technical data Seat Leon 5D 2009 Owner's manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2009, Model line: Leon 5D, Model: Seat Leon 5D 2009Pages: 304, PDF Size: 7.72 MB

Page 245 of 304

If and when243

Safety First

Controls and equipment

Practical tips

Technical Data

–Remove the wheel and then mount the spare wheel

– Lower the vehicle.

– Tighten the wheel bolts firmly with the box spanner.

– Replace the wheel trim.After changing a wheel

After changing the wheel there are still tasks to complete.– Put the tools and jack back in the luggage compartment.

– Place the wheel with the defective tyre in the luggage compart-

ment and secure it.

– Check the tyre pressure of the newly fitted tyre as soon as possible.

– Have the tightening torque of th e wheel bolts checked as soon as

possible with a torque wrench. Th e prescribed torque must be

120 Nm.

Note•If you notice that the wheel bolts are corroded and difficult to turn when

changing a wheel, they must be replaced before having the wheel bolt torque

checked.•For your safety, drive at moderate speeds until the wheel bolt torque has

been checked.

Wheel trims

The wheel trims must be removed to gain access to the wheel

bolts.Removing

– Insert the extraction hook from the tools into the designated

ring, located in one of the bolt hole covers of the wheel cover

⇒ fig. 156 .

–Pull off the hub cap.

Fig. 156 Changing the

wheel: Removing a hub

cap

Leon_EN.book Seite 243 Dienstag, 8. September 2009 5:25 17

Page 247 of 304

If and when245

Safety First

Controls and equipment

Practical tips

Technical Data

WARNING

Loosen the wheel bolts only about one turn before raising the vehicle with

the jack, loosening the wheel bolts more than one turn can result in an acci-

dent.

Note

•Do not use the hexagonal socket in the screwdriver handle to loosen or

tighten the wheel bolts.•If the wheel bolt is very tight, you may be able to loosen it by pushing

down the end of the spanner carefully with your foot. Hold on to the vehicle

for support and take care not to slip.Raising the vehicle

In order to remove the wheel, the vehicle must be raised with

a jack.

– Locate the jacking point under the door sill closest to the wheel to be changed ⇒fig. 158 .

– Place the jack under the jacking point and turn the crank until the arm of the jack is directly below the vertical rib under the door

sill.

– Align the jack so that the arm of the jack fits around the rib under the door sill and the movable base plate of the jack is flat on the

ground ⇒fig. 159 .

– Raise the jack until the defective wheel is just clear of the ground.Recesses at the front and rear of the door sills mark the jacking points

⇒ fig. 158 . There is only one jacking point for each wheel. Do not fit the jack

anywhere else.

An unstable surface under the jack may cause the vehicle to slip off the jack.

Therefore, the jack must be fitted on solid ground offering good support. Use

Fig. 158 The jacking

points

Fig. 159 Fitting the jack

Leon_EN.book Seite 245 Dienstag, 8. September 2009 5:25 17

Page 249 of 304

If and when247

Safety First

Controls and equipment

Practical tips

Technical Data

Anti-theft wheel bolts

A special adapter is required to turn the anti-theft wheel

bolts.– Insert the adapter onto the wheel bolt and push it on as far as it

will go ⇒ fig. 161.

– Fit the box spanner as far as it will go over the adapter.

– Loosen or tighten the wheel bolt as appropriate.Error code

The code number of the anti-theft wheel bolt is stamped onto the front part of

the adaptor.

The code number should be noted and kept in a safe place, as it is only by

using the code number that a duplicate adaptor can be obtained from an

Authorised Service Centre.

Tyres with directional tread pattern

Tyres with directional tread pattern must be fitted so that they

rotate in the correct direction.A directional tread pattern can be identified by arrows on the sidewall that

point in the direction of rotation. Always note the direction of rotation indi-

cated when fitting the wheel. This is important so that these tyres can give

maximum grip and avoid excessive noise, tread wear and aquaplaning.

If, in an emergency, you have to mount the spare wheel so it rotates in the

wrong direction, you must drive extremely carefully. The tyre will not give

optimum performance. This is particularly important when driving on wet

roads.

To benefit from the advantages of tyres with this type of tread pattern, the

defective tyre should be replaced as soon as possible so that all tyres again

rotate in the correct direction.Tyre repair kit (Tyre-Mobility-System)*General information and safety notesYour vehicle is equipped with a tyre repair kit: the Ty re Mo bil it y Syste m.

In the event of a tyre puncture, a sealing compound and an air compressor are

located in the luggage compartment under the floor panel.

The Tyre Mobility System will reliably seal punctures caused by the penetra-

tion of a foreign body of up to about 4 mm in diameter.

It is not necessary to remove the foreign body from the tyre.

Instructions for the sealing compound are located on the sealing compound

container.

Fig. 161 Anti-theft wheel

bolt

Leon_EN.book Seite 247 Dienstag, 8. September 2009 5:25 17

Page 251 of 304

If and when249

Safety First

Controls and equipment

Practical tips

Technical Data

Tyre repair

The following sections describe the procedures for repairing

a tyre.Using the sealing compound

– The instructions on the container give detailed information on

how to use the sealing compound.

Inflating the tyre.

– Remove the air compressor and hose from the container.

– Screw the retaining nut onto the valve.

– Plug the compressor cable into a 12 volt power point.

– Turn on compressor and monitor the pressure shown on the pres- sure gauge.

Completing the repair

– Remove the compressor hose from the valve.

– Fit the valve cap.

– Unplug the compressor from the socket.

– Return all tools to their proper storing location.

Note•If the vehicle is equipped with tyre pressure control, enter the new tyre

pressures using the SET button on the central console.•The compressor should never be allowed to run for longer than 6

minutes.

FusesChanging a fuse

Blown fuses must be replaced

Fig. 162 Left side of dash

panel: Fuse box coverFig. 163 Fuse box cover

in engine compartment

Leon_EN.book Seite 249 Dienstag, 8. September 2009 5:25 17

Page 253 of 304

If and when251

Safety First

Controls and equipment

Practical tips

Technical Data

•If you replace a fuse with higher-rating fuse, you could cause damage to

another location in the electrical system.•Always keep some spare fuses in the vehicle. These are available from

SEAT dealers.•In addition to the fuses listed in the following tables, there are other fuses

which must be replaced by the Technical Service Workshop.

Leon_EN.book Seite 251 Dienstag, 8. September 2009 5:25 17

Page 255 of 304

If and when253

Safety First

Controls and equipment

Practical tips

Technical Data

Some of the electrical items listed in the table are only fitted on certain

models or are optional extras.

Please note that the above list, while correct at the time of printing, is subject

to alterations. If discrepancies should occur, please refer to the sticker on the

inside of the fuse cover for the correct information for your model.

Fuses layout, engine compartment, left partFuses

40

Fan switch

40

41

Rear wiper motor / Switchboard wiring

20

42

12 V socket/ Cigarette lighter

20

43

Trailer bracket preinstallation

15

44

Trailer bracket preinstallation

20

45

Trailer bracket preinstallation

15

46

Vaca n t

47

Engine management

10

48

Engine management

10

49

Vaca n t

Number

Consumer

Amperes

1

Windscreen wipers

30

2

DQ200 gearbox

30

3

Cable control unit

5

Number

Consumer

Amperes

4

ABS

20

5

AQ gearbox

15

6

Instrument panel/Steering column

5

7

Ignition key

40

8

Radio

15

9

Telephone/TomTom Navigator

5

10

Engine management

5

Engine management

10

11

Vaca n t

12

Electronic control unit

5

13

Petrol injection module supply

15

Diesel injection module supply

30

14

Coil

20

15

Engine management

5

Pump relay

10

16

Right lighting

30

17

Horn

15

18

Vaca n t

19

Clean

30

20

Water pump

10

Pressure sensor pump for 1.8 engine

20

21a)

Lambda probe

15

22

Brake pedal, speed sensor

5

Number

Consumer

Amperes

Leon_EN.book Seite 253 Dienstag, 8. September 2009 5:25 17

Page 257 of 304

If and when255

Safety First

Controls and equipment

Practical tips

Technical Data

Rear tailgate light unit

Fog light (driver's side) - P21W

Reverse (passenger's side) - P21W

Position - W5W

Side indicator

Side indicator - W5W

Registration plate light

Registration plate light - C5W

Glove box lamp

Glove box lamp - W5W

Note

•Depending on weather conditions (cold or wet), the front lights, the fog

lights, the rear lights and the indicators may be temporarily misted. This has

no influence on the life expectancy of the lighting system. By switching on the

lights, the area through which the beam of light is projected will quickly be

demisted. However, the edges may continue to be misted.•Please check at regular intervals that all lighting (especially the exterior

lighting) on your vehicle is functioning pr operly. This is not only in the interest

of your own safety, but also in that of all other road users.•Due to the difficulty in accessing the lamps, any replacement work should

be done by a SEAT dealer. However, the following is a description of how to

change the lamps except for the fog lights* and interior lamps.

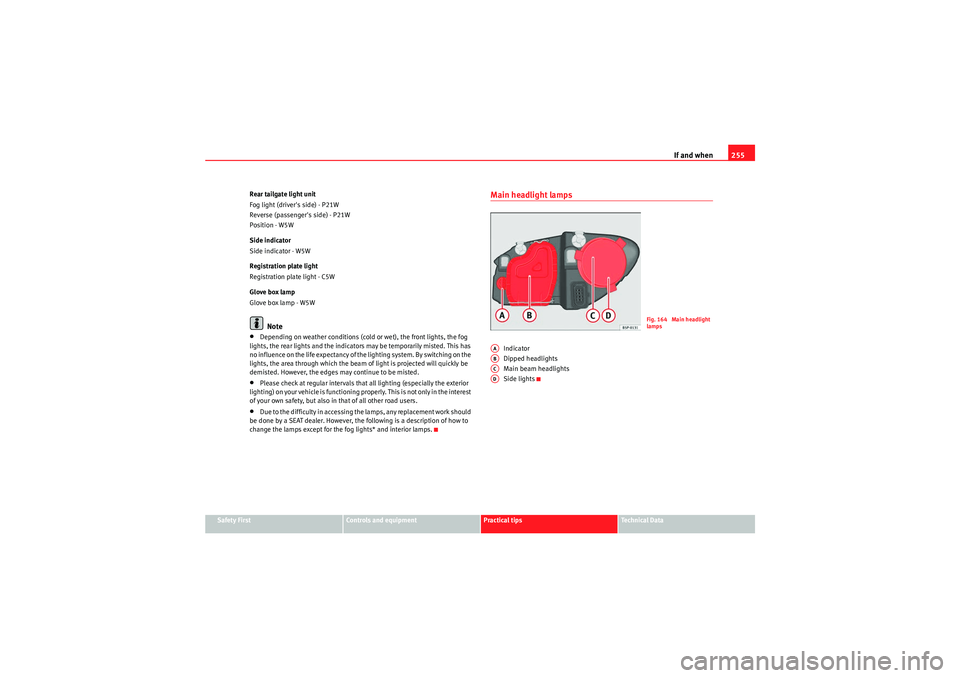

Main headlight lamps

Indicator

Dipped headlights

Main beam headlights

Side lights

Fig. 164 Main headlight

lamps

AAABACAD

Leon_EN.book Seite 255 Dienstag, 8. September 2009 5:25 17

Page 259 of 304

If and when257

Safety First

Controls and equipment

Practical tips

Technical Data

– Remove the loops ⇒page 256, fig. 166 in the direction of

the arrow and remove the cover.

– Remove the connector ⇒page 256, fig. 167 from the bulb.

– Disengage the retainer spring ⇒ page 256, fig. 167 pressing

inwards to the right.

– Extract the bulb and fit the replacement so that the rim of the attachment plate is on the reflector cut-out.Main beam lights

– Raise the bonnet

– Remove the cover ⇒fig. 168 by pulling on this.

– Remove the connector ⇒fig. 169 from the bulb.

– Press the spring ⇒fig. 169 inwards and to the right.

– Extract the bulb and fit the replacement so that it sits correctly into the cut-out on the reflector.

– Installation is done in the reverse order.

A1

A2

A3

Fig. 168 Main beam

headlights

Fig. 169 Main beam

headlights

AC

A1

A2

Leon_EN.book Seite 257 Dienstag, 8. September 2009 5:25 17

Page 261 of 304

If and when259

Safety First

Controls and equipment

Practical tips

Technical Data

Indicator, side and brake lights on the bodywork– Press on the side pin outwards and take out the lamp holder.

– Extract the failed bulb and change it for a new one.

– To refit follow the steps in reverse order, taking special care when

fitting the lamp holder.

Position light, fog light and reverse light on the tailgate–Open the tailgate.

– Use a screwdriver to remove the cover ⇒fig. 173 .

Fig. 172 Indicator, side

and brake lights on the

bodywork

Fig. 173 Lights on the

tailgateFig. 174 Removing the

lampholder

Leon_EN.book Seite 259 Dienstag, 8. September 2009 5:25 17

Page 263 of 304

If and when261

Safety First

Controls and equipment

Practical tips

Technical Data

Luggage compartment lights– Remove the bulb by pressing on the inside edge of this -arrow-

using the flat side of a screwdriver ⇒fig. 176 . – Press the lamp sideways and remove from its housing

⇒fig. 177 .

– Installation is in the reverse order.

Fig. 176 Luggage

compartment lightFig. 177 Luggage

compartment light

Leon_EN.book Seite 261 Dienstag, 8. September 2009 5:25 17