engine Seat Mii 2015 User Guide

[x] Cancel search | Manufacturer: SEAT, Model Year: 2015, Model line: Mii, Model: Seat Mii 2015Pages: 232, PDF Size: 4.23 MB

Page 32 of 232

The essentials

Level control Fi l

lin

g the fuel tank

Fuel tank capacity

Petrol enginesAround 35.0 l,

of which approximately 4.0 are the reserve.

Natural gas en-

gineNatural gas: approx. 11 kg; of whichmax. 1.5 kg reserve

Petrol: approx. 10 l; of which approx. 5 l reserve

Windscreen washer tank capacity

The washer bottle capacity is approximately 3 litres.Fuel

Fig. 39

Open fuel tank flap with tank cap in

the ho l

der Opening the fuel tank cap

The t

ank fl

ap is at the rear of the vehicle on

the right.

● Pull the rear zone of the fuel tank flap to

open.

● Unfold the key shaft if necessary

›››

page 90.

● Insert the vehicle key into the lock cylinder

of the fuel

tank plug and turn the key in an

anticlockwise direction.

● Take out the fuel tank plug by turning it in

an anticlock

wise direction and rest it on the

upper part of the fuel tank flap ››› Fig. 39.

Closing the fuel tank cap

● Screw on the fuel tank filler plug in a clock-

wise dir

ection until it is fully inserted with a

click.

● Insert the vehicle key into the lock cylinder

of the fuel

tank plug, turn the key in a clock-

wise direction and remove the key.

● Press the tank flap until you hear it click in-

to pl

ace. The tank flap must be flush with the

body contour.

››› in Introduction on page 180

››› page 183 Oil

Fig. 40

Engine oil dipstick. Fig. 41

In the engine compartment: Engine

oi l

fi

ller cap The level is measured using the dipstick loca-

t

ed in the en

gine c

ompartment.

The oil should leave a mark between zones A and

C . It should never exceed zone

A .

● Zone A : Do not add oil.

30

Page 33 of 232

The essentials

● Zone B : You can add oil but keep the level

in th at

zone.

● Zone C : Add oil up to zone

B .

T op

pin

g up engine oil

● Unscrew cap from oil filler opening.

● Add oil slowly.

● At the same time, check the level to ensure

you do not a

dd too much.

● When the oil level reaches at least zone B ,

u n

s

crew the engine oil filler cap carefully.

Specifications of engine oil with a service de-

pendent on time/distance travelled

44 kW - 55 kW Petrol en-

ginesVW 504 00, VW 502 00

Natural gas engineVW 502 00

››› in Topping up engine oil on

page 189

››› page 186 Coolant

Fig. 42

Engine compartment: coolant expan-

s ion t

ank

cap. The coolant tank is located in the engine

c

omp

ar

tment.

When the engine is cold, replace the coolant

when the level is below .

Coolant specifications

The engine cooling system is supplied from

the factory with a specially treated mixture of

water and at least 40 % of the additive G13

(TL-VW 774 J), purple. This mixture gives the

necessary frost protection down to -25 °C

(-13 °F) and protects the light alloy parts of

the engine cooling system against corrosion.

It also prevents scaling and considerably rai-

ses the boiling point of the coolant.

To protect the cooling system, the percentage

of additive must always be at least 40 %, even in warm climates where anti-freeze pro-

tection is

not required.

If for weather reasons further protection is

necessary, the proportion of additive may be

increased, but only up to 60 %; otherwise an-

tifreeze protection will diminish and this will

worsen cooling.

When the coolant is topped up, use a mixture

of distilled water and at least 40 % of the

G13 or G12 plus-plus (TL-VW 774 G) additive

(both are purple) to obtain an optimum anti-

corrosion protection ››› in Checking the

c oo

l

ant level and topping up on page 191.

The mixture of G13 with G12 plus (TL-VW 774

F), G12 (red) or G11 (green-blue) engine cool-

ants will significantly reduce anti-corrosion

protection and should therefore be avoided

››› in Checking the coolant level and top-

pin g up on p

ag

e 191.

››› in Checking the coolant level and

topping up on page 190

››› page 189 31

Page 34 of 232

The essentials

Brake fluid Fig. 43

Engine compartment: brake fluid res-

er v

oir c

ap The brake fluid reservoir is located in the en-

gine c

omp

ar

tment.

The level should be between the and

marks. If it is below , please visit a Techni-

cal Service.

››› in Checking the brake fluid level on

page 192

››› page 191 Windscreen washer

Fig. 44

In the engine compartment: wind-

s c

r

een washer reservoir top. The windscreen washer reservoir is located in

the en

gine c

omp

artment.

To top up, mix water with a product recom-

mended by SEAT.

In cold temperatures, add anti-freeze for the

windshield cleaner.

››› in Checking and topping up the

windscreen washer reservoir with water

on page 193

››› page 193 Battery

The battery is located in the engine compart-

ment. It

doe

s not require maintenance. It is

checked as part of the Inspection Service.

››› in Introduction on page 194

››› page 193 32

Page 35 of 232

The essentials

Emergencies F u

se

s

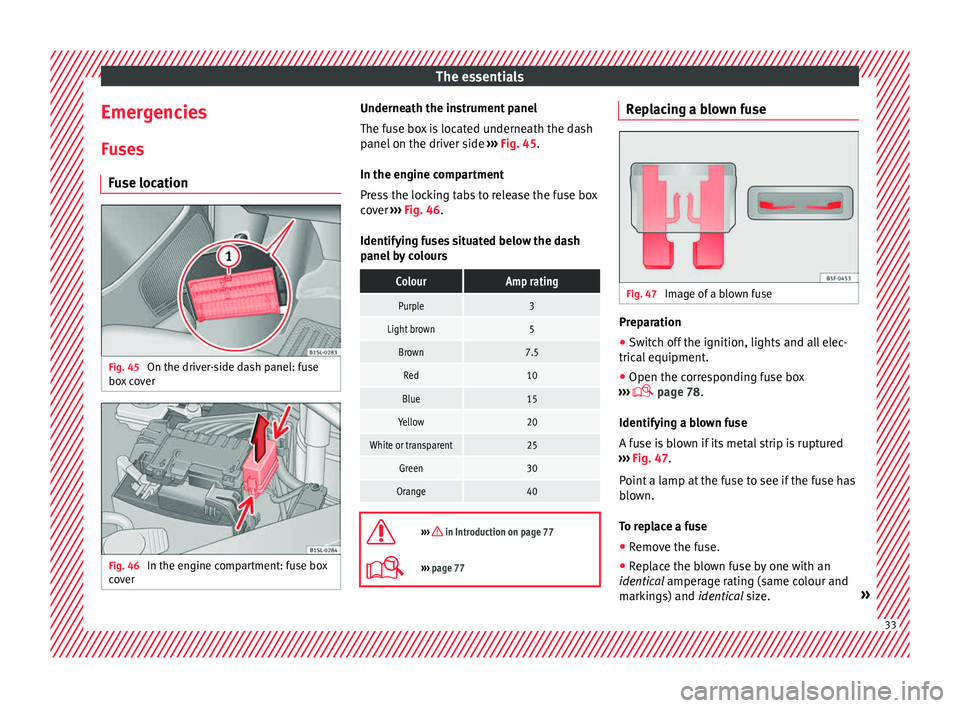

Fuse location Fig. 45

On the driver-side dash panel: fuse

bo x

c

over Fig. 46

In the engine compartment: fuse box

c o v

er Underneath the instrument panel

The f

use bo

x is located underneath the dash

panel on the driver side ››› Fig. 45.

In the engine compartment

Press the locking tabs to release the fuse box

cover ››› Fig. 46.

Identifying fuses situated below the dash

panel by colours

ColourAmp rating

Purple3

Light brown5

Brown7.5

Red10

Blue15

Yellow20

White or transparent25

Green30

Orange40

››› in Introduction on page 77

›››

page 77 Replacing a blown fuse

Fig. 47

Image of a blown fuse Preparation

● Switch off the ignition, lights and all elec-

tric al

equipment

.

● Open the corresponding fuse box

›››

page 78.

Identifying a blown fuse

A fuse is blown if its metal strip is ruptured

››› Fig. 47.

Point a lamp at the fuse to see if the fuse has

blown.

To replace a fuse

● Remove the fuse.

● Replace the blown fuse by one with an

identica

l amperage rating (same colour and

markings) and identical size. » 33

Page 37 of 232

The essentials

● Sc r

ew the infl

ator tube ››› Fig. 48 3 into

the se al

ant

bottle. The bottle's seal will break

automatically.

● Remove the lid from the filling tube

›››

Fig. 48 3 and screw the open end of the

t ube int

o the ty

re valve.

● With the tyre sealant bottle upside down,

fill

the tyre with the contents of the sealant

bottle.

● Remove the bottle from the valve.

● Place the insert back into the tyre valve us-

ing the too

l ››› Fig. 48 1 .

Infl atin

g the ty

re

● Screw the compressor tyre inflator tube

›››

Fig. 48 5 into the tyre valve.

● Check that the air bleed screw is closed

› ›

›

Fig. 48 7 .

● Start the engine and leave it running.

● Insert the connector ››

›

Fig. 48 9 into the

v ehic

l

e's 12-volt socket ›››

page 117.

● Turn the air compressor on with the ON/OFF

switc

h ››› Fig. 48 8 .

● Keep the air compressor running until it

r e

ac

hes 2.0 to 2.5 bar

(29-36 psi/200-250 kPa). a maximum of 8

minutes.

● Disconnect the air compressor.

● If it does not reach the pressure indicated,

uns

crew the tyre inflator tube from the valve. ●

Move the

vehicle 10m so that the sealant is

distributed throughout the tyre.

● Screw the compressor tyre inflator into the

valve.

● R

epeat the inflation process.

● If the indicated pressure still cannot be

reac

hed, the tyre is too badly damaged. Stop

and request assistance from an authorised

technician.

● Disconnect the air compressor. Unscrew

the tyre infl

ator tube from the tyre valve.

● When the tyre pressure is between 2.5 and

2.0 bars, c

ontinue driving without exceeding

80 km/h (50 mph).

● Check the pressure again after 10 minutes

›››

page 73.

››› in TMS (Tyre Mobility System)* on

page 72

››› page 71 Changing a wheel

V ehic

l

e tool kit Fig. 49

Components of the vehicle tool kit Screwdriver with hexagon socket in the

h

andl

e

Ad

apter for anti-theft bolt.

Towline anchorage, removable.

Wire hook for removing the hub caps.

Jack.

Wheel spanner.

Wheel bolt cap clips.

››› in What to do first on page 34

››› page 69 1

2

3

4

5

6

7

35

Page 41 of 232

The essentials

WARNING

If the vehicle is not correctly raised, it could

fa l

l off the jack causing serious injury. Please

observe the following rules to minimise the

risk of injury:

● You should only use a jack approved by

SEAT f

or your vehicle. Other jacks, even those

approved for other SEAT models, might slip

out of place.

● The ground should be firm and flat. If the

ground i

s sloped or soft then the vehicle

could slip and fall off the jack. If necessary,

support the jack on a wide solid base.

● If the ground is slippery, such as tiles,

plac

e a non-slip surface (a floor mat, for in-

stance) beneath the jack to avoid slipping.

● Only fit the jack at the prescribed jacking

points. The c

law of the jack should grip the

reinforcement nerve on the underbody

››› Fig. 56.

● You should never place a body limb such as

an arm or leg u

nder a raised vehicle that is

solely supported by the jack.

● If you have to work underneath the vehicle,

you mus

t use suitable stands additionally to

support the vehicle, there is a risk of acci-

dent!.

● Never raise the vehicle if it is tilting to one

side or the engine i

s running.

● Never start the engine when the vehicle is

raised.

The vehicle may come loose from the

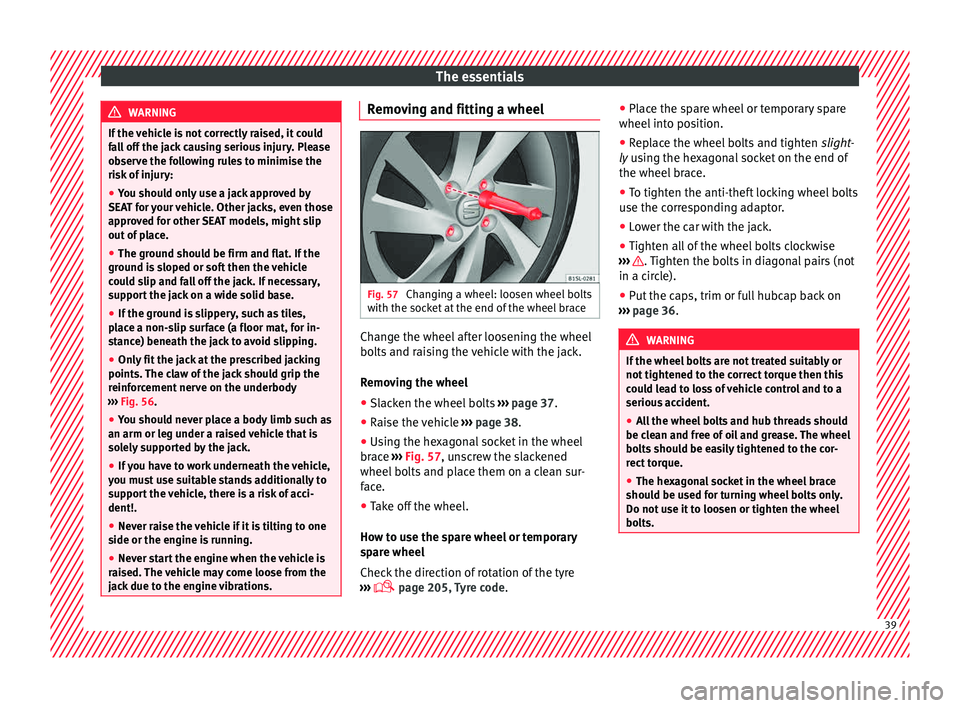

jack due to the engine vibrations. Removing and fitting a wheel

Fig. 57

Changing a wheel: loosen wheel bolts

w ith the soc

k

et at the end of the wheel brace Change the wheel after loosening the wheel

bo

lts

and r

aising the vehicle with the jack.

Removing the wheel

● Slacken the wheel bolts ›››

page 37.

● Raise the vehicle ›››

page 38.

● Using the hexagonal socket in the wheel

brace ›

›› Fig. 57, unscrew the slackened

wheel bolts and place them on a clean sur-

face.

● Take off the wheel.

How to u

se the spare wheel or temporary

spare wheel

Check the direction of rotation of the tyre

››› page 205, Tyre code. ●

Place the s

pare wheel or temporary spare

wheel into position.

● Replace the wheel bolts and tighten slight

-

ly using the hexagonal socket on the end of

the wheel brace.

● To tighten the anti-theft locking wheel bolts

use the corr

esponding adaptor.

● Lower the car with the jack.

● Tighten all of the wheel bolts clockwise

›››

. Tighten the bolts in diagonal pairs (not

in a c ir

c

le).

● Put the caps, trim or full hubcap back on

›››

page 36. WARNING

If the wheel bolts are not treated suitably or

not tight ened t

o the correct torque then this

could lead to loss of vehicle control and to a

serious accident.

● All the wheel bolts and hub threads should

be cle

an and free of oil and grease. The wheel

bolts should be easily tightened to the cor-

rect torque.

● The hexagonal socket in the wheel brace

should be u

sed for turning wheel bolts only.

Do not use it to loosen or tighten the wheel

bolts. 39

Page 43 of 232

The essentials

CAUTION

● Remo v

e the snow chains to drive on roads

without snow. Otherwise they will impair

vehicle handling, damage the tyres and wear

out very quickly.

● Wheel rims may be damaged or scratched if

the chain

s come into direct contact with

them. SEAT recommends the use of covered

snow chains. Note

Snow chains are available in different sizes

acc or

ding to the vehicle type. Emergency towing of the vehi-

c

l

e

T

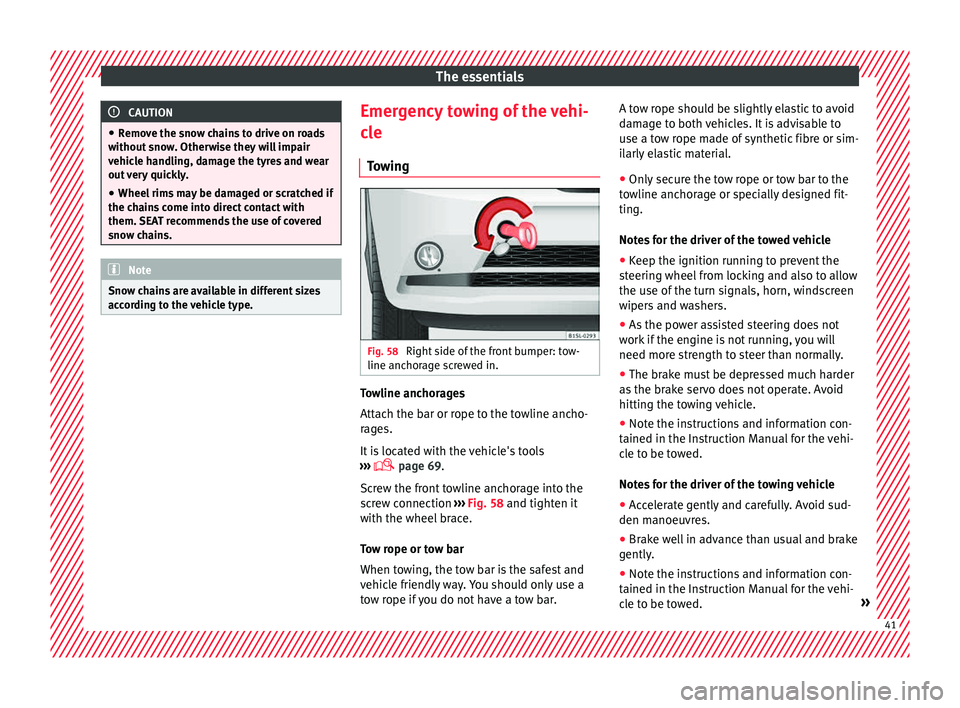

owing Fig. 58

Right side of the front bumper: tow-

line anc hor

ag

e screwed in. Towline anchorages

Att

ac

h the b

ar or rope to the towline ancho-

rages.

It is located with the vehicle's tools

››› page 69.

Screw the front towline anchorage into the

screw connection ››› Fig. 58 and tighten it

with the wheel brace.

Tow rope or tow bar

When towing, the tow bar is the safest and

vehicle friendly way. You should only use a

tow rope if you do not have a tow bar. A tow rope should be slightly elastic to avoid

damag

e to both vehicles. It is advisable to

use a tow rope made of synthetic fibre or sim-

ilarly elastic material.

● Only secure the tow rope or tow bar to the

towline anc

horage or specially designed fit-

ting.

Notes for the driver of the towed vehicle

● Keep the ignition running to prevent the

steerin

g wheel from locking and also to allow

the use of the turn signals, horn, windscreen

wipers and washers.

● As the power assisted steering does not

work if

the engine is not running, you will

need more strength to steer than normally.

● The brake must be depressed much harder

as the br

ake servo does not operate. Avoid

hitting the towing vehicle.

● Note the instructions and information con-

tained in the Ins

truction Manual for the vehi-

cle to be towed.

Notes for the driver of the towing vehicle

● Accelerate gently and carefully. Avoid sud-

den manoeuvr

es.

● Brake well in advance than usual and brake

gently.

● Not

e the instructions and information con-

tained in the In s

truction Manual for the vehi-

cle to be towed. » 41

Page 44 of 232

The essentials

Driving style

T o

w

ing requires some experience, especially

when using a tow rope. Both drivers should

realise how difficult it is to tow a vehicle. In-

experienced drivers should not attempt to

tow.

Do not pull too hard with the towing vehicle

and take care to avoid jerking the tow rope.

When towing on an unpaved road, there is al-

ways a risk of overloading and damaging the

anchorage points.

Switch on the ignition so that the turn sig-

nals, windscreen wipers and windscreen

washer can work. Ensure that the steering

wheel is unlocked and moves freely.

Place the gear lever in neutral on vehicles

with a manual gearbox. With an automatic

gearbox, place the lever in N.

To brake, press the brake pedal firmly. The

brake servo does not work when the engine

is switched off.

The power steering only works when the igni-

tion is switched on and the vehicle is moving,

provided that the battery is sufficiently charg-

ed. Otherwise, it will need more force.

Ensure that the tow rope remains taut at all

times. ››› in Instructions for tow-starting on

page 75

››› page 74 Tow-starting

In general, the vehicle should not be started

by

t

owing. Jump-starting is much more pref-

erable ››› page 42.

For technical reasons, the following vehicles

can not be tow started:

● Vehicles with an automatic gearbox.

● If the vehicle battery is flat, it is possible

that the en

gine control unit does not operate

correctly.

However, if your vehicle must absolutely be

tow-started (manual gearbox):

● Put it into second or third gear.

● Keep the clutch pressed down.

● Switch on the ignition and the hazard warn-

ing lights.

● Rel

ease the clutch when both vehicles are

movin

g.

● As soon as the engine starts, press the

clutc

h and move the gear lever into neutral.

This helps to prevent a collision with the tow-

ing vehicle. How to jump start

Jump lea

ds If the engine fails to start because of a dis-

ch

ar

ged battery, the battery of another vehi-

cle can be used to start the engine. Before

starting, check the magic eye on the battery

››› page 193.

For starting assistance, jump lead cables con-

forming to the standard DIN 72553 are re-

quired (see the cable manufacturer instruc-

tions). The cable section in vehicles with pet-

rol engine must be at least 25 mm 2

. WARNING

Incorrect use of jump leads and incorrectly

jump st ar

ting could cause the battery to ex-

plode resulting in serious injury. Please ob-

serve the following rules to minimise the risk

of a battery explosion:

● The battery providing current must have

the same v

oltage (12V) and approximately

the same capacity (see markings on battery)

as the flat battery.

● Never charge a frozen or recently thawed

batter

y. A flat battery can also freeze at tem-

peratures close to 0 °C (+32 °F).

● If a battery is frozen and/or has been frozen

then it mus

t be replaced.

● A highly explosive mixture of gases is re-

lea

sed when the battery is being charged. Al-

ways keep lit cigarettes, flames, sparks and 42

Page 45 of 232

The essentials

fire far from the battery. Never use a mobile

tel

ephone when c

onnecting and removing the

jump leads.

● Charge the battery only in well ventilated

area

s given that when the battery is charged

by outside assistance, it creates a mix of

highly explosive gases.

● Jump leads should never enter into contact

with mov

ing parts in the engine compart-

ment.

● Never switch the positive and negative

pole

s or connect the jump leads incorrectly.

● Note the instruction manual provided by

the manufact

urer of the jump leads. CAUTION

To avoid considerable damage to the vehicle

electric a

l system, note the following careful-

ly:

● If the jump leads are incorrectly connected,

this c

ould result in a short circuit.

● The vehicles must not touch each other,

otherwi

se electricity could flow as soon as

the positive terminals are connected. How to jump start: description

Fig. 59

Diagram of connections for vehicles

w ithout

Start Stop system Fig. 60

Diagram of connections for vehicles

w ith

St

art Stop system Jump lead terminal connections

1. Switch off the ignition of both vehicles

››

›

.2. Connect one end of the

re

d

jump lead to

the positive + terminal of the vehicle

w ith the fl

at

battery A

› ››

Fig. 59

.

3.

Connect the other end of the red

jump

lead to the positive terminal + in the ve-

hic l

e pr

oviding assistance B .

4. For vehicles without Start-Stop system:

connect

one end of

the black jump lead to

the negative terminal – of the vehicle

pr o

v

iding the current B

› ››

Fig. 59

.

– F

or vehicles with Start-Stop system: con-

nect one end of

the black jump lead X to a

s uit

ab

le ground terminal, to a solid piece of

metal in the engine block, or to the engine

block itself ››› Fig. 60.

5. Connect the other end of the black

jump

lead X to a solid metal component bolted

t o the en

gine b

lock or to the engine block

itself of the vehicle with the flat battery.

Do not connect it to a point near the bat-

tery A .

6. Position the leads in such a way that they cannot

c

ome into contact with any moving

parts in the engine compartment.

Starting

7. Start the engine of the vehicle with the boostin

g battery and let it run at idling

speed. » 43

Page 46 of 232

The essentials

8. Start the engine of the vehicle with the flat batt

er

y and wait for 2 or 3 minutes until

the engine is running.

Removing the jump leads

9. Before you remove the jump leads, switch off the dipped be

am headlights (if they

are switched on).

10.Turn on the heater blower and heated rear window in the

vehicle with the flat battery.

This helps minimise voltage peaks which

are generated when the leads are discon-

nected.

11.

When the engine is running, disconnect

the leads in reverse order to the details

given above.

Make sure the battery clamps have sufficient

metal-to-metal contact with the battery termi-

nals.

If the engine fails to start, switch off the start-

er after about 10 seconds and try again after

about 1 minute. WARNING

● Ple a

se note the safety warnings referring to

working in the engine compartment

››› page 184.

● The battery providing assistance must have

the same v

oltage as the flat battery (12V) and

approximately the same capacity (see imprint on battery). Failure to comply could result in

an exp

lo

sion.

● Never use jump leads when one of the bat-

teries

is frozen. Danger of explosion! Even af-

ter the battery has thawed, battery acid could

leak and cause chemical burns. If a battery

freezes, it should be replaced.

● Keep sparks, flames and lighted cigarettes

awa

y from batteries, danger of explosion.

Failure to comply could result in an explo-

sion.

● Observe the instructions provided by the

manufact

urer of the jump leads.

● Do not connect the negative cable from the

other vehic

le directly to the negative terminal

of the flat battery. The gas emitted from the

battery could be ignited by sparks. Danger of

explosion.

● Do not attach the negative cable from the

other vehic

le to parts of the fuel system or to

the brake line.

● The non-insulated parts of the battery

clamp

s must not be allowed to touch. The

jump lead attached to the positive battery

terminal must not touch metal parts of the ve-

hicle, this can cause a short circuit.

● Position the leads in such a way that they

cannot c

ome into contact with any moving

parts in the engine compartment.

● Do not lean on the batteries. This could re-

sult

in chemical burns. Note

The vehicles must not touch each other, oth-

erw i

se electricity could flow as soon as the

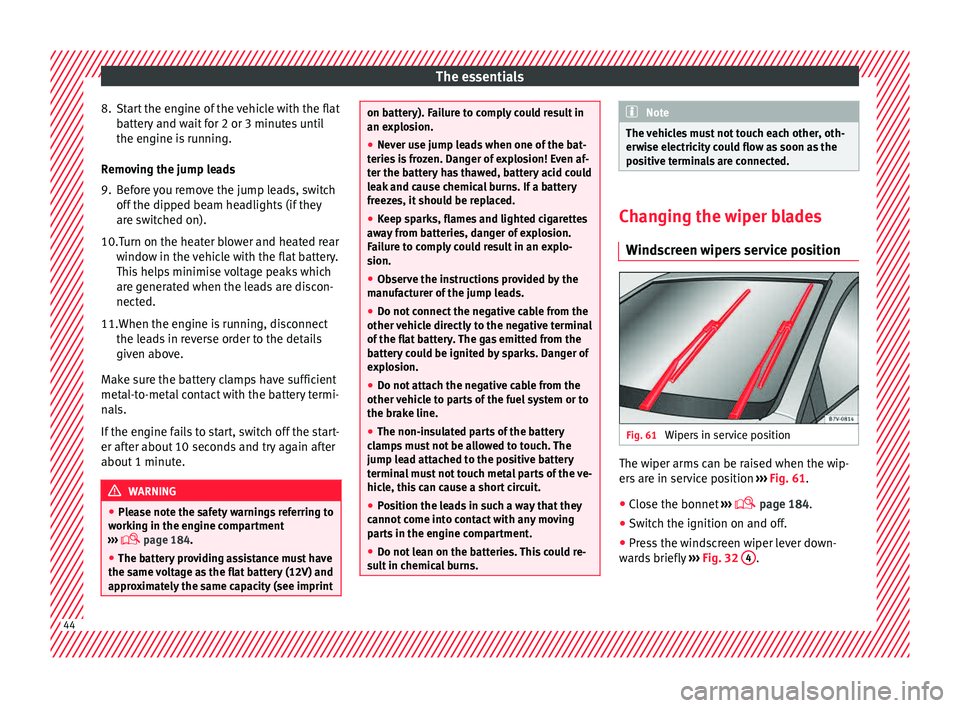

positive terminals are connected. Changing the wiper blades

Wind s

creen wipers service position Fig. 61

Wipers in service position The wiper arms can be raised when the wip-

er

s

ar

e in service position ››› Fig. 61.

● Close the bonnet ›››

page 184.

● Switch the ignition on and off.

● Press the windscreen wiper lever down-

ward

s briefly ››› Fig. 32 4 .

44