fuel Seat Mii 2014 Owner's Guide

[x] Cancel search | Manufacturer: SEAT, Model Year: 2014, Model line: Mii, Model: Seat Mii 2014Pages: 219, PDF Size: 4.19 MB

Page 142 of 219

Advice

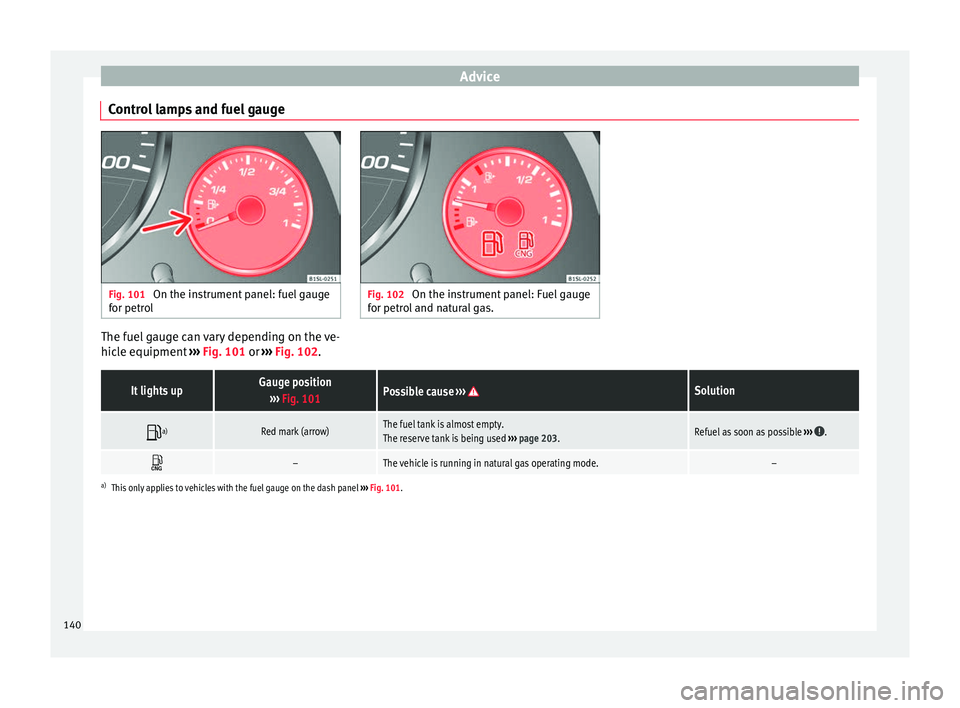

Control lamps and fuel gauge Fig. 101

On the instrument panel: fuel gauge

for petrol Fig. 102

On the instrument panel: Fuel gauge

for petrol and natural gas. The fuel gauge can vary depending on the ve-

hicle equipment

››› Fig. 101 or

›

›› Fig. 102.

It lights upGauge position

››› Fig. 101Possible cause ››› Solution

a)Red mark (arrow)The fuel tank is almost empty.

The reserve tank is being used

››› page 203.Refuel as soon as possible ››› .

–The vehicle is running in natural gas operating mode.–

a)

This only applies to vehicles with the fuel gauge on the dash panel ››› Fig. 101.

140

Page 143 of 219

Checking and refilling levelsFlashes for about 10

secondsState of the barsPossible cause ››› Solution

and the segments

remaining a)Reserve zone (four small segments)The fuel tank is almost empty.

The reserve tank is being used

››› page 203.Refuel as soon as possible ››› .

–The vehicle is running in natural gas operating mode.–

a)

This only applies to vehicles with the fuel gauge on the dash panel display.

Several warning and control lamps light up

for a few seconds when the ignition is switch-

ed on, signalling that the function is being

verified. They will switch off after a few sec-

onds.

In natural gas engines

The warning lamp lights up when both fuel

type

s (petrol and natural gas) have reached

reserve level.

The warning lamp lights up when the vehi-

cl

e is running in natural gas operating mode.

The warning lamp switches off when the

natural gas is exhausted. The engine

changes to operate with petrol.

Problem:

if the vehicle is left parked for a

long time just after refuelling, the gas level

indicator does not accurately indicate the

same level shown after refuelling when the

vehicle is started up again. This is not due to

a leak in the system, but to a drop in pres-

sure in the gas tank for technical reasons af- ter a cooling phase immediately after refuel-

ling. WARNING

Driving with insufficient fuel reserve could re-

sult in the vehicle breaking down in traffic

and a serious accident.

● If the fuel level is too low then the fuel sup-

ply to the engine can become irregular espe-

cially on slopes.

● If the engine “is choked” or stalls due to

lack of or irregularity of the fuel supply, the

power steering as well as all of the driver as-

sistance systems including braking assis-

tance will stop working.

● Always refuel when there is only one quar-

ter of the fuel tank left to avoid running out of

fuel. CAUTION

● Always pay attention to any lit control

lamps and to the corresponding descriptions and instructions to avoid damage to the vehi-

cle.

● Never run the fuel tank completely dry. An

irregular fuel supply may lead to ignition

faults and unburnt fuel could enter the ex-

haust system. This could damage the catalyt-

ic converter. Note

The arrow next to the fuel pump symbol on

the instrument panel ››› Fig. 101 indicates the

s ide of

the vehicle on which the tank flap is

located. 141

Technical specifications

Advice

Operation

Safety

Page 144 of 219

Advice

Refuelling with petrol Fig. 103

Open tank flap with tank cap attach-

ed to the holder Before refuelling, always turn off the engine,

the ignition, mobile telephones, auxiliary

heating and keep them off during refuelling.

Opening the fuel tank cap

● The tank flap is at the rear of the vehicle on

the right.

● Pull the rear zone of the fuel tank flap to

open.

● Unfold the key shaft if necessary

››› page 43 .

● Inser

t the vehicle key into the lock cylinder

of the fuel tank plug and turn the key in an

anticlockwise direction.

● Take out the fuel tank plug by turning it in

an anticlockwise direction and rest it on the

upper part of the fuel tank flap ››› Fig. 103. Ref

uelling

The correct petrol type for the vehicle is loca-

ted on a sticker inside the fuel tank flap

››› page 137.

● If the aut

omatic filler nozzle is operated

correctly, it will switch itself off as soon as

the fuel tank is full ››› .

● Do not continue to refuel if it is turned off!

Otherwise, this will fill the expansion cham-

ber and fuel may leak out if the ambient con-

ditions are warm.

Closing the fuel tank cap

● Screw on the fuel tank filler plug in a clock-

wise direction until it is fully inserted with a

click.

● Insert the vehicle key into the lock cylinder

of the fuel tank plug, turn the key in a clock-

wise direction and remove the key.

● Press the tank flap until you hear it click in-

to place. The tank flap must be flush with the

body contour. WARNING

Do not continue refilling once the fuel nozzle

has switched itself off. The fuel tank may be

filled too much. As a result, fuel may spurt

out and spill. This could lead to a fire, explo-

sion and severe injuries. CAUTION

● Always remove any fuel spilled anywhere

on the vehicle to avoid damage to the wheel

housing, the tyre and vehicle paintwork. For the sake of the environment

Fuels can contaminate the environment. Col-

lect any spilt service fluids and allow a pro-

fessional to dispose of them. Refuelling with natural gas

Fig. 104

Tank flap open: gas filler mouth 1 ,

filler mouth retainer 2 Before

refuelling, the engine and the igni-

tion, mo b

ile telephone and heating must be

switched off separately ››› .

It is also essential to carefully read the in-

structions for the natural gas pump.

142

Page 145 of 219

Checking and refilling levels

The vehicle is only prepared for refuelling

with Compressed Natural Gas (CNG) ››› . Re-

fuelling with another type of natural gas is

not allowed, e.g. Liquefied Nature Gas (LNG)

or hydromethane.

Opening the fuel tank cap

The natural gas filler mouth is behind the fuel

tank cap, next to the petrol filler mouth.

● Unlock the vehicle with the key or with the

central locking button situated on the driv-

er door ›

›

› page 48.

● Press on the rear area of the flap and open

it.

Refuelling

Problem:

If the ambient temperature is very

high, the natural gas pump protection

against overheating disconnects this auto-

matically.

● Remove the plug from the gas filler mouth

››› Fig. 104

1 .

● Connect the pump filling nozzle to the gas

filler mouth.

● The fuel tank will be full when the pump

c ompr

essor automatically cuts the supply.

● If you wish to finish refuelling in advance,

press the button on the pump to stop the

flow. Closing the fuel tank cap

●

Check that the gas filler mouth retainer 2 is not trapped with the filler nozzle. If neces-

sary, place it in the filler mouth again.

●

Insert the plug in the filler mouth.

● Close the tank flap. Make sure you hear it

click into place. WARNING

Natural gas is a highly explosive, easily flam-

mable substance. Incorrect handling of the

natural gas can cause accidents serious

burns and other injuries.

● Before refuelling with natural gas, the fill-

ing mouth must be correctly engaged. If you

can smell gas, stop refuelling immediately. WARNING

The vehicle is not prepared to use liquefied

natural gas (LNG) and this fuel must not be

added under any circumstances. Liquefied

natural gas can cause the natural gas tank to

explode, resulting in serious injury. Note

● The filling nozzles of natural gas pumps

can differ in the way they are operated. If you

are unacquainted with the pump, it is advisa-

ble that a member of staff of the service sta-

tion performs the refuelling operation. ●

Noises heard when refuelling are normal

and do not indicate the presence of a fault in

the system.

● The vehicle natural gas system is prepared

both for refuelling with a small compressor

(slow refuel) and a large compressor (fast re-

fuel) in natural gas service stations. Bonnet

Working in the engine compartment Before working in the engine compartment,

make sure that the vehicle is parked on hori-

zontal and firm ground.

The engine compartment of the vehicle is a

hazardous area. Never work on the engine or

in the engine compartment if you are not fa-

miliar with the operations to be carried out,

the applicable safety standards and especial-

ly if you do not have the necessary instru-

ments, liquids and tools

››› ! If required,

have any work carried out by a specialised

workshop. Negligent work can cause serious

injury. WARNING

If the vehicle moves unexpectedly, this could

cause serious injury. » 143

Technical specifications

Advice

Operation

Safety

Page 147 of 219

Checking and refilling levels

parts of the engine. Before any work, re-

move ties and jewellery (necklaces, etc),

tie long hair back and tie all items of

loose clothing to your body to make sure

that they cannot be trapped by engine

components.

– Take extreme caution when operating the

accelerator and remain attentive. The ve-

hicle could move, even if the handbrake

is applied.

● Always make sure you have not left any ob-

jects, such as cleaning cloths and tools, in

the engine compartment. If any object is left

in the engine compartment, this could cause

malfunctions, engine faults and even a fire. WARNING

Refill liquids and certain materials can catch

fire easily in the engine compartment, caus-

ing a fire and serious injury!

● Never smoke.

● Never work close to places exposed to

flames or sparks.

● Never pour service fluids over the engine.

These fluid may ignite hot engine parts and

cause injuries.

● If it is necessary to work on the fuel system

or the electrical system, please follow the in-

structions below:

–Always disconnect the vehicle battery.

– Never work close to heaters, heat sources

or places exposed to flames or sparks. ●

Always keep a recently serviced and per-

fectly working fire extinguisher close by.

● Never cover the engine with additional in-

sulating materials such as a blanket. Risk of

fire! CAUTION

When refilling or changing service liquids,

ensure that you put the liquids into the right

tank. Making a mistake when refilling could

cause serious malfunctions and damage the

engine! For the sake of the environment

Service fluids leaks are harmful to the envi-

ronment. For this reason you should make

regular checks on the ground underneath

your vehicle. Take the vehicle to a specialised

workshop to be checked if you see stains, oil

or other fluids on the ground. Collect any

spilt service fluids and allow a professional to

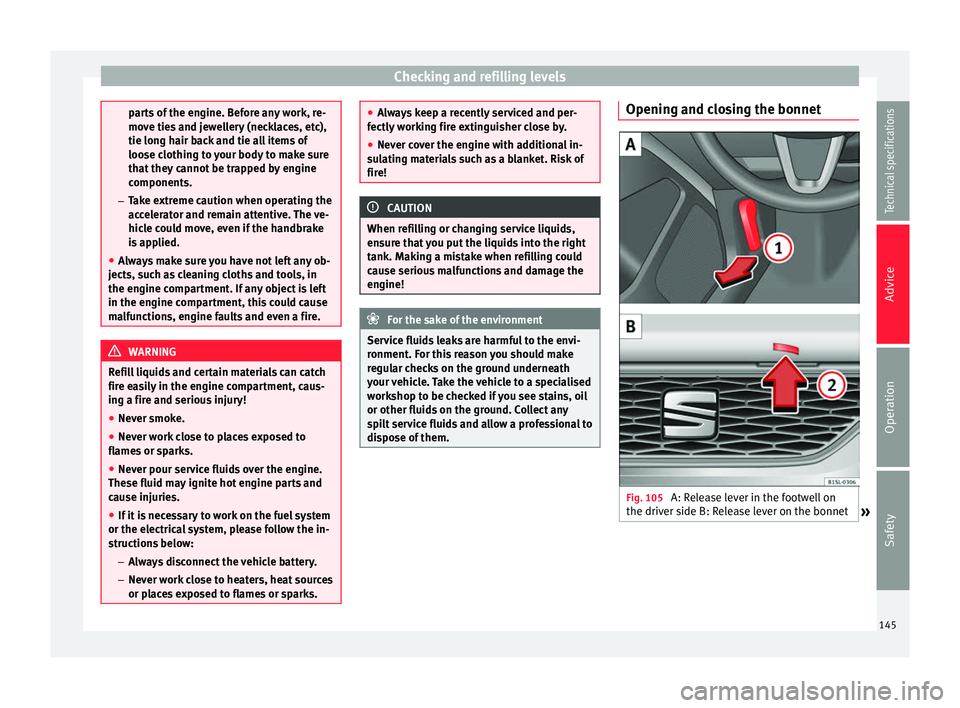

dispose of them. Opening and closing the bonnet

Fig. 105

A: Release lever in the footwell on

the driver side B: Release lever on the bonnet » 145Technical specifications

Advice

Operation

Safety

Page 161 of 219

Wheels and tyres

Note

For technical reasons, it is not generally pos-

sible to use the wheels from other vehicles.

In some cases, this may also be true for the

same model of wheel. Please refer to the ve-

hicle documentation or ask at a technical

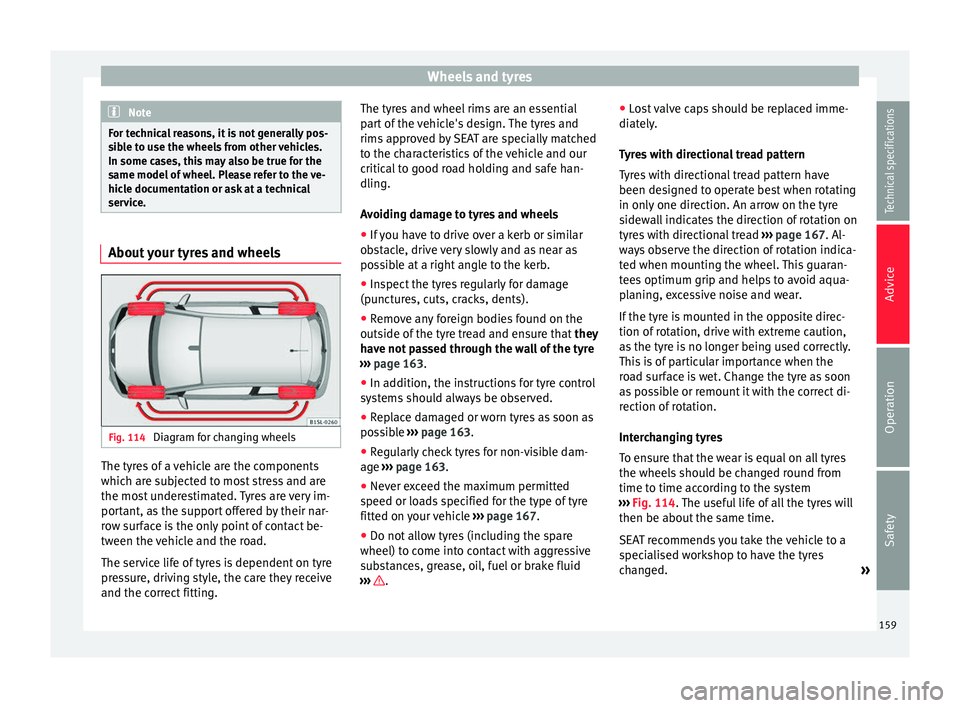

service. About your tyres and wheels

Fig. 114

Diagram for changing wheels The tyres of a vehicle are the components

which are subjected to most stress and are

the most underestimated. Tyres are very im-

portant, as the support offered by their nar-

row surface is the only point of contact be-

tween the vehicle and the road.

The service life of tyres is dependent on tyre

pressure, driving style, the care they receive

and the correct fitting. The tyres and wheel rims are an essential

part of the vehicle's design. The tyres and

rims approved by SEAT are specially matched

to the characteristics of the vehicle and our

critical to good road holding and safe han-

dling.

Avoiding damage to tyres and wheels

● If you have to drive over a kerb or similar

obstacle, drive very slowly and as near as

possible at a right angle to the kerb.

● Inspect the tyres regularly for damage

(punctures, cuts, cracks, dents).

● Remove any foreign bodies found on the

outside of the tyre tread and ensure that they

have not passed through the wall of the tyre

››› page 163 .

● In a d

dition, the instructions for tyre control

systems should always be observed.

● Replace damaged or worn tyres as soon as

possible ››› page 163.

● Re

gularly check tyres for non-visible dam-

age ››› page 163

.

● Never exceed the maximum permitted

speed or loads specified for the type of tyre

fitted on your vehicle ››› page 167.

● Do not allow tyres (including the spare

wheel) to come into contact with aggressive

substances, grease, oil, fuel or brake fluid

››› .●

Lost valve caps should be replaced imme-

diately.

Tyres with directional tread pattern

Tyres with directional tread pattern have

been designed to operate best when rotating

in only one direction. An arrow on the tyre

sidewall indicates the direction of rotation on

tyres with directional tread ››› page 167. Al-

ways observe the direction of rotation indica-

ted when mounting the wheel. This guaran-

tees optimum grip and helps to avoid aqua-

planing, excessive noise and wear.

If the tyre is mounted in the opposite direc-

tion of rotation, drive with extreme caution,

as the tyre is no longer being used correctly.

This is of particular importance when the

road surface is wet. Change the tyre as soon

as possible or remount it with the correct di-

rection of rotation.

Interchanging tyres

To ensure that the wear is equal on all tyres

the wheels should be changed round from

time to time according to the system

››› Fig. 114 . The useful life of all the tyres will

then be about the s

ame time.

SEAT recommends you take the vehicle to a

specialised workshop to have the tyres

changed. »

159

Technical specifications

Advice

Operation

Safety

Page 162 of 219

Advice

Tyres that are over 6 years old

Tyres are subject to an ageing process as a

result of physical and chemical processes.

This may affect their performance. Tyres

which are stored for long periods of time

without being used, harden and become

more fragile than tyres which are in constant

use.

SEAT recommends that tyres over six years

old are replaced with new tyres. This also ap-

plies to tyres (including the spare wheel)

which appear to be in perfect condition on

the outside and which have a tread depth

within the values stipulated by the Law ››› .

The date of manufacture, part of the tyre

identification number (TIN), indicates the age

of the tyre ( ) ››› page 167 .

St orin

g tyres

Mark tyres when you remove them to indicate

the direction of rotation (left, right, forwards,

backwards). This ensures you will be able to

mount them correctly when you replace

them. When removed, the wheels and/or

tyres should be stored in a cool, dry and pref-

erably dark location. Do not place tyres

mount

ed on the wheel in a vertical position.

Protect tyres not mounted on wheels from

dirt by storing them in suitable bags and

standing them on the ground on their tread. WARNING

Aggressive fluids or substances could result

in visible or invisible damage with the conse-

quent risks.

● Always ensure that tyres do not come into

contact with chemical products, oil, grease,

fuel, brake fluid or other aggressive substan-

ces. WARNING

Old tyres, even if they have never been used,

may lose air or burst unexpectedly while driv-

ing, resulting in serious accident or damage.

● If tyres are over six years old, they should

only be used in an emergency and with ex-

treme caution. For the sake of the environment

Old tyres must be disposed of by qualified

personnel according to the laws in the coun-

try concerned. Wheel rims

The design of wheel bolts is matched to the

rims. If different rims are fitted, the correct

wheel bolts with the right length and correct-

ly shaped bolt heads must be used. This en-

sures that wheels are fitted securely and that

the brake system functions correctly

››› page 174 . F

or t

echnical reasons, it is not generally pos-

sible to use the wheels from other vehicles.

In some cases, this may also be true for the

same model of wheel.

The tyres and rims approved by SEAT are spe-

cially matched to the characteristics of the

vehicle and are critical to good road holding

and safe handling.

Note for Italy:

A SEAT Service Centre should

be consulted whether different sized wheels

or tyres to those originally fitted by SEAT may

be fitted, as well as the combinations al-

lowed between the front axle (axle 1) and

back axle (axle 2).

Wheel bolts

Wheel bolts must be tightened to the correct

torque ››› page 174

.

Beadlock wheel rims

Beadlock wheel rims have various compo-

nents. These are joined together by special

bolts using a special procedure. This ensures

good performance, a better seal, improved

safety and wheel run out. Therefore, worn

rims should always be replaced and must on-

ly be repaired in a specialised workshop.

SEAT recommends visiting a technical service

››› .

160

Page 165 of 219

Wheels and tyres

CAUTION

● Take care not to tilt the manometer when

placing it on the valve. Otherwise, the valve

may be damaged.

● If tyre valves are not protected by caps, or if

the caps are not screwed on correctly, they

may become damaged. Check that the caps

are identical to the standard caps and have

been correctly tightened. For the sake of the environment

Under-inflated tyres will increase fuel con-

sumption. Tread depth and wear indicators

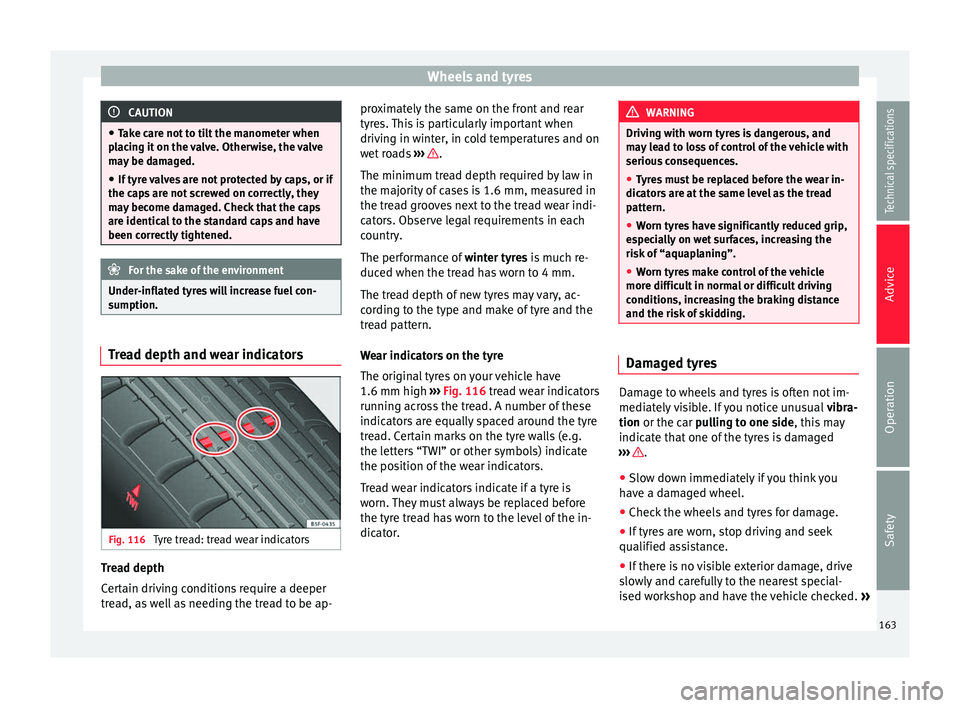

Fig. 116

Tyre tread: tread wear indicators Tread depth

Certain driving conditions require a deeper

tread, as well as needing the tread to be ap- proximately the same on the front and rear

tyres. This is particularly important when

driving in winter, in cold temperatures and on

wet roads

››› .

The minimum tread depth required by law in

the majority of cases is 1.6 mm, measured in

the tread grooves next to the tread wear indi-

cators. Observe legal requirements in each

country.

The performance of winter tyres is much re-

duced when the tread has worn to 4 mm.

The tread depth of new tyres may vary, ac-

cording to the type and make of tyre and the

tread pattern.

Wear indicators on the tyre

The original tyres on your vehicle have

1.6 mm high ››› Fig. 116 tread wear indicators

ru nnin

g across the tread. A number of these

indicators are equally spaced around the tyre

tread. Certain marks on the tyre walls (e.g.

the letters “TWI” or other symbols) indicate

the position of the wear indicators.

Tread wear indicators indicate if a tyre is

worn. They must always be replaced before

the tyre tread has worn to the level of the in-

dicator. WARNING

Driving with worn tyres is dangerous, and

may lead to loss of control of the vehicle with

serious consequences.

● Tyres must be replaced before the wear in-

dicators are at the same level as the tread

pattern.

● Worn tyres have significantly reduced grip,

especially on wet surfaces, increasing the

risk of “aquaplaning”.

● Worn tyres make control of the vehicle

more difficult in normal or difficult driving

conditions, increasing the braking distance

and the risk of skidding. Damaged tyres

Damage to wheels and tyres is often not im-

mediately visible. If you notice unusual

vibra-

tion or the car

pulling to one side

, this may

indicate that one of the tyres is damaged

››› .

● Slow down immediately if you think you

have a damaged wheel.

● Check the wheels and tyres for damage.

● If tyres are worn, stop driving and seek

qualified assistance.

● If there is no visible exterior damage, drive

slowly and carefully to the nearest special-

ised workshop and have the vehicle checked. »

163

Technical specifications

Advice

Operation

Safety

Page 166 of 219

Advice

Foreign bodies in the tyre

● Do not remove foreign bodies if they have

penetrated through the tyre wall!

● You should obtain professional assistance

immediately.

Wear of tyres

The wear of tyres depends on a number of

factors, for example:

● Driving style.

● Unbalanced wheels.

● Running gear settings.

Driving style : Driving round bends quickly or

sudden acceleration or braking speed accel-

erates tyre wear. When the driving style is

normal, if the tyres wear too quickly, have the

running gear settings checked at a special-

ised workshop.

Wheel run-out : The wheels on new vehicles

ar e b

alanced. However, certain circumstan-

ces may lead to imbalance (run-out), which is

detected as vibrations in the steering wheel.

Run-out leads to wear of the steering and

suspension. In the event of run out, the

wheels should be balanced again. When a

new wheel is fitted, it should be balanced

again.

Running gear settings : an incorrectly posi-

tioned running gear increases the wear of

tyres and affects your safety while driving. If tyres wear too quickly, have the wheel align-

ment checked at a specialised workshop. WARNING

If you notice unusual vibration or the car pulls

to one side while driving, this may indicate

that one of the tyres is damaged.

● Reduce speed immediately and stop, while

observing the highway code.

● Check the wheels and tyres for damage.

● Never carry on driving on worn tyres or

wheels. Request qualified assistance immedi-

ately.

● If there is no visible exterior damage, drive

slowly and carefully to the nearest special-

ised workshop and have the vehicle checked. Tyre monitoring system*

Fig. 117

Centre console: tyre monitor system

button The tyre control lamp compares wheel revolu-

tions and with it, the wheel diameter of each

wheel using the ESC. If the diameter of a

wheel changes, the tyre control lamp

lights up. The wheel diameter changes when:

● Tyre pressure is insufficient.

● The tyre structure is damaged.

● The vehicle is unbalanced because of a

load.

● The wheels of one axle are under more

pressure (for example, driving with a trailer or

on steep slopes).

● The vehicle is fitted with snow chains.

● The temporary spare wheel is fitted.

● The wheel on one axle is changed.

Tyre pressure adjustment

On adjusting tyre pressure or changing one

or more wheels, the ››› Fig. 117 button must

be k ept

pressed down, with the ignition on,

until an acoustic signal is heard.

If the wheels are under excessive load (for ex-

ample, driving with a trailer or heavy load),

the tyre pressure must be increased to the

recommended value for a full load (see the

sticker on the inside of the fuel flap). If the

tyre monitor system button is pressed down,

the new tyre pressures are confirmed.

164

Page 174 of 219

Advice

drawing attention to your vehicle. This meth-

od must comply with traffic legislation. WARNING

A faulty vehicle in traffic represents a risk of

accident for the driver and for other road

users.

● Stop the vehicle safely as soon as possible.

Park the vehicle a safe distance from sur-

rounding traffic to lock all the doors in case of

an emergency. Turn on the hazard warning

lights to warn other road users.

● Never leave children or disabled people

alone in the vehicle if the doors are to be

locked. In case of an emergency, passengers

will be trapped inside the vehicle. Individuals

locked in the vehicle can be exposed to very

high or very low temperatures. WARNING

The components of the exhaust system reach

very high temperatures. This could cause a

fire and considerable damage.

● Always park your vehicle so that no part of

the exhaust system can come in contact with

flammable materials (such as dried grass or

fuel). Note

● The vehicle battery will discharge and run

down if the hazard warning lights remain on

for too long (even with the ignition turned

off). ●

For some vehicles, the brake lights will

blink when braking suddenly at speeds of ap-

proximately 80 km/h (50 mph) to alert vehi-

cles to the rear. If braking continues, the haz-

ard warning lights system will automatically

be turned on at a speed of less than approxi-

mately 10 km/h (6 mph). The brake lights re-

main lit. Upon accelerating, the hazard warn-

ing lights will be automatically turned off. Vehicle tool kit*

Introduction When securing the vehicle in case of a break-

down, please note the legal requirements for

each country.

Vehicle tool kit

For vehicles with a factory-fitted spare wheel

or temporary spare wheel, in addition to win-

ter wheels, the luggage compartment may

contain additional vehicle tools

››› page 172. WARNING

When the vehicle tool kit, tire mobility set

and spare wheel are loose in the interior they

can be violently thrown in case of a sudden

manoeuvre or braking and especially in acci-

dents, causing serious injury.

● Ensure that the vehicle tool kit, the tire mo-

bility set and the spare wheel or temporary spare wheel are safely secured in the luggage

compartment.

WARNING

Unsuitable or damaged vehicle tools can

cause injury or accidents.

● Never work with inappropriate or damaged

tools. Location

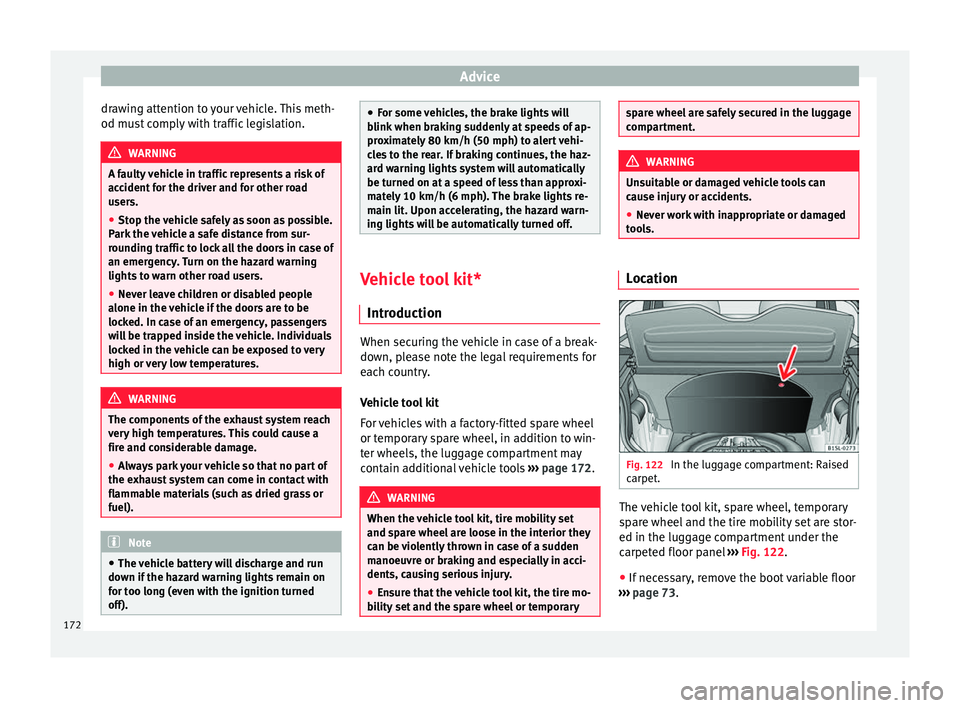

Fig. 122

In the luggage compartment: Raised

carpet. The vehicle tool kit, spare wheel, temporary

spare wheel and the tire mobility set are stor-

ed in the luggage compartment under the

carpeted floor panel

›››

Fig. 122 .

● If nec

essary, remove the boot variable floor

››› page 73.

172