technical specifications Seat Mii 2014 Owners Manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2014, Model line: Mii, Model: Seat Mii 2014Pages: 219, PDF Size: 4.19 MB

Page 183 of 219

Emergencies

WARNING

When inflating the wheel, the air compressor

and the inflator tube may become hot.

● Protect hands and skin from hot parts.

● Do not place the hot flexible inflator tube or

hot air compressor on flammable material.

● Allow them to cool before storing the de-

vice.

● If it is not possible to inflate the tyre to at

least 2.0 bars (29 psi / 200 kPa), the tyre is

too badly damaged. The sealant is not in a

good condition to seal the tyre. Do not con-

tinue driving. Seek specialist assistance. CAUTION

Switch off the air compressor after a maxi-

mum of 8 operational minutes to avoid over-

heating! Before switching on the air compres-

sor again, let it cool for several minutes. Check after 10 minutes of driving

Screw in the inflator tube

›››

Fig. 132 5 again and check the pressure on the gauge

6 .

1.3 bar (19 psi / 130 kPa) and lower:

● Stop the vehicle! The tyre cannot be sealed

sufficiently with the tyre mobility set.

● You should obtain professional assistance

››› . 1.4 bar (20 psi / 140 kPa) and higher:

●

Set the tyre pressure to the correct value

again ››› page 158 .

● Car

efully resume your journey until you

reach the nearest specialised workshop with-

out exceeding 80 km/h (50 mph).

● Have the damaged tyre replaced. WARNING

Driving with an unsealed tyre is dangerous

and can cause accidents and serious injury.

● Do not continue driving if the tyre pressure

is 1.3 bar (19 psi / 130 kPa) and lower.

● Seek specialist assistance. Starting assistance

Introduction If the engine fails to start because of a dis-

charged battery, the battery of another vehi-

cle can be used to start the engine. Before

starting, check the magic eye on the battery

››› page 154 .

F or s

tarting assistance, jump lead cables con-

forming to the standard DIN 72553 are re-

quired (see the cable manufacturer instruc-

tions). The cable section in vehicles with pet-

rol engine must be at least 25 mm 2

. WARNING

Incorrect use of jump leads and incorrectly

jump starting could cause the battery to ex-

plode resulting in serious injury. Please ob-

serve the following rules to minimise the risk

of a battery explosion:

● The battery providing current must have

the same voltage (12V) and approximately

the same capacity (see markings on battery)

as the flat battery.

● Never charge a frozen or recently thawed

battery. A flat battery can also freeze at tem-

peratures close to 0 °C (+32 °F).

● If a battery is frozen and/or has been frozen

then it must be replaced.

● A highly explosive mixture of gases is re-

leased when the battery is being charged. Al-

ways keep lit cigarettes, flames, sparks and

fire far from the battery. Never use a mobile

telephone when connecting and removing the

jump leads.

● Charge the battery only in well ventilated

areas given that when the battery is charged

by outside assistance, it creates a mix of

highly explosive gases.

● Jump leads should never enter into contact

with moving parts in the engine compart-

ment.

● Never switch the positive and negative

poles or connect the jump leads incorrectly.

● Note the instruction manual provided by

the manufacturer of the jump leads. » 181

Technical specifications

Advice

Operation

Safety

Page 185 of 219

Emergencies

Connect the battery clamps so they have

good metal-to-metal contact with the battery

terminals.

If the engine fails to start, switch off the start-

er after about 10 seconds and try again after

about 1 minute. WARNING

● Please note the safety warnings referring to

working in the engine compartment

››› page 143.

● The b att

ery providing assistance must have

the same voltage as the flat battery (12V) and

approximately the same capacity (see imprint

on battery). Failure to comply could result in

an explosion.

● Never use jump leads when one of the bat-

teries is frozen. Danger of explosion! Even af-

ter the battery has thawed, battery acid could

leak and cause chemical burns. If a battery

freezes, it should be replaced.

● Keep sparks, flames and lighted cigarettes

away from batteries, danger of explosion.

Failure to comply could result in an explo-

sion.

● Observe the instructions provided by the

manufacturer of the jump leads.

● Do not connect the negative cable from the

other vehicle directly to the negative terminal

of the flat battery. The gas emitted from the

battery could be ignited by sparks. Danger of

explosion. ●

Do not attach the negative cable from the

other vehicle to parts of the fuel system or to

the brake line.

● The non-insulated parts of the battery

clamps must not be allowed to touch. The

jump lead attached to the positive battery

terminal must not touch metal parts of the ve-

hicle, this can cause a short circuit.

● Position the leads in such a way that they

cannot come into contact with any moving

parts in the engine compartment.

● Do not lean on the batteries. This could re-

sult in chemical burns. Note

The vehicles must not touch each other, oth-

erwise electricity could flow as soon as the

positive terminals are connected. Towing and tow starting

Introduction When towing or tow starting, respect the le-

gal requirements.

For technical reasons, it is not possible to

tow a vehicle if the battery is flat. WARNING

A vehicle with a flat battery should never be

towed.

● Never remove the key from the ignition

lock. Otherwise, the steering wheel lock

could suddenly lock. The vehicle would not

be controlled and a serious accident could

ensue. WARNING

When towing the vehicle, the handling and

braking efficiency change considerably.

Please observe the following instructions to

minimise the risk of serious accidents and in-

jury:

● As the driver of the vehicle being towed:

– The brake must be depressed must hard-

er as the brake servo does not operate.

Always remain aware to avoid collision

with the towing vehicle.

– More strength is required at the steering

wheel as the power steering does not op-

erate when the engine is switched off.

● As the driver of the towing vehicle:

– Accelerate gently and carefully.

– Avoid sudden braking and manoeuvres.

– Brake well in advance than usual and

brake gently.

» 183

Technical specifications

Advice

Operation

Safety

Page 187 of 219

Emergencies

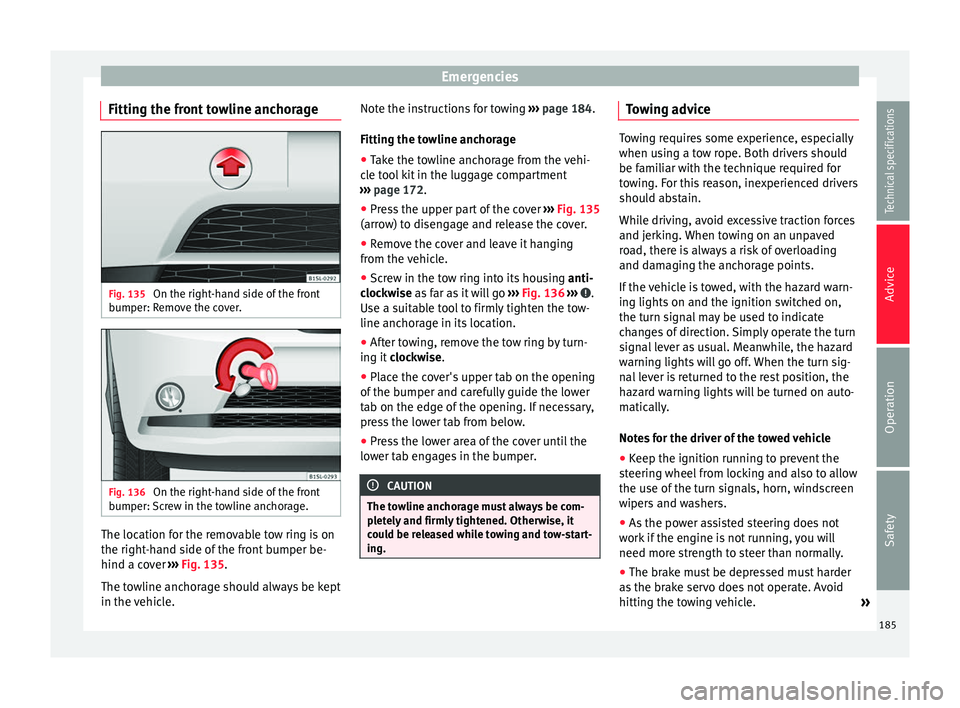

Fitting the front towline anchorage Fig. 135

On the right-hand side of the front

bumper: Remove the cover. Fig. 136

On the right-hand side of the front

bumper: Screw in the towline anchorage. The location for the removable tow ring is on

the right-hand side of the front bumper be-

hind a cover

››› Fig. 135 .

The t o

wline anchorage should always be kept

in the vehicle. Note the instructions for towing

››› page 184.

Fitting the towline anchorage

● Take the towline anchorage from the vehi-

cle tool kit in the luggage compartment

››› page 172.

● Pre

ss the upper part of the cover ››› Fig. 135

(arrow) to disengage and release the cover.

● Remove the cover and leave it hanging

from the vehicle.

● Screw in the tow ring into its housing anti-

clockwise as far as it will go ››

› Fig. 136 ››› .

Use a suitable tool to firmly tighten the tow-

line anchorage in its location.

● After towing, remove the tow ring by turn-

ing it clockwise .

● Plac

e the cover's upper tab on the opening

of the bumper and carefully guide the lower

tab on the edge of the opening. If necessary,

press the lower tab from below.

● Press the lower area of the cover until the

lower tab engages in the bumper. CAUTION

The towline anchorage must always be com-

pletely and firmly tightened. Otherwise, it

could be released while towing and tow-start-

ing. Towing advice

Towing requires some experience, especially

when using a tow rope. Both drivers should

be familiar with the technique required for

towing. For this reason, inexperienced drivers

should abstain.

While driving, avoid excessive traction forces

and jerking. When towing on an unpaved

road, there is always a risk of overloading

and damaging the anchorage points.

If the vehicle is towed, with the hazard warn-

ing lights on and the ignition switched on,

the turn signal may be used to indicate

changes of direction. Simply operate the turn

signal lever as usual. Meanwhile, the hazard

warning lights will go off. When the turn sig-

nal lever is returned to the rest position, the

hazard warning lights will be turned on auto-

matically.

Notes for the driver of the towed vehicle

●

Keep the ignition running to prevent the

steering wheel from locking and also to allow

the use of the turn signals, horn, windscreen

wipers and washers.

● As the power assisted steering does not

work if the engine is not running, you will

need more strength to steer than normally.

● The brake must be depressed must harder

as the brake servo does not operate. Avoid

hitting the towing vehicle. »

185

Technical specifications

Advice

Operation

Safety

Page 189 of 219

Emergencies

Manually locking the passenger side

door Fig. 138

To the front of the passenger side

door: Emergency lock, hidden by a rubber

cap. Fig. 139

Emergency locking of the vehicle us-

ing the vehicle key The passenger door can be manually locked.

● Door open. ●

Remove the rubber cap to the front of the

door. The rubber cap is marked with a lock

symbol ››› Fig. 138 .

● Unf o

ld the key shaft if necessary

››› page 43

.

● Insert the key shaft horizontally into the

opening and moved the coloured lever for-

ward ››› Fig. 139.

● Rep

lace the rubber cap and close the door.

● Check if the door is locked.

● Have the vehicle checked by a specialised

workshop. Note

The doors can be opened and unlocked indi-

vidually from the inside by pulling the inside

door handle. If necessary, pull the inner door

release lever twice ››› page 45. Emergency unlocking the rear lid

Fig. 140

From the luggage compartment:

Emergency unlocking of the booth hatch. ●

If necessary, fold the rear seat bench back-

rest forward ››› page 64 .

● Remo

ve equipment to access the inside of

the rear lid.

● Unfold the key shaft ››› page 43.

● Insert the key shaft into the rear lid open-

ing ››› Fig. 140 and press the release lever in

the direction of

the arrow to unlock the rear

lid.

187

Technical specifications

Advice

Operation

Safety

Page 191 of 219

Fuses and bulbs

CAUTION

● Damaged or dirty windscreen wipers could

scratch the glass.

● If products containing solvents, rough

sponges or sharp objects are used to clean

the blades, the graphite layer will be dam-

aged.

● Never use fuel, nail varnish remover, paint

thinner or similar products to clean the win-

dows. Note

If wax deposits, other cleaning products from

the automatic car wash, or other care prod-

ucts, are left on the windscreen and the rear

window, the blades can scratch the glass. Re-

move wax deposits with a special product or

cleaning cloths. Fuses and bulbs

Fuses Introduction Due to the constant updating of vehicles,

fuse assignments based on equipment and

the use of the same fuse for various electrical

components, it is not possible to provide an

up-to-date summary of the fuse positions for

the electrical components at the time of

printing this manual. For detailed information

about the fuse positions, please consult a

technical service.

In general, a fuse can be assigned to various

electrical components. Likewise, an electrical

component can be protected by several

fuses.

Only replace fuses when the cause of the

problem has been solved. If a newly inserted

fuse blows after a short time, you must have

the electrical system checked by a special-

ised workshop as soon as possible.

WARNING

The high voltages in the electrical system can

give serious electrical shocks, causing burns

and even death!

● Never touch the electrical wiring of the igni-

tion system. ●

Take care not to cause short circuits in the

electrical system. WARNING

Using unsuitable fuses, repairing fuses or

bridging a current circuit without fuses can

cause a fire and serious injury.

● Never use a fuse with a higher value. Only

replace fuses with a fuse of the same amper-

age (same colour and markings) and size.

● Never repair a fuse.

● Never replace a fuse by a metal strip, staple

or similar. CAUTION

● To prevent damage to the vehicle's electric

system, before replacing a fuse always turn

off the ignition, the lights and all electrical

elements and remove the key from the igni-

tion.

● If you replace a fuse with higher-rating

fuse, you could cause damage to another part

of the electrical system.

● Protect the fuse boxes when open to pre-

vent the entry of dust or humidity as they can

damage the electrical system. Note

One component may have more than one

fuse. » 189Technical specifications

Advice

Operation

Safety

Page 193 of 219

Fuses and bulbs

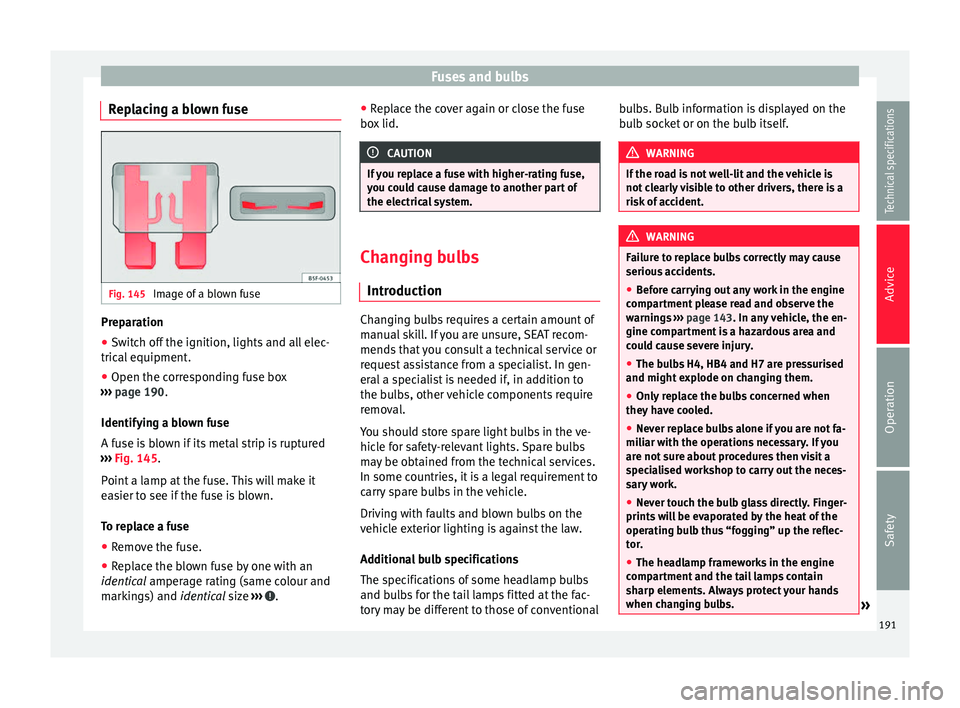

Replacing a blown fuse Fig. 145

Image of a blown fuse Preparation

● Switch off the ignition, lights and all elec-

trical equipment.

● Open the corresponding fuse box

››› page 190 .

Identif y

ing a blown fuse

A fuse is blown if its metal strip is ruptured

››› Fig. 145.

Point a lamp at the fuse. This will make it

easier to see if the fuse is blown.

To replace a fuse ● Remove the fuse.

● Replace the blown fuse by one with an

identical amperage rating (same colour and

mark

ings) and identical size ››› .●

Replace the cover again or close the fuse

box lid. CAUTION

If you replace a fuse with higher-rating fuse,

you could cause damage to another part of

the electrical system. Changing bulbs

Introduction Changing bulbs requires a certain amount of

manual skill. If you are unsure, SEAT recom-

mends that you consult a technical service or

request assistance from a specialist. In gen-

eral a specialist is needed if, in addition to

the bulbs, other vehicle components require

removal.

You should store spare light bulbs in the ve-

hicle for safety-relevant lights. Spare bulbs

may be obtained from the technical services.

In some countries, it is a legal requirement to

carry spare bulbs in the vehicle.

Driving with faults and blown bulbs on the

vehicle exterior lighting is against the law.

Additional bulb specifications

The specifications of some headlamp bulbs

and bulbs for the tail lamps fitted at the fac-

tory may be different to those of conventionalbulbs. Bulb information is displayed on the

bulb socket or on the bulb itself.

WARNING

If the road is not well-lit and the vehicle is

not clearly visible to other drivers, there is a

risk of accident. WARNING

Failure to replace bulbs correctly may cause

serious accidents.

● Before carrying out any work in the engine

compartment please read and observe the

warnings ››› page 143. In any vehicle, the en-

gine c omp

artment is a hazardous area and

could cause severe injury.

● The bulbs H4, HB4 and H7 are pressurised

and might explode on changing them.

● Only replace the bulbs concerned when

they have cooled.

● Never replace bulbs alone if you are not fa-

miliar with the operations necessary. If you

are not sure about procedures then visit a

specialised workshop to carry out the neces-

sary work.

● Never touch the bulb glass directly. Finger-

prints will be evaporated by the heat of the

operating bulb thus “fogging” up the reflec-

tor.

● The headlamp frameworks in the engine

compartment and the tail lamps contain

sharp elements. Always protect your hands

when changing bulbs. » 191

Technical specifications

Advice

Operation

Safety

Page 195 of 219

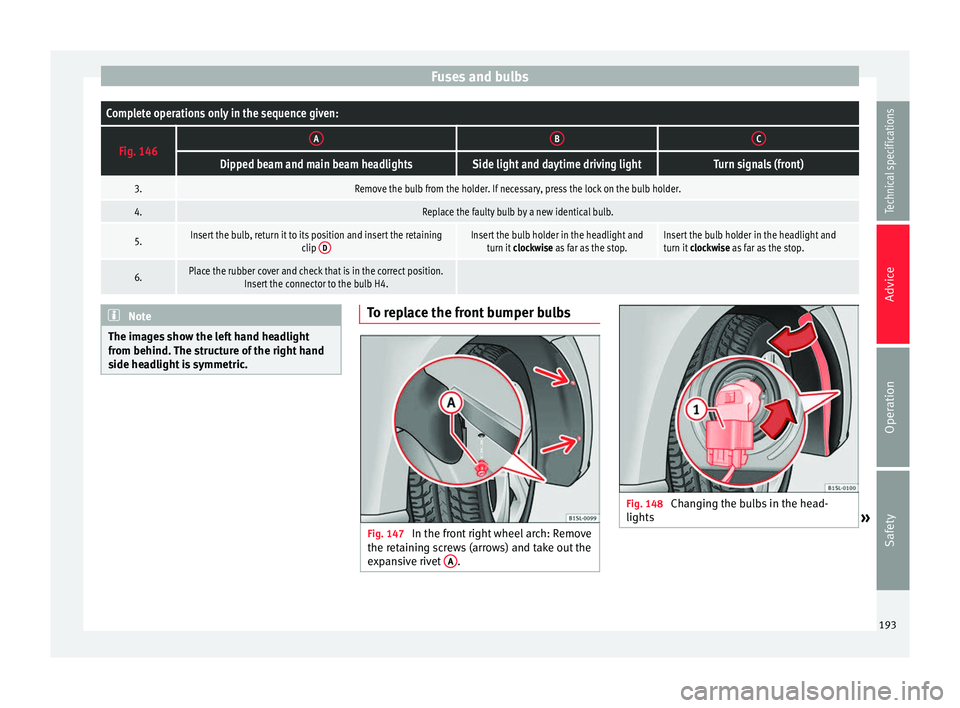

Fuses and bulbsComplete operations only in the sequence given:

Fig. 146ABC

Dipped beam and main beam headlightsSide light and daytime driving lightTurn signals (front)

3.Remove the bulb from the holder. If necessary, press the lock on the bulb holder.

4.Replace the faulty bulb by a new identical bulb.

5.Insert the bulb, return it to its position and insert the retaining

clip DInsert the bulb holder in the headlight and

turn it clockwise as far as the stop.Insert the bulb holder in the headlight and

turn it clockwise as far as the stop.

6.Place the rubber cover and check that is in the correct position.

Insert the connector to the bulb H4. Note

The images show the left hand headlight

from behind. The structure of the right hand

side headlight is symmetric. To replace the front bumper bulbs

Fig. 147

In the front right wheel arch: Remove

the retaining screws (arrows) and take out the

expansive rivet A . Fig. 148

Changing the bulbs in the head-

lights » 193

Technical specifications

Advice

Operation

Safety

Page 197 of 219

Fuses and bulbs5.Unscrew the wing nut

5

››› Fig. 149 B.

6.Remove the tail light from the bodywork by careful-

ly pulling backwards.

7.Disassemble the tail light unit and place it on a

flat, clean surface. To change the bulb

8.Unlock the bulb holder locking tab (arrow)

››› Fig. 150 C and remove the bulb holder from the

tail light.

9.Replace the faulty bulb by a new identical bulb

››› Fig. 150 D.

10.Place the lamp holder in the tail light unit. The at-

tachment tabs (arrow) should audibly click into

place ››› Fig. 150 C. Assembling the tail light units

11.Carefully insert the tail light unit into the opening

in the bodywork.

12.Support the tail light with one hand in the assem-

bly position and securely screw the wing nut with

the other

5

››› Fig. 149 B.

13.Ensure that the tail light unit has been correctly

fitted and is firmly secured.

14.Insert the connector 2 into the bulb holder and

press the lock 3 on the connector in the oppo-

site direction to the arrow ››› Fig. 149 B.

15.Insert the cover. The cover should lock into place.

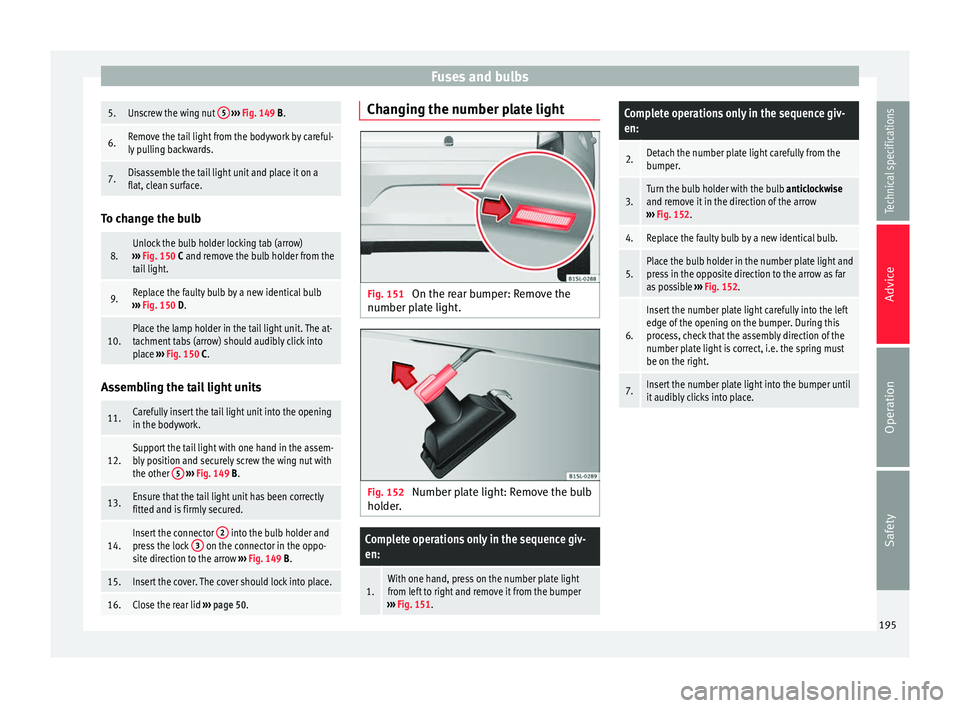

16.Close the rear lid ››› page 50. Changing the number plate light

Fig. 151

On the rear bumper: Remove the

number plate light. Fig. 152

Number plate light: Remove the bulb

holder.

Complete operations only in the sequence giv-

en:

1.With one hand, press on the number plate light

from left to right and remove it from the bumper

››› Fig. 151.

Complete operations only in the sequence giv-

en:

2.Detach the number plate light carefully from the

bumper.

3.Turn the bulb holder with the bulb anticlockwise

and remove it in the direction of the arrow

››› Fig. 152.

4.Replace the faulty bulb by a new identical bulb.

5.Place the bulb holder in the number plate light and

press in the opposite direction to the arrow as far

as possible ››› Fig. 152.

6.

Insert the number plate light carefully into the left

edge of the opening on the bumper. During this

process, check that the assembly direction of the

number plate light is correct, i.e. the spring must

be on the right.

7.Insert the number plate light into the bumper until

it audibly clicks into place. 195

Technical specifications

Advice

Operation

Safety

Page 199 of 219

Technical features

Technical specifications

Technical features

Important information Introduction The information in the vehicle documentation

always takes precedence over the informa-

tion in this Instruction Manual.

All technical specifications provided in this

documentation are valid for the standard

model in Spain. The vehicle data card inclu-

ded in the Maintenance Programme or the

vehicle registration documents shows which

engine is installed in the vehicle.

The figures may be different depending

whether additional equipment is fitted, for

different models, for special vehicles and for

other countries.

Abbreviations used in the Technical

Specifications sectionAbbrevi-

ationMeaning

kWKilowatt, engine power measurement.

PSPferdestärke (horsepower), formerly used

to denote engine power.

rpmRevolutions per minute - engine speed.

NmNewton metres, unit of engine torque.

litres per100 kmFuel consumption in litres per 100 km (70

miles).

g/kmCarbon dioxide emissions in grams per km

(mile) travelled.

CO 2Carbon dioxide

CNCetane number, indication of the diesel

combustion power.

RONResearch octane number, indication of the

knock resistance of petrol. Vehicle identification data

Fig. 155

Vehicle data label. Fig. 156

Vehicle identification number. Vehicle identification number

The vehicle identification number (chassis

number) can be read from outside the vehicle

through a viewer in the windscreen

››› Fig. 156 . This viewer is located in the lower

»

197

Technical specifications

Advice

Operation

Safety

Page 200 of 219

Technical specifications

part of the windscreen. The vehicle identifica-

tion number (chassis number) is also stam-

ped on the right water drain channel. The wa-

ter drain channel is located between the sus-

pension tower and the wing. Open the bon-

net to read the vehicle identification number

.

V ehic

le data plate

The vehicle data label ››› Fig. 155 is at the

front

of the spare wheel well. It contains the

following data:

Vehicle identification number (chassis

number).

Vehicle type, engine power, gearbox type.

Engine and gearbox code, paint number,

interior equipment.

Optional extras, PR numbers.

These data are also provided in the Mainte-

nance Programme.

Specific vehicle weight information The instructions in the official vehicle docu-

ments take precedence. All the technical data

provided in this documentation is applicable

to the basic model. The vehicle data label in

the Maintenance Programme or the vehicle

documentation shows which engine is instal-

led in your vehicle.1 2

3

4 The figures may be different depending

whether additional equipment is fitted, for

different models and for special vehicles.

Kerb weight values shown in the following ta-

ble apply to a vehicle with driver (75 kg), liq-

uids including a fuel tank 90% full, in addi-

tion to tools and a spare wheel

››› . The

kerb weight indicated increases with optional

equipment and retrofitting of accessories,

while proportionally reducing carrying ca-

pacity.

The load is equivalent to the following

weights:

● Passengers.

● Total equipment.

● Roof load, included in the carrier. WARNING

Exceeding the maximum authorised weight

and the load on the axles could cause dam-

age to the vehicle, accidents and serious in-

juries.

● The real load on the axles should never ex-

ceed the maximum permitted.

● The load and its distribution in the vehicle

have effects on the vehicle handling and the

braking ability. Always drive at a suitable

speed. CAUTION

Distribute the load as uniformly and as low

down on the vehicle as possible. When trans-

porting heavy objects in the luggage com-

partment, these should be placed as far for-

ward as possible or over the rear axle to have

as little influence on handling as possible. Information on fuel consumption

The consumption and emission values indi-

cated do not refer to one specific vehicle.

They are only to be used to compare the val-

ues of the different vehicle versions. The fuel

consumption and CO

2 emissions of a vehicle

not only depend on the effective use of fuel.

They also depend on your driving style and

other non-technical factors.

Calculation of fuel consumption

Fuel consumption and emission values are

determined according to the current version

of the 715/2007/EC or 80/1268/EEC regula-

tion and are valid for the vehicle kerb weight.

The specifications do not

refer to an individu-

al

vehicle. To measure the fuel consumption,

two measuring cycles are carried out on a

rolling road test bed. The test criteria are as

follows:

198