ignition Seat Leon 5D 2010 Manual PDF

[x] Cancel search | Manufacturer: SEAT, Model Year: 2010, Model line: Leon 5D, Model: Seat Leon 5D 2010Pages: 309, PDF Size: 8.2 MB

Page 218 of 309

Checking and refilling levels

216LPG system*Refuelling with LPG

The LPG filler neck is behind the fuel cap, next to the petrol filler neck.

Refuelling with LPG

– Before refuelling, stop the engine and switch off the ignition.

–Open the tank flap.

– Before refuelling, please read the instructions on the pump.

– Unscrew the cap of the gas filler neck .

– Screw the required adapter on the gas filler neck .

– Refuel as indicated in the instructions on the pump.

–Unscrew the adapter .

F ig. 139 Fuel tank ope n with LPG fille r neck and adap ter.

Fig. 140 LPG tank in

spare wheel well

A1

A2

A1

A2

Leon_EN.book Seite 216 Mittwoch, 1. September 2010 6:16 18

Page 221 of 309

Checking and refilling levels219

Safety First

Operating Instructions

Practical Tips

Technical Specifications

The safety of the LPG system guarantees operation without risk. The following

safety measures have been adopted:

•The LPG tank has a solenoid valve which closes automatically when the

engine is switched off (ignition off) or when running on petrol.•A solenoid type main valve disconnects the supply of gas to the engine

compartment when the engine is switched off or running on petrol.•A safety valve in the LPG tank with pipes to the outside prevents the gas

from entering the vehicle interior.•All anchorage points and materials have been designed to ensure the

maximum possible levels of safety.

The condition of the LPG system should be checked regularly to guarantee

safe driving conditions ⇒ . These checks are included in the Maintenance

Programme.WARNING

•If there is a smell of gas or a suspected leak, stop the vehicle immedi-

ately and switch off the ignition. Open the doors to ventilate the vehicle. Do

not carry on driving! Take the vehicle to a specialised workshop and have

the fault repaired.•Immediately extinguish any cigarettes and remove from the vehicle any

objects which might produce a spark or cause a fire, and switch off imme-

diately if gas is smelt or a leak is detected.•LGP tanks are subject to pressure and must be checked regularly. The

owner of the vehicle must check that these services are performed

correctly.•When parking the vehicle in a closed area (for example in a garage),

make sure that there is adequate ventilation, either natural or mechanical,

to neutralise the LPG in the event of a leak.

Note

For any fault in the LGP system, please refer to the SEAT web page, which lists

the workshops authorised to repair these faults.PetrolPetrol types

The recommended fuel types are listed on a sticker inside the

fuel tank flap.Only unleaded petrol conforming to standard DIN EN 228 may be used for

vehicles with catalytic converters (EN = “European Standard”).

Fuel types are differentiated by the octane rating, e.g: 91, 95, 98 RON (RON

= “Research Octane Number”, unit for determining the knock resistance of

petrol). You may use petrol with a higher octane number than the one recom-

mended for your engine. However, this has no advantage in terms of fuel

consumption and engine power.

The correct fuel type for your vehicle is given in the technical table for the

engine, in the Technical Data section.

Caution

•Petrol with standard EN 228 may be mixed with small quantities of

ethanol. However, the so-called “bioethanol fuels” available at commercial

establishments with reference E50 or E85, which contain a high percentage

of ethanol, may not be used, as they will damage the fuel system.•Even one tankful of leaded fuel would permanently impair the efficiency

of the catalytic converter.

Leon_EN.book Seite 219 Mittwoch, 1. September 2010 6:16 18

Page 222 of 309

Checking and refilling levels

220•High engine speed and full throttle can damage the engine when using

petrol with an octane rating lower than the correct grade for the engine.For the sake of the environment

Just one full tank of leaded fuel would seriously impair the efficiency of the

catalytic converter.Petrol additives

Petrol additives improve the quality of the petrol.The quality of the petrol influences the performance, power and life of the

engine. For this reason, you should use good quality petrol containing addi-

tives. These additives will help to prevent corrosion, keep the fuel system

clean and prevent deposits from building up in the engine.

If good quality petrol with additives is not available or engine problems occur,

the required additives must be added during refuelling.DieselDiesel*Diesel fuel must conform to DIN EN 590 (EN = “European Standard”). It must

have a cetane number (CN) of at least 51. The cetane number indicates the

ignition quality of the diesel fuel.

Notes on refuelling ⇒page 214.

Biodiesel*

Caution

•Your vehicle is not designed to use biodiesel fuel. Never, under any

circumstances refuel with biodiesel. The use of biodiesel fuel could damage

the engine and the fuel system. The addition of biodiesel to diesel fuel by the

diesel manufacturer in accordance with standard EN 590 or DIN 51628 is

authorised and will not cause damage to the engine or the fuel system.•The diesel engine has been designed to be used exclusively with diesel

fu el con for m i ng to sta nda rd E N 59 0 . Never refuel or use petrol, kerosene, fuel

oil or any other type of fuel. If you accidentally fill up the vehicle with the

wrong type of fuel, do not start the engine. Seek assistance from specialised

personnel. The composition of these fuels may severely damage the fuel

system and the engine.Winter driving

Diesel can thicken in winter.Winter diesel

When using summer diesel fuel, difficulties may be experienced at tempera-

tures below 0 °C because the fuel thickens due to wax separation. Therefore,

winter diesel fuel is available in some countries during the cold months. It can

be used at temperatures as low as -22 °C.

In countries with different climatic conditions the diesel fuel generally sold

has different temperature characteristics. Check with an Authorised Service

Centre or filling stations in the country concerned regarding the type of diesel

fuels available.

Leon_EN.book Seite 220 Mittwoch, 1. September 2010 6:16 18

Page 223 of 309

Checking and refilling levels221

Safety First

Operating Instructions

Practical Tips

Technical Specifications

Filter pre-heater

Your vehicle is fitted with a fuel filter glow plug system, making it well

equipped for operation in winter. This ensures that the fuel system remains

operational to approx. -24 °C, provided you use winter diesel which is safe to

-15 °C.

However, if the fuel has waxed to such an extent that the engine will not start

at temperatures of under -24 °C, simply place the vehicle in a warm place for

a while.

Caution

Do not mix fuel additives (thinners or similar products) with diesel fuel.Working in the engine compartmentSafety instructions on workin

g in the engine compartment

Any work carried out in the engine compartment or on the

engine must be carried out cautiously.Before starting any work on the engine or in the engine compart-

ment:

1. Switch off the engine and remove the key from the ignition.

2. Apply the handbrake.

3. Move the gear lever to neutral or the selector lever to position P.

4. Wait for the engine to cool down.

5. Keep children away from the vehicle. 6. Raise the bonnet

⇒page 223.

You should not do any work in the engine compartment unless you know

exactly how to carry out the jobs and have the correct tools! Have the work

carried out by a specialised workshop if you are uncertain.

All service fluids and consumables, e.g. coolant, engine oil, spark plugs and

batteries, are being constantly developed. SEAT provides a constant flow of

information to the Authorised Service Centres concerning modifications. For

this reason, we recommend you to have service fluids and consumables

replaced by an Authorised Service Centre. Please observe the relevant

instructions ⇒page 212. The engine compartment of the vehicle is a

hazardous area ⇒.

WARNING

All work on the engine or in the engine compartment, e.g. checking and

refilling fluids, involves a risk of injury and scalding as well as the risk of

accident or fire.•Never open the bonnet if you see steam, smoke or coolant escaping

from the engine compartment. Otherwise, there is a risk of sustaining

burns. Wait until no more steam or coolant is emitted, then allow the

engine to cool before carefully opening the bonnet.•Switch off the engine and remove the key from the ignition.•Apply the handbrake and move the gear lever to neutral or selector

lever to position P.•Keep children away from the vehicle.•Never touch hot engine parts. There is a risk of burns.•Never spill liquids on a hot engine or on a hot exhaust gas system. This

is a fire hazard.•Avoid causing short-circuits in the electrical system, particularly at the

points where the jump leads are attached ⇒page 268. The battery could

explode.

Leon_EN.book Seite 221 Mittwoch, 1. September 2010 6:16 18

Page 224 of 309

Checking and refilling levels

222•Never touch the radiator fan. It is temperature controlled and could

start automatically, even when the engine has been switched off and the

key removed from the ignition!•Do not unscrew the cap on the coolant reservoir when the engine is hot.

If the coolant is hot, the cooling system will be pressurised!•Protect face, hands and arms by covering the cap with a large, thick

cloth to protect against escaping coolant and steam.•Al wa ys m ake s u re yo u ha ve n o t l e f t a ny o bj e c t s , s u ch as cl e an i n g cl o t h s

and tools, in the engine compartment.•If you have to work underneath the vehicle, you must use suitable

stands additionally to support the vehicle, there is a risk of accident!. A

hydraulic jack is insufficient for securing the vehicle and there is a risk of

injury.•If any work has to be performed when the engine is started or with the

engine running, there is an additional, potentially fatal, safety risk from the

rotating parts, such as the drive belts, alternator, radiator fan, etc., and

from the high-voltage ignition system. You should also observe the

following points:

−Never touch the electrical wiring of the ignition system.

− Ensure that jewellery, loose clothing and long hair do not get

trapped in rotating engine parts. Da nger of death. Before starting any

work remove jewellery, tie back and cover hair, and wear tight-fitting

clothes.

− Never accelerate with a gear engaged without taking the necessary

precautions. The vehicle could move, even if the handbrake is applied.

Danger of death.•If work has to be carried out on the fuel system or on electrical compo-

nents, you must observe the following safety notes in addition to the above

warnings:

−Always disconnect the battery. The vehicle must be unlocked when

this is done, otherwise the alarm will be triggered. −

Do not smoke.

− Never work near naked flames.

− Always have a fire extinguisher on hand.

Caution

When topping up service fluids, make sure not to mistake them. Using the

wrong fluids could cause serious malfunctions and engine damage!

For the sake of the environment

Service fluids leaks are harmful to the environment. For this reason you

should make regular checks on the grou nd underneath your vehicle. If you

find spots of oil or other fluids, have your vehicle inspected at a specialised

workshop.

WARNING (continued)

WARNING (continued)

Leon_EN.book Seite 222 Mittwoch, 1. September 2010 6:16 18

Page 237 of 309

Checking and refilling levels235

Safety First

Operating Instructions

Practical Tips

Technical Specifications

charge. Never short the battery terminals. High-energy sparks can cause

injury.

•A highly explosive mixture of gases is released when the battery is

under charge. The batteries should be charged in a well-ventilated room

only.•Keep children away from acid and batteries.•Before working on the electrical system, you must switch off the

engine, the ignition and all consumers. The negative cable on the battery

must be disconnected. When a light bulb is changed, you need only switch

off the light.•Deactivate the anti-theft alarm by unlocking the vehicle before you

disconnect the battery! The alarm will otherwise be triggered.•When disconnecting the battery from the vehicle electrical system,

disconnect first the negative cable and then the positive cable.•Switch off all electrical consumers before reconnecting the battery.

Reconnect first the positive cable and then the negative cable. Never

reverse the polarity of the connections. This could cause an electrical fire.•Never charge a frozen battery, or one which has thawed. This could

result in explosions and chemical burns. Always replace a battery which

has frozen. A flat battery can freeze at temperatures around 0 °C.•Ensure that the vent hose is always connected to the battery.•Never use a defective battery. This could cause an explosion. Replace a

damaged battery immediately.Caution

•Never disconnect the battery if the ignition is switched on or if the engine

is running. This could damage the electrical system or electronic compo-

nents.•Do not expose the battery to direct sunlight over a long period of time, as

the intense ultraviolet radiation can damage the battery housing.

•If the vehicle is left standing in cold conditions for a long period, protect

the battery from freezing. If it freezes it will be damaged.Checking the electrolyte level

The electrolyte level should be checked regularly in high-

mileage vehicles, in hot countries and in older batteries.– Open the engine bonnet and the battery cover ⇒ in “Safety

instructions on working in the engine compartment” on

page 221 ⇒ in “Warnings on handling the battery” on

page 234.

– Check the colour display in the "magic eye" on the top of the battery.

– If there are air bubbles in the window, tap the window gently until they disperse.The position of the battery is shown in the corresponding engine compart-

ment diagram ⇒page 277.

The “magic eye” indicator, located on the top of the battery changes colour,

depending on the charge state and electrolyte level of the battery.

There are two different colours:•Black: correct charge status.•Transparent/clear yellow: the battery must be replaced. Contact a special-

ised workshop.

WARNING (continued)

Leon_EN.book Seite 235 Mittwoch, 1. September 2010 6:16 18

Page 257 of 309

If and when255

Safety First

Operating Instructions

Practical Tips

Technical Specifications

Fuse cover underneath the steering wheel

– Switch off the ignition and the component concerned.

– Identify the fuse corresponding to the damaged electric

consumer ⇒page 257.

– Take the plastic clip from inside the fuse cover, fit it onto the blown fuse and pull the fuse out.

– Replace the blown fuse (which will have a melted metal strip) with a new fuse of the same ampere rating.

Fuse cover in engine compartment

– Switch off the ignition and its failed electrical component.

– Remove the fuse cover in the engine compartment by pressing the tabs towards the centre of the cover ⇒page 254, fig. 162 .

– Identify the fuse for the affected component ⇒ page 257.

– Take the plastic clip from inside the fuse cover (at left-hand end of the dash panel), fit it onto the blown fuse and pull the fuse out.

– Replace the blown fuse (which will have a melted metal strip) with a new fuse of the same ampere rating.

– Carefully fit the fuse cover back on to ensure no water can enter the fuse box.The individual electrical circuits are protected by fuses. The fuses are located

behind a cover at the left-hand end of the dash panel and on the left-hand

side of the engine compartment. The electric windows are protected by circuit breakers

. These reset automat-

ically after a few seconds when the overload (caused for example by frozen

windows) has been corrected.

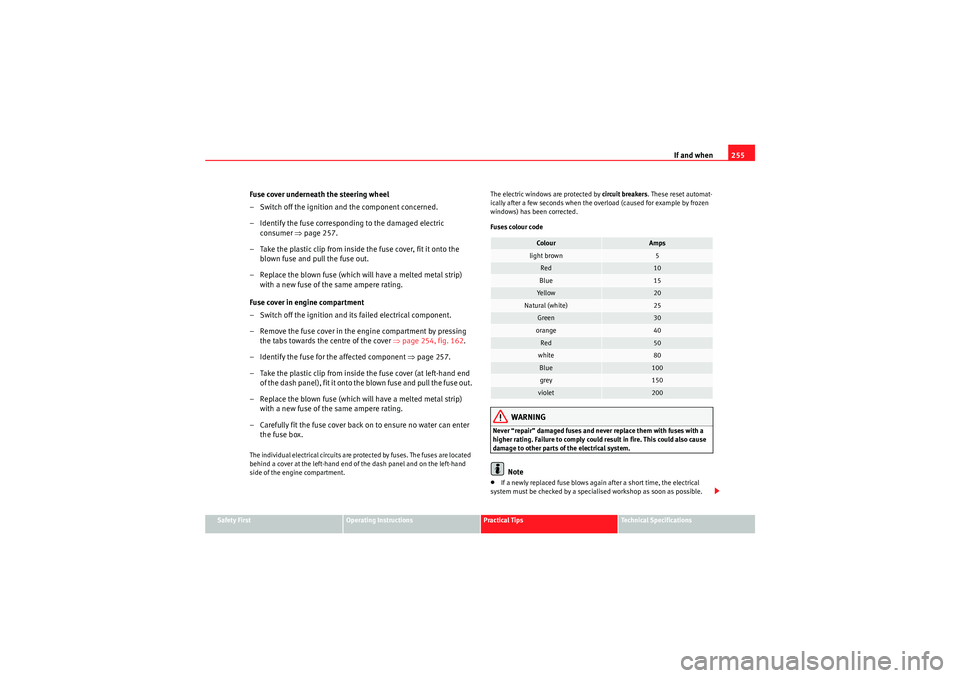

Fuses colour code

WARNING

Never “repair” damaged fuses and never replace them with fuses with a

higher rating. Failure to comply could result in fire. This could also cause

damage to other parts of the electrical system.

Note

•If a newly replaced fuse blows again after a short time, the electrical

system must be checked by a specialised workshop as soon as possible.

Colour

Amps

light brown

5

Red

10

Blue

15

Ye l l o w

20

Natural (white)

25

Green

30

orange

40

Red

50

white

80

Blue

100

grey

150

violet

200

Leon_EN.book Seite 255 Mittwoch, 1. September 2010 6:16 18

Page 260 of 309

If and when

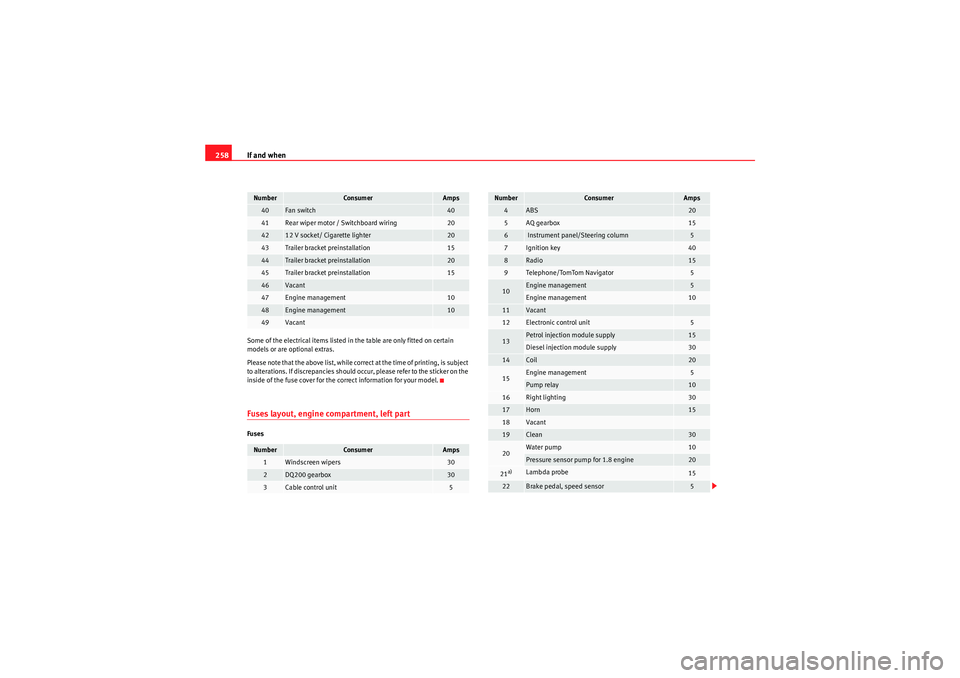

258Some of the electrical items listed in the table are only fitted on certain

models or are optional extras.

Please note that the above list, while correct at the time of printing, is subject

to alterations. If discrepancies should occur, please refer to the sticker on the

inside of the fuse cover for the correct information for your model.Fuses layout, engine compartment, left partFuses

40

Fan switch

40

41

Rear wiper motor / Switchboard wiring

20

42

12 V socket/ Cigarette lighter

20

43

Trailer bracket preinstallation

15

44

Trailer bracket preinstallation

20

45

Trailer bracket preinstallation

15

46

Vacant

47

Engine management

10

48

Engine management

10

49

Vacant

Number

Consumer

Amps

1

Windscreen wipers

30

2

DQ200 gearbox

30

3

Cable control unit

5

Number

Consumer

Amps

4

ABS

20

5

AQ gearbox

15

6

Instrument panel/Steering column

5

7

Ignition key

40

8

Radio

15

9

Telephone/TomTom Navigator

5

10

Engine management

5

Engine management

10

11

Vacant

12

Electronic control unit

5

13

Petrol injection module supply

15

Diesel injection module supply

30

14

Coil

20

15

Engine management

5

Pump relay

10

16

Right lighting

30

17

Horn

15

18

Vacant

19

Clean

30

20

Water pump

10

Pressure sensor pump for 1.8 engine

20

21a)

Lambda probe

15

22

Brake pedal, speed sensor

5

Number

Consumer

Amps

Leon_EN.book Seite 258 Mittwoch, 1. September 2010 6:16 18

Page 261 of 309

If and when259

Safety First

Operating Instructions

Practical Tips

Technical Specifications

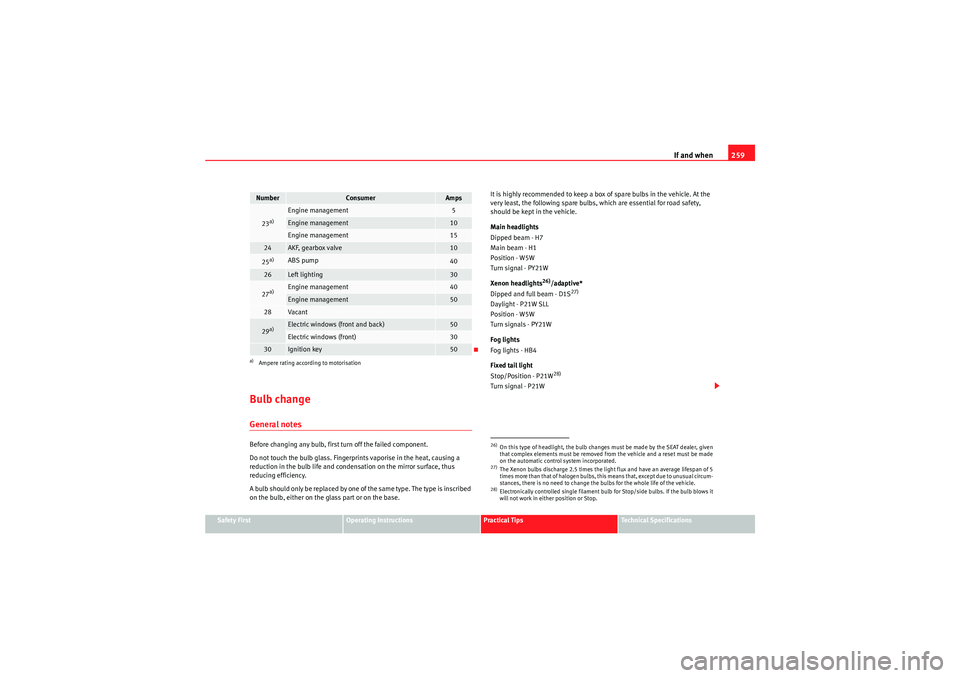

Bulb changeGeneral notesBefore changing any bulb, first turn off the failed component.

Do not touch the bulb glass. Fingerprints vaporise in the heat, causing a

reduction in the bulb life and condensation on the mirror surface, thus

reducing efficiency.

A bulb should only be replaced by one of the sam e type. The type is inscribed

on the bulb, either on the glass part or on the base. It is highly recommended to keep a box of spare bulbs in the vehicle. At the

very least, the following spare bulbs, which are essential for road safety,

should be kept in the vehicle.

Main headlights

Dipped beam - H7

Main beam - H1

Position - W5W

Turn signal - PY21W

Xenon headlights

26)/adaptive*

Dipped and full beam - D1S

27)

Daylight - P21W SLL

Position - W5W

Turn signals - PY21W

Fog lights

Fog lights - HB4

Fixed tail light

Stop/Position - P21W

28)

Turn signal - P21W

23a)

Engine management

5

Engine management

10

Engine management

15

24

AKF, gearbox valve

10

25a)

ABS pump

40

26

Left lighting

30

27a)

Engine management

40

Engine management

50

28

Vaca n t

29a)

Electric windows (front and back)

50

Electric windows (front)

30

30

Ignition key

50

a)Ampere rating according to motorisationNumber

Consumer

Amps

26)On this type of headlight, the bulb changes must be made by the SEAT dealer, given

that complex elements must be removed from the vehicle and a reset must be made

on the automatic control system incorporated.27)The Xenon bulbs discharge 2.5 times the light flux and have an average lifespan of 5

times more than that of halogen bulbs, this means that, except due to unusual circum-

stances, there is no need to change the bulbs for the whole life of the vehicle.28)Electronically controlled single filament bulb for Stop/side bulbs. If the bulb blows it

will not work in either position or Stop.

Leon_EN.book Seite 259 Mittwoch, 1. September 2010 6:16 18

Page 270 of 309

If and when

268How to jump start: descriptionJump lead terminal connections

1. Switch off the ignition of both vehicles ⇒. 2. Connect one end of the

red jump lead to the positive terminal

⇒ fig. 181 or ⇒fig. 182 of the vehicle with the flat

battery .

3. Connect the other end of the red jump lead to the positive

terminal in the vehicle providing assistance .

4. On vehicles with no Start-Stop system , connect one end of the

black jump lead to the negative terminal in the vehicle

providing assistance ⇒fig. 181 .

5. On vehicles with the Start-Stop system , connect one end of the

black jump lead to a suitable ground terminal, to a solid metal

part bolted to the engine block or to the engine block itself

⇒ fig. 182 .

6. Connect the other end of the black jump lead to a solid metal

component bolted to the engine block or to the engine block

itself of the vehicle with the flat battery. Do not connect it to a

point near the battery .

7. Position the leads in such a way that they cannot come into contact with any moving parts in the engine compartment.

Starting

8. Start the engine of the vehicle with the boosting battery and let it run at idling speed.

9. Start the engine of the vehicle with the flat battery and wait one or two minutes until the engine is running.

Removing the jump leads

10. Before you remove the jump leads, switch off the headlights (if they are switched on).

Fig. 181 Diagram for

connecting jump leads if

the vehicle providing

assistance the current is

not fitted with the Start-

Stop system: flat battery and battery providing

current .AA

AB

Fig. 182 Diagram for

connecting jump leads if

the vehicle providing

assistance is fitted with

the Start-Stop system:

flat battery and

battery providing current .

AA

AB

A+

A+

AAA+

AB

A-

AB

AX

AX

AA

Leon_EN.book Seite 268 Mittwoch, 1. September 2010 6:16 18