from your vehicle. – Take the

vehicle tools and the spare wheel out of the luggage

compartment.

WARNING

Put the hazard warning lights on and place the warning triangle in position.

This is for your own safety and also warns other road users.

Caution

If you have to change the wheel on a gradient, block the wheel opposite the

wheel being changed by placing a stone or similar object under it to prevent

the vehicle from rolling away.

Note

Please observe legal requirements when doing so.Changing a wheelChange the wheel as described below

–Pull off the hub cap . See ⇒page 232, fig. 154 .

–Slacken the wheel bolts.

– Raise the car with the jack in the corresponding zone.

– Ta k e o f f the wheel and then put on the spare wheel.

– Lower the vehicle.

leon ingles.book Seite 231 Dienst ag, 11. September 2007 1:47 13

Page 236 of 302

If and when

234

WARNING

Loosen the wheel bolts only about one turn before raising the vehicle with

the jack, loosening the wheel bolts more than one turn can result in an acci-

dent.

Note

•

Do not use the hexagonal socket in the screwdriver handle to loosen or

tighten the wheel bolts.

•

If the wheel bolt is very tight, you may be able to loosen it by pushing

down the end of the spanner carefully with your foot. Hold on to the vehicle

for support and take care not to slip.

leon ingles.book Seite 234 Dienst ag, 11. September 2007 1:47 13

Page 237 of 302

If and when235

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

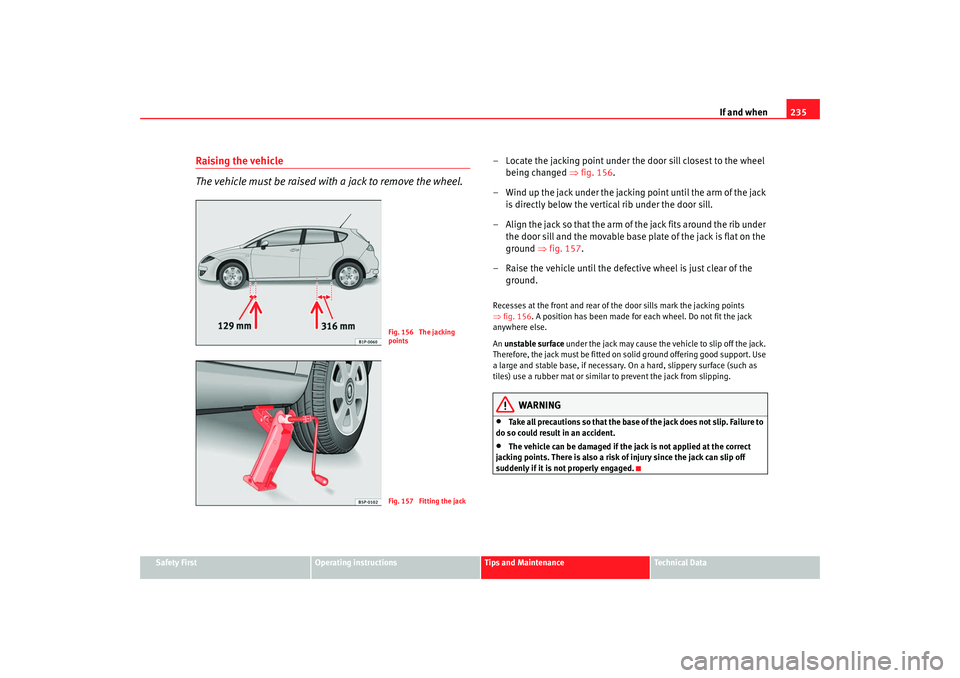

Raising the vehicle

The vehicle must be raised with a jack to remove the wheel.

– Locate the jacking point under the door sill closest to the wheel

being changed ⇒fig. 156.

– Wind up the jack under the jacking point until the arm of the jack is directly below the vertical rib under the door sill.

– Align the jack so that the arm of the jack fits around the rib under the door sill and the movable base plate of the jack is flat on the

ground ⇒fig. 157.

– Raise the vehicle until the defect ive wheel is just clear of the

ground.Recesses at the front and rear of the door sills mark the jacking points

⇒ fig. 156 . A position has been made for each wheel. Do not fit the jack

anywhere else.

An unstable surface under the jack may cause the vehicle to slip off the jack.

Therefore, the jack must be fitted on solid ground offering good support. Use

a large and stable base, if necessary. On a hard, slippery surface (such as

tiles) use a rubber mat or similar to prevent the jack from slipping.

WARNING

•

Take all precautions so that the base of the jack does not slip. Failure to

do so could result in an accident.

•

The vehicle can be damaged if the jack is not applied at the correct

jacking points. There is also a risk of injury since the jack can slip off

suddenly if it is not properly engaged.

Fig. 156 The jacking

pointsFig. 157 Fitting the jack

leon ingles.book Seite 235 Dienst ag, 11. September 2007 1:47 13

Page 239 of 302

If and when237

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

– Insert the adapter onto the wheel bolt and push it on as far as it

will go ⇒page 236, fig. 159 .

– Fit the box spanner as far as it will go over the adapter.

– Loosen or tighten the wheel bolt as appropriate.Error code

The code number of the anti-theft wheel bolt is stamped on the front of the

adaptor.

The code number should be noted and kept in a safe place, as it is only by

using the code number that a duplicat e adaptor can be obtained from an

Authorised Service Centre.Tyres with directional tread pattern

Tyres with directional tread pattern must be fitted so that they

rotate in the correct direction.A directional tread pattern can be identified by arrows on the sidewall that

point in the direction of rotation. Always note the direction of rotation indi-

cated when fitting the wheel. This is important so that these tyres can give

maximum grip and avoid excessive noise, tread wear and aquaplaning.

If, in an emergency, you have to mount the spare wheel so it rotates in the

wrong direction, you must drive extrem ely carefully. The tyre will not give

optimum performance. This is particularly important when driving on wet

roads.

To benefit from the advantages of tyres with this type of tread pattern, the

defective tyre should be replaced as soon as possible so that all tyres again

rotate in the correct direction.

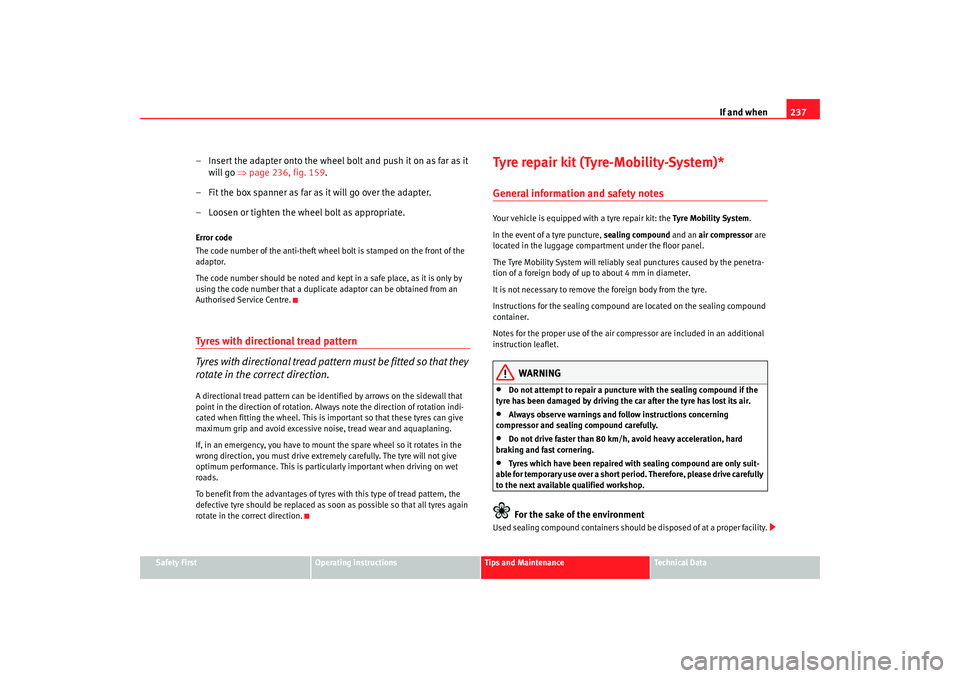

Tyre repair kit (Tyre-Mobility-System)*General information and safety notesYour vehicle is equipped with a tyre repair kit: the Tyre Mobility System.

In the event of a tyre puncture, sealing compound and an air compressor are

located in the luggage compartment under the floor panel.

The Tyre Mobility System will reliably seal punctures caused by the penetra-

tion of a foreign body of up to about 4 mm in diameter.

It is not necessary to remove the foreign body from the tyre.

Instructions for the sealing compound are located on the sealing compound

container.

Notes for the proper use of the air compressor are included in an additional

instruction leaflet.

WARNING

•

Do not attempt to repair a puncture with the sealing compound if the

tyre has been damaged by driving the car after the tyre has lost its air.

•

Always observe warnings and follow instructions concerning

compressor and sealing compound carefully.

•

Do not drive faster than 80 km/h, avoid heavy acceleration, hard

braking and fast cornering.

•

Tyres which have been repaired with sealing compound are only suit-

able for temporary use over a short period. Therefore, please drive carefully

to the next available qualified workshop.For the sake of the environment

Used sealing compound containers should be disposed of at a proper facility.

leon ingles.book Seite 237 Dienst ag, 11. September 2007 1:47 13

Page 240 of 302

If and when

238

NoteSeek professional assistance if the repair of a tyre puncture is not possible

with the sealing compound.Preparation work

Certain steps must be taken before repairing a tyre.– If you have a flat tyre or puncture, park the vehicle as far away from the flow of traffic as possible.

–Apply the handbrake firmly.

–Engage first gear, or put the selector lever to position P.

– All passengers should leave the vehicle. They should wait in a

safe area (for instance behind the roadside crash barrier).

– Check whether a repair is possible using the Tyre Mobility System “General information and safety notes.”

– Unscrew inflation cap from the affected wheel.

– Take the tyre repair kit out of the luggage compartment.

WARNING

Put the hazard warning lights on and pl ace the warning triangle in position.

This is for your own safety and also warns other road users.

Caution

Take special care if you have to repair a tyre on a gradient.

Note

Please observe legal requirements when doing so.Tyre repair

The following sections describe the procedures for repairing

a tyre.Using the sealing compound

– The instructions on the container give detailed information on how to use the sealing compound.

Inflating the tyre.

– Remove the air compressor and hose from the container.

– Screw the retaining nut onto the valve.

– Plug the compressor cable into a 12 volt socket.

– Turn on compressor and monitor the pressure shown on the pres- sure gauge.

Completing the repair

– Remove the compressor hose from the valve.

– Fit the valve cap.

– Unplug the compressor from the socket.

– Return all tools to their proper storing location.

leon ingles.book Seite 238 Dienst ag, 11. September 2007 1:47 13

Page 242 of 302

If and when

240

– Take the plastic clip from inside the fuse cover (at left-hand end of the dash panel), fit it onto the blown fuse and pull the fuse out.

– Replace the blown fuse (which will have a melted metal strip) with a new fuse of the same ampere rating.

– Carefully fit the fuse cover back on to ensure no water can enter

the fuse box.The individual electrical circuits are pr otected by fuses. The fuses are located

behind a cover at the left-hand end of the dash panel and on the left-hand

side of the engine compartment.

The electric windows are protected by circuit breakers. These reset automat-

ically after a few seconds when the overload (caused for example by frozen

windows) has been corrected.

Colour coding of fuses

WARNING

Never “repair” damaged fuses and neve r replace them with fuses with a

higher rating. Failure to comply could result in fire. This could also cause

damage to other parts of the electrical system.

Note

•

If a newly replaced fuse blows again after a short time, the electrical

system must be checked by a qualifi ed workshop as soon as possible.

•

If you replace a fuse with a stronger fuse, you could cause damage to

another location in th e electrical system.

•

Always keep some spare fuses in the vehicle. These are available from

SEAT dealers.

Colour

Amperes

light brown 5

red 10

Blue 15

yellow 20

natural (white) 25

green 30

orange 40

red 50

white 80

Blue100

grey 150

violet 200

Colour

Amperes

leon ingles.book Seite 240 Dienstag, 11. September 2007 1:47 13

Page 259 of 302

If and when257

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

WARNING

•

Please note the safety warnings referring to working in the engine

compartment ⇒page 204, “Working in the engine compartment”.

•

The battery providing assistance must have the same voltage as the flat

battery (12V) and approximately the same capacity (see imprint on

battery). Failure to comply could result in an explosion.

•

Never use jump leads when one of the batteries is frozen. Danger of

explosion! Even after the battery has thawed, battery acid could leak and

cause chemical burns. If a battery freezes, it should be replaced.

•

Keep sparks, flames and lighted cigarettes away from batteries, danger

of explosion. Failure to comply could result in an explosion.

•

Observe the instructions provided by the manufacturer of the jump

leads.

•

Do not connect the negative cable from the other vehicle directly to the

negative terminal of the flat battery. The gas emitted from the battery could

be ignited by sparks. Danger of explosion.

•

Do not attach the negative cable from the other vehicle to parts of the

fuel system or to the brake line.

•

The non-insulated parts of the battery clamps must not be allowed to

touch. The jump lead attached to the positive battery terminal must not

touch metal parts of the vehicle, this can cause a short circuit.

•

Position the leads in such a way that they cannot come into contact

with any moving parts in the engine compartment.

•

Do not bend over the batteries. This could result in chemical burns.Note

The vehicles must not touch each other, otherwise electricity could flow as

soon as the positive terminals are connected.

leon ingles.book Seite 257 Dienst ag, 11. September 2007 1:47 13

Page 260 of 302

If and when

258To w i n g a n d t o w - s t a r t i n gTo w - s t a r t i n g

The use of jump leads is preferable to tow-starting.We recommend that you do not t o w - s t a r t yo u r v e h i c l e . J u m p - s ta r t i n g

is preferable ⇒page 255.

However, if your vehicle has to be tow-started:

– Engage the 2

nd or the 3

rd gear.

– Keep the clutch pressed down.

– Switch on the ignition.

– Once both vehicles are moving, release the clutch.

– As soon as the engine starts, press the clutch and move the gear lever into neutral. This helps to prevent driving into the towing

vehicle.

WARNING

The risk of accidents is high when tow-starting. The vehicle being towed

can easily collide with the towing vehicle.

Caution

When tow-starting, fuel could enter the catalytic converter and damage it.

CommentsPlease observe the following points if you use a tow-rope:

Notes for the driver of the towing vehicle

– Drive slowly at first until the tow-rope is taut. Then accelerate gradually.

– Begin and change gears cautiously. If you are driving an auto- matic vehicle, accelerate gently.

– Remember that the brake servo and power steering are not working in the vehicle you are towing. Brake earlier than you

would normally, but with a more gentle pressure on the brake.

Notes for the driver of the towed vehicle

– Ensure that the tow-rope remains taut at all times when towing.Tow-rope or tow-bar

It is easier and safer to tow a vehicle with a tow-bar. You should only use a

tow-rope if you do not have a tow-bar.

A tow-rope should be slightly elastic to reduce the loading on both vehicles.

It is advisable to use a tow-rope made of synthetic fibre or similarly elastic

material.

Attach the tow-rope or the tow-bar only to the towing eyes provided or a

towing bracket.

Driving style

Towing requires some experience, espec ially when using a tow-rope. Both

drivers should be familiar with the te chnique required for towing. Inexperi-

enced drivers should not attempt to tow-start or tow away another vehicle.

leon ingles.book Seite 258 Dienst ag, 11. September 2007 1:47 13