engine Seat Leon SC 2015 Owner's Guide

[x] Cancel search | Manufacturer: SEAT, Model Year: 2015, Model line: Leon SC, Model: Seat Leon SC 2015Pages: 308, PDF Size: 5.93 MB

Page 65 of 308

The essentials

Jump leads must comply with standard DIN

72553 (see c ab

l

e manufacturer's instruc-

tions). The wire cross section must be at least

25 mm 2

for petrol engines and at least

35 mm 2

for diesel engines. Note

● The v ehic

les must not touch each other,

otherwise electricity could flow as soon as

the positive terminals are connected.

● The discharged battery must be properly

connected t

o the on-board network. How to jump start: description

Fig. 78

Diagram of connections for vehicles

w ithout

Start Stop system Fig. 79

Diagram of connections for vehicles

with St

art Stop system Jump lead terminal connections

1. Switch off the ignition of both vehicles

››

›

.

2. Connect one end of the re

d

jump lead to

the positive + terminal of the vehicle

w ith the fl

at

battery A

› ›

› Fig. 78 .

3. Connect the other end of the red

jump

lead to the positive terminal + in the ve-

hic l

e pr

oviding assistance B .

4. For vehicles without Start-Stop system:

connect

one end of

the black jump lead to

the negative terminal – of the vehicle

pr o

v

iding the current B

› ›

› Fig. 78 .

– For vehicles with Start-Stop system: con-

nect one end of

the black jump lead X to a

s uit

ab

le ground terminal, to a solid piece of

metal in the engine block, or to the engine

block itself ››› Fig. 79. 5. Connect the other end of the

black

jump

lead X to a solid metal component bolted

t o the en

gine b

lock or to the engine block

itself of the vehicle with the flat battery.

Do not connect it to a point near the bat-

tery A .

6. Position the leads in such a way that they cannot

c

ome into contact with any moving

parts in the engine compartment.

Starting

7. Start the engine of the vehicle with the boostin

g battery and let it run at idling

speed.

8. Start the engine of the vehicle with the flat batter

y and wait for 2 or 3 minutes until

the engine is running.

Removing the jump leads

9. Before you remove the jump leads, switch off the dipped be

am headlights if they are

switched on.

10.

Turn on the heater blower and heated rear

window in the vehicle with the flat battery.

This helps minimise voltage peaks which

are generated when the leads are discon-

nected.

11.When the engine is running, disconnect the lea

ds in reverse order to the details

given above. » 63

Page 66 of 308

The essentials

Make sure the battery clamps have sufficient

met al-t

o-met

al contact with the battery termi-

nals.

If the engine fails to start after about 10 sec-

onds, switch off the starter and try again after

about 1 minute. WARNING

● Ple a

se note the safety warnings referring to

working in the engine compartment

››› page 246.

● The battery providing assistance must have

the same v

oltage as the flat battery (12V) and

approximately the same capacity (see imprint

on battery). Failure to comply could result in

an explosion.

● Never use jump leads when one of the bat-

teries

is frozen. Danger of explosion! Even af-

ter the battery has thawed, battery acid could

leak and cause chemical burns. If a battery

freezes, it should be replaced.

● Keep sparks, flames and lighted cigarettes

awa

y from batteries, danger of explosion.

Failure to comply could result in an explo-

sion.

● Observe the instructions provided by the

manufact

urer of the jump leads.

● Do not connect the negative cable from the

other vehic

le directly to the negative terminal

of the flat battery. The gas emitted from the

battery could be ignited by sparks. Danger of

explosion. ●

Do not att ac

h the negative cable from the

other vehicle to parts of the fuel system or to

the brake line.

● The non-insulated parts of the battery

clamp

s must not be allowed to touch. The

jump lead attached to the positive battery

terminal must not touch metal parts of the ve-

hicle, this can cause a short circuit.

● Position the leads in such a way that they

cannot c

ome into contact with any moving

parts in the engine compartment.

● Do not lean on the batteries. This could re-

sult

in chemical burns. Note

The vehicles must not touch each other, oth-

erw i

se electricity could flow as soon as the

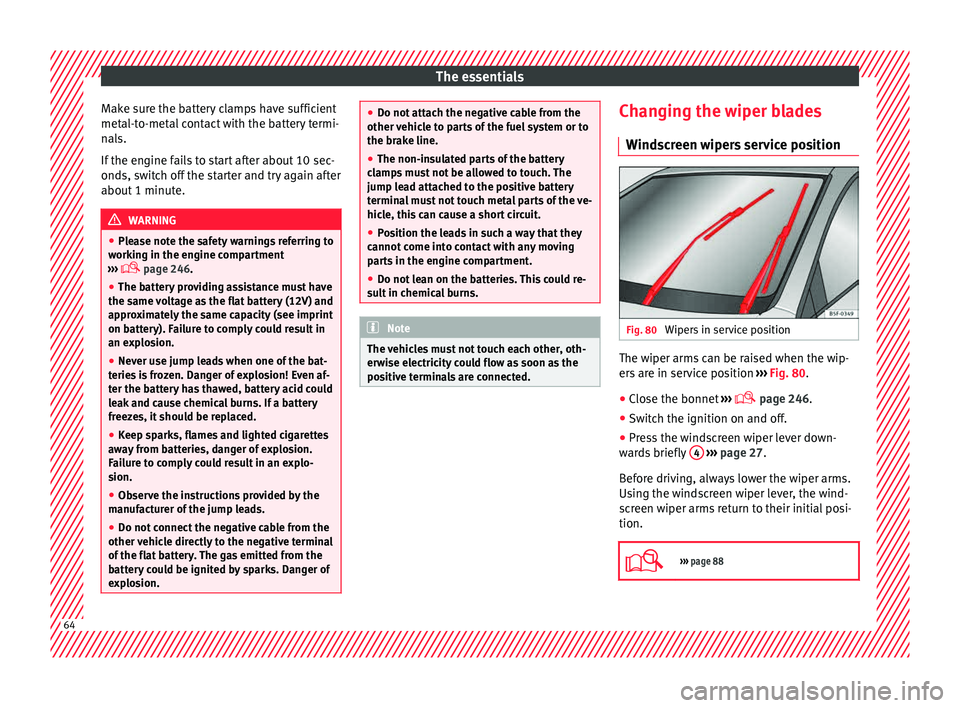

positive terminals are connected. Changing the wiper blades

W ind

s

creen wipers service position Fig. 80

Wipers in service position The wiper arms can be raised when the wip-

er

s

ar

e in service position ››› Fig. 80.

● Close the bonnet ›››

page 246.

● Switch the ignition on and off.

● Press the windscreen wiper lever down-

ward

s briefly 4

› ›

› page 27.

Before driving, always lower the wiper arms.

Using the windscreen wiper lever, the wind-

screen wiper arms return to their initial posi-

tion.

››› page 88 64

Page 81 of 308

Airbag system

such as the properties of the object the vehi-

c l

e hits

(hard/soft), angle of impact, vehicle

speed, etc.

Deceleration trajectory is key for airbag acti-

vation.

The control unit analyses the collision trajec-

tory and activates the respective restraint

system.

If the deceleration rate is below the prede-

fined reference value in the control unit the

airbags will not be triggered, even though

the accident may cause extensive damage to

the car.

The following airbags are triggered in seri-

ous head-on collisions

● Driver airbag.

● Front passenger front airbag

● Knee airbag for the driver.

The fol

lowing airbags are triggered in seri-

ous side-on collisions

● Front side airbag on the side of the acci-

dent.

● Re

ar side airbag on the side of the acci-

dent.

● Cur

tain (head) airbag on the side of the ac-

cident. In an ac

cident with airbag activation:

● the interior lights switch on (if the interior

light swit

ch is in the courtesy light position);

● the hazard warning lights switch on;

● all doors are unlocked;

● the fuel supply to the engine is cut.

Airbag safety instructions Front airb

ags Read the additional information carefully

› ›

›

page 17. WARNING

● The deplo yment

space between the front

passengers and the airbags must not in any

case be occupied by other passenger, pets

and objects.

● The airbags provide protection for just one

accident; r

eplace them once they have de-

ployed.

● It is also important not to attach any ob-

jects

such as cup holders or telephone

mountings to the surfaces covering the air-

bag units.

● Do not attempt to modify components of

the airbag sys

tem in any way. Knee airbag*

Read the additional information carefully

›› ›

page 19. WARNING

● The knee airbag i s

deployed in front of the

driver's knees. Always keep the deployment

areas of the knee airbags free.

● Never not fix objects to the cover or in the

deployment

area of the knee airbag.

● Adjust the driver seat so that there is a dis-

tance of

at least 10 cm (4 inches) between

your knees and the location of the this air-

bag. If your physical constitution prevents

you from meeting these requirements, make

sure you contact a specialised workshop. Side airbags*

Read the additional information carefully

› ›

›

page 19. WARNING

● If you do not wear a seat belt, if you lean

for w

ard, or are not seated correctly while the

vehicle is in motion, you are at a greater risk

of injury if the side airbag system is triggered

in an accident.

● In order for the side airbags to provide their

maximum pr

otection, the prescribed sitting » 79

Technical data

Advice

Operation

Emergencies

Safety

Page 88 of 308

Emergencies

Emergencies

Self -help

V ehic

le tool kit anti-puncture kit* The tools and anti-puncture kit* are stored

under the floor p

anel

in the luggage compart-

ment.

To access the vehicle tools:

– Lift up the floor surface by the plastic han-

dle u nti

l it is fastened to the tabs on both

sides.

Depending on the vehicle equipment, the an-

ti-puncture kit* is located under the floor

panel in the luggage compartment.

The tool kit includes:

● Jack*

● Wire hook for pulling off the wheel cov-

er*/wheel bolt

cap clip.

● Box spanner for wheel bolts*

● Towline anchorage

● Adapter for the anti-theft wheel bolts*

● Towing bracket device

Some of the items

listed are only provided in

certain model versions, or are optional ex-

tras. Note

The jack does not generally require any main-

ten anc

e. If required, it should be greased us-

ing universal type grease. Tyre repair

TMS (T

yre Mobility System)* Read the additional information carefully

›› ›

page 57

The Anti-puncture kit* (Tyre Mobility System)

will reliably seal punctures caused by the

penetration of a foreign body of up to about

4 mm in diameter. Do not remove foreign ob-

jects, e.g. screws or nails, from the tyre.

After inserting the sealant residue in the tyre,

you must again check the tyre pressure about

10 minutes after starting the engine.

You should only use the tyre mobility set if

the vehicle is parked in a safe place, you are

familiar with the procedure and you have the

necessary tyre mobility set! Otherwise, you

should seek professional assistance.

Do not use the tyre sealant in the following

cases:

● If the wheel rim has been damaged.

● In outside temperatures below -20°C (-4°F). ●

In the ev ent

of

cuts or perforations in the

tyre greater than 4 mm.

● If you have been driving with very low pres-

sure or a c

ompletely flat tyre.

● If the sealant bottle has passed its use by

date. WARNING

Using the tyre mobility system can be dan-

ger ou

s, especially when filling the tyre at the

roadside. Please observe the following rules

to minimise the risk of injury:

● Stop the vehicle safely as soon as possible.

Park it

at a safe distance from surrounding

traffic to fill the tyre.

● Ensure the ground on which you park is flat

and solid.

● Al

l passengers and particularly children

must

keep a safe distance from the work area.

● Turn on the hazard warning lights to warn

other roa

d users.

● Use the tyre mobility system only if you are

famili

ar with the necessary procedures. Oth-

erwise, you should seek professional assis-

tance.

● The tyre mobility set is intended for tempo-

rary

emergency use only until you can reach

the nearest specialised workshop.

● Replace the repaired tyre with the tyre mo-

bility

set as soon as possible.86

Page 89 of 308

Self-help

●

The sea l

ant is a health hazard and must be

cleaned immediately if it comes into contact

with the skin.

● Always keep the tyre mobility set out of the

reac

h of small children.

● Never use an equivalent jack, even if it has

been appro

ved for your vehicle.

● Always stop the engine, apply the hand-

brake l

ever firmly and engage gear if using a

manual gearbox, in order to reduce the risk of

vehicle involuntary movement. WARNING

A tyre filled with sealant does not have the

same per f

ormance properties as a conven-

tional tyre.

● Never drive faster than 80 km/h (50 mph).

● Avoid heavy acceleration, hard braking and

fas

t cornering.

● Drive for only 10 minutes at a maximum

speed of 80

km/h (50 mph) and then check

the tyre. For the sake of the environment

Dispose of used or expired sealant observing

any l

egal requirements. Note

A new bottle of sealant can be purchased at

SEA T de

alerships. Note

Take into account the separate instruction

manua l

of the tyre mobility set* manufactur-

er. Contents of the anti-puncture kit*

Fig. 97

Standard representation: contents of

the anti-p u

nct

ure kit. The anti-puncture kit is located underneath

the floor c

o

v

ering in the luggage compart-

ment. It includes the following components

››› Fig. 97:

Tyre valve remover

Sticker indicating maximum speed “max.

80 km/h” or “max. 50 mph”

Filler tube with cap

1 2

3 Air compressor

T

ube f

or infl

ating tyres

Warning provided by tyre pressure moni-

toring system (it can also be integrated in

the compressor).

Air bleed screw (in its place, the compres-

sor may have a button).

ON/OFF switch

12 volt connector

Bottle of sealant

Spare tyre valve

The valve insert remover 1 has a gap at the

lo w

er end f

or a valve insert. The valve insert

can only be screwed or unscrewed in this

way. This also applies to its replacement part 11 .

WARNING

When inflating the wheel, the air compressor

and the inflat or t

ube may become hot.

● Protect hands and skin from hot parts.

● Do not place the hot flexible inflator tube or

hot air compr

essor on flammable material.

● Allow them to cool before storing the de-

vice.

● If

it is not possible to inflate the tyre to at

lea

st 2.0 bars (29 psi / 200 kPa), the tyre is

too badly damaged. The sealant is not in a

good condition to seal the tyre. Do not con-

tinue driving. Seek specialist assistance. » 4

5

6

7

8

9

10

11

87

Technical data

Advice

Operation

Emergencies

Safety

Page 93 of 308

Fuses and bulbs

Towing vehicles with a manual gear-

bo x Towing is relatively straightforward.

Ple

a

se observe the relevant instructions

››› page 89.

The vehicle can be towed using a tow bar or

tow rope in the normal way, with all four

wheels on the road; it can also be towed with

either the front or rear wheels lifted off the

road. The maximum towing speed is 50 km/h

(30 mph).

Towing a vehicle equipped with auto-

matic g

earbox Certain restrictions must be observed when

t

o

w

ing your vehicle.

Please observe the relevant instructions

››› page 89.

The vehicle can be towed with a tow bar or

tow rope in the normal way, with all four

wheels on the ground. When doing so,

please note the following points:

● Make sure the selector l

ever is in the N po-

sition.

● The vehicle must not be towed faster than

50 km/h (30 mph).

● The vehicle must not be towed further than

50 km (30 mile

s). Reason: when the engine is not running, the gearbox oil pump does

not work

and the gearbox is not adequately

lubricated for higher speeds or longer distan-

ces.

If the vehicle has to be towed with a break-

down truck, it must only be suspended at the

front wheels. Reason: the drive shafts are lo-

cated on the front wheels. If the car is towed

with the rear wheels lifted off the road (I.e.

travelling backwards), the drive shafts also

turn backwards. The planetary gears in the

automatic gearbox then turn at such high

speeds that the gearbox will be severely

damaged in a short time. Note

● If it i

s not possible to tow the vehicle in the

normal way, or if it has to be towed further

than 50 km (30 miles), it must be transported

on a special car transporter or trailer.

● Should the power supply to the selector

lever be int

errupted in position P, the selector

lever will be locked. Before the vehicle can be

recovered/manoeuvred you must manually

release the selector lever ›››

page 44. Fuses and bulbs

F u

se

s

Introduction In general, a fuse can be assigned to various

electric

al

components. Likewise, an electrical

component can be protected by several

fuses.

Only replace fuses when the cause of the

problem has been solved. If a newly inserted

fuse blows after a short time, you must have

the electrical system checked by a special-

ised workshop as soon as possible. WARNING

The high voltages in the electrical system can

give seriou s

electrical shocks, causing burns

and even death!

● Never touch the electrical wiring of the igni-

tion syst

em.

● Take care not to cause short circuits in the

electrica

l system. WARNING

Using unsuitable fuses, repairing fuses or

bridging a c urr

ent circuit without fuses can

cause a fire and serious injury. » 91

Technical data

Advice

Operation

Emergencies

Safety

Page 94 of 308

Emergencies

●

Never u se a f

use with a higher value. Only

replace fuses with a fuse of the same amper-

age (same colour and markings) and size.

● Never repair a fuse.

● Never replace a fuse by a metal strip, staple

or simil

ar. CAUTION

● To pr ev

ent damage to the vehicle's electric

system, before replacing a fuse always turn

off the ignition, the lights and all electrical

elements and remove the key from the igni-

tion.

● If you replace a fuse with higher-rating

fuse,

you could cause damage to another part

of the electrical system.

● Protect the fuse boxes when open to pre-

vent the entr

y of dust or humidity as they can

damage the electrical system. Note

● One component m

ay have more than one

fuse.

● Several components may run on a single

fuse. Vehicle fuses

Fig. 101

On the driver-side dash panel: fuse

bo x

c

over Fig. 102

In the engine compartment: fuse box

c o

v

er Read the additional information carefully

› ›

›

page 55

Only replace fuses with a fuse of the same

amperage (same colour and markings) and

size. Opening and closing the fuse box situated

below the da

sh panel

● Opening: fold the cover down ››

› Fig. 101.

● Closing: push back the cover it in until it

clic

ks into place.

To open the engine compartment fuse box

● Open the bonnet ›››

page 246.

● Press the locking tabs to release the fuse

box c

over ››› Fig. 102.

● Then lift the cover out.

● To fit the cover, place it on the fuse box.

Pu

sh the locking tabs down until they click

audibly into place.

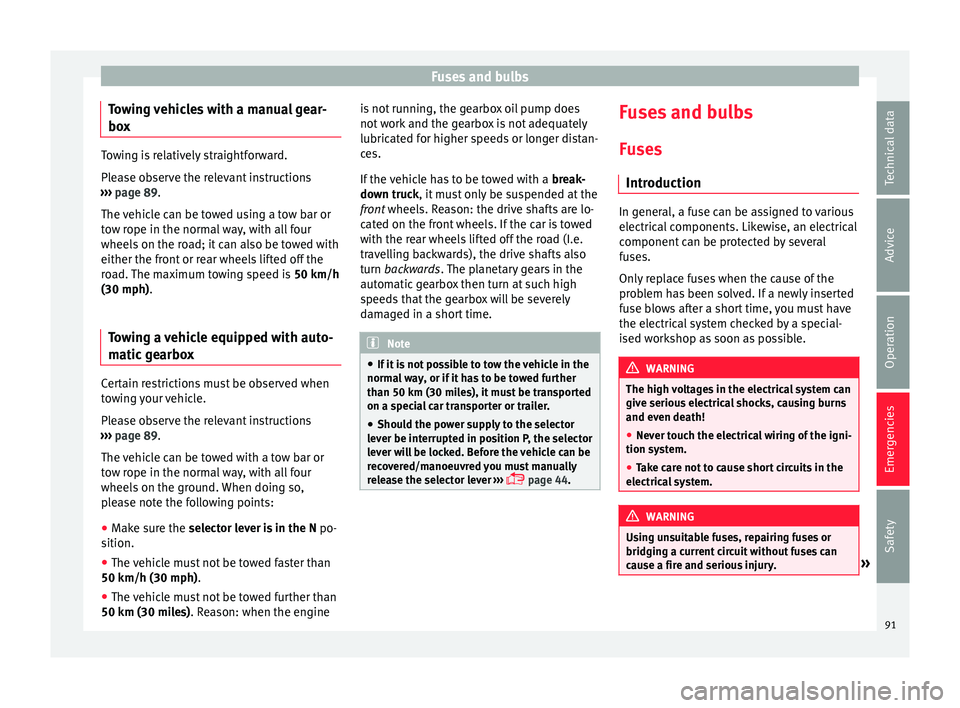

Fuses in the vehicle interior

No.Consumers/Amps

4Taxis3

5Gateway5

6Automatic gearbox lever5

7Air conditioning and heating control

panel, heating the back window.10

8Diagnosis, handbrake switch, light

switch, reverse light, interior lighting10

9Steering column5

10Radio display5

12Radio20 92

Page 95 of 308

Fuses and bulbsNo.Consumers/Amps

13Driving mode.15

14Air conditioner fan30

17Instrument panel5

18Rear camera7.5

214x4 Haldex Control Unit15

22Trailer15

23Right lights40

24Electric sunroof30

25Left door30

26Heated seats20

28Trailer25

31Left lights40

32Parking aid control unit7.5

33Airbag5

34Reverse switch, clima sensor, electro-

chromic mirror7.5

35Diagnosis, headlight control unit,

headlight adjuster10

36Front camera, Radar10

38Trailer25

39Right door30

4012V socket20

No.Consumers/Amps

42Central locking40

43Interior light30

44Trailer15

45Electric driver's seat15

47Rear window wiper15

49Starter motor; clutch sensor5

53Heated rear window30

Fuse arrangement in engine compartment

No.Consumers/Amps

1ESP control unit40/20

2ESP control unit40

3Engine control unit (diesel/pet-

rol)30/15

4Engine sensors5/10

5Engine sensors7.5/10

6Brake light sensor5

7Engine power supply5/10

8Lambda probe10/15

9Engine5/10/20

10Fuel pump control unit10/15/20

11PTC40

No.Consumers/Amps

12PTC40

13Automatic gearbox control unit15/30

15Horn15

16Fuel pump control unit5/15/20

17Engine control unit7.5

18Terminal 30 (positive reference)5

19Front windscreen washer30

20Alarm horn10

22Engine control unit5

23Starter motor30

24PTC40

31Electronic differential CUPRA15

CAUTION

● Alw a

ys carefully remove the fuse box cov-

ers and refit them correctly to avoid problems

with your vehicle.

● Protect the fuse boxes when open to avoid

the entry of

dust or humidity. Dirt and humid-

ity inside fuse boxes can cause damage to

the electrical system. » 93

Technical data

Advice

Operation

Emergencies

Safety

Page 96 of 308

Emergencies

Note

● In the v ehic

le, there are more fuses than

those indicated in this chapter. These should

only be changed by a specialised workshop.

● Positions not containing a fuse do not ap-

pear in the fo

llowing tables.

● Some of the equipment listed in the tables

below pert

ain only to certain versions of the

model or are optional extras.

● Please note that the above lists, while cor-

rect at

the time of printing, are subject to

change. Bulbs

Ch an

gin

g a bulbRead the additional information carefully

› ›

›

page 56.

Changing bulbs requires a certain degree of

practical skill.

If you choose to change the engine compart-

ment lamps yourself, remember that it is a

dangerous area ››› in Work in the engine

c omp

ar

tment on page 246.

Always use identical bulbs with the same

designation. The name can be found on the

base of the bulb holder. Depending on how equipped the vehicle is,

there are diff

erent sets of headlights and tail

lights:

● Halogen headlights

● Full-LED main headlights*

● Rear bulb light

● LED rear light*

Ful

l-LED headlight system*

Full-LED headlights handle all light functions

(daylight, side light, turn signal, dipped

beam and route light) with light emitting di-

odes (LEDs) as a light source.

Full-LED headlights are designed to last the

lifetime of the car and light bulbs cannot be

replaced. In case of headlight failure, go to

an authorised workshop to have it replaced. WARNING

● Tak e p

articular care when working on com-

ponents in the engine compartment if the en-

gine is warm. Risk of burns.

● Bulbs are highly sensitive to pressure. The

glas

s can break when you touch the bulb,

causing injury.

● When changing bulbs, please take care not

to injure

yourself on sharp edges, in particu-

lar on the headlight housing. CAUTION

● Remo v

e the ignition key before working on

the electric system. Otherwise, a short circuit

could occur.

● Switch off the lights and the parking light

before c

hanging a bulb.

● Take good care to avoid damaging any com-

ponents. For the sake of the environment

Please ask your specialist retailer how to dis-

pose of u

sed bulbs in the proper manner. Note

● Ple a

se check at regular intervals that all

lighting (especially the exterior lighting) on

your vehicle is functioning properly. This is

not only in the interest of your own safety,

but also that of all other road users.

● Before changing a bulb, make sure you

have the c

orrect new bulb.

● Do not touch the glass part of the bulb with

your bar

e hands, use a cloth or paper towel

instead, since the fingerprints left on the

glass will vaporise as a result of the heat gen-

erated by the bulb, they will be deposited on

the reflector and will impair its surface. 94

Page 106 of 308

Operation

Instruments and warning/control lamps

In s

trument

s

View of instrument panel Fig. 124

Instrument panel, on dash panel Details of the instruments

››

›

Fig. 124:

Rev counter (with the engine running, in

hundreds of revolutions per minute).

The beginning of the red zone of the rev

counter indicates the maximum speed in

any gear after running-in and with the en-

gine hot. However, it is advisable to

change up a gear or move the selector

lever to D (or lift your foot off the acceler-

1 ator) before the needle reaches the red

z

one

›

›

› .

En gine c

oo

lant temperature display

››› page 107 or the natural gas level indi-

cator in vehicles with natural gas engine

(CNG) ››› page 108.

Displays on the screen ››› page 105.

Adjuster button and display

››› page 107.

2

3

4 Speedometer.

F

uel

g

auge ››› page 108. WARNING

Any distraction may lead to an accident, with

the risk of

injury.

● Do not operate the instrument panel con-

trol

s when driving. 5

6

104