brake Seat Mii 2012 Workshop Manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2012, Model line: Mii, Model: Seat Mii 2012Pages: 308, PDF Size: 4.13 MB

Page 214 of 308

212Vehicle care and maintenance

perfect condition on the outside and which have a tread depth within the

values stipulated by the Law ⇒

.

The date of manufacture, part of the tyre identification number (TIN), indi-

cates the age of the tyre ( ) ⇒ page 218.

Storing tyres

Mark tyres when you remove them to indicate the direction of rotation (left,

right, forwards, backwards). This ensures you will be able to mount them

correctly when you replace them. When removed, the wheels and/or tyres

should be stored in a cool, dry and preferably dark location. Do not place

tyres mounted on the wheel in a vertical position.

Protect tyres not mounted on wheels from dirt by storing them in suitable

bags and standing them on the ground on their tread.

WARNING

Aggressive fluids or substances could result in visible or invisible dam-

age with the consequent risks.

● Always ensure that tyres do not come into contact with chemical

products, oil, grease, fuel, brake fluid or other aggressive substances.

WARNING

Old tyres, even if they have never been used, may lose air or burst unex-

pectedly while driving, resulting in serious accident or damage.

● If tyres are over six years old, they should only be used in an emer-

gency and with extreme caution.

For the sake of the environment

Old tyres must be disposed of by qualified personnel according to the laws

in the country concerned. Wheel rims

The design of wheel bolts is matched to the rims. If different rims are fitted,

the correct wheel bolts with the right length and correctly shaped bolt

heads must be used. This ensures that wheels are fitted securely and that

the brake system functions correctly

⇒ page 250.

For technical reasons, it is not generally possible to use the wheels from

other vehicles. In some cases, this may also be true for the same model of

wheel.

The tyres and rims approved by SEAT are specially matched to the character-

istics of the vehicle and are critical to good road holding and safe handling.

Wheel bolts

Wheel bolts must be tightened to the correct torque ⇒ page 250.

Beadlock wheel rims

Beadlock wheel rims have various components. These are joined together

by special bolts using a special procedure. This ensures good performance,

a better seal, improved safety and wheel run out. Therefore, worn rims

should always be replaced and must only be repaired in a Specialised work-

shop. SEAT recommends visiting a Technical Service ⇒

.

Wheel trims with bolted trims

Wheel trims may be fitted with interchangeable trim parts which are attach-

ed to the rim using self-locking bolts. Worn trims should only be replaced at

a Specialised workshop. SEAT recommends visiting a Technical Service

⇒

.

Page 215 of 308

213

Vehicle care and maintenance

WARNING

The use of worn or damaged wheel trims could make driving more dan-

gerous and result in serious accidents and damage.

● Only wheel trims which have been approved for use with your vehicle

should be used.

● Inspect wheel trims regularly for damage and replace as required.

WARNING

If the bolted joints of wheel trims with bolted ring trims are not correctly

tightened or loosened, this could result in serious accident.

● Never loosen the bolted joints of wheel trims with bolted ring trims.

● Any work relating to wheel trims with bolted trims should be carried

out at Specialised workshop. SEAT recommends visiting a Technical Serv-

ice.

Replacement of new tyres and wheel trims

New tyres

● When tyres are new, drive with extreme caution for the first 600 km

(400 miles), as all tyres need to be run-in. Tyres which have not been run-in

do not have such good grip ⇒

or braking capacity ⇒ .

● All four wheels must be fitted with radial tyres of the same type, size

(rolling circumference) and the same tread pattern.

● The tread depth of new tyres may vary, according to the type and make

of tyre and the tread pattern. Replacing tyres

●

Where possible, always replace both wheels on an axle (both wheels on

the front axle or both wheels on the rear axle) ⇒

.

● Only replace used tyres with those authorised by SEAT for the corre-

sponding type vehicle. Pay special attention to size, diameter, and maxi-

mum load and speed capacity.

● Never use tyres which are larger than SEAT approved tyres. If the tyres

are too big, they may knock or rub against the chassis or other components,

resulting in damage.

WARNING

New tyres do not give maximum grip and will not have reached their max-

imum braking capacity to start with, and therefore need running in.

● To prevent accidents and major damage, extreme caution should be

taken for the first 600 km (400 miles).

WARNING

There should be adequate space between the tyres and the vehicle in ac-

cordance with the vehicle design. If this is not the case, the tyres may

rub against parts of the running gear, chassis or brake lines, leading to

faults in the brake system or to tread detachment, and the risk of burst

tyres.

● The true tyre dimension should not be greater than the dimensions of

tyres manufactured and approved by SEAT and should not rub against

parts of the vehicle.

Note

Although tyres may be shown as being the same size, the true dimensions

of different types of tyre may vary with respect to the nominal size, or tread

patterns may be different.

Vehicle diagramPrior to a journey...While drivingCare, cleaning and mainte-

nanceIf and whenTechnical Data

Page 225 of 308

223

Vehicle care and maintenance

Running-in

Please observe the instructions for running-in new components.

Running-in the engine

The engine needs to be run in over the first 1500 km (1000 miles). During

its first few hours of running, the internal friction in the engine is greater

than later on when all the moving parts have bedded down.

How the vehicle is driven for the first 1500 km (1000 miles) influences the

future engine performance. Throughout the life of the vehicle, it should be

driven at a moderate speed, especially when the engine is cold, as this will

reduce engine wear and increase its useful life. Never drive at extremely low

engine speeds. Change down to a lower gear when the engine no longer

runs “smoothly”. Up to 1000 kilometres the following instructions apply:

● Do not use full throttle.

● Do not force the engine above two thirds of its maximum speed.

Between 1000 and 1500 kilometres (600 to 1000 miles), gradually in-

crease power until reaching the maximum speed and high engine speeds.

Running in new tyres and brake pads

● Replacement of new tyres and wheel trims ⇒ page 210

● Notes on the brakes ⇒ page 134

For the sake of the environment

If the engine is run in gently, the life of the engine will be increased and the

engine oil consumption reduced.

Accessories and spare parts

SEAT recommends you consult an Official Service before purchasing acces-

sories and spare parts or consumables. For example, when fitting accesso- ries at a later date, or when replacing a component. A SEAT Official Service

will advise you as to the legal requirements and manufacturer's recommen-

dations regarding accessories, spare parts and other components.

SEAT recommend you use only approved

SEAT accessories and genuine

SEAT spare parts ®

. These parts and accessories have been specially tested

by SEAT for suitability, reliability and safety. In addition the SEAT Technical

Service will guarantee that the assembly is carried out professionally.

Although we continually monitor the market, SEAT cannot guarantee that

products not approved by SEAT are reliable, safe and suitable for the vehi-

cle. Therefore, SEAT cannot accept liability, even in those cases authorised

by an officially recognised technical inspection office or other official body.

Any retro-fitted equipment which has a direct effect on vehicle control must

be approved by SEAT for use in your vehicle and bear the e mark (the Euro-

pean Union's authorisation symbol). This includes cruise control systems or

electronically controlled suspension.

If any additional electrical components are fitted which do not serve to con-

trol the vehicle itself, these must bear the mark (European Union manu-

facturer conformity declaration). This includes refrigerator boxes, laptops or

ventilator fans.

WARNING

Unprofessional repairs or modifications to the vehicle may affect the per-

formance of the airbags, resulting in operating faults or fatal accident.

● Never mount, fasten or fit objects such as drink holders or telephone

cradles over or next to the covers of the airbag modules or within their

deployment zones.

● Objects placed over the airbag covers, or within their deployment

zones, could lead to serious injury or loss of life if the airbags are trig-

gered.

Vehicle diagramPrior to a journey...While drivingCare, cleaning and mainte-

nanceIf and whenTechnical Data

Page 242 of 308

240Practical information

In case of emergency

Introduction

Additional information and warnings:

● Braking, stopping and parking ⇒ page 134

● Emergency locking and unlocking ⇒ page 243

● Vehicle tools ⇒ page 246

● Change wheel ⇒ page 250

WARNING

A faulty vehicle in traffic represents a risk of accident for the driver and

for other road users.

● Stop the vehicle safely as soon as possible. Park the vehicle a safe

distance from surrounding traffic to lock all the doors in case of an emer-

gency. Turn on the hazard warning lights to warn other road users.

● Never leave children or disabled people alone in the vehicle if the

doors are to be locked. In case of an emergency, passengers will be trap-

ped inside the vehicle. Individuals locked in the vehicle can be exposed

to very high or very low temperatures.

Protecting yourself and securing the vehicle

Fig. 130 Dash panel:

Button to switch on and

off the hazard warning

lights system

Always fulfil legal requirements for securing a broken down vehicle. In a

number of countries it is now obligatory, for example, to turn on the hazard

warning lights and use a reflective safety vest ⇒ page 242.

Checklist

For your own safety and that of other passengers, the following points

should be observed in the order given ⇒

:

1. Park the vehicle a safe distance from traffic and on suitable ground ⇒

.

2. Turn on the hazard warning lights system with the button

⇒ Fig. 130.

3. Apply the handbrake firmly ⇒ page 134.

4. Put the gearbox lever in neutral or the selector lever in position P ⇒ page 124.

5. Switch off the engine and remove the key from the ignition.

6. Have all occupants leave the vehicle and move to safety, for example behind a guard rail.

Page 243 of 308

241

Practical information

Checklist (Continued) 7. When leaving the vehicle, take all keys with you.

8. Place an emergency warning triangle to indicate the position of your vehicle to other road users.

9. Allow the engine to cool and check if a specialist is required.

When being towed with the hazard warning lights system on, a change in

direction or traffic lane can be indicated as usual using the turn signals lev-

er. The hazard lights will be interrupted temporarily.

Examples of when to use the hazard warning lights system:

● If the vehicles ahead suddenly slow down or reach the end of a traffic

jam, to warn the vehicles behind.

● In case of an emergency.

● If the vehicle breaks down.

● When tow-starting or towing.

Always comply with the applicable laws regarding the use of hazard warn-

ing lights.

If the hazard warning lights system is not working, you must use an alterna-

tive method of drawing attention to your vehicle. This method must comply

with traffic legislation.

WARNING

Failure to follow the checklist prepared for your own safety could lead to

accidents and severe injuries.

● Always complete the operations given in the checklist and observe

the general rules of safety.

WARNING

The components of the exhaust system reach very high temperatures.

This could cause a fire and considerable damage.

● Always park your vehicle so that no part of the exhaust system can

come in contact with flammable materials (such as dried grass or fuel).

Note

The vehicle battery will discharge and run down if the hazard warning lights

remain on for too much time (even with the ignition turned off).

Note

For some vehicles, the brake lights will blink when braking suddenly at

speeds of approximately 80 km/h (50 mph) to warn vehicles behind. If brak-

ing continues, then the hazard warning lights system will automatically be

turned on at the speed of less than approximately 10 km/h (6 mph). The

brake lights remain lit. Upon accelerating, the hazard warning lights system

will be automatically turned off.

Vehicle diagramPrior to a journey...While drivingCare, cleaning and mainte-

nanceIf and whenTechnical Data

Page 250 of 308

248Practical information

Wheel trims

Introduction

Additional information and warnings:

● Caring for and cleaning the vehicle exterior ⇒ page 197

● Vehicle tools ⇒ page 246

● Change wheel ⇒ page 250

● Tire Mobility Set ⇒ page 256

WARNING

If the wheel trims are not appropriate or not fitted correctly, they could

cause major accidents or damage.

● Incorrectly mounted wheel trims may come off while driving and en-

danger other road users.

● Damaged trims must never be mounted on the wheels.

● Always ensure that the brake ventilation and cooling is not cut off or

blocked. This is also valid if hubcaps are fitted later. If there is not

enough air, you may require significantly longer braking distances.

CAUTION

Remove and remount wheel trims taking care to avoid damage to the vehi-

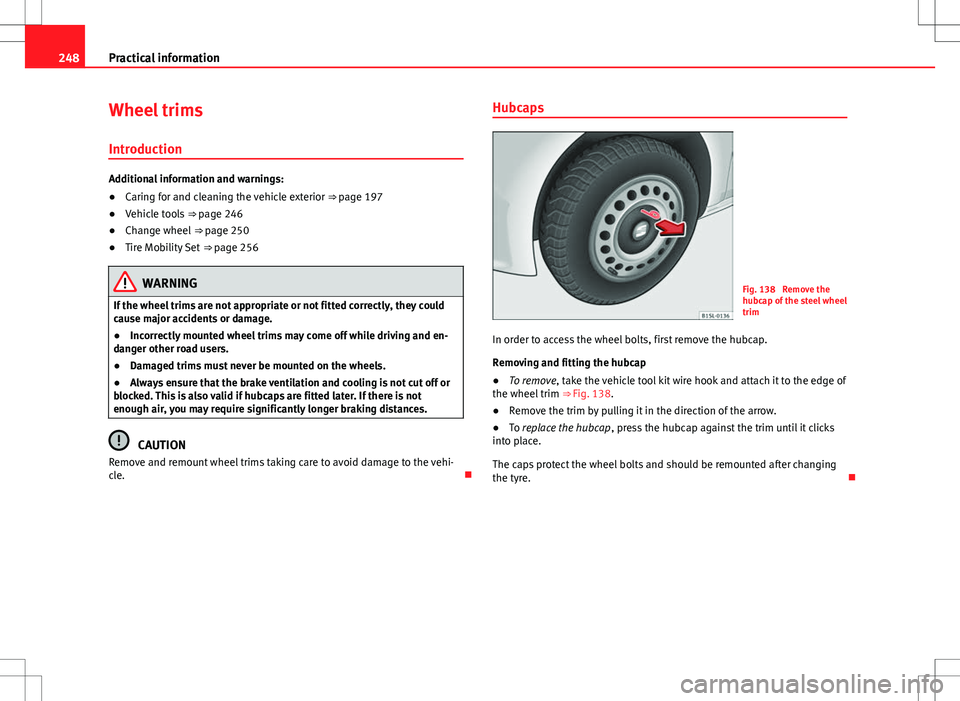

cle. Hubcaps

Fig. 138 Remove the

hubcap of the steel wheel

trim

In order to access the wheel bolts, first remove the hubcap.

Removing and fitting the hubcap

● To remove, take the vehicle tool kit wire hook and attach it to the edge of

the wheel trim ⇒ Fig. 138.

● Remove the trim by pulling it in the direction of the arrow.

● To replace the hubcap , press the hubcap against the trim until it clicks

into place.

The caps protect the wheel bolts and should be remounted after changing

the tyre.

Page 252 of 308

250Practical information

Changing a wheel

Introduction

Some vehicle versions and models do not have a factory-fitted jack or box

spanner. In this case, we recommend consulting a Specialised workshop to

change the wheel.

You should only change the wheels yourself if the vehicle is parked in a safe

place, you are familiar with the procedure and you have all the necessary

tools! Otherwise, you should seek professional assistance.

Additional information and warnings:

● Exterior detail ⇒ page 6

● Vehicle key set ⇒ page 28

● Wheels and tyres ⇒ page 210

● In case of emergency ⇒ page 240

● Vehicle tools ⇒ page 246

● Wheel trims ⇒ page 248

WARNING

Changing a wheel can be dangerous, especially on the hard shoulder.

Please observe the following rules to minimise the risk of injury:

● Stop the vehicle safely as soon as possible. Park your vehicle as safe

distance from surrounding traffic to change a wheel.

● When changing a wheel, keep all passengers and particularly chil-

dren a safe distance away from the work area.

● Turn on the hazard warning lights to warn other road users.

● Ensure the ground on which you park is flat and solid. If necessary,

support the jack on a wide solid base.

WARNING (Continued)

● If you are changing a wheel yourself, you should be familiar with the

required procedure. Otherwise, you should seek professional assistance.

● Only use suitable tools that are not damaged when changing a wheel.

● Always stop the engine, apply the handbrake lever firmly and place

the selector lever in position P, or engage a gear for a manual gearbox to

reduce the risk of the vehicle moving accidentally.

● Have the tightening torque of the wheel bolts checked as soon as

possible with a reliable torque wrench.

Page 253 of 308

251

Practical information

Preparations for changing a wheel

Check list

Before changing a wheel, complete the following operations in the order

given ⇒

:

1. In the event of a flat tyre, park the vehicle a safe distance from traffic and on suitable ground.

2. Apply the handbrake firmly ⇒ page 134.

3. Automatic gearbox: move the selector lever to position P

⇒ page 124.

4. Stop the engine and remove the key from the ignition ⇒ page 119.

5. Manual gearbox: Select a gear ⇒ page 124.

6. Have all vehicle occupants get out of the vehicle and wait in a safe place (for example, behind the safety barrier).

7. Chock the wheel opposite the wheel being changed with a stone or similar object.

8. If the luggage compartment is full: take the baggage out of the vehi- cle.

9. Remove the spare wheel or the temporary spare wheel and the vehi- cle tool kit from the luggage compartment.

10. Remove the wheel trims ⇒ page 248.

WARNING

Failure to follow the checklist prepared for your own safety could lead to

accidents and severe injuries.

● Always complete the operations given in the checklist and observe

the general rules of safety.

Wheel bolts

Fig. 141 Changing the

wheel: Slacken the wheel

bolts

Fig. 142 Changing the

wheel: Tyre valve

1 and

position of anti-theft

wheel locking bolt 2

Only use the tool supplied with the vehicle to loosen the wheel bolts.

Loosen the wheel bolts only about one turn before raising the vehicle with

the jack.

Vehicle diagramPrior to a journey...While drivingCare, cleaning and mainte-

nanceIf and whenTechnical Data

Page 254 of 308

252Practical information

If the wheel bolt is very tight, you may be able to loosen it by pushing down

on the end of the wheel brace carefully with your foot. Hold on to the vehicle

for support and take care not to slip.

Loosening wheel bolts

● Fit the wheel brace as far as it will go over the wheel bolt ⇒ Fig. 141.

● Hold the wheel brace at the end and rotate the bolt approximately one

turn anticlockwise ⇒

.

Loosening anti-theft wheel bolts

For wheels with full hubcap, the anti-theft wheel lock must be threaded into

position ⇒ Fig. 142 2

before mounting the hubcap. Otherwise it will not be

possible to mount the full hubcap.

● Take the adapter for anti-theft wheel bolts out of the vehicle tool kit.

● Insert the adapter onto the wheel bolt ⇒ Fig. 142. Push it on as far as it

will go.

● Fit the wheel brace onto the adapter as far as possible.

● Hold the wheel brace at the end and rotate the bolt approximately one

turn anticlockwise ⇒

.

Important information about wheel bolts

The wheel rims and bolts have been designed to be fitted to factory op-

tions. If different rims are fitted, the correct wheel bolts with the right length

and correctly shaped bolt heads must be used. This ensures that wheels are

fitted securely and that the brake system functions correctly.

In some circumstances, wheel bolts from the same model vehicle should

not be used.

Wheel bolt tightening torque

The prescribed tightening torque for wheel bolts for steel and alloy wheels

is 110 Nm. Have the tightening torque of the wheel bolts checked as soon

as possible with a reliable torque wrench. If wheel bolts are rusty and it is difficult to tighten them, the threads should

be replaced and cleaned before checking the tightening torque.

Never grease or lubricate wheel bolts or the wheel hub threads. Although

they have been tightened to the prescribed torque, they could come loose

while driving.

WARNING

If the wheel bolts are not fitted correctly they could be released while

driving leading to loss of vehicle control and serious damage.

● Only use wheel bolts which correspond to the wheel rims in question.

● Never use different wheel bolts.

● The bolts and threads should be clean, free of oil and grease and easy

to thread.

● To loosen and tighten the wheel bolts, always use the wheel brace

supplied with the vehicle.

● Loosen the wheel bolts only about one turn before raising the vehicle

with the jack.

● Never grease or lubricate wheel bolts or the wheel hub threads. Al-

though they have been tightened to the prescribed torque, they could

come loose while driving.

● Never loosen the bolted joints of wheel trims with bolted ring trims.

● If the wheel bolts are not tightened to the correct torque, they may

come loose while driving, and the bolts and rims may come out. If the

tightening torque is too high, the wheel bolts and threads can be dam-

aged.

Page 256 of 308

254Practical information

Check list

For your own safety and that of other passengers, the following points

should be observed in the order given ⇒

:

1. Select a suitable flat and firm surface for raising the vehicle.

2. Switch off the engine, engage a gear (manual gearbox) or place the selector lever in position P ⇒ page 124 and engage the handbrake

⇒ page 134.

3. Block the wheel diagonally opposite the wheel being changed with collapsible wheel chocks or other suitable objects.

4. Loosen the wheel bolts on the wheel to be changed ⇒ page 251.

5. Look below the vehicle for the jacking point ⇒ Fig. 143 closest to the

tyre which has to be changed.

6. Raise the jack with the handle until it can be inserted below the jack- ing point.

7. Ensure that the foot of the jack is firmly on the ground and that it is placed, at a vertical angle, immediately below the lifting point on the

vehicle ⇒ Fig. 144.

8. Straighten the jack and continue raising it using the handle until the claw holds the vertical reinforcement beneath the vehicle ⇒ Fig. 144.

9. Raise the vehicle until the wheel is clear of the ground.

WARNING

If the vehicle is not correctly raised, it could fall off the jack causing seri-

ous injury. Please observe the following rules to minimise the risk of in-

jury:

● You should only use a jack approved by SEAT for your vehicle. Other

jacks, even those approved for other SEAT models, might slip out of

place.

WARNING (Continued)

● The ground should be firm and flat. If the ground is sloped or soft

then the vehicle could slip and fall off the jack. If necessary, support the

jack on a wide solid base.

● If the ground is slippery (for example, on tiles), place a non-slip sur-

face (for example a floor mat) beneath the jack to avoid slipping.

● Only fit the jack at the prescribed jacking points. The claw of the jack

should grip the reinforcement nerve on the underbody ⇒ Fig. 144.

● You should never have any limbs beneath a raised vehicle which is

only supported by a jack.

● If you have to work underneath the vehicle, you must use suitable

stands additionally to support the vehicle, there is a risk of accident!.

● Never raise the vehicle if it is tilting to one side or the engine is run-

ning.

● Never start the engine when the vehicle is raised. The vehicle may

come loose from the jack due to the engine vibrations.

WARNING

Failure to follow the checklist prepared for your own safety could lead to

accidents and severe injuries.

● Always complete the operations given in the checklist and observe

the general rules of safety.