light Seat Leon SC 2013 Owner's manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2013, Model line: Leon SC, Model: Seat Leon SC 2013Pages: 339, PDF Size: 4.8 MB

Page 259 of 339

257

Checking and refilling levels

WARNING

Only change the engine oil yourself if you have the specialist knowledge

required!

● Before opening the bonnet, read and observe the warnings

⇒ page 251.

● Wait for the engine to cool down. Hot oil may cause burn injuries.

● Wear eye protection to avoid injuries, such as acid burns, caused by

splashes of oil.

● When removing the oil drain plug with your fingers, keep your arm

horizontal to help prevent oil from running down your arm.

● Wash your skin thoroughly if it comes into contact with engine oil.

● Engine oil is poisonous! Used oil must be stored in a safe place out of

the reach of children.

CAUTION

No additives should be used with engine oil. This could result in engine

damage. Any damage caused by the use of such additives would not be

covered by the factory warranty.

For the sake of the environment

● Because of the disposal problems, the necessary special tools and spe-

cialist knowledge required, we recommend that you have the engine oil and

filter changed by a Technical Service.

● Never pour oil down drains or into the ground.

● Use a suitable container when draining the used oil. It must be large

enough to hold all the engine oil. Cooling system

Engine coolant specifications

The engine cooling system is supplied from the factory with a specially trea-

ted mixture of water and, at least, 40 % of the additive G 13 (TLVW 774 J).

The engine coolant additive is recognisable by its purple colour. This mix-

ture of water and additive gives the necessary frost protection down to

-25°C (-13 °F) and protects the light alloy parts of the cooling system

against corrosion. It also prevents scaling and considerably raises the boil-

ing point of the coolant.

To protect the engine cooling system, the percentage of additive must al-

ways be at least 40 %, even in warm climates where anti-freeze protection is

not required.

If greater frost protection is required in very cold climates, the proportion of

additive can be increased. However, the percentage of additive should not

exceed 60 %, as this would reduce the frost protection and, in turn, de-

crease the cooling capacity.

When the coolant is topped up, use a mixture of distilled water and, at

least, 40 % of the G 13 or G 12 plus-plus (TL-VW 774 G) additive (both are

purple) to obtain an optimum anticorrosion protection ⇒

. The mixture of

G 13 with G 12 plus (TL-VW 774 F), G 12 (red) or G 11 (green-blue) engine

coolants will significantly reduce the anticorrosion protection and should,

therefore be avoided ⇒

.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 260 of 339

258Checking and refilling levels

WARNING

If there is not enough anti-freeze in the coolant system, the engine may

fail leading to serious damage.

● Please make sure that the percentage of additive is correct with re-

spect to the lowest expected ambient temperature in the zone in which

the vehicle is to be used.

● When the outside temperature is very low, the coolant could freeze

and the vehicle would be immobilised. In this case, the heating would

not work either and inadequately dressed passengers could die of cold.

CAUTION

The original additives should never be mixed with coolants which are not

approved by SEAT. Otherwise, you run the risk of causing severe damage to

the engine and the engine cooling system.

● If the fluid in the expansion tank is not purple but is, for example,

brown, this indicates that the G 13 additive has been mixed with an inade-

quate coolant. The coolant must be changed as soon as possible if this is

the case! This could result in serious faults and engine damage.

For the sake of the environment

Coolants and additives can contaminate the environment. If any fluids are

spilled, they should be collected and correctly disposed of, with respect to

the environment. Topping up coolant

Top up coolant when the level is below the MIN (minimum)

mark.

Fig. 156 Engine com-

partment: Coolant expan-

sion tank cap

Checking coolant level

– Park the vehicle in a horizontal position.

– Switch the ignition off

– Read off the coolant level on coolant expansion tank. When the

engine is cold, the coolant level should be between the marks.

When the engine is hot, it may be slightly above the upper

mark.

Topping up coolant

– Wait for the engine to cool down.

– Cover the coolant expansion tank cap with a cloth and carefully

unscrew it to the left ⇒

.

Page 261 of 339

259

Checking and refilling levels

– Top up the coolant only if there is still coolant in the expansion

tank, otherwise you could damage the engine. If there is no

coolant in the expansion tank, do not continue driving. You

should obtain professional assistance ⇒

.

– If there is still some coolant in the expansion tank, top up to the

upper mark.

– Top up with coolant to the upper mark until the level becomes

stable.

– Screw the cap back on correctly.

Any loss of coolant fluid normally indicates a leak in the cooling system.

Take the vehicle straight to a specialised workshop to have the cooling sys-

tem examined. If there are no leaks in the engine cooling system, a loss of

coolant can only occur if the coolant boils and is forced out of the system as

a result of overheating.

WARNING

● The cooling system is under pressure. Do not unscrew the cap on the

coolant expansion tank when the engine is hot: risk of burns!

● The antifreeze and coolant fluid can be a health hazard. Therefore,

the antifreeze should be stored in the original container in a safe place

out of reach of children. Failure to comply could result in poisoning.

● If working inside the engine compartment, remember that, even when

the ignition is switched off, the radiator fan may start up automatically,

and therefore there is a risk of injury.

CAUTION

Do not top up the expansion tank with coolant fluid if it is empty! Air could

enter the cooling system. In this case, stop driving. Seek specialist assis-

tance. Otherwise, there is a risk of engine damage. Brake fluid

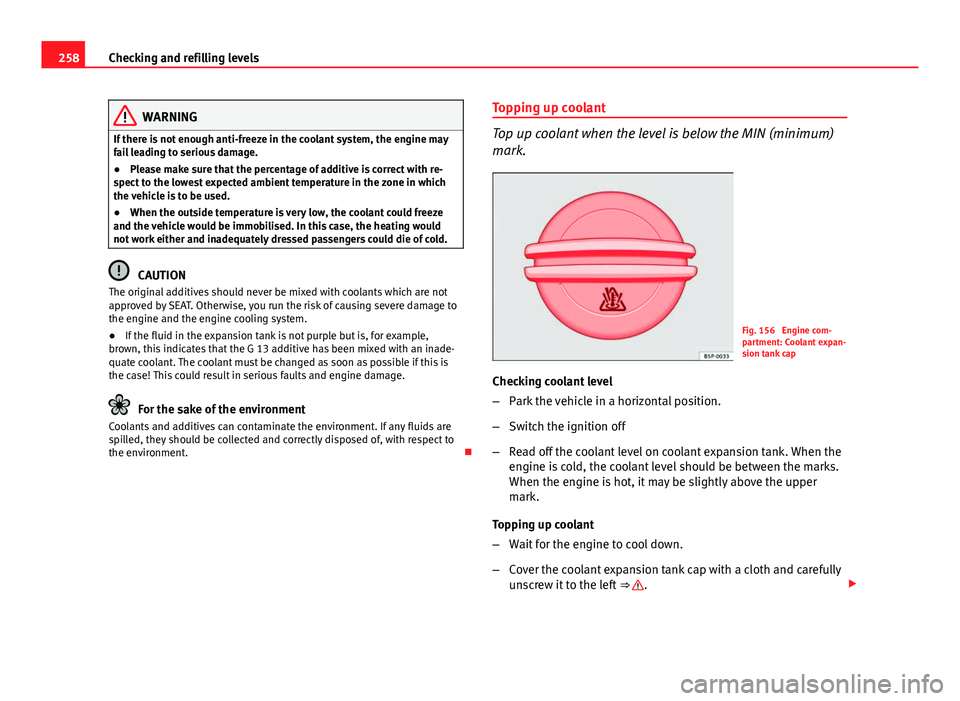

Fig. 157 Engine com-

partment: brake fluid res-

ervoir, lid

Checking the brake fluid level

The brake fluid level must be between the MIN and MAX markings.

However, if the brake fluid level goes down noticeably in a short time, or

drops below the MIN mark, there may be a leak in the brake system. Seek

specialist assistance. A warning light on the instrument panel display moni-

tors the brake fluid level ⇒ page 69.

In right-hand drive vehicles the brake fluid reservoir is on the other side of

the engine compartment.

Changing brake fluid

The regular intervals at which the brake fluid should be replaced are listed

in the Service Plan. We recommend you have the brake fluid replaced at a

SEAT Official Service, during an Inspection Service.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 262 of 339

260Checking and refilling levels

WARNING

● Brake fluid should be stored in the closed original container in a safe

place out of reach of children. Risk of poisoning!

● If the brake fluid is left in the system for too long and the brakes are

subjected to heavy use, vapour bubbles may form in the brake system.

This would seriously affect the efficiency of the brakes and the safety of

the vehicle. This may cause an accident.

CAUTION

Brake fluid should not come into contact with the vehicle paintwork, as it is

abrasive.

Battery General information

The battery is located in the engine compartment and is almost mainte-

nance-free. It is checked as part of the Inspection Service. Nevertheless,

check the terminals are clean and have the correct tightening torque, espe-

cially in summer and winter.

Disconnecting the battery

The battery should only be disconnected in exceptional cases. When the

battery is disconnected, some of the vehicle's functions are “lost” ( ⇒ table

on page 260). These functions will require resetting after the battery is re-

connected.

Deactivate the anti-theft alarm* before you disconnect the battery Other-

wise the alarm will be triggered.

effectReprogrammingOne-touch function of the electric

windows⇒ page 104, One-touch opening and

closing*

Remote control keyIf the vehicle does not respond to the

key, they should be synchronised

⇒ page 91

Digital clock⇒ page 63

ESC warning lampAfter driving for a few metres, the

warning lamp goes out again.

If the vehicle is not used for long periods

The vehicle has a system for monitoring the current consumption when the

engine is left unused for long periods of time ⇒ page 226. Some functions,

such as the interior lights, or the remote door opening, may be temporarily

disabled to prevent the battery from running flat. These functions will come

back on as soon as the ignition is switched on and the engine started.

Winter conditions

During the winter, the starting power may be reduced, and if necessary, the

battery should be charged ⇒

in Important safety warnings for handling a

vehicle battery on page 261

Important safety warnings for handling a vehicle battery

All work on batteries requires specialist knowledge. Please refer to a SEAT

Official Service or a workshop specialising in batteries: risk of burns or ex-

ploding battery!

The battery must not be opened. Never try to change the fluid level of the

battery. Explosive gas is released from the battery that could cause an ex-

plosion.

Page 265 of 339

263

Checking and refilling levels

The windscreen washer reservoir contains the cleaning fluid for the wind-

screen, the rear window and the headlight washer system* ⇒ Fig. 158. Res-

ervoir capacity: ⇒ page 323.

To prevent the nozzles from becoming blocked with chalk deposits, fill res-

ervoir with water with a low calcium content (distilled water). Always add

washer fluid to the water (with anti-freeze additive in winter).

CAUTION

● Never put radiator anti-freeze or other additives into the windscreen

washer fluid.

● Never use washer fluid which contains paint thinners or solvents as it

can damage the paintwork.

Cleaning and changing the wiper blades of the windscreen

and rear window

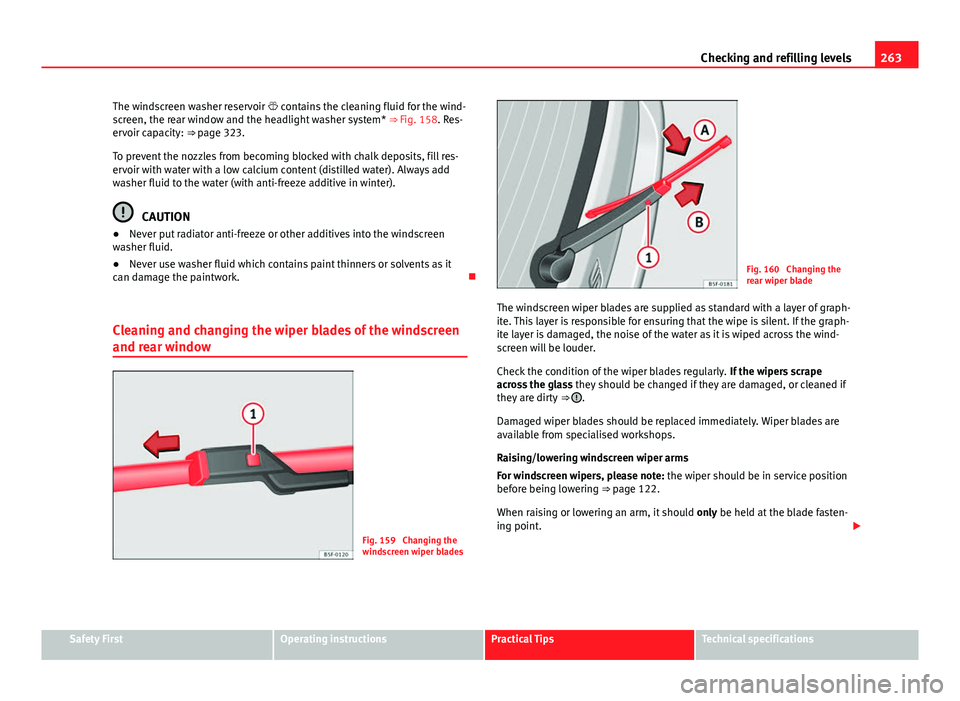

Fig. 159 Changing the

windscreen wiper blades

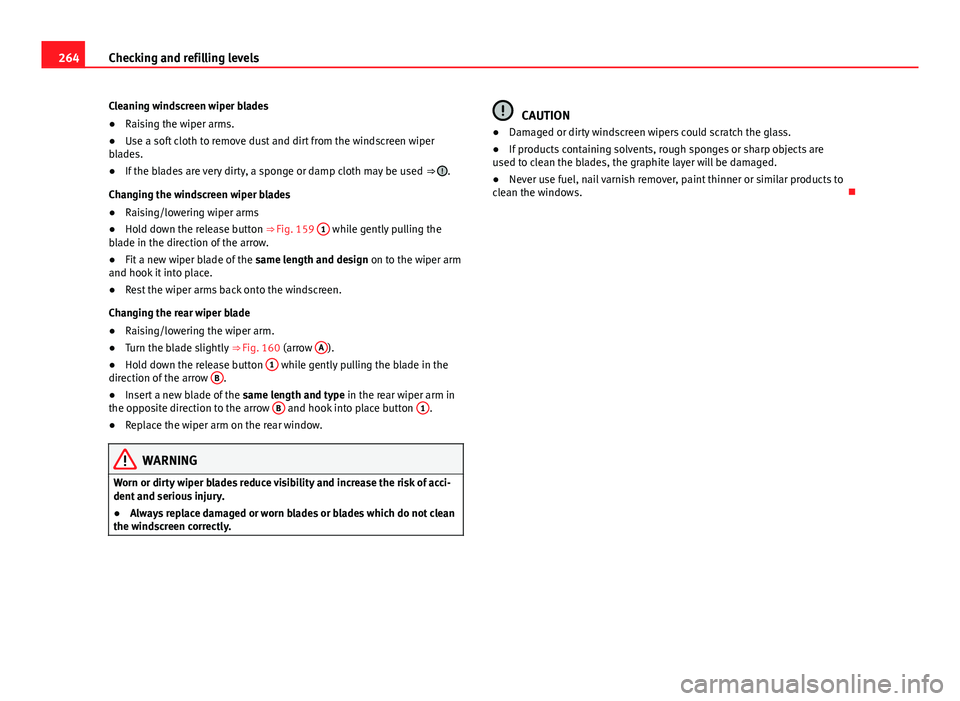

Fig. 160 Changing the

rear wiper blade

The windscreen wiper blades are supplied as standard with a layer of graph-

ite. This layer is responsible for ensuring that the wipe is silent. If the graph-

ite layer is damaged, the noise of the water as it is wiped across the wind-

screen will be louder.

Check the condition of the wiper blades regularly. If the wipers scrape

across the glass they should be changed if they are damaged, or cleaned if

they are dirty ⇒

.

Damaged wiper blades should be replaced immediately. Wiper blades are

available from specialised workshops.

Raising/lowering windscreen wiper arms

For windscreen wipers, please note: the wiper should be in service position

before being lowering ⇒ page 122. When raising or lowering an arm, it should only be held at the blade fasten-

ing point.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 266 of 339

264Checking and refilling levels

Cleaning windscreen wiper blades

● Raising the wiper arms.

● Use a soft cloth to remove dust and dirt from the windscreen wiper

blades.

● If the blades are very dirty, a sponge or damp cloth may be used ⇒

.

Changing the windscreen wiper blades

● Raising/lowering wiper arms

● Hold down the release button ⇒ Fig. 159 1

while gently pulling the

blade in the direction of the arrow.

● Fit a new wiper blade of the same length and design on to the wiper arm

and hook it into place.

● Rest the wiper arms back onto the windscreen.

Changing the rear wiper blade

● Raising/lowering the wiper arm.

● Turn the blade slightly ⇒ Fig. 160 (arrow A

).

● Hold down the release button 1 while gently pulling the blade in the

direction of the arrow B.

● Insert a new blade of the same length and type in the rear wiper arm in

the opposite direction to the arrow B

and hook into place button 1.

● Replace the wiper arm on the rear window.

WARNING

Worn or dirty wiper blades reduce visibility and increase the risk of acci-

dent and serious injury.

● Always replace damaged or worn blades or blades which do not clean

the windscreen correctly.

CAUTION

● Damaged or dirty windscreen wipers could scratch the glass.

● If products containing solvents, rough sponges or sharp objects are

used to clean the blades, the graphite layer will be damaged.

● Never use fuel, nail varnish remover, paint thinner or similar products to

clean the windows.

Page 268 of 339

266Wheels and tyres

–The tyre pressure should only be checked when the tyres are

cold. The slightly raised pressures of warm tyres must not be re-

duced.

– Adjust tyre pressure to the load being carried by the vehicle.

– In vehicles with a tyre pressure indicator, save the pressure of

modified tyres ⇒ page 214, ⇒ page 265.

– Avoid fast cornering and hard acceleration.

– Inspect the tyres for irregular wear from time to time.

The useful life of your tyres depends on the following factors:

Tyre pressure

Tyre pressure values are indicated on the inside of the fuel tank flap.

Insufficient or excessive pressure greatly reduces the useful life of the tyres

and adversely affects vehicle performance and ride. Correct inflation pres-

sures are very important, especially at high speeds.

If you want a more comfortable ride, you can inflate tyres to the pressure

corresponding to the normal vehicle load (up to 3 people) if the vehicle is

carrying a normal load. If the vehicle is going to carry the maximum load,

the tyre pressure should be increased to maximum value indicated.

The tyre pressure must be adjusted according to the load the vehicle is car-

rying. We recommend adhering to the tyre pressure specifications for a max-

imum load.

Do not forget the spare wheel when checking the tyre pressures: Keep the

spare wheel inflated to the highest pressure required for the road wheels.

In the case of a minimised temporary spare wheel (125/70 R16 or 125/70

R18) inflate to a pressure of 4.2 bar as indicated on the tyre pressure label

on the fuel tank flap. Driving style

Fast cornering, heavy acceleration and hard braking (squealing tyres) all in-

crease tyre wear.

Wheel balance

The wheels on new vehicles are balanced. However, certain circumstances

may lead to imbalance (run-out), which is detected as vibrations in the

steering wheel.

Unbalanced wheels should be rebalanced, as they otherwise cause exces-

sive wear on steering, suspension and tyres. A wheel must also be reba-

lanced when a new tyre is fitted or if a tyre is repaired.

Incorrect wheel alignment

Incorrect wheel alignment causes excessive tyre wear, impairing the safety

of the vehicle. If you notice excessive tyre wear, you should check wheel

alignment at a SEAT Official Service.

WARNING

● Always adapt the tyre pressure accordingly when the vehicle load

changes.

● A tyre with low air pressure has to flex a lot more when the vehicle is

heavily loaded or at high speeds, therefore causing overheating to occur.

Under these conditions, the tyre bead may be released or the tyre may

burst. Risk of accident!

For the sake of the environment

Under-inflated tyres will increase fuel consumption.

Page 276 of 339

274Emergencies

Emergencies

General information

– If you have a flat tyre or puncture, park the car as far away from

the flow of traffic as possible in a safe place. If you have a punc-

ture, stop the vehicle on a horizontal surface. If you are on a

slope, take extra care.

– Apply the handbrake.

– Switch on the hazard warning lights.

– Always wear a reflective vest ⇒ page 274.

– Set up the warning triangle.

– All vehicle occupants should leave the car. They should wait in

a safe place (for instance behind the roadside crash barrier).

WARNING

Always observe the above steps and protect yourself and other road

users.

Equipment

Reflective vests

Wearing a reflective vest makes you more visible to other road

users.

Note

● Always wear a reflective vest when you get out of the vehicle in moving

traffic (for example, in the event of breakdown or to load/unload the vehi-

cle).

● Observe the applicable legislation for each country.

Vehicle tools/Tyre repair kit/Compressor*

The vehicle tools, the tyre repair kit and the compressor* are stor-

ed under the floor panel in the luggage compartment.

To access the vehicle tools:

– Lift up the floor panel by the plastic handle until it is fastened to

the tabs on both sides.

Depending on the vehicle equipment, you will find the tyre repair set and

the compressor* under the floor panel cover.

Page 282 of 339

280Emergencies

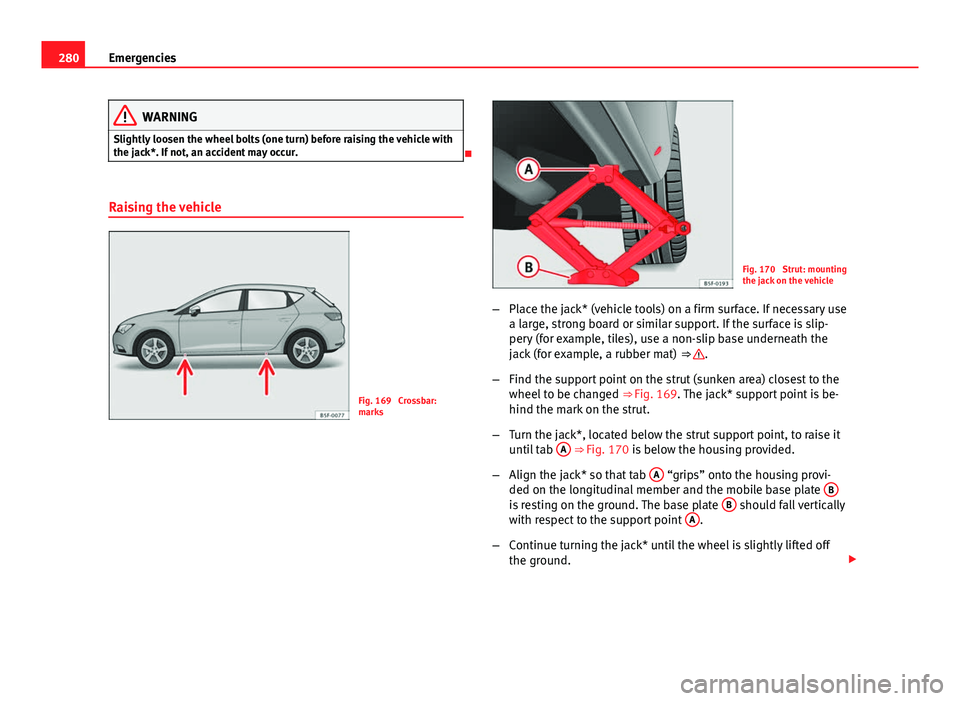

WARNING

Slightly loosen the wheel bolts (one turn) before raising the vehicle with

the jack*. If not, an accident may occur.

Raising the vehicle

Fig. 169 Crossbar:

marks

Fig. 170 Strut: mounting

the jack on the vehicle

– Place the jack* (vehicle tools) on a firm surface. If necessary use

a large, strong board or similar support. If the surface is slip-

pery (for example, tiles), use a non-slip base underneath the

jack (for example, a rubber mat) ⇒

.

– Find the support point on the strut (sunken area) closest to the

wheel to be changed ⇒ Fig. 169. The jack* support point is be-

hind the mark on the strut.

– Turn the jack*, located below the strut support point, to raise it

until tab A

⇒ Fig. 170 is below the housing provided.

– Align the jack* so that tab A

“grips” onto the housing provi-

ded on the longitudinal member and the mobile base plate B

is resting on the ground. The base plate B should fall vertically

with respect to the support point A.

– Continue turning the jack* until the wheel is slightly lifted off

the ground.

Page 287 of 339

285

Emergencies

6. Position the leads in such a way that they cannot come into contact with any moving parts in the engine compartment.

Starting

7. Start the engine of the vehicle with the boosting battery and let it run at idling speed.

8. Start the engine of the vehicle with the flat battery and wait two or three minutes until the engine is “running”.

Removing the jump leads

9. Before you remove the jump leads, switch off the dipped beam headlights (if they are switched on).

10.Turn on the heater blower and heated rear window in the vehi- cle with the flat battery. This helps minimise voltage peaks

which are generated when the leads are disconnected.

11.When the engine is running, disconnect the leads in reverse or- der to the details given above.

Connect the battery clamps so they have good metal-to-metal contact with

the battery terminals.

If the engine fails to start, switch off the starter after about 10 seconds and

try again after about half a minute.

WARNING

● Please note the safety warnings referring to working in the engine

compartment ⇒ page 251.

● The battery providing assistance must have the same voltage as the

flat battery (12V) and approximately the same capacity (see imprint on

battery). Failure to comply could result in an explosion.

● Never use jump leads when one of the batteries is frozen. Danger of

explosion! Even after the battery has thawed, battery acid could leak and

cause chemical burns. If a battery freezes, it should be replaced.

● Keep sparks, flames and lighted cigarettes away from batteries, dan-

ger of explosion. Failure to comply could result in an explosion.

● Observe the instructions provided by the manufacturer of the jump

leads.

● Do not connect the negative cable from the other vehicle directly to

the negative terminal of the flat battery. The gas emitted from the battery

could be ignited by sparks. Danger of explosion.

● Do not attach the negative cable from the other vehicle to parts of the

fuel system or to the brake line.

● The non-insulated parts of the battery clamps must not be allowed to

touch. The jump lead attached to the positive battery terminal must not

touch metal parts of the vehicle, this can cause a short circuit.

● Position the leads in such a way that they cannot come into contact

with any moving parts in the engine compartment.

● Do not lean on the batteries. This could result in chemical burns.

Note

The vehicles must not touch each other, otherwise electricity could flow as

soon as the positive terminals are connected.

Safety FirstOperating instructionsPractical TipsTechnical specifications