change wheel Seat Leon 5D 2008 Owner's Guide

[x] Cancel search | Manufacturer: SEAT, Model Year: 2008, Model line: Leon 5D, Model: Seat Leon 5D 2008Pages: 293, PDF Size: 8.67 MB

Page 226 of 293

Wheels and tyres225

Safety First

Operating instructions

Practical tips

Te c h n i c a l D a t a

Wear indicators

The original tyres on your vehicle have 1.6 mm high “tread wear indicators”

⇒

page 224, fig. 147 , running across the tread. Depending on the make,

there will be six to eight of them evenly spaced around the tyre. Markings on

the tyre sidewall (for instance the letters “TWI” or other symbols) indicate the

positions of the tread wear indicators. The minimum tread depth required by

law is 1.6 mm (measured in the tread grooves next to the tread wear indica-

tors). Worn tyres must be replaced. Different figures may apply in export

countries ⇒.

Tyre pressure

Incorrect tyre pressure causes premature wear and could cause tyre blow-out.

For this reason, the tyre pressure should be checked at least once per month

⇒ page 222.

Driving style

Fast cornering, heavy acceleration and hard braking all increase tyre wear.

Changing wheels around

If the front tyres are worn considerably more than the rear ones it is advisable

to change them around as shown ⇒page 224, fig. 148 . All the tyres will then

last for about the same time.

Wheel balance

The wheels on new vehicles are balanced. However, various factors encoun-

tered in normal driving can cause them to become unbalanced, which results

in steering vibration.

Unbalanced wheels should be rebalanced, as they otherwise cause excessive

wear on steering, suspension and tyres. A wheel must also be rebalanced

when a new tyre is fitted.

Incorrect wheel alignment

Incorrect wheel alignment causes excessive tyre wear, impairing the safety of

the vehicle. If tyres show excessive wear, you should have the wheel align-

ment checked by an Authorised Service Centre.

WARNING

There is a serious danger of accidents if a tyre bursts during driving!•

The tyres must be replaced at the latest when the tread is worn down to

the tread wear indicators. Failure to do so could result in an accident. Worn

tyres do not grip well at high speeds on wet roads. There is also a greater

risk of “aquaplaning”

•

At continuously high speeds, a tyre with insufficient pressure flexes

more. This causes it to overheat. This can cause tread separation and tyre

blow-out. Risk of accident. Always observe the recommended tyre pres-

sures.

•

If tyres show excessive wear, you should have the running gear checked

by an Authorised Service Centre.

•

Keep chemicals such as oil, fuel and brake fluid away from tyres.

•

Damaged wheels and tyres must be replaced immediately!For the sake of the environment

Under-inflated tyres will increase fuel consumption.Anti-puncture tyres

Anti-puncture tyres allow you to continue driving even with a

punctured tyre, in the majority of cases.Vehicles equipped with anti-puncture

22)

tyres from the factory indi-

cate the loss of tyre pressure on the instrument panel.

22)Depending upon version and country.

leon_ingles Seite 225 Montag, 26. Januar 2009 4:29 16

Page 227 of 293

Wheels and tyres

226

Driving with anti-puncture tyres (emergency gear)

– Leave the ESP/TCS (electronic stabilisation programme) switched on, or switch on ⇒page 176.

– Continue driving carefully and slowly (80 km/h maximum).

– Avoid sudden manoeuvres and sharp turns.

– Avoid driving over obstacles (for example kerbs) or potholes.

– Look out for the ESP/TCS intervening often, smoke coming from the tyres or the smell of rubber, the vehicle vibrating or a clat-

tering noise. If any of these occur, stop the vehicle.The anti-puncture tyres have a tag on the side of the tyre, with the description:

“DSST”, “Eufonia”, “RFT”, “ROF”, “RSC”, “SSR” or “ZP”.

The sides of this type of tyre are reinforced. When the tyres lose air they are

supported on the sides (emergency driving).

The loss of pressure in the tyre is shown on the instrument panel. You can

then drive a maximum of 80 km and if the circumstances are favourable (for

example, low load), even more.

The damaged tyre should be changed as soon as possible. The rim should be

checked in a specialist workshop to detect possible damage and replace it if

necessary. We recommend you contact Technical Service. If more than one

tyre is being used under emergency co nditions, this reduces the distance

which can be travelled.

Starting driving in emergency conditions

When the loss in tyre pressure is displayed on the instrument panel, this

implies that at least one tyre is being driven in emergency conditions ⇒.

End of emergency operation

Do not drive on if:

•

smoke is coming from one of the tyres,

•

there is a smell of rubber,

•

the vehicle vibrates,

•

there is a rattling noise.

When is it no longer possible to co ntinue driving even using anti-puncture

tyres?

•

If one of the tyres has been severely damaged in an accident, etc. If a tyre

has been badly damaged there is a risk that parts of the tread can be thrown

off and cause damage to the fuel lines, brake pipes or fuel filler.

•

It is also advisable to stop driving if severe vibrations occur, or if the wheel

starts overheating and gives off smoke.

WARNING

When driving in emergency conditions, the driving quality of the vehicle is

considerably impaired.•

The maximum permitted speed of 80 km/h is subject to road and

weather conditions. Please observe legal requirements when doing so.

•

Avoid sharp turns and rapid manoeuvres, and brake earlier than usual.

•

Avoid driving over obstacles (for example kerbs) or potholes.

•

If one or more tyres is being driven in emergency conditions, the driving

quality of the vehicle is impaired and there is a risk of accident.Note

•

The anti-puncture tyres do not “deflate” on losing pressure because they

are supported on the reinforced sides. Th erefore defects in the tyre can not be

detected with a visual inspection.

•

Snow chains must not be used on front tyres used in emergency

conditions.

leon_ingles Seite 226 Montag, 26. Januar 2009 4:29 16

Page 229 of 293

Wheels and tyres

228Wheel bolts

Wheel bolts must be tightened to the correct torque.The design of wheel bolts is matched to the rims. If different wheel rims are

fitted, the correct wheel bolts with the right length and correctly shaped bolt

heads must be used. This ensures that wheels are fitted securely and that the

brake system functions correctly.

In certain circumstances, you may not use wheel bolts from a different car -

even if it is the same model ⇒page 200.

After the wheels have been changed, the tightening torque of the wheel bolts

should be checked as soon as possible with a torque wrench. ⇒ The tight-

ening torque for steel and alloy wheels is 120 Nm.

WARNING

If the wheel bolts are not tightened correctly, the wheel could become

loose while driving. Risk of accident.•

The wheel bolts must be clean and turn easily. Never apply grease or oil

to them.

•

Use only wheel bolts which belong to the wheel.

•

If the torque of the wheel bolts is to o low, they could loosen whilst the

vehicle is in motion. Risk of accident! If the tightening torque is too high,

the wheel bolts and threads can be damaged.Caution

The prescribed torque for wheel bolts for steel and alloy wheels is 120 Nm.

Winter tyres

Winter tyres will improve the vehicles handling on snow and

ice.In winter conditions winter tyres will considerably improve the vehicles

handling. The design of summer tyres (width, rubber compound, tread

pattern) gives less grip on ice and snow.

Winter tyres must be inflated to a pressure 0.2 bar higher than the pressures

specified for summer tyres (see sticker on tank flap).

Winter tyres must be fitted on all four wheels.

Information on permitted winter tyre sizes can be found in the vehicle's regis-

tration documents. Use only radial winter tyres. All tyre sizes listed in the

vehicle documentation also apply to winter tyres.

Winter tyres lose their effectiveness when the tread is worn down to a depth

of 4 mm.

The speed rating code ⇒page 227, “New tyres and wheels” determines the

following speed limits for winter tyres: ⇒

Q max. 160 km/h

S max. 180 km/h

T max. 190 km/h

H max. 210 km/h

In some countries, vehicles which can exceed the speed rating of the fitted

tyre must have an appropriate sticker in the driver's field of view. These

stickers are available from your Authorised Service Centre. The legal require-

ments of each country must be followed.

Do not have winter tyres fitted for unnecessarily long periods. Vehicles with

summer tyres handle better when the roads are free of snow and ice.

If you have a flat tyre, please refer to the notes on the spare wheel

⇒ page 227, “New tyres and wheels”.

leon_ingles Seite 228 Montag, 26. Januar 2009 4:29 16

Page 232 of 293

If and when231

Safety First

Operating instructions

Practical tips

Te c h n i c a l D a t a

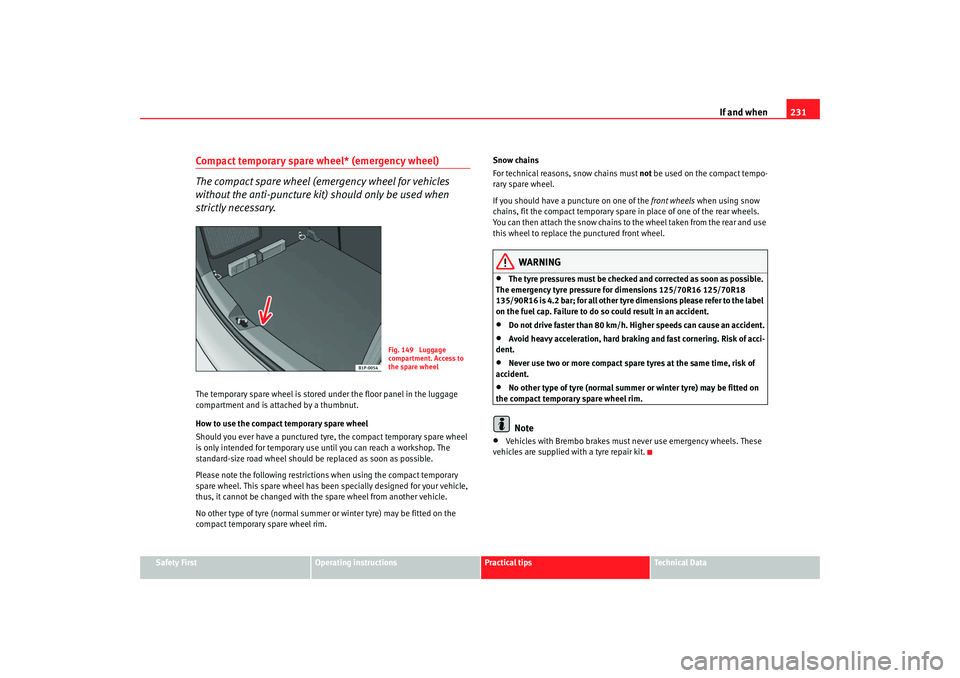

Compact temporary spare wheel* (emergency wheel)

The compact spare wheel (emergency wheel for vehicles

without the anti-puncture kit) should only be used when

strictly necessary.The temporary spare wheel is stored under the floor panel in the luggage

compartment and is attached by a thumbnut.

How to use the compact temporary spare wheel

Should you ever have a punctured tyre, the compact temporary spare wheel

is only intended for temporary use until you can reach a workshop. The

standard-size road wheel should be replaced as soon as possible.

Please note the following restrictions when using the compact temporary

spare wheel. This spare wheel has been specially designed for your vehicle,

thus, it cannot be changed with th e spare wheel from another vehicle.

No other type of tyre (normal summer or winter tyre) may be fitted on the

compact temporary spare wheel rim. Snow chains

For technical reasons, snow chains must not

be used on the compact tempo-

rary spare wheel.

If you should have a puncture on one of the front wheels when using snow

chains, fit the compact temporary spare in place of one of the rear wheels.

You can then attach the snow chains to the wheel taken from the rear and use

this wheel to replace the punctured front wheel.

WARNING

•

The tyre pressures must be checked and corrected as soon as possible.

The emergency tyre pressure for dimensions 125/70R16 125/70R18

135/90R16 is 4.2 bar; for all other tyre di mensions please refer to the label

on the fuel cap. Failure to do so could result in an accident.

•

Do not drive faster than 80 km/h. Hi gher speeds can cause an accident.

•

Avoid heavy acceleration, hard braking and fast cornering. Risk of acci-

dent.

•

Never use two or more compact spare tyres at the same time, risk of

accident.

•

No other type of tyre (normal summer or winter tyre) may be fitted on

the compact temporary spare wheel rim.Note

•

Vehicles with Brembo brakes must never use emergency wheels. These

vehicles are supplied with a tyre repair kit.

Fig. 149 Luggage

compartment. Access to

the spare wheel

leon_ingles Seite 231 Montag, 26. Januar 2009 4:29 16

Page 233 of 293

If and when

232Tyre repair kit*

The tyre repair kit (for vehicles not including a spare wheel) is

stored under the floor panel in the luggage compartment.Your vehicle is equipped with the Tyre Mobility System “Tyre repair kit”.

The tyre repair kit consists of a container with sealing compound to repair the

puncture and a compressor to generate the required tyre pressure. The kit will

reliably seal punctures up to a size of about 4 mm caused by the penetration

of a foreign body into the tyre.

Note

•

Seek professional assistance if the repair of a tyre puncture is not

possible with the sealing compound.

Wheel changePreparation work

What you must do before changing a wheel.– If you have a flat tyre or puncture, park the vehicle as far away from the flow of traffic as possible. Choose a location that is as

level as possible.

– All passengers should leave the ve hicle. They should wait in a

safe area (for instance behind the roadside crash barrier).

– Switch off the engine. Switch on the hazard warning lights.

–Apply the handbrake firmly. – Engage the

first gear, or put the selector lever to position P for

those vehicles with an automatic gearbox.

– If you are towing a trailer, unhitch it from your vehicle.

–Take the vehicle tools and the spare wheel out of the luggage

compartment.

WARNING

Put the hazard warning lights on and place the warning triangle in position.

This is for your own safety and also warns other road users.

Caution

If you have to change the wheel on a gradient, block the wheel opposite the

wheel being changed by placing a stone or similar object under it to prevent

the vehicle from rolling away.

Note

Please observe legal requirements when doing so.Changing a wheelChange the wheel as described below

–Pull off the hub cap. See ⇒ page 233, fig. 150.

– Slacken the wheel bolts.

– Raise the car with the jack in the corresponding zone.

leon_ingles Seite 232 Montag, 26. Januar 2009 4:29 16

Page 236 of 293

If and when235

Safety First

Operating instructions

Practical tips

Te c h n i c a l D a t a

WARNING

Loosen the wheel bolts only about one tu rn before raising the vehicle with

the jack, loosening the wheel bolts more than one turn can result in an acci-

dent.

Note

•

Do not use the hexagonal socket in th e screwdriver handle to loosen or

tighten the wheel bolts.

•

If the wheel bolt is very tight, you may be able to loosen it by pushing

down the end of the spanner carefully with your foot. Hold on to the vehicle

for support and take care not to slip.

Raising the vehicle

In order to remove the wheel, the vehicle must be raised with

a jack.

– Locate the jacking point under the door sill closest to the wheel to be changed ⇒fig. 152.

– Place the jack under the jacking point and turn the crank until the arm of the jack is directly below the vertical rib under the door

sill.

– Align the jack so that the arm of the jack fits around the rib under the door sill and the movable base plate of the jack is flat on the

ground ⇒fig. 153.

– Raise the jack until the defective wheel is just clear of the ground.Recesses at the front and rear of the door sills mark the jacking points

⇒ fig. 152 . There is only one jacking point for each wheel. Do not fit the jack

anywhere else.

An unstable surface under the jack may cause the vehicle to slip off the jack.

Therefore, the jack must be fitted on solid ground offering good support. Use

Fig. 152 The jacking

points

Fig. 153 Fitting the jack

leon_ingles Seite 235 Montag, 26. Januar 2009 4:29 16

Page 263 of 293

General notes on the technical data

262To w i n g a t r a i l e rTrailer weightsTrailer weights

The trailer weights and drawbar loads approved are selected in intensive

trials according to precisely defined criteria. The approved trailer weights are

valid for vehicles in the EU for maximum speeds of 80 km/h (in certain

circumstances up to 100 km/h). The figu res may be different in other coun-

tries. All data in the official vehicl e documents take precedence over these

data ⇒ .

Drawbar load

The maximum permitted weight exerted by the trailer drawbar on the ball joint

of the towing bracket must not exceed 75 kg.

In the interest of road safety, we recommend that you always tow

approaching the maximum drawbar load. The response of the trailer on the

road will be poor if the drawbar load is too small.

If the maximum permissible drawbar loa d cannot be met (e.g. with small,

empty and light-weight single axle trailers or tandem axle trailers with an axle

base of less than 1 metre), at least 4% of the actual trailer weight is a legal

stipulation for a drawbar load.

WARNING

•

For safety reasons, do not exceed the 80 km/h limit. This is also valid in

countries where higher speeds are permitted.

•

Never exceed the maximum trailer weights or the draw bar loading. If

the permissible axle load or the permissible total weight is exceeded, the

driving characteristics of the vehicle may change, leading to accidents,

injuries and damage to the vehicle.

WheelsTyre pressure, snow chains, wheel boltsTyre pressures

The sticker with the tyre pressure values can be found on the inside of the

tank flap. The tyre pressure values given there are for cold tyres. The slightly

raised pressures of warm tyres must not be reduced ⇒.

Snow chains

Snow chains may be fitted only to the front wheels.

Consult the chapter “wheels” of this manual.

Wheel bolts

After the wheels have been changed, the tightening torque of the wheel bolts

should be checked as soon as possible with a torque wrench ⇒. The tight-

ening torque for steel and alloy wheels is 120 Nm.

WARNING

•

Check the tyre pressure at least once per month. Checking tyre pressure

value is very important. If the tyre pressure is too high or too low, there is

an increased danger of accidents, particularly at high speeds.

•

If the torque of the wheel bolts is too low, they could loosen while the

vehicle is in motion. Risk of accident! If the tightening torque is too high,

the wheel bolts and threads can be damaged.Note

We recommend that you ask your Authorised Service Centre for information

about appropriate wheel, tyre and snow chain size.

leon_ingles Seite 262 Montag, 26. Januar 2009 4:29 16

Page 282 of 293

Technical Data281

Safety First

Operating instructions

Practical tips

Te c h n i c a l D a t a

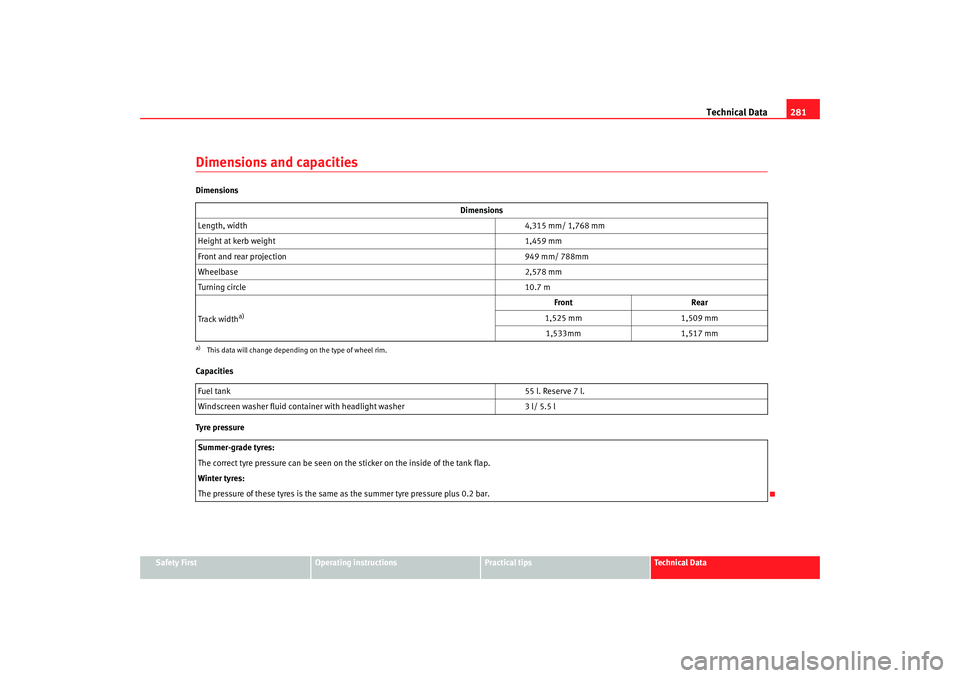

Dimensions and capacitiesDimensions

Capacities

Tyre pressure Dimensions

Length, width 4,315 mm/ 1,768 mm

Height at kerb weight 1,459 mm

Front and rear projection 949 mm/ 788mm

Wheelbase 2,578 mm

Turning circle 10.7 m

Track width

a)

a)This data will change depending on the type of wheel rim.

Front Rear

1,525 mm 1,509 mm

1,533mm 1,517 mm

Fuel tank 55 l. Reserve 7 l.

Windscreen washer fluid container with headlight washer 3 l/ 5.5 l

Summer-grade tyres:

The correct tyre pressure can be seen on the sticker on the inside of the tank flap.

Winter tyres:

The pressure of these tyres is the same as the summer tyre pressure plus 0.2 bar.

leon_ingles Seite 281 Montag, 26. Januar 2009 4:29 16

Page 284 of 293

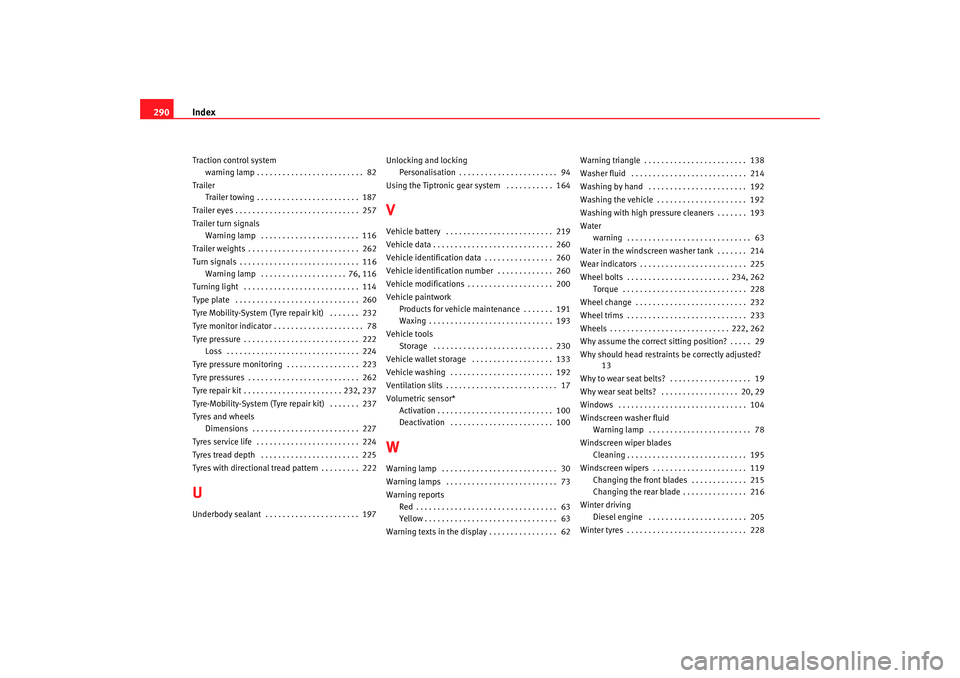

Index283

Index

AABS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Warning lamp . . . . . . . . . . . . . . . . . . . . . . . . . 77

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

Acoustic signal . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Acoustic warning . . . . . . . . . . . . . . . . . . . . . . . . 156

Adjusting the seat belt height . . . . . . . . . . . . . . 26

AFS (curve lights) . . . . . . . . . . . . . . . . . . . . . . . . 113

Air conditioner* 2C-Climatronic* . . . . . . . . . . . . . . . . . . . . . . 148

Air conditioning system General notes . . . . . . . . . . . . . . . . . . . . . . . . 152

Air conditioning* . . . . . . . . . . . . . . . . . . . . . . . . 144

Air recirculation mode 2C-Climatronic . . . . . . . . . . . . . . . . . . . . . . . 152

Manual air conditioning . . . . . . . . . . . . . . . 146

Airbag covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Airbag system . . . . . . . . . . . . . . . . . . . . . . . . . . . 29 Curtain airbags . . . . . . . . . . . . . . . . . . . . . . . 40

front airbags . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Side airbags . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Warning lamp . . . . . . . . . . . . . . . . . . . . . . . . . 30

Alarm system Switching off . . . . . . . . . . . . . . . . . . . . . . . . 100

Alternator Warning lamp . . . . . . . . . . . . . . . . . . . . . . . . . 78

Ambient temperature display . . . . . . . . . . . . 62, 69 Anti-freeze . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

Anti-lock brake system . . . . . . . . . . . . . . . . . . . 176

Warning lamp . . . . . . . . . . . . . . . . . . . . . . . . . 77

Anti-puncture tyres . . . . . . . . . . . . . . . . . . . . . . 225

Anti-theft alarm system . . . . . . . . . . . . . . . . . . . 100 Switching off . . . . . . . . . . . . . . . . . . . . . . . . 100

Anti-theft wheel bolts . . . . . . . . . . . . . . . . . . . . 234

Aquaplaning . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Ashtray* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Aspects to take into account before starting the vehicle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Automatic anti-dazzle interior mirror* Activating the anti-dazzle function . . . . . . 124

Deactivating anti-dazzle function . . . . . . . . 124

Automatic car wash tunnel . . . . . . . . . . . . . . . . 192

Automatic gearbox / DS G automatic gearbox . 161

Automatic lighting . . . . . . . . . . . . . . . . . . . . . . . 110

Automatic mode 2C-Climatronic . . . . . . . . . . . . . . . . . . . . . . . 150

Automatic wiper/wash function for the rear window 122

Auxiliary audio connection: AUX-IN . . . . . . . . . 137

BBall coupling . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

BAS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175 Battery

Changing . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

Charging . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

Winter conditions . . . . . . . . . . . . . . . . . . . . 219

Before starting the vehicle . . . . . . . . . . . . . . . . . . 8

Belt tension device Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Warning lamp . . . . . . . . . . . . . . . . . . . . . . . . 30

Belt tension devices . . . . . . . . . . . . . . . . . . . . . . 27

Biodiesel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

Biodiesel fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

Bonnet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Boot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Brake assist system . . . . . . . . . . . . . . . . . . . . . 175

Brake fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217 Brake fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Changing . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

Brake pads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Brake servo . . . . . . . . . . . . . . . . . . . . . . . 175, 182

Brake system . . . . . . . . . . . . . . . . . . . . . . . . . . . 217 Brake servo . . . . . . . . . . . . . . . . . . . . . . . . . 180

Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Warning lamp . . . . . . . . . . . . . . . . . . . . . . . . 79

Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Braking distance . . . . . . . . . . . . . . . . . . . . . . . . 182

Bulb changes general notes . . . . . . . . . . . . . . . . . . . . . . . . 244

leon_ingles Seite 283 Montag, 26. Januar 2009 4:29 16

Page 291 of 293

Index

290Traction control system

warning lamp . . . . . . . . . . . . . . . . . . . . . . . . . 82

Trailer Trailer towing . . . . . . . . . . . . . . . . . . . . . . . . 187

Trailer eyes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

Trailer turn signals Warning lamp . . . . . . . . . . . . . . . . . . . . . . . 116

Trailer weights . . . . . . . . . . . . . . . . . . . . . . . . . . 262

Turn signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116 Warning lamp . . . . . . . . . . . . . . . . . . . . 76, 116

Turning light . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Type plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

Tyre Mobility-System (Tyre repair kit) . . . . . . . 232

Tyre monitor indicator . . . . . . . . . . . . . . . . . . . . . 78

Tyre pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . 222 Loss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

Tyre pressure monitoring . . . . . . . . . . . . . . . . . 223

Tyre pressures . . . . . . . . . . . . . . . . . . . . . . . . . . 262

Tyre repair kit . . . . . . . . . . . . . . . . . . . . . . . 232, 237

Tyre-Mobility-System (Tyre repair kit) . . . . . . . 237

Tyres and wheels Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . 227

Tyres service life . . . . . . . . . . . . . . . . . . . . . . . . 224

Tyres tread depth . . . . . . . . . . . . . . . . . . . . . . . 225

Tyres with directional tread pattern . . . . . . . . . 222UUnderbody sealant . . . . . . . . . . . . . . . . . . . . . . 197 Unlocking and locking

Personalisation . . . . . . . . . . . . . . . . . . . . . . . 94

Using the Tiptronic gear syst em . . . . . . . . . . . 164

VVehicle battery . . . . . . . . . . . . . . . . . . . . . . . . . 219

Vehicle data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

Vehicle identification data . . . . . . . . . . . . . . . . 260

Vehicle identification number . . . . . . . . . . . . . 260

Vehicle modifications . . . . . . . . . . . . . . . . . . . . 200

Vehicle paintwork

Products for vehicle maintenance . . . . . . . 191

Waxing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Vehicle tools Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Vehicle wallet storage . . . . . . . . . . . . . . . . . . . 133

Vehicle washing . . . . . . . . . . . . . . . . . . . . . . . . 192

Ventilation slits . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Volumetric sensor* Activation . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Deactivation . . . . . . . . . . . . . . . . . . . . . . . . 100WWarning lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Warning lamps . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Warning reportsRed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Yellow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Warning texts in the display . . . . . . . . . . . . . . . . 62 Warning triangle . . . . . . . . . . . . . . . . . . . . . . . . 138

Washer fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

Washing by hand . . . . . . . . . . . . . . . . . . . . . . . 192

Washing the vehicle . . . . . . . . . . . . . . . . . . . . . 192

Washing with high pressure cleaners . . . . . . . 193

Water

warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Water in the windscreen washer tank . . . . . . . 214

Wear indicators . . . . . . . . . . . . . . . . . . . . . . . . . 225

Wheel bolts . . . . . . . . . . . . . . . . . . . . . . . . 234, 262 Torque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

Wheel change . . . . . . . . . . . . . . . . . . . . . . . . . . 232

Wheel trims . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

Wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222, 262

Why assume the correct sitting position? . . . . . 29

Why should head restraints be correctly adjusted? 13

Why to wear seat belts? . . . . . . . . . . . . . . . . . . . 19

Why wear seat belts? . . . . . . . . . . . . . . . . . . 20, 29

Windows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Windscreen washer fluid Warning lamp . . . . . . . . . . . . . . . . . . . . . . . . 78

Windscreen wiper blades Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

Windscreen wipers . . . . . . . . . . . . . . . . . . . . . . 119 Changing the front blades . . . . . . . . . . . . . 215

Changing the rear blade . . . . . . . . . . . . . . . 216

Winter driving Diesel engine . . . . . . . . . . . . . . . . . . . . . . . 205

Winter tyres . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

leon_ingles Seite 290 Montag, 26. Januar 2009 4:29 16