technical specifications Seat Leon SC 2014 Owner's manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2014, Model line: Leon SC, Model: Seat Leon SC 2014Pages: 284, PDF Size: 5.85 MB

Page 203 of 284

Checking and refilling levels

Oil propertiesEngine typeSpecification

Petrol without flexible

service intervalVW 502 00/VW 504 00

Petrol with flexible serv-

ice interval (LongLife)VW 504 00

Diesel. Engines without

Particulate filter (DPF)VW 505 01/VW 506 01/VW

507 00

Diesel. Particulate Filter

Engines (DPF).

With or without flexible

service interval (with

and without LongLife) a)VW 507 00

Natural gas enginesVW 502 00

a)

Only use recommended oils, otherwise you may damage the

engine.

Engine oil additives

No type of additive should be mixed with the

engine oil. The deterioration caused by these

additives is not covered by the warranty. Note

Before a long trip, we recommend finding an

engine oil that conforms to the correspond-

ing VW specifications and recommend keep-

ing it in the vehicle. This way, the correct en-

gine oil will always be available for a top-up if

needed. Checking engine oil level

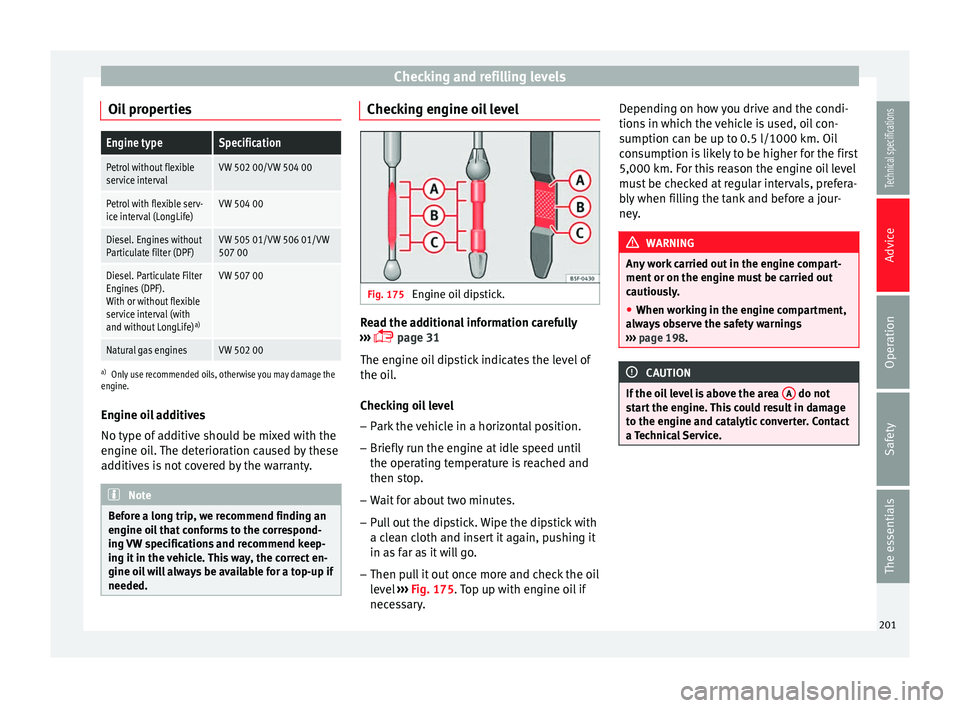

Fig. 175

Engine oil dipstick. Read the additional information carefully

››› page 31

The engine oil dipstick indicates the level of

the oil.

Checking oil level

– Park the vehicle in a horizontal position.

– Briefly run the engine at idle speed until

the operating temperature is reached and

then stop.

– Wait for about two minutes.

– Pull out the dipstick. Wipe the dipstick with

a clean cloth and insert it again, pushing it

in as far as it will go.

– Then pull it out once more and check the oil

level ››› Fig. 175 . Top up with engine oil if

nec e

ssary. Depending on how you drive and the condi-

tions in which the vehicle is used, oil con-

sumption can be up to 0.5 l/1000 km. Oil

consumption is likely to be higher for the first

5,000 km. For this reason the engine oil level

must be checked at regular intervals, prefera-

bly when filling the tank and before a jour-

ney.

WARNING

Any work carried out in the engine compart-

ment or on the engine must be carried out

cautiously.

● When working in the engine compartment,

always observe the safety warnings

››› page 198. CAUTION

If the oil level is above the area A do not

start the engine. This could result in damage

to the engine and catalytic converter. Contact

a Technical Service. 201

Technical specifications

Advice

Operation

Safety

The essentials

Page 205 of 284

Checking and refilling levels

Cooling system Engine coolant specifications The engine cooling system is supplied from

the factory with a specially treated mixture of

water and, at least, 40 % of the additive

G 13

(TLVW 774 J). The engine coolant additive is

recognisable by its purple colour. This mix-

ture of water and additive gives the necessa-

ry frost protection down to -25°C (-13°F) and

protects the light alloy parts of the cooling

system against corrosion. It also prevents

scaling and considerably raises the boiling

point of the coolant.

To protect the engine cooling system, the

percentage of additive must always

be at

l e

ast 40 %, even in warm climates where an-

ti-freeze protection is not required.

If greater frost protection is required in very

cold climates, the proportion of additive can

be increased. However, the percentage of ad-

ditive should not exceed 60%, as this would

reduce the frost protection and, in turn, de-

crease the cooling capacity.

When the coolant is topped up, use a mixture

of distilled water and, at least, 40 % of the G

13 or G 12 plu

s-plus (TL-VW 774 G) additive

(both are purple) to obtain an optimum anti-

corrosion protection ››› . The mixture of G

13 with G 12 plus (TL-VW 774 F), G 12 (red) or

G 11 (green-blue) engine coolants will signifi- cantly reduce the anticorrosion protection

and should, therefore be avoided

››› .

WARNING

If there is not enough anti-freeze in the cool-

ant system, the engine may fail leading to se-

rious damage.

● Please make sure that the percentage of

additive is correct with respect to the lowest

expected ambient temperature in the zone in

which the vehicle is to be used.

● When the outside temperature is very low,

the coolant could freeze and the vehicle

would be immobilised. In this case, the heat-

ing would not work either and inadequately

dressed passengers could die of cold. CAUTION

The original additives should never be mixed

with coolants which are not approved by

SEAT. Otherwise, you run the risk of causing

severe damage to the engine and the engine

cooling system. ● If the fluid in the expansion tank is not pur-

ple but is, for example, brown, this indicates

that the G 13 additive has been mixed with

an inadequate coolant. The coolant must be

changed as soon as possible if this is the

case! This could result in serious faults and

engine damage. For the sake of the environment

Coolants and additives can contaminate the

environment. If any fluids are spilled, they

should be collected and correctly disposed

of, with respect to the environment. Topping up coolant

Read the additional information carefully

››› page 32

Top up coolant when the level is below the

MIN (minimum) mark.

Checking coolant level – Park the vehicle in a horizontal position.

– Switch the ignition off.

– Read off the coolant level on coolant ex-

pansion tank. When the engine is cold, the

coolant level should be between the marks.

When the engine is hot, it may be slightly

above the upper mark.

Topping up coolant – Wait for the engine to cool down.

– Cover the coolant expansion tank cap with

a cloth and carefully unscrew it to the left

››› .

– Top up the coolant only if there is still cool-

ant in the expansion tank, otherwise you »

203

Technical specifications

Advice

Operation

Safety

The essentials

Page 207 of 284

Checking and refilling levels

Check the water level in the windscreen

washer reservoir regularly and top up as re-

quired.

The container for the windscreen washer con-

tains the cleaning fluid for the windscreen,

the rear window and the headlight washer

system*.

● Open the bonnet ››› page 198.

● The windscreen washer reservoir is marked

with the symbol on the cap.

● Chec k

there is enough windscreen water in

the reservoir.

Recommended windscreen wipers

● For the hottest seasons we recommend

summer G 052 184 A1 for clear glass. Propor-

tions of the mixture in the washer fluid tank:

1:100 (1 part concentrate per 100 parts wa-

ter).

● All year round, G 052 164 A2 for clear

glass. Approximate proportion of the winter

mixture, up to -18°C (0°F): 1:2 (1 part con-

centrate per 2 parts water); otherwise, a 1:4

proportion of mixture in the washer fluid

tank.

Top-up quantities

The reservoir holds approximately 3 litres in

versions without headlight washer and 5 li-

tres in versions with headlight washer. WARNING

If the water from the windscreen washer does

not contain enough anti-freeze, it may freeze

on the windscreen and rear window, reducing

forward and rear visibility.

● In winter, ensure the windscreen washer

contains enough anti-freeze.

● In cold conditions, you should not use the

windscreen washer system unless you have

warmed the windscreen with the ventilation

system. The antifreeze could freeze on the

windscreen and reduce visibility. WARNING

Never mix an unsuitable antifreeze or other

similar additives with the windscreen washer

water. A greasy layer may be formed on the

windscreen which will impair visibility.

● Use clean water with a window cleaner rec-

ommended by SEAT.

● If necessary, add a suitable antifreeze to

the water in the reservoir. CAUTION

● Do not mix cleaning products recommen-

ded by SEAT with other products. This could

lead to flocculation and may block the wind-

screen washer jets.

● When topping up service fluids, make abso-

lutely certain that you fill the fluids into the

correct reservoirs. Using the wrong fluids could cause serious malfunctions and engine

damage!

● Not having windscreen wiper fluid reduces

visibility through the windscreen, and leads

to loss of visibility in headlights in models

with headlight washer. Battery

General information The battery is located in the engine compart-

ment and is almost

maintenance-free. It is

checked as part of the Inspection Service.

Nevertheless, check the terminals are clean

and have the correct tightening torque, espe-

cially in summer and winter.

Disconnecting the battery

The battery should only be disconnected in

exceptional cases. When the battery is dis-

connected, some of the vehicle's functions

are “lost” ( ››› table on page 206). These

functions will require resetting after the bat-

tery is reconnected.

Deactivate the anti-theft alarm* before you

disconnect the battery Otherwise the alarm

will be triggered. »

205

Technical specifications

Advice

Operation

Safety

The essentials

Page 209 of 284

Checking and refilling levels

exclusively to an earth on the bodywork

(–) .

– On ly

use a charger which is compatible for

use with 12 V nominal voltage batteries.

The charge must not exceed a voltage of 15

V.

– Now connect the battery charger to the

power socket and switch on.

– After charging the battery: switch off the

battery charger and disconnect the power

socket cable.

– Finally disconnect the charger cables from

the battery.

– Replace the battery cover correctly.

– Close the bonnet ››› page 199.

Important: Before you charge the battery

make sure you read the manufacturer's in-

structions for using the battery charger. WARNING

Never charge a battery that has frozen: re-

place battery! Failure to do so may lead to an

explosion. Note

Use only the terminals in the engine compart-

ment to charge the battery. Replacing the battery

The new battery should have the same speci-

fications (amperage, load and voltage) as the

used battery.

Your vehicle is equipped with an intelligent

power management system to control the

distribution of electrical energy

››› page 191.

The power management function ensures

that the battery is charged much more effi-

ciently than on vehicles without a power

management system. To maintain this func-

tion after replacing the battery, we recom-

mend that the replacement battery used is of

the same make and type as the original fitted

battery. To make proper use of the power

management function after the battery has

been changed, have the battery coded to the

power management mode at a specialised

workshop. CAUTION

● Some vehicles, for example those with the

Start-Stop system* are fitted with a special

battery (AGM-type or EFB-type battery). If any

other type of battery is fitted, the Start-Stop

function may be considerably reduced and

the vehicle may not stop on repeated occa-

sions.

● Make sure that the vent hose is always at-

tached to the original opening on the side of

the battery. Gases or battery acid can other-

wise escape and possibly cause damage. ●

The battery holder and clamps must always

be correctly secured.

● Before starting any work on the battery, al-

ways observe the warnings listed under

››› page 206, Important safety warnings for

handling a vehicle battery .

● Do not forget to replace the battery cover-

ings, where applicable. It is a protection for

high temperatures. This in turn extends the

vehicle service life. For the sake of the environment

Batteries contain toxic substances includ-

in g s

ulphuric acid and lead. They must be

disposed of appropriately and must not be

disposed of with ordinary household waste.

Make sure disconnected batteries cannot tip

over. Sulphuric acid could be spilt! 207

Technical specifications

Advice

Operation

Safety

The essentials

Page 211 of 284

Wheels

Depending on the vehicle, tyre pressure can

be adjusted (“comfort” tyre pressure) to in-

crease driving comfort. When driving with

comfort tyre pressure fuel consumption may

increase slightly.

The tyre pressure must be adjusted according

to the load the vehicle is carrying. If the vehi-

cle is going to carry the maximum load, the

tyre pressure should be increased to maxi-

mum value indicated on the sticker on the in-

side of the fuel tank flap.

Do not forget the spare wheel when checking

the tyre pressures: Keep this spare wheel in-

flated to the highest pressure required for the

road wheels.

In the case of a minimised temporary spare

wheel (125/70 R16 or 125/70 R18) inflate to

a pressure of 4.2 bar as indicated on the tyre

pressure label on the fuel tank flap.

Driving style

Fast cornering, heavy acceleration and hard

braking (squealing tyres) all increase tyre

wear.

Wheel balance

The wheels on new vehicles are balanced.

However, certain circumstances may lead to

imbalance (run-out), which is detected as vi-

brations in the steering wheel. Unbalanced wheels should be rebalanced, as

they otherwise cause excessive wear on

steering, suspension and tyres. A wheel must

also be rebalanced when a new tyre is fitted

or if a tyre is repaired.

Incorrect wheel alignment

Incorrect wheel alignment causes excessive

tyre wear, impairing the safety of the vehicle.

If you notice excessive tyre wear, you should

check wheel alignment at a SEAT Official

Service.

WARNING

● Always adapt the tyre pressure accordingly

when the vehicle load changes.

● A tyre with low air pressure has to flex a lot

more when the vehicle is heavily loaded or at

high speeds, therefore causing overheating

to occur. Under these conditions, the tyre

bead may be released or the tyre may burst.

Risk of accident! For the sake of the environment

Under-inflated tyres will increase fuel con-

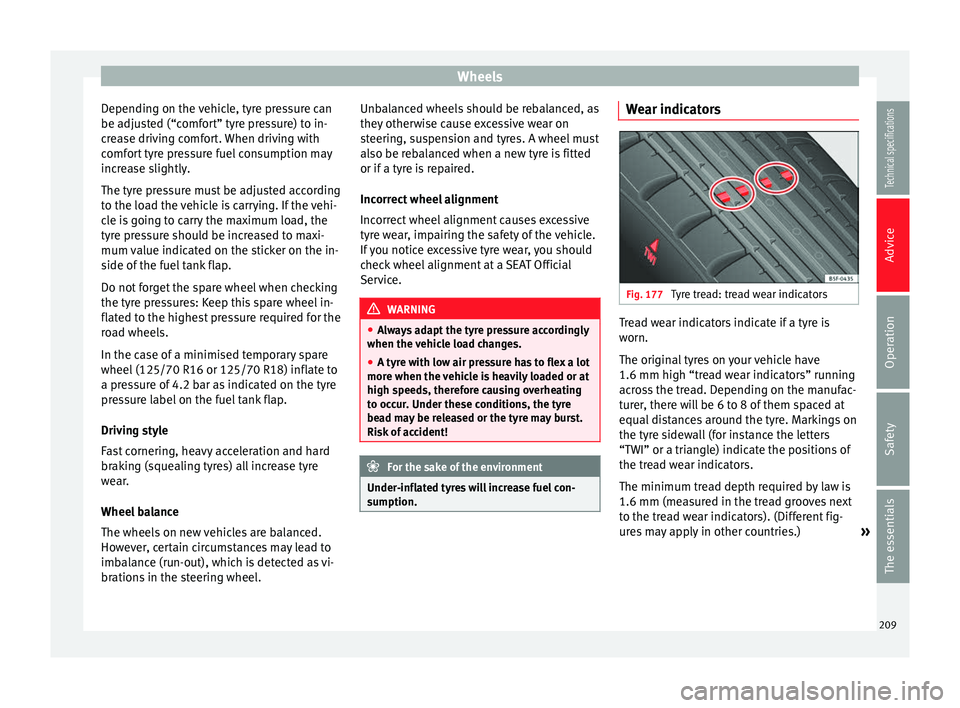

sumption. Wear indicators

Fig. 177

Tyre tread: tread wear indicators Tread wear indicators indicate if a tyre is

worn.

The original tyres on your vehicle have

1.6 mm high “tread wear indicators” running

across the tread. Depending on the manufac-

turer, there will be 6 to 8 of them spaced at

equal distances around the tyre. Markings on

the tyre sidewall (for instance the letters

“TWI” or a triangle) indicate the positions of

the tread wear indicators.

The minimum tread depth required by law is

1.6 mm (measured in the tread grooves next

to the tread wear indicators). (Different fig-

ures may apply in other countries.)

»

209Technical specifications

Advice

Operation

Safety

The essentials

Page 213 of 284

Wheels

205/55 R16 91V

This contains the following information:205Tyre width in mm

55Height/width ratio in %

RTyre construction: Radial

16Rim diameter in inches

91Load rating code

VSpeed index The

manufacturing date

is also indicated on

the ty

re sidewall (possibly only on the inner

part):

DOT... 2212...

it means, for example, that the tyre was man-

ufactured in the 22nd week of 2012.

But note that with some types of tyre, the ac-

tual tyre size can differ from the nominal size

marked on the tyre (for instance 205/55 R 16

91 W), and there may be significant differen-

ces in the contours of the tyres, even though

the tyres are marked with the same nominal

size designation. When replacing the tyres,

it is therefore important to make sure that

the actual size of the new tyres does not ex-

ceed the dimensions of the factory-approved

makes of tyre.

Failure to observe this requirement can af-

fect the clearance needed for the tyres. If the tyres rub against the bodywork, in certain

circumstances the tyres , suspension or

bodywork and pipes may be damaged, and

vehicle safety could be severely impaired

››› .

If you use tyres that are approved by SEAT

you can be sure that the actual tyre dimen-

sions will be correct for your vehicle. If you

decide to fit a different type of tyre, you must

obtain the appropriate manufacturer's certif-

icate from the tyre retailer to confirm that

the tyres are suitable for your vehicle. Keep

this certificate in a safe place.

Your SEAT Official Service will be able to ad-

vise you on which tyres may be fitted to your

vehicle.

It is best to have all servicing of wheels and

tyres performed by a specialised workshop.

They are familiar with the procedure and

have the necessary special tools and spare

parts as well as the proper facilities for dis-

posing of the old tyres respecting the envi-

ronment. WARNING

● It is very important to ensure that the tyres

you have chosen have adequate clearance.

When selecting replacement tyres, do not re-

ly entirely on the nominal tyre size marked on

the tyre, since the effective tyre size can dif-

fer significantly depending on the manufac-

turer. Inadequate tyre clearance can result in

damage to the tyres or the vehicle, causing a serious safety risk. Risk of accident! It may

also invalidate the vehicle's registration for

use on public roads.

●

Avoid running the vehicle on tyres that are

more than 6 years old. If you have no alterna-

tive, you should drive slowly and with extra

care at all times.

● If wheel trims are fitted after the car is pur-

chased, ensure that there is an adequate flow

of air for cooling the brake system. For the sake of the environment

Old tyres must be disposed of according to

the laws in the country concerned. Note

● Never mount used tyres if you are not sure

of their “previous history”.

● For technical reasons, it is not generally

possible to use the wheels from other vehi-

cles. In some cases, this may also be true for

the same model of wheel. Wheel bolts

The

wheel bolts

ar

e m

atched to the rims.

When installing different wheels (for instance

alloy wheels or wheels with winter tyres) it is

important to use the correct wheel bolts with

the right length and correctly shaped bolt

heads. This ensures that wheels are fitted »

211

Technical specifications

Advice

Operation

Safety

The essentials

Page 215 of 284

Wheels

control of the vehicle and a serious or fatal

accident.

●

If the warning lamp lights up, stop im-

mediately and check the tyres.

● If the tyres are inflated at different pres-

sures or if a tyre pressure is too low, this will

increase tyre wear, negatively affecting vehi-

cle stability and increasing braking distan-

ces.

● If tyres are inflated at different pressures or

a tyre pressure is too low, a tyre may be dam-

aged and burst resulting in a loss of control

of the vehicle.

● The driver is responsible for ensuring that

all of the vehicle tyres are correctly inflated

to the right pressure. The recommended tyre

pressure is indicated on the label

››› page 243.

● The ty r

e monitoring system can only oper-

ate correctly if all of the tyres are inflated to

the correct pressure when cold.

● Driving with tyres at the wrong pressure

can damage them and result in an accident.

Ensure that the tyre pressures of all the tyres

correspond to the vehicle load.

● Before starting a journey, always inflate

tyres to the correct pressure.

● Tyres with insufficient pressure are subjec-

ted to more flexing. Due to this, the tyre

could become excessively hot, causing tread

separation and also tyre blow-out.

● With an overloaded vehicle at high speed,

the tyres can overheat and burst resulting in

a loss of vehicle control. ●

Tyre pressures which are too high or too

low reduce the useful life of the tyre, affect-

ing vehicle performance.

● If a tyre has not been punctured and it does

not have to be changed immediately, drive to

the nearest specialised workshop at a moder-

ate speed and have the tyre checked and in-

flated to the correct pressure. WARNING

Observe the safety warnings ››› in Control

and warning lamps on page 71. Note

● If excessively low tyre pressure is detected

with the ignition on, an audible warning will

sound. In the event that there is a fault in the

system, an audible warning will sound.

● Driving on dirt tracks for a long period of

time or driving in a sporty style can tempora-

rily deactivate the TPMS. The control lamp

shows a fault, but disappears when road con-

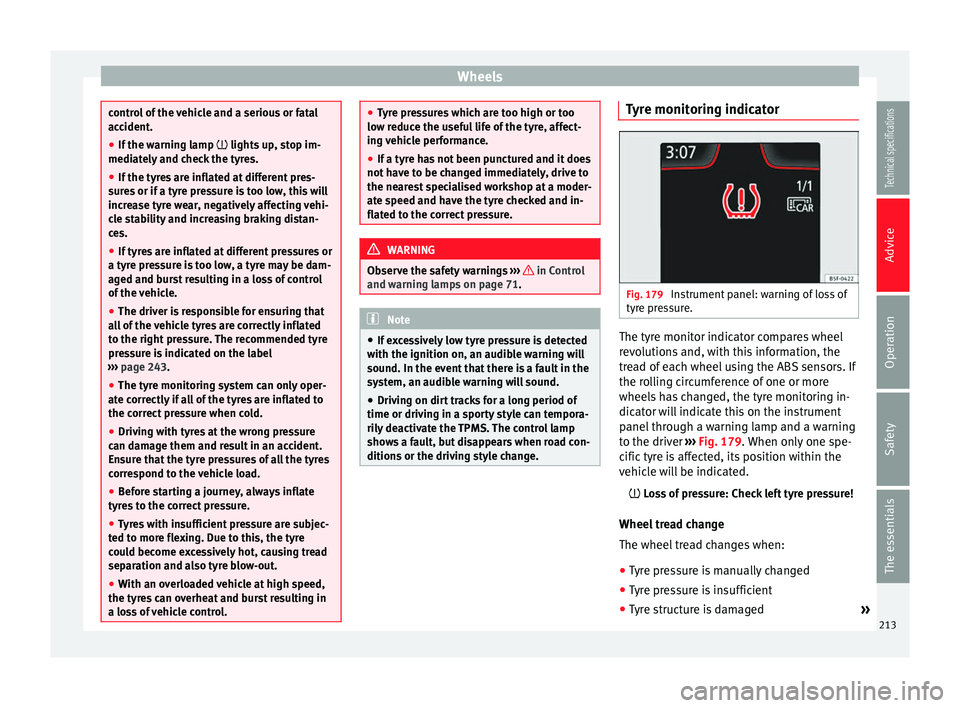

ditions or the driving style change. Tyre monitoring indicator

Fig. 179

Instrument panel: warning of loss of

tyre pressure. The tyre monitor indicator compares wheel

revolutions and, with this information, the

tread of each wheel using the ABS sensors. If

the rolling circumference of one or more

wheels has changed, the tyre monitoring in-

dicator will indicate this on the instrument

panel through a warning lamp and a warning

to the driver

››› Fig. 179 . When only one spe-

c ific

tyre is affected, its position within the

vehicle will be indicated.

Loss of pressure: Check left tyre pressure!

Wheel tread change

The wheel tread changes when: ● Tyre pressure is manually changed

● Tyre pressure is insufficient

● Tyre structure is damaged »

213

Technical specifications

Advice

Operation

Safety

The essentials

Page 217 of 284

Wheels

Removing the temporary spare wheel

– Lift and hold up the floor panel to remove

the temporary spare wheel ››› Fig. 181 .

– Turn the thumb wheel anti-clockwise.

– Take out the temporary spare wheel.

Chains

For technical reasons, snow chains must not

be used on the temporary spare wheel.

If you have a puncture on one of the front

wheels when using snow chains, fit the tem-

porary spare wheel in place of one of the rear

wheels. Fit the snow chains on the rear wheel

that you have removed and replace the punc-

tured front wheel with this wheel. WARNING

● After fitting the temporary spare wheel,

check the tyre pressures as soon as possible.

Failure to do so may cause an accident. The

tyre pressures are listed on the inside of the

fuel tank flap.

● Do not drive at over 80 km/h (50 mph)

when the temporary spare wheel is fitted on

the vehicle: risk of accident!

● Avoid heavy acceleration, hard braking and

fast cornering: risk of accident!

● Never use more than one temporary spare

wheel at the same time, risk of accident. ●

No other type of tyre (normal summer or

winter tyre) may be fitted on the compact

temporary spare wheel rim.

● If you are driving using the spare wheel,

the ACC system could automatically switch

off during the journey. Switch off the system

when starting off. Extraction of the spare wheel in

vehicles with SEAT SOUND 10

speakers (with

subwoofer)* –

Disassemble the subwoofer's

floor panel

(c

arpet) as follows:

– LEON/LEON SC model: first, pull the carpet

in the direction of the backrest and then

pull it upwards to remove it. LEON ST mod-

el: lift and secure the floor storage com-

par

tment as explained in ››› page 121.

– Disconnect the subwoofer's speaker cable.

– Turn the sec

uring wheel anti-clockwise.

– Remove the subwoofer speaker and the

s

pare wheel.

– When replacing the spare wheel, place the

subwoofer speaker in the direction indica-

ted b

y the arrow and with the word

“FRONT” facing forward.

– Reconnect the speaker cable and firmly ro-

tate the securing wheel clockwise so that the subwoofer system and wheel are firmly

in place.

Winter service Winter tyres –

Winter tyres must be fitted on all four

wheels.

– Only use winter tyres that are approved for

your vehicle.

– Please note that the maximum permissible

speed for winter tyres may be lower than

for summer tyres.

– Also note that winter tyres are no longer ef-

fective when the tread is worn down.

– Af

ter fitting the wheels you must always

check the tyre pressures. The correct tyre

pressures are listed on the sticker on the

inside of the fuel tank flap ›››

page 208.

In winter road conditions winter tyres will

considerably improve vehicle handling. The

design of summer tyres (width, rubber com-

pound, tread pattern) gives less grip on ice

and snow. This applies particularly to vehi-

cles equipped with wide section tyres or with

high speed tyres (code letters H, V or Y on

the sidew

all). »

215

Technical specifications

Advice

Operation

Safety

The essentials

Page 219 of 284

Emergencies

Snow chains will improve braking ability as

well as traction in winter conditions.

F or t

echnical reasons snow chains may only

be used with the following wheel rim/tyre

combination.

195/65 R15Chains with links of maximum 15 mm

205/55 R16Chains with links of maximum 15 mm

225/45 R17Chains with links of maximum 9 mm

225/40 R18Chains with links of maximum 9 mm Remove wheel covers and any

integral trim

ring before fitting snow chains.

R emo

ve the chains when roads are free of

snow

. Otherwise they will impair handling,

damage the tyres and wear out very quickly. Emergencies

Changing a wheel What to do first Read the additional information carefully

››› page 34

– If you have a flat tyre or puncture, park the

car as far away from the flow of traffic as

possible in a safe place. If you have a punc-

ture, stop the vehicle on a horizontal sur-

face. If you are on a slope, take extra care.

– Apply the handbrake.

– Switch on the hazard warning lights.

– Manual gearbox: select the 1st gear.

– Automatic gearbox: move the selector lever

to P.

– When towing a trailer: unhitch the trailer

from your vehicle.

– Have the vehicle tool kit ›››

page 220 and

the spare wheel ready ›››

page 214.

– Observe the applicable legislation for each

country (reflective vest, warning triangles,

etc.).

– All vehicle occupants should leave the car.

They should wait in a safe area (for in-

stance behind the roadside crash barrier). WARNING

● Always observe the above steps and pro-

tect yourself and other road users.

● If you change the wheel on a slope, block

the wheel on the opposite side of the car with

a stone or similar to prevent the vehicle from

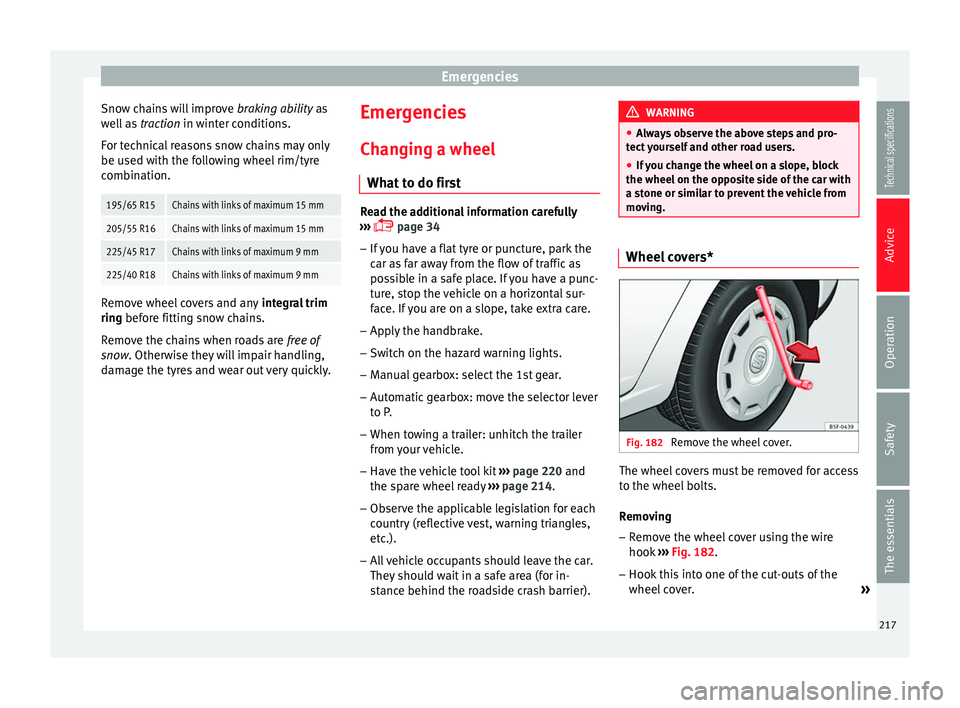

moving. Wheel covers*

Fig. 182

Remove the wheel cover. The wheel covers must be removed for access

to the wheel bolts.

Removing

– Remove the wheel cover using the wire

hook ›››

Fig. 182 .

– Hook thi

s into one of the cut-outs of the

wheel cover. »

217

Technical specifications

Advice

Operation

Safety

The essentials

Page 221 of 284

Emergencies

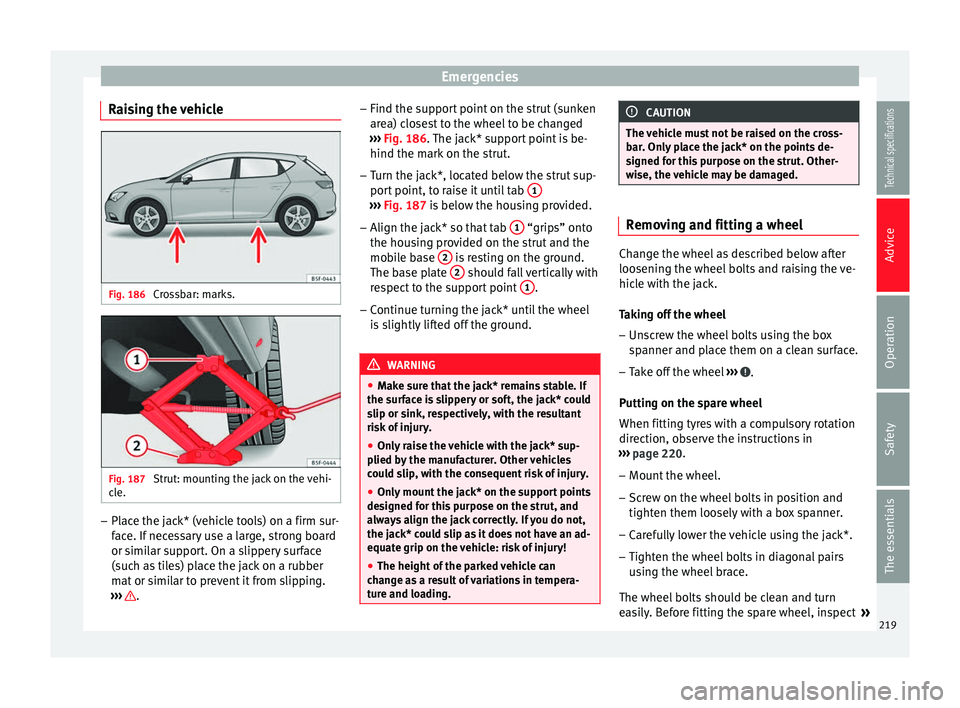

Raising the vehicle Fig. 186

Crossbar: marks. Fig. 187

Strut: mounting the jack on the vehi-

cle. –

Place the jack* (vehicle tools) on a firm sur-

face. If necessary use a large, strong board

or similar support. On a slippery surface

(such as tiles) place the jack on a rubber

mat or similar to prevent it from slipping.

››› . –

Find the support point on the strut (sunken

area) closest to the wheel to be changed

››› Fig. 186 . The jack* support point is be-

hind the m ark

on the strut.

– Turn the jack*, located below the strut sup-

port point, to raise it until tab 1 ›››

Fig. 187 is below the housing provided.

– Align the j

ack* so that tab 1 “grips” onto

the housing provided on the strut and the

mobile base 2 is resting on the ground.

The base plate 2 should fall vertically with

respect to the support point 1 .

– Continue turning the jack* until the wheel

is slightly lifted off the ground. WARNING

● Make sure that the jack* remains stable. If

the surface is slippery or soft, the jack* could

slip or sink, respectively, with the resultant

risk of injury.

● Only raise the vehicle with the jack* sup-

plied by the manufacturer. Other vehicles

could slip, with the consequent risk of injury.

● Only mount the jack* on the support points

designed for this purpose on the strut, and

always align the jack correctly. If you do not,

the jack* could slip as it does not have an ad-

equate grip on the vehicle: risk of injury!

● The height of the parked vehicle can

change as a result of variations in tempera-

ture and loading. CAUTION

The vehicle must not be raised on the cross-

bar. Only place the jack* on the points de-

signed for this purpose on the strut. Other-

wise, the vehicle may be damaged. Removing and fitting a wheel

Change the wheel as described below after

loosening the wheel bolts and raising the ve-

hicle with the jack.

Taking off the wheel

– Unscrew the wheel bolts using the box

spanner and place them on a clean surface.

– Take off the wheel ››› .

Putting on the spare wheel

When fitting tyres with a compulsory rotation

direction, observe the instructions in

››› page 220 .

– Mou nt

the wheel.

– Screw on the wheel bolts in position and

tighten them loosely with a box spanner.

– Carefully lower the vehicle using the jack*.

– Tighten the wheel bolts in diagonal pairs

using the wheel brace.

The wheel bolts should be clean and turn

easily. Before fitting the spare wheel, inspect »

219

Technical specifications

Advice

Operation

Safety

The essentials