light Seat Leon 5D 2011 Owner's manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2011, Model line: Leon 5D, Model: Seat Leon 5D 2011Pages: 302, PDF Size: 4.17 MB

Page 256 of 302

254If and when

Bulb change

General notes

Before changing any bulb, first turn off the failed component.

Do not touch the bulb glass. Fingerprints vaporise in the heat, causing a re-

duction in the bulb life and condensation on the mirror surface, thus reduc-

ing efficiency.

A bulb should only be replaced by one of the same type. The type is inscri-

bed on the bulb, either on the glass part or on the base.

It is highly recommended to keep a box of spare bulbs in the vehicle. At the

very least, the following spare bulbs, which are essential for road safety,

should be kept in the vehicle.

Main headlights

● Dipped beam – H7

● Main beam – H1

● Side light – W5W

● Turn signal – PY21W Xenon headlights

1)

/adaptive*

● Dipped and main beam – D1S 2)

● DRL – P21W SLL

● Side light – W5W

● Turn signals – PY21W

Fog lights

● Fog light – HB4

Fixed tail light

● Stop/Side light – P21W 3)

or LED module 4)

● Turn signal – P21W

Mobile tailgate light

● Fog light (driver side) – P21W

● Reverse (passenger side) – P21W

● Side light – W5W or LED module 4)

Side turn signal

● Turn signal repeater – W5W

1)

On this type of headlight, the bulb changes must be made by the SEAT dealer, given that

complex elements must be removed from the vehicle and a reset must be made on the

automatic control system incorporated.

2) The Xenon bulbs discharge 2.5 times the light flux and have an average lifespan of 5 times

more than that of halogen bulbs, this means that, except due to unusual circumstances,

there is no need to change the bulbs for the whole life of the vehicle.

3) Electronically controlled single filament bulb for Stop/side bulbs. If the bulb blows it will

not work in either position or Stop.

4) Only in the LED light models. The LED modules cannot be replaced. The other lights, turn

signal light, fog light and reverse light can be replaced. If the warning lamp for the brake

light or side light (LED lights) lights up, the tail light assembly should be replaced. The fail-

ure of the lamp is only shown when the LED function goes out completely. Sometimes, a

LED will stop working, without displaying the warning as the function continues to operate.

Page 257 of 302

255

If and when

Number plate light

● Number plate light – C5W

Glove compartment lamp

● Glove compartment light – W5W

Note

● Depending on weather conditions (cold or wet), the front lights, the fog

lights, the tail lights and the turn signals may be temporarily misted. This

has no influence on the useful life of the lighting system. By switching on

the lights, the area through which the beam of light is projected will quickly

be demisted. However, the edges may continue to be misted.

● Please check at regular intervals that all lighting (especially the exterior

lighting) on your vehicle is functioning properly. This is not only in the inter-

est of your own safety, but also that of all other road users.

● Due to the difficulty in accessing some of the bulbs, any replacement

work should be done by a SEAT dealer. However, the following is a descrip-

tion of how to change the lamps except for the fog lights* and interior

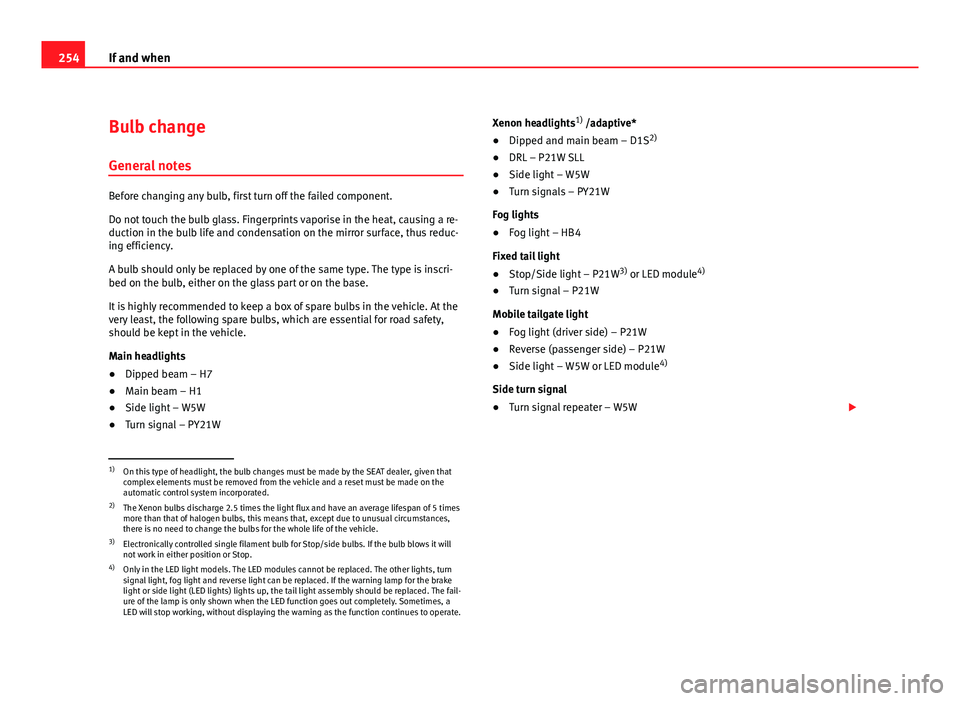

lamps. Main headlight bulbs

Fig. 162 Main headlight

bulbs

Turn signal

Dipped beam headlights

Main beam headlights

Side lights

A

BCD

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 258 of 302

256If and when

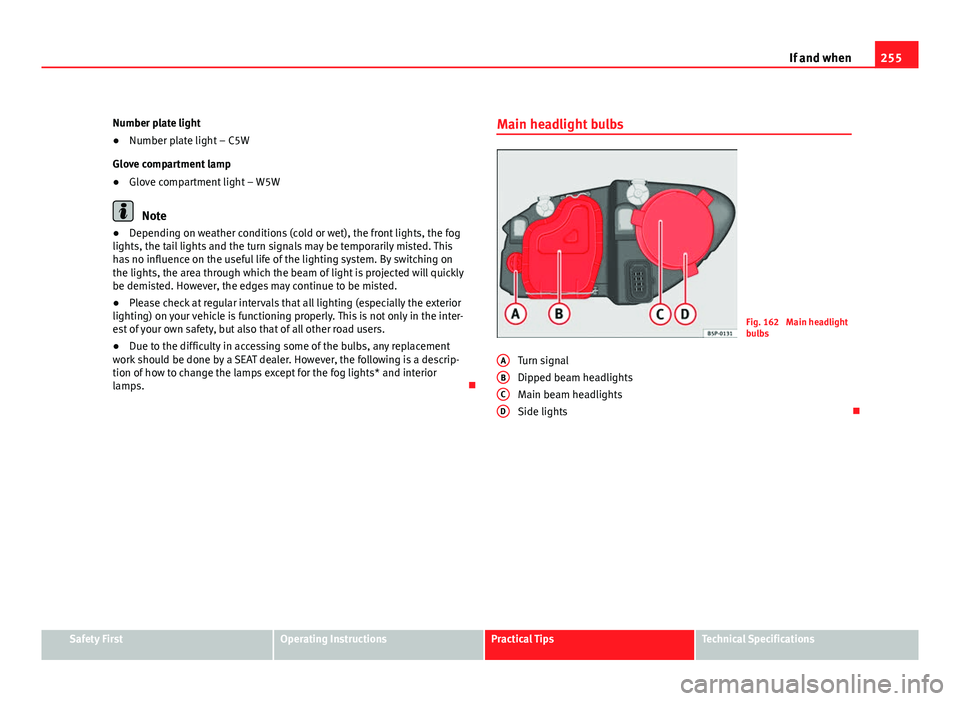

Turn signal bulbs

Fig. 163 Turn signal

– Raise the bonnet.

– Rotate the bulb holder ⇒ fig. 163 A

to the left and pull.

– Remove the bulb by pressing on the bulb holder and rotating at

the same time to the left.

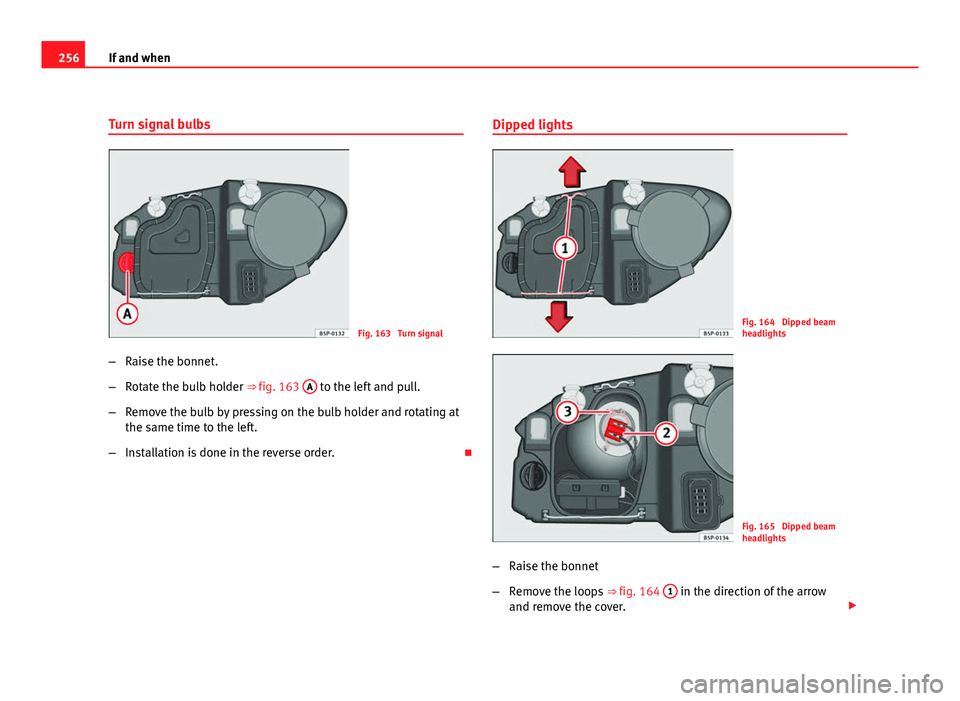

– Installation is done in the reverse order. Dipped lights

Fig. 164 Dipped beam

headlights

Fig. 165 Dipped beam

headlights

– Raise the bonnet

– Remove the loops ⇒ fig. 164 1

in the direction of the arrow

and remove the cover.

Page 259 of 302

257

If and when

– Remove the connector ⇒ fig. 165 2

from the bulb.

– Unclip the retainer spring ⇒ fig. 165 3

pressing inwards to the

right.

– Extract the bulb and fit the replacement so that the rim of the

attachment plate is on the reflector cut-out.

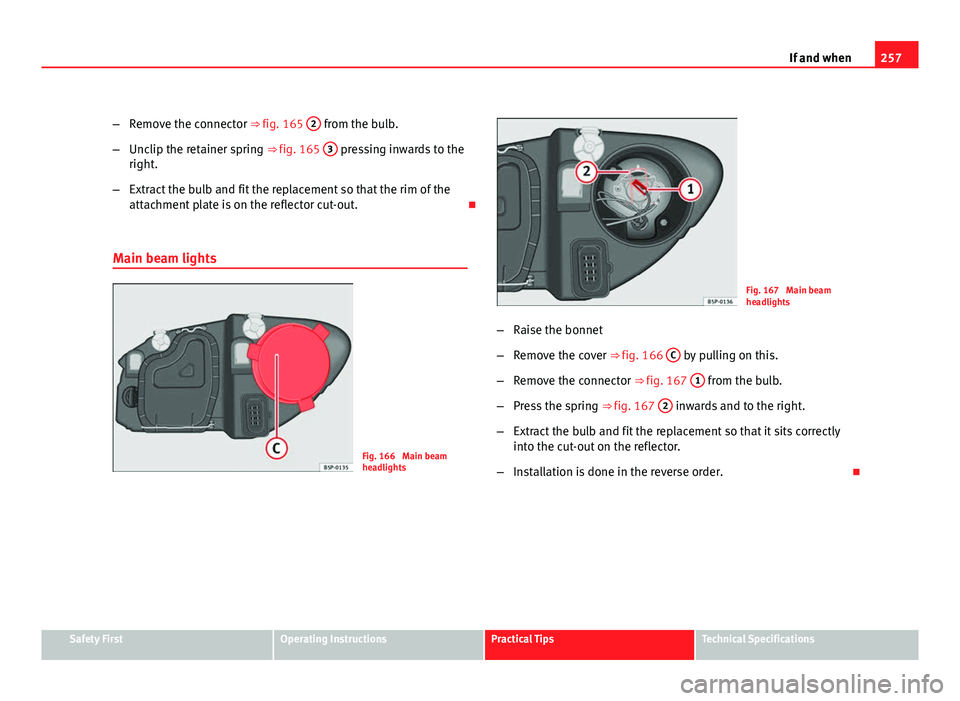

Main beam lights

Fig. 166 Main beam

headlights

Fig. 167 Main beam

headlights

– Raise the bonnet

– Remove the cover ⇒ fig. 166 C

by pulling on this.

– Remove the connector ⇒ fig. 167 1

from the bulb.

– Press the spring ⇒ fig. 167 2

inwards and to the right.

– Extract the bulb and fit the replacement so that it sits correctly

into the cut-out on the reflector.

– Installation is done in the reverse order.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 260 of 302

258If and when

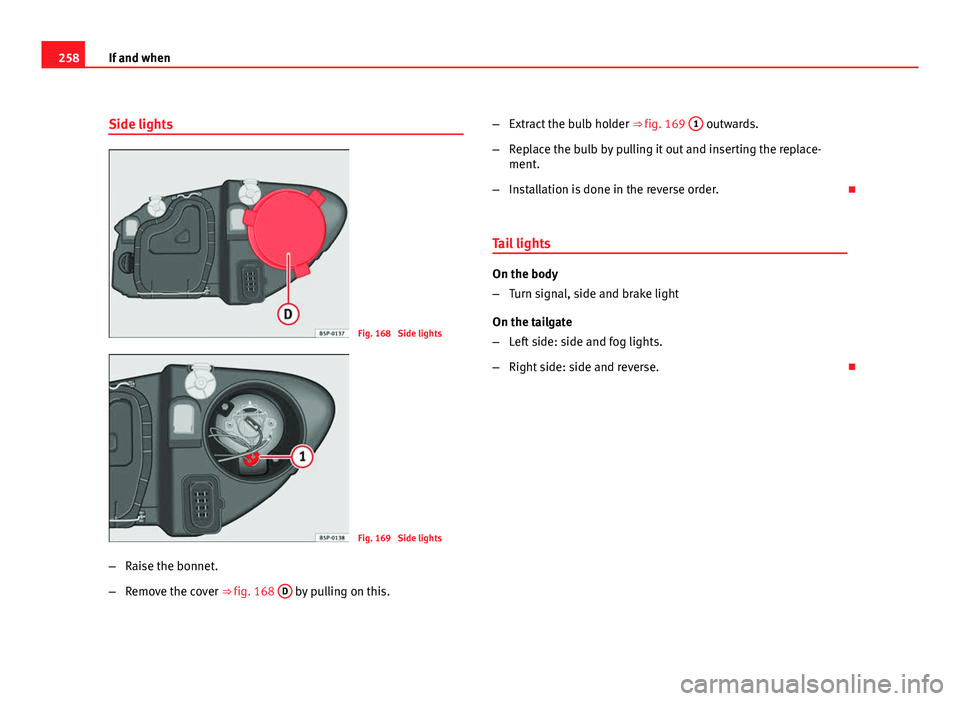

Side lights

Fig. 168 Side lights

Fig. 169 Side lights

– Raise the bonnet.

– Remove the cover ⇒ fig. 168 D

by pulling on this. –

Extract the bulb holder ⇒ fig. 169 1

outwards.

– Replace the bulb by pulling it out and inserting the replace-

ment.

– Installation is done in the reverse order.

Tail lights

On the body

– Turn signal, side and brake light

On the tailgate

– Left side: side and fog lights.

– Right side: side and reverse.

Page 261 of 302

259

If and when

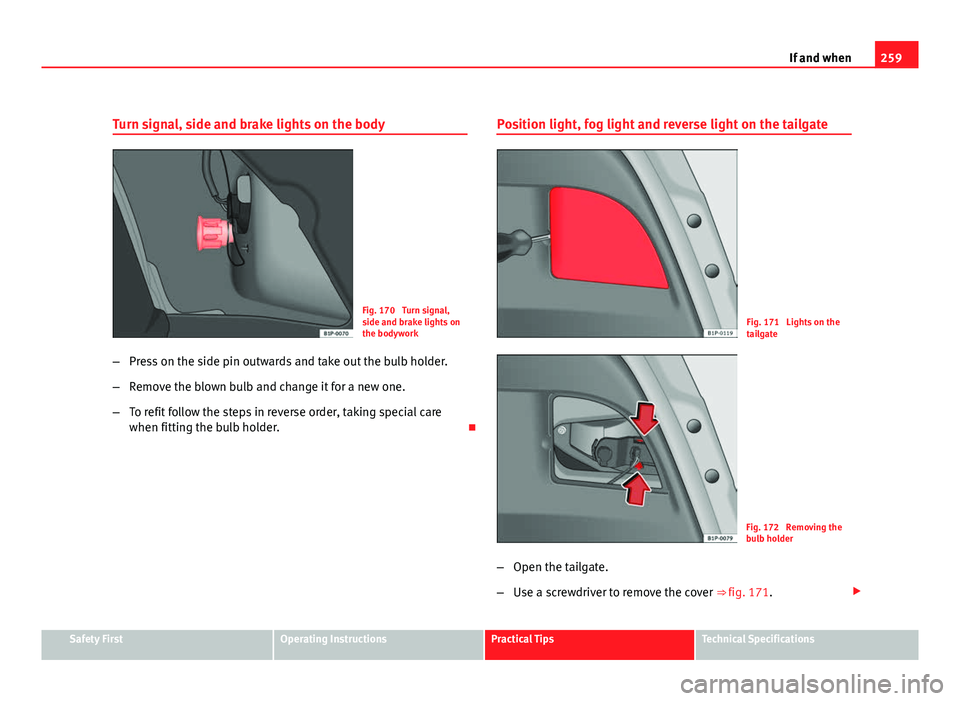

Turn signal, side and brake lights on the body

Fig. 170 Turn signal,

side and brake lights on

the bodywork

– Press on the side pin outwards and take out the bulb holder.

– Remove the blown bulb and change it for a new one.

– To refit follow the steps in reverse order, taking special care

when fitting the bulb holder. Position light, fog light and reverse light on the tailgateFig. 171 Lights on the

tailgate

Fig. 172 Removing the

bulb holder

– Open the tailgate.

– Use a screwdriver to remove the cover ⇒ fig. 171.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 262 of 302

260If and when

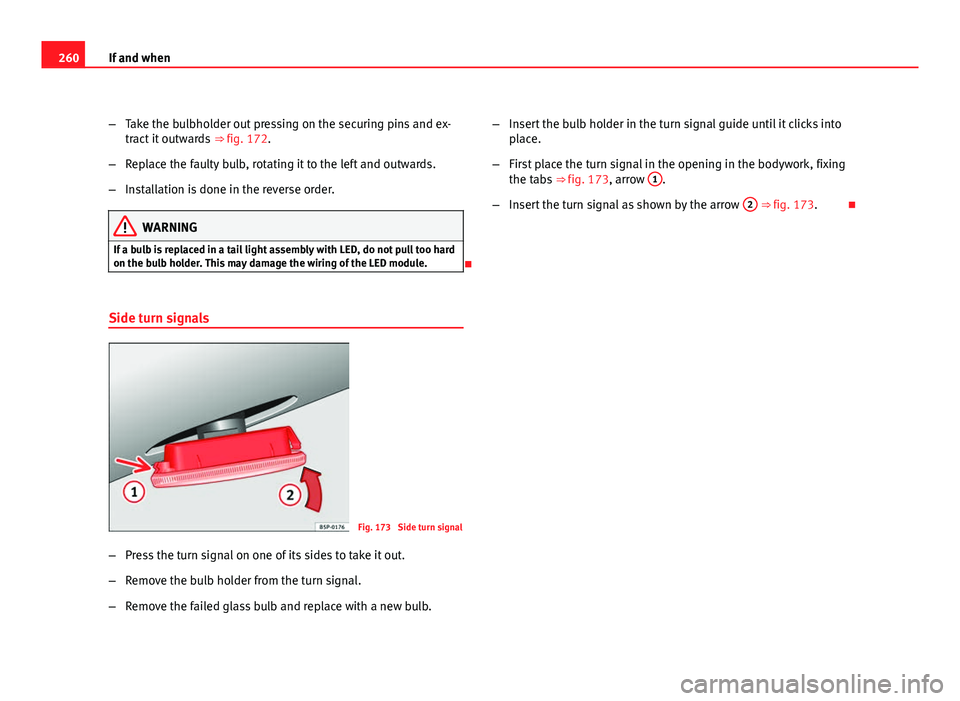

–Take the bulbholder out pressing on the securing pins and ex-

tract it outwards ⇒ fig. 172.

– Replace the faulty bulb, rotating it to the left and outwards.

– Installation is done in the reverse order.

WARNING

If a bulb is replaced in a tail light assembly with LED, do not pull too hard

on the bulb holder. This may damage the wiring of the LED module.

Side turn signals

Fig. 173 Side turn signal

– Press the turn signal on one of its sides to take it out.

– Remove the bulb holder from the turn signal.

– Remove the failed glass bulb and replace with a new bulb. –

Insert the bulb holder in the turn signal guide until it clicks into

place.

– First place the turn signal in the opening in the bodywork, fixing

the tabs ⇒ fig. 173, arrow 1

.

– Insert the turn signal as shown by the arrow 2

⇒ fig. 173.

Page 263 of 302

261

If and when

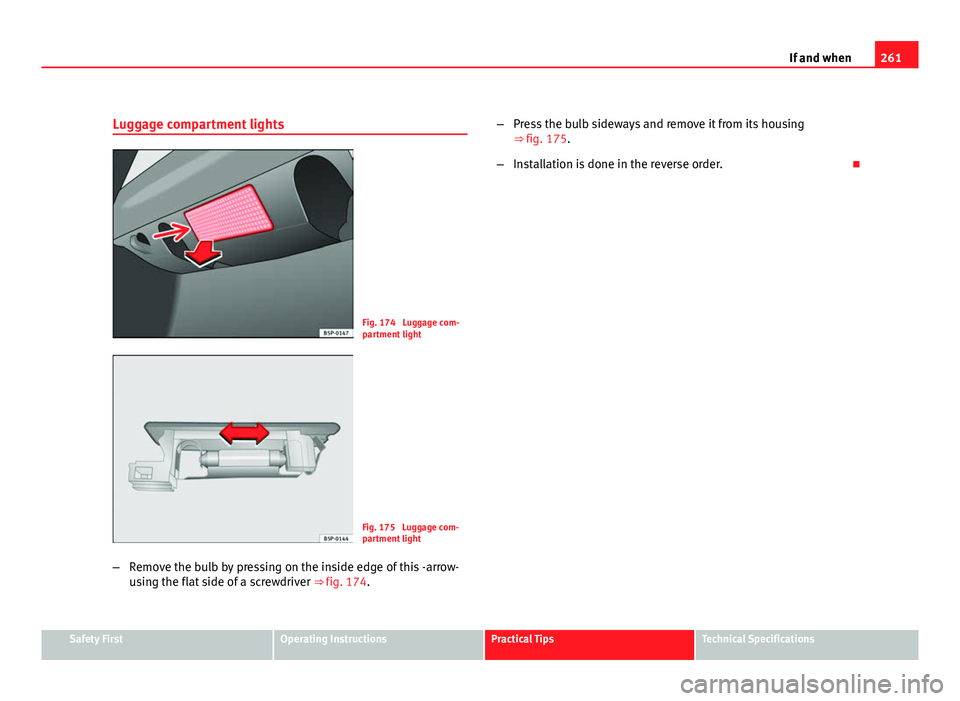

Luggage compartment lights

Fig. 174 Luggage com-

partment light

Fig. 175 Luggage com-

partment light

– Remove the bulb by pressing on the inside edge of this -arrow-

using the flat side of a screwdriver ⇒ fig. 174.–

Press the bulb sideways and remove it from its housing

⇒ fig. 175.

– Installation is done in the reverse order.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 264 of 302

262If and when

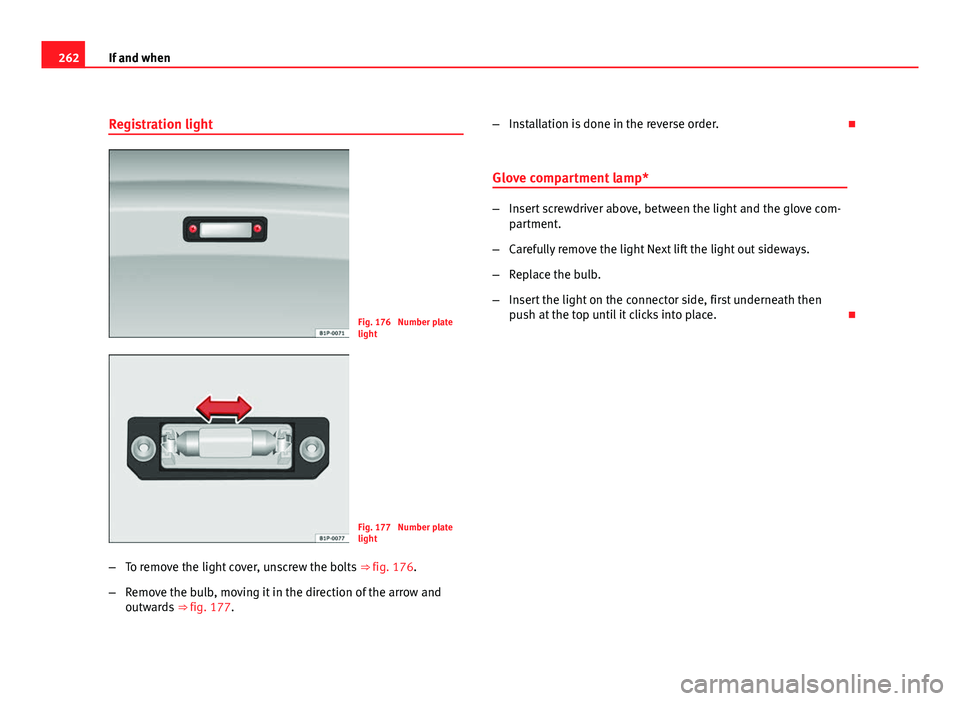

Registration light

Fig. 176 Number plate

light

Fig. 177 Number plate

light

– To remove the light cover, unscrew the bolts ⇒ fig. 176.

– Remove the bulb, moving it in the direction of the arrow and

outwards ⇒ fig. 177. –

Installation is done in the reverse order.

Glove compartment lamp*

– Insert screwdriver above, between the light and the glove com-

partment.

– Carefully remove the light Next lift the light out sideways.

– Replace the bulb.

– Insert the light on the connector side, first underneath then

push at the top until it clicks into place.

Page 265 of 302

263

If and when

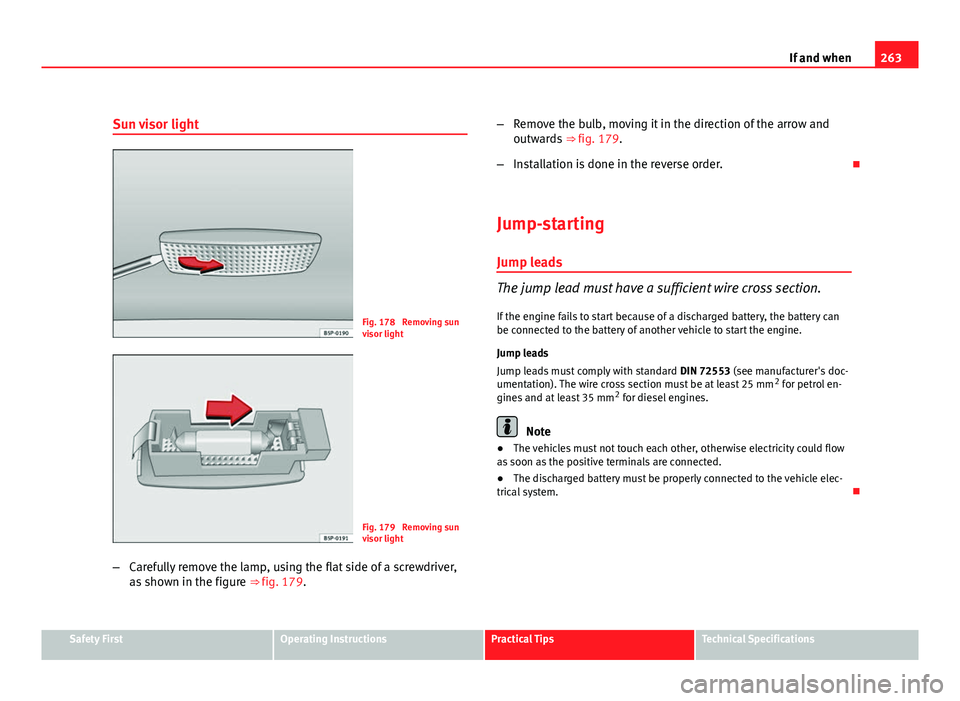

Sun visor light

Fig. 178 Removing sun

visor light

Fig. 179 Removing sun

visor light

– Carefully remove the lamp, using the flat side of a screwdriver,

as shown in the figure ⇒ fig. 179. –

Remove the bulb, moving it in the direction of the arrow and

outwards ⇒ fig. 179.

– Installation is done in the reverse order.

Jump-starting

Jump leads

The jump lead must have a sufficient wire cross section. If the engine fails to start because of a discharged battery, the battery can

be connected to the battery of another vehicle to start the engine.

Jump leads

Jump leads must comply with standard DIN 72553 (see manufacturer's doc-

umentation). The wire cross section must be at least 25 mm 2

for petrol en-

gines and at least 35 mm 2

for diesel engines.

Note

● The vehicles must not touch each other, otherwise electricity could flow

as soon as the positive terminals are connected.

● The discharged battery must be properly connected to the vehicle elec-

trical system.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications