light Seat Leon 5D 2015 User Guide

[x] Cancel search | Manufacturer: SEAT, Model Year: 2015, Model line: Leon 5D, Model: Seat Leon 5D 2015Pages: 308, PDF Size: 5.93 MB

Page 48 of 308

The essentials

To switch a specific function on, press the ap-

pr opri

at

e button. Press the button again to

switch off the function. The LED on each control lights up to indicate

that the r

espective function of a control has

been switched on.

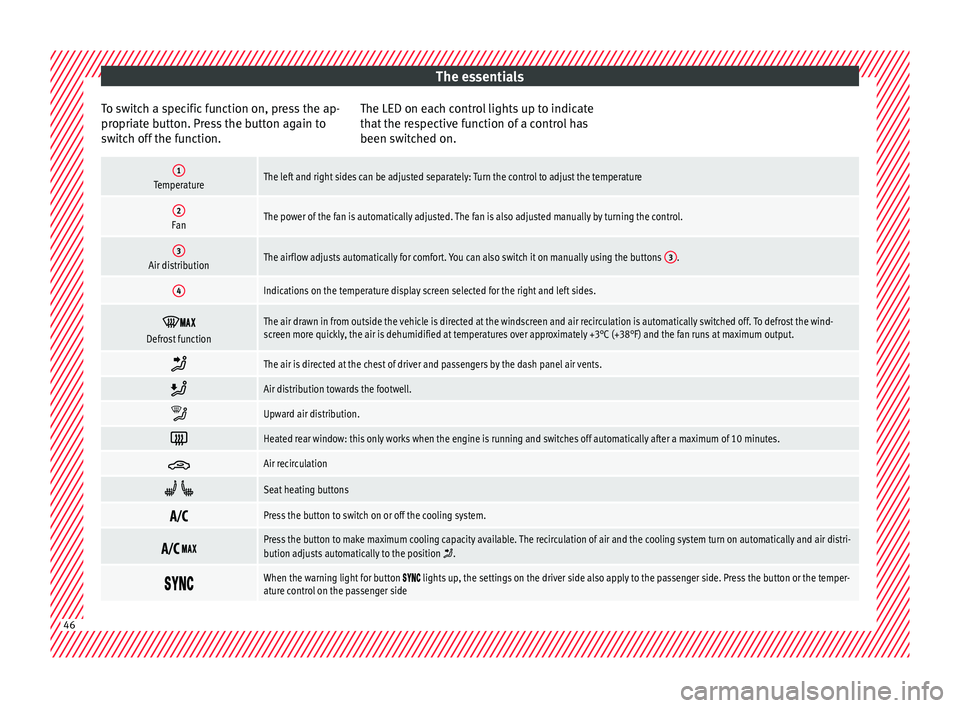

1TemperatureThe left and right sides can be adjusted separately: Turn the control to adjust the temperature

2FanThe power of the fan is automatically adjusted. The fan is also adjusted manually by turning the control.

3Air distributionThe airflow adjusts automatically for comfort. You can also switch it on manually using the buttons 3.

4Indications on the temperature display screen selected for the right and left sides.

Defrost functionThe air drawn in from outside the vehicle is directed at the windscreen and air recirculation is automatically switched off. To defrost the wind-

screen more quickly, the air is dehumidified at temperatures over approximately +3°C (+38°F) and the fan runs at maximum output.

The air is directed at the chest of driver and passengers by the dash panel air vents.

Air distribution towards the footwell.

Upward air distribution.

Heated rear window: this only works when the engine is running and switches off automatically after a maximum of 10 minutes.

Air recirculation

Seat heating buttons

Press the button to switch on or off the cooling system.

Press the button to make maximum cooling capacity available. The recirculation of air and the cooling system turn on automatically and air distri-

bution adjusts automatically to the position .

When the warning light for button lights up, the settings on the driver side also apply to the passenger side. Press the button or the temper-

ature control on the passenger side 46

Page 49 of 308

The essentials

Automatic adjustment of temperature, fan, and air distribution. Press the button: the warning lamp on the button will light up .

Press the configuration button : the air conditioning operation menu will be displayed on the Easy Connect system screen.

Switching offTurn the blower control to the position or press the button.

››› in Introduction on page 160

›››

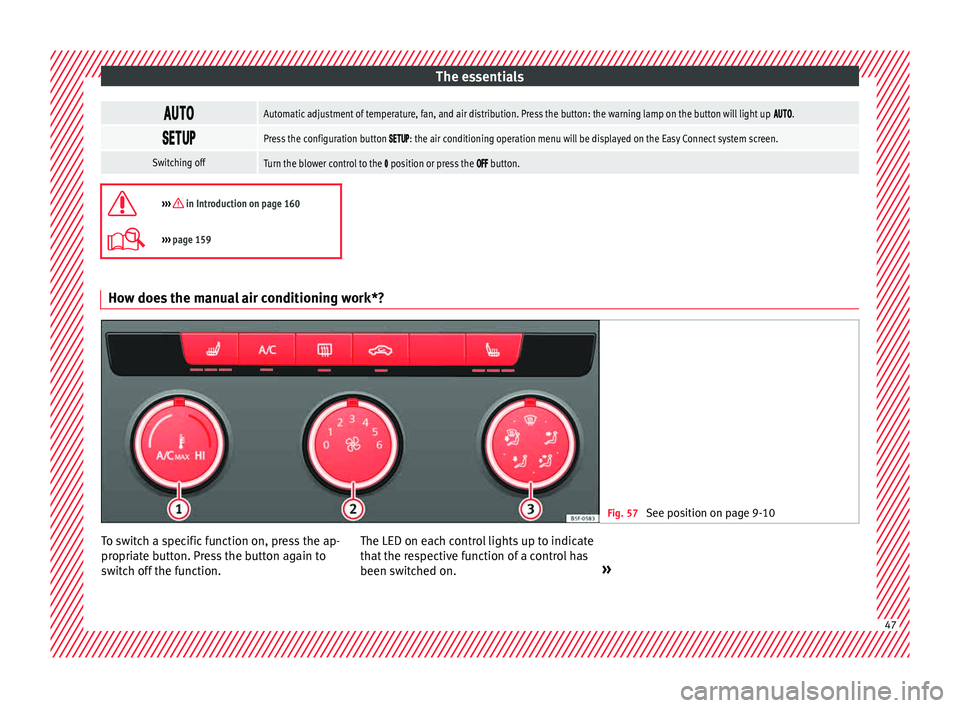

page 159 How does the manual air conditioning work*?

Fig. 57

See position on page 9-10 To switch a specific function on, press the ap-

pr

opri at

e button. Press the button again to

switch off the function. The LED on each control lights up to indicate

that the r

espective function of a control has

been switched on. » 47

Page 51 of 308

The essentials

How does the heating and the fresh air system work? Fig. 58

See position on page 9-10 To switch a specific function on, press the ap-

pr

opri

at

e button. Press the button again to

switch off the function. The LED on each control lights up to indicate

that the r

espective function of a control has

been switched on.

1TemperatureTurn the control to adjust the temperature. The temperature cannot be lower than that of the exterior air temperature, as this system cannot cool

or dehumidify the air

2FanSetting 0: blower, heating and fresh air systems switched off

Level 6: maximum fan level

3Air distributionRotate the continuous control to direct the airflow to the desired area.

Defrost functionThe airflow is directed at the windscreen.

The air is directed at the chest of driver and passengers by the dash panel air vents.

Distribution of air towards the chest and the footwell area.»

49

Page 53 of 308

The essentials

Level control Fi l

lin

g capacities

Tank level

Petrol and diesel

engines50 l, of which, approx. 7 l reserveVehicles with all-wheel-drive :

55 l, of which, approx. 8.5 l re- serve

Natural gas en-

ginea)approx. 15 kg

a)

The capacity depends on the efficacy and characteristics of

the natural gas pumps. The capacity indicated is based on a

minimum loading pressure of 200 bar.

Capacity of the windscreen washer fluid container

Versions without

headlight washer

systemapprox. 3 litres

Versions with

headlight washer

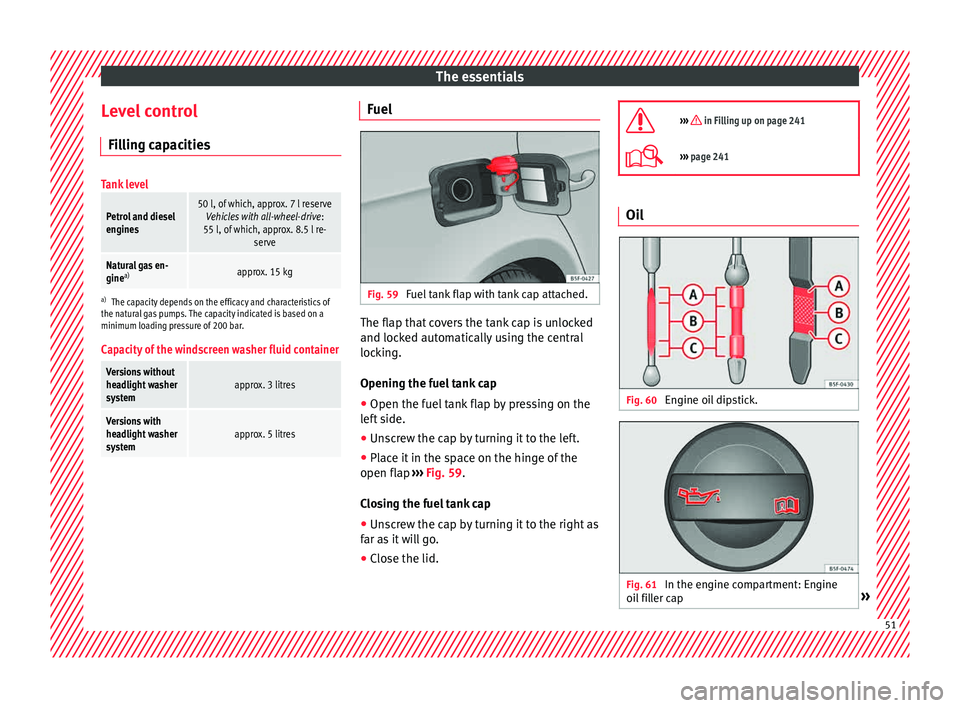

systemapprox. 5 litres Fuel

Fig. 59

Fuel tank flap with tank cap attached. The flap that covers the tank cap is unlocked

and loc

k

ed aut

omatically using the central

locking.

Opening the fuel tank cap

● Open the fuel tank flap by pressing on the

left

side.

● Unscrew the cap by turning it to the left.

● Place it in the space on the hinge of the

open flap ››

› Fig. 59.

Closing the fuel tank cap

● Unscrew the cap by turning it to the right as

far as

it will go.

● Close the lid.

››› in Filling up on page 241

›››

page 241 Oil

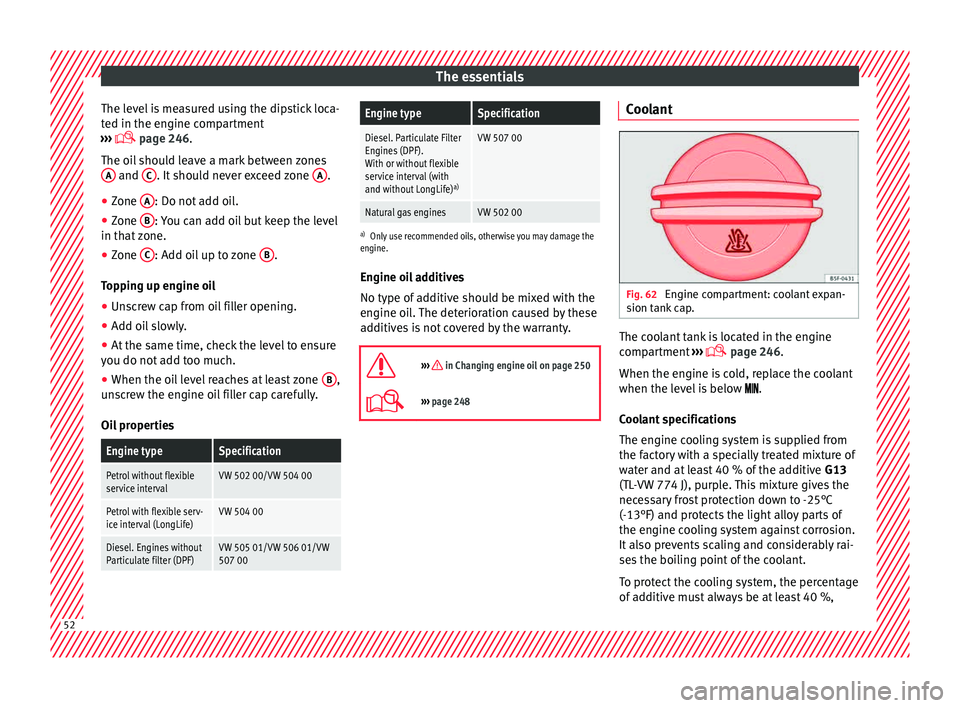

Fig. 60

Engine oil dipstick. Fig. 61

In the engine compartment: Engine

oi l

fi

ller cap » 51

Page 54 of 308

The essentials

The level is measured using the dipstick loca-

t ed in the en

gine c

ompartment

››› page 246.

The oil should leave a mark between zones A and

C . It should never exceed zone

A .

● Zone A : Do not add oil.

● Zone B : You can add oil but keep the level

in th at

zone.

● Zone C : Add oil up to zone

B .

T op

pin

g up engine oil

● Unscrew cap from oil filler opening.

● Add oil slowly.

● At the same time, check the level to ensure

you do not a

dd too much.

● When the oil level reaches at least zone B ,

u n

s

crew the engine oil filler cap carefully.

Oil properties

Engine typeSpecification

Petrol without flexible

service intervalVW 502 00/VW 504 00

Petrol with flexible serv-

ice interval (LongLife)VW 504 00

Diesel. Engines without

Particulate filter (DPF)VW 505 01/VW 506 01/VW

507 00

Engine typeSpecification

Diesel. Particulate Filter

Engines (DPF).

With or without flexible

service interval (with

and without LongLife) a)VW 507 00

Natural gas enginesVW 502 00

a)

Only use recommended oils, otherwise you may damage the

engine.

Engine oil additives

No type of additive should be mixed with the

engine oil. The deterioration caused by these

additives is not covered by the warranty.

››› in Changing engine oil on page 250

››› page 248 Coolant

Fig. 62

Engine compartment: coolant expan-

s ion t

ank

cap. The coolant tank is located in the engine

c

omp

ar

tment ›››

page 246.

When the engine is cold, replace the coolant

when the level is below .

Coolant specifications

The engine cooling system is supplied from

the factory with a specially treated mixture of

water and at least 40 % of the additive G13

(TL-VW 774 J), purple. This mixture gives the

necessary frost protection down to -25°C

(-13°F) and protects the light alloy parts of

the engine cooling system against corrosion.

It also prevents scaling and considerably rai-

ses the boiling point of the coolant.

To protect the cooling system, the percentage

of additive must always be at least 40 %, 52

Page 57 of 308

The essentials

Emergencies F u

se

s

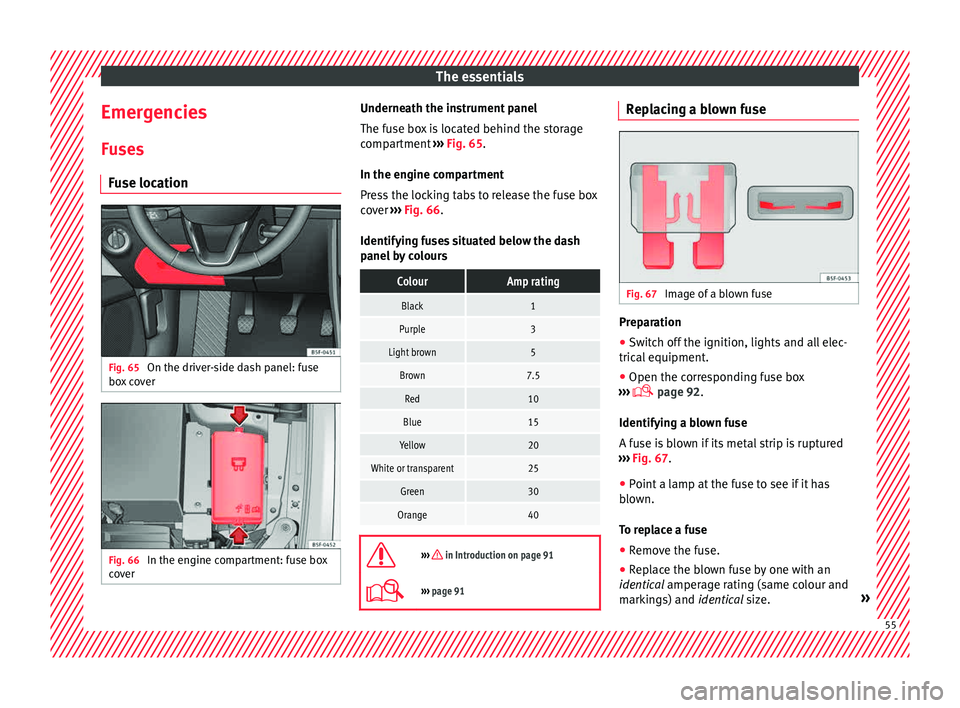

Fuse location Fig. 65

On the driver-side dash panel: fuse

bo x

c

over Fig. 66

In the engine compartment: fuse box

c o

v

er Underneath the instrument panel

The f

use bo

x is located behind the storage

compartment ››› Fig. 65.

In the engine compartment

Press the locking tabs to release the fuse box

cover ››› Fig. 66.

Identifying fuses situated below the dash

panel by colours

ColourAmp rating

Black1

Purple3

Light brown5

Brown7.5

Red10

Blue15

Yellow20

White or transparent25

Green30

Orange40

››› in Introduction on page 91

›››

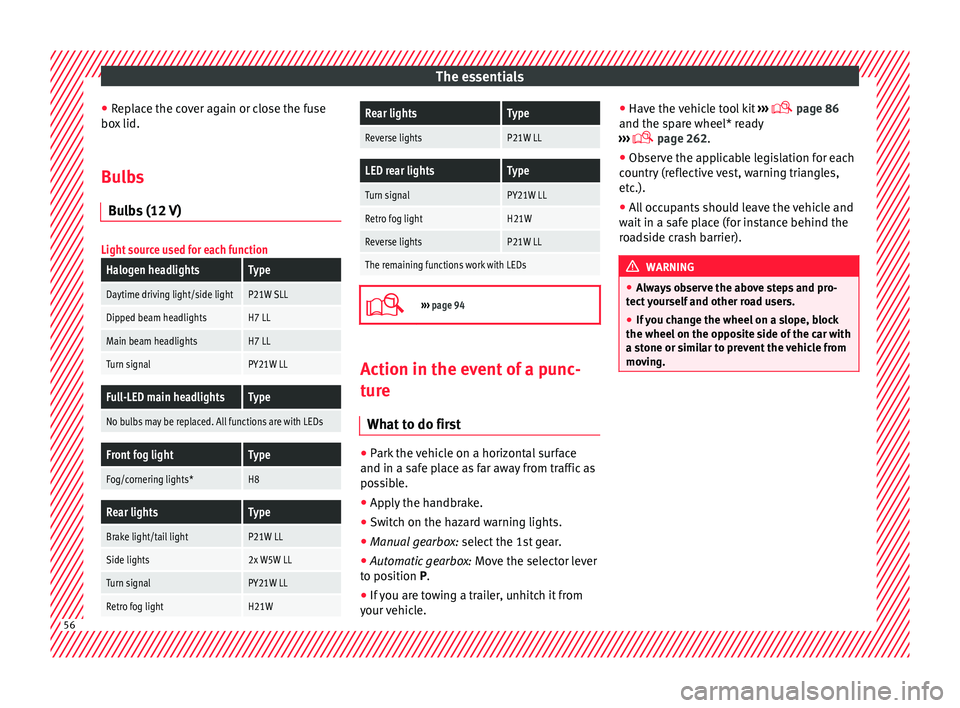

page 91 Replacing a blown fuse

Fig. 67

Image of a blown fuse Preparation

● Switch off the ignition, lights and all elec-

tric al

equipment

.

● Open the corresponding fuse box

›››

page 92.

Identifying a blown fuse

A fuse is blown if its metal strip is ruptured

››› Fig. 67.

● Point a lamp at the fuse to see if it has

blown.

T

o replace a fuse

● Remove the fuse.

● Replace the blown fuse by one with an

identica

l amperage rating (same colour and

markings) and identical size. » 55

Page 58 of 308

The essentials

● Rep

l

ace the cover again or close the fuse

box lid.

Bulbs Bul

bs (12 V)

Light source used for each function

Halogen headlightsType

Daytime driving light/side lightP21W SLL

Dipped beam headlightsH7 LL

Main beam headlightsH7 LL

Turn signalPY21W LL

Full-LED main headlightsType

No bulbs may be replaced. All functions are with LEDs

Front fog lightType

Fog/cornering lights*H8

Rear lightsType

Brake light/tail lightP21W LL

Side lights2x W5W LL

Turn signalPY21W LL

Retro fog lightH21W

Rear lightsType

Reverse lightsP21W LL

LED rear lightsType

Turn signalPY21W LL

Retro fog lightH21W

Reverse lightsP21W LL

The remaining functions work with LEDs

›››

page 94 Action in the event of a punc-

t

ur

e

Wh

at to do first ●

Park the vehicle on a horizontal surface

and in a s af

e p

lace as far away from traffic as

possible.

● Apply the handbrake.

● Switch on the hazard warning lights.

● Manual gearbox: select the 1s

t gear.

● Automatic gearbox: Move the sel

ector lever

to position P.

● If you are towing a trailer, unhitch it from

your v

ehicle. ●

Have the v

ehicle tool kit ›››

page 86

and the spare wheel* ready

››› page 262.

● Observe the applicable legislation for each

countr

y (reflective vest, warning triangles,

etc.).

● All occupants should leave the vehicle and

wait in a s

afe place (for instance behind the

roadside crash barrier). WARNING

● Alw a

ys observe the above steps and pro-

tect yourself and other road users.

● If you change the wheel on a slope, block

the wheel on the oppo

site side of the car with

a stone or similar to prevent the vehicle from

moving. 56

Page 61 of 308

The essentials

Anti-theft wheel bolts Fig. 72

Anti-theft wheel bolt with cap and

a d

apt

er. ●

Remove the wheel cover* or the cap*.

● Insert the special adapter (vehicle tools)

ont o the anti-thef

t

wheel bolt and push it on

as far as it will go.

● Insert the wheel brace (vehicle tools) onto

the adapt

er as far as it will go.

● Remove the wheel bolt ›››

page 59 . Note

Make a note of the code number of the anti-

theft wheel

bolt and keep it in a safe place,

but not in your vehicle. If you need a new

adapter, you can obtain it from the SEAT Offi-

cial Service, indicating the code number. Loosening the wheel bolts

Fig. 73

Wheel: loosen the wheel bolts. ●

Insert the box spanner (vehicle tools) onto

the wheel bo

lt

as far as it will go. An adapter

is required to unscrew or tighten the anti-

theft wheel bolts ››› page 59.

● Turn the wheel bolt approximately one turn

to the lef

t ››› Fig. 73 (arrow). To apply the re-

quired torque, hold the wheel brace at the

end. If it is not possible to loosen a wheel

bolt, carefully apply pressure with one foot

on the end of the box spanner. Hold on to the

vehicle for support and take care not to slip. WARNING

Slightly loosen the wheel bolts (one turn) be-

for e r

aising the vehicle with the jack*. If not,

an accident may occur. Lifting the vehicle

Fig. 74

Crossbar: marks. Fig. 75

Strut: mounting the jack on the vehi-

c l

e. ●

Place the jack* (vehicle tools) on firm

gr ou

nd. If

necessary use a large, strong

board or similar support. If the surface is slip-

pery (for example tiles) place the jack on a

rubber mat or similar to prevent it from slip-

ping ››› .

» 59

Page 62 of 308

The essentials

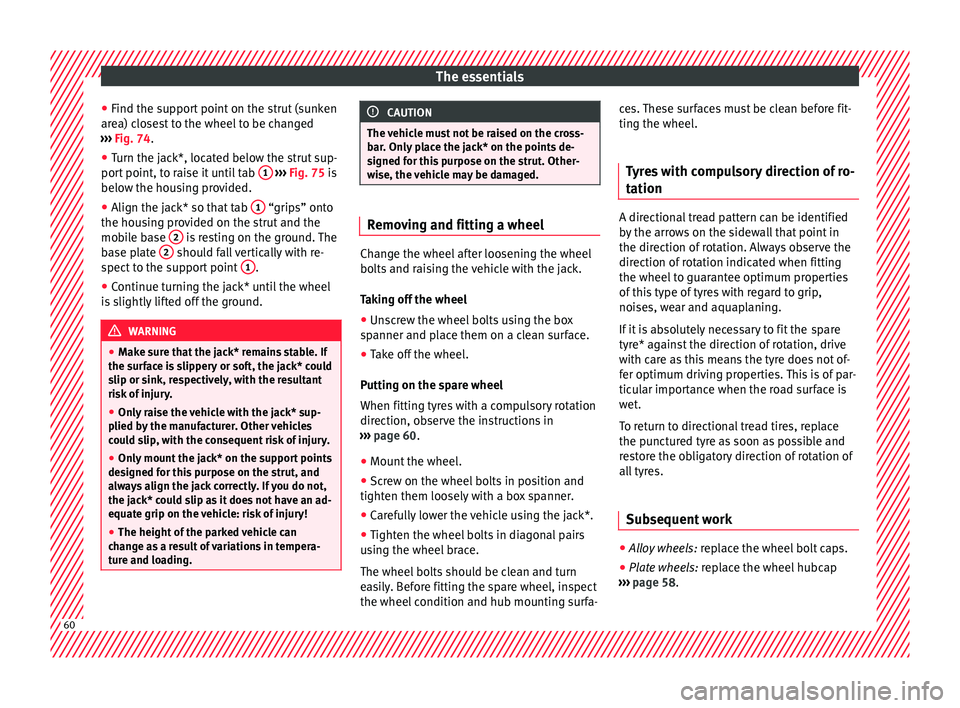

● Find the s up

por

t point on the strut (sunken

area) closest to the wheel to be changed

››› Fig. 74.

● Turn the jack*, located below the strut sup-

port point, t

o raise it until tab 1

› ››

Fig. 75

is

below the housing provided.

● Align the jack* so that tab 1 “grips” onto

the hou s

in

g provided on the strut and the

mobile base 2 is resting on the ground. The

b a

se p

late 2 should fall vertically with re-

s pect

t

o the support point 1 .

● Continue turning the jack* until the wheel

i s

s

lightly lifted off the ground. WARNING

● Mak e s

ure that the jack* remains stable. If

the surface is slippery or soft, the jack* could

slip or sink, respectively, with the resultant

risk of injury.

● Only raise the vehicle with the jack* sup-

plied by

the manufacturer. Other vehicles

could slip, with the consequent risk of injury.

● Only mount the jack* on the support points

designed f

or this purpose on the strut, and

always align the jack correctly. If you do not,

the jack* could slip as it does not have an ad-

equate grip on the vehicle: risk of injury!

● The height of the parked vehicle can

chan

ge as a result of variations in tempera-

ture and loading. CAUTION

The vehicle must not be raised on the cross-

bar . On

ly place the jack* on the points de-

signed for this purpose on the strut. Other-

wise, the vehicle may be damaged. Removing and fitting a wheel

Change the wheel after loosening the wheel

bolts

and r

aising the vehicle with the jack.

Taking off the wheel ● Unscrew the wheel bolts using the box

sp anner and p

lace them on a clean surface.

● Take off the wheel.

Putting on the s

pare wheel

When fitting tyres with a compulsory rotation

direction, observe the instructions in

››› page 60.

● Mount the wheel.

● Screw on the wheel bolts in position and

tighten them loosely

with a box spanner.

● Carefully lower the vehicle using the jack*.

● Tighten the wheel bolts in diagonal pairs

usin

g the wheel brace.

The wheel bolts should be clean and turn

easily. Before fitting the spare wheel, inspect

the wheel condition and hub mounting surfa- ces. These surfaces must be clean before fit-

ting the wheel.

T

yres with compulsory direction of ro-

tation A directional tread pattern can be identified

by

the arr

ows on the sidewall that point in

the direction of rotation. Always observe the

direction of rotation indicated when fitting

the wheel to guarantee optimum properties

of this type of tyres with regard to grip,

noises, wear and aquaplaning.

If it is absolutely necessary to fit the spare

tyre* against the direction of rotation, drive

with care as this means the tyre does not of-

fer optimum driving properties. This is of par-

ticular importance when the road surface is

wet.

To return to directional tread tires, replace

the punctured tyre as soon as possible and

restore the obligatory direction of rotation of

all tyres.

Subsequent work ●

Alloy wheels: rep

l

ace the wheel bolt caps.

● Plate wheels: rep l

ace the wheel hubcap

››› page 58.60

Page 65 of 308

The essentials

Jump leads must comply with standard DIN

72553 (see c ab

l

e manufacturer's instruc-

tions). The wire cross section must be at least

25 mm 2

for petrol engines and at least

35 mm 2

for diesel engines. Note

● The v ehic

les must not touch each other,

otherwise electricity could flow as soon as

the positive terminals are connected.

● The discharged battery must be properly

connected t

o the on-board network. How to jump start: description

Fig. 78

Diagram of connections for vehicles

w ithout

Start Stop system Fig. 79

Diagram of connections for vehicles

with St

art Stop system Jump lead terminal connections

1. Switch off the ignition of both vehicles

››

›

.

2. Connect one end of the re

d

jump lead to

the positive + terminal of the vehicle

w ith the fl

at

battery A

› ›

› Fig. 78 .

3. Connect the other end of the red

jump

lead to the positive terminal + in the ve-

hic l

e pr

oviding assistance B .

4. For vehicles without Start-Stop system:

connect

one end of

the black jump lead to

the negative terminal – of the vehicle

pr o

v

iding the current B

› ›

› Fig. 78 .

– For vehicles with Start-Stop system: con-

nect one end of

the black jump lead X to a

s uit

ab

le ground terminal, to a solid piece of

metal in the engine block, or to the engine

block itself ››› Fig. 79. 5. Connect the other end of the

black

jump

lead X to a solid metal component bolted

t o the en

gine b

lock or to the engine block

itself of the vehicle with the flat battery.

Do not connect it to a point near the bat-

tery A .

6. Position the leads in such a way that they cannot

c

ome into contact with any moving

parts in the engine compartment.

Starting

7. Start the engine of the vehicle with the boostin

g battery and let it run at idling

speed.

8. Start the engine of the vehicle with the flat batter

y and wait for 2 or 3 minutes until

the engine is running.

Removing the jump leads

9. Before you remove the jump leads, switch off the dipped be

am headlights if they are

switched on.

10.

Turn on the heater blower and heated rear

window in the vehicle with the flat battery.

This helps minimise voltage peaks which

are generated when the leads are discon-

nected.

11.When the engine is running, disconnect the lea

ds in reverse order to the details

given above. » 63