jacking points Seat Mii 2015 Owner's manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2015, Model line: Mii, Model: Seat Mii 2015Pages: 232, PDF Size: 4.23 MB

Page 40 of 232

The essentials

●

Only u

se wheel bolts which correspond to

the wheel rims in question.

● Never use different wheel bolts.

● The bolts and threads should be clean, free

of oil

and grease and easy to thread.

● To loosen and tighten the wheel bolts, al-

way

s use the wheel brace supplied with the

vehicle.

● Loosen the wheel bolts only about one turn

before r

aising the vehicle with the jack.

● Never grease or lubricate wheel bolts or the

wheel hub thre

ads. Although they have been

tightened to the prescribed torque, they

could come loose while driving.

● Never loosen the bolted joints of wheel

rims with bo

lted ring trims.

● If the wheel bolts are not tightened to the

correct

torque, they may come loose while

driving, and the bolts and rims may come

out. If the tightening torque is too high, the

wheel bolts and threads can be damaged. Raising the vehicle with the jack

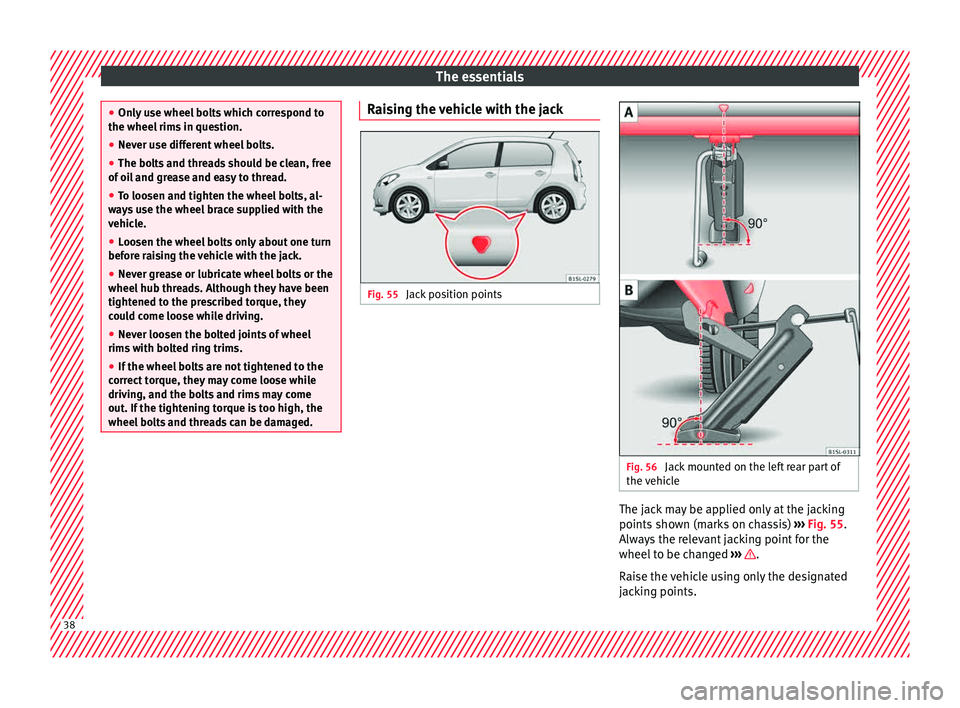

Fig. 55

Jack position points Fig. 56

Jack mounted on the left rear part of

the v

ehic

le The jack may be applied only at the jacking

points

sho

wn (m

arks on chassis) ››› Fig. 55.

Always the relevant jacking point for the

wheel to be changed ››› .

R ai

se the

vehicle using only the designated

jacking points. 38

Page 41 of 232

The essentials

WARNING

If the vehicle is not correctly raised, it could

fa l

l off the jack causing serious injury. Please

observe the following rules to minimise the

risk of injury:

● You should only use a jack approved by

SEAT f

or your vehicle. Other jacks, even those

approved for other SEAT models, might slip

out of place.

● The ground should be firm and flat. If the

ground i

s sloped or soft then the vehicle

could slip and fall off the jack. If necessary,

support the jack on a wide solid base.

● If the ground is slippery, such as tiles,

plac

e a non-slip surface (a floor mat, for in-

stance) beneath the jack to avoid slipping.

● Only fit the jack at the prescribed jacking

points. The c

law of the jack should grip the

reinforcement nerve on the underbody

››› Fig. 56.

● You should never place a body limb such as

an arm or leg u

nder a raised vehicle that is

solely supported by the jack.

● If you have to work underneath the vehicle,

you mus

t use suitable stands additionally to

support the vehicle, there is a risk of acci-

dent!.

● Never raise the vehicle if it is tilting to one

side or the engine i

s running.

● Never start the engine when the vehicle is

raised.

The vehicle may come loose from the

jack due to the engine vibrations. Removing and fitting a wheel

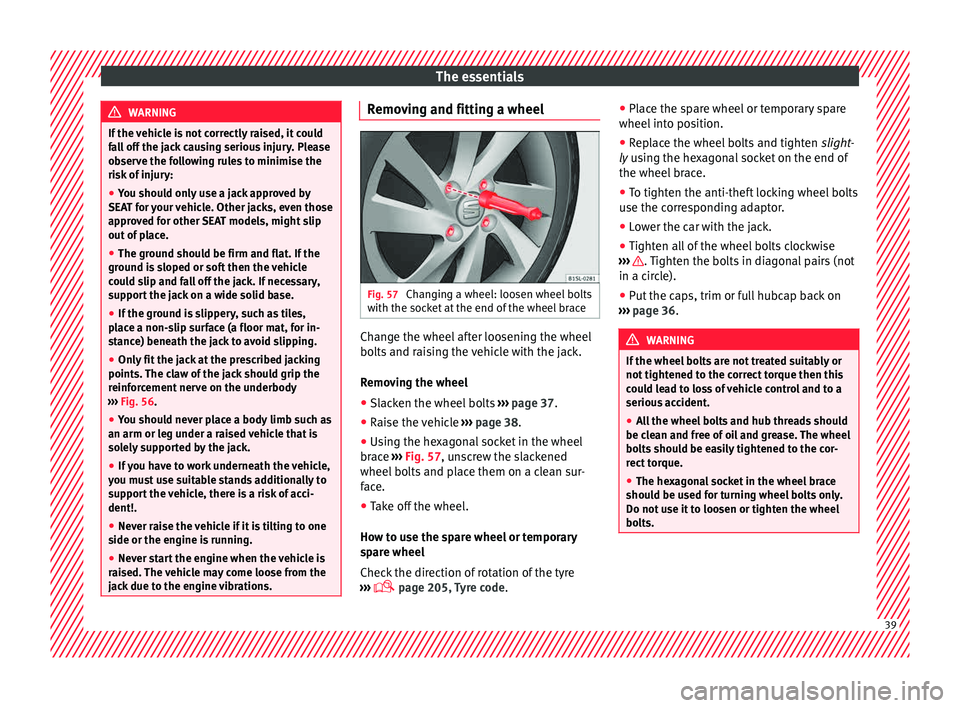

Fig. 57

Changing a wheel: loosen wheel bolts

w ith the soc

k

et at the end of the wheel brace Change the wheel after loosening the wheel

bo

lts

and r

aising the vehicle with the jack.

Removing the wheel

● Slacken the wheel bolts ›››

page 37.

● Raise the vehicle ›››

page 38.

● Using the hexagonal socket in the wheel

brace ›

›› Fig. 57, unscrew the slackened

wheel bolts and place them on a clean sur-

face.

● Take off the wheel.

How to u

se the spare wheel or temporary

spare wheel

Check the direction of rotation of the tyre

››› page 205, Tyre code. ●

Place the s

pare wheel or temporary spare

wheel into position.

● Replace the wheel bolts and tighten slight

-

ly using the hexagonal socket on the end of

the wheel brace.

● To tighten the anti-theft locking wheel bolts

use the corr

esponding adaptor.

● Lower the car with the jack.

● Tighten all of the wheel bolts clockwise

›››

. Tighten the bolts in diagonal pairs (not

in a c ir

c

le).

● Put the caps, trim or full hubcap back on

›››

page 36. WARNING

If the wheel bolts are not treated suitably or

not tight ened t

o the correct torque then this

could lead to loss of vehicle control and to a

serious accident.

● All the wheel bolts and hub threads should

be cle

an and free of oil and grease. The wheel

bolts should be easily tightened to the cor-

rect torque.

● The hexagonal socket in the wheel brace

should be u

sed for turning wheel bolts only.

Do not use it to loosen or tighten the wheel

bolts. 39

Page 168 of 232

Advice

Support points for raising the vehicle Fig. 158

Front jacking points for raising vehi-

c l

e w

ith lifting platform or jack Fig. 159

Rear jacking points for raising vehi-

c l

e w

ith lifting platform or jack Always use the jacking points indicated in

the figur

e

s

››› Fig. 158 and ››› Fig. 159 when

raising the vehicle. If the vehicle is not lifted

at these points, it could be seriously dam-

aged ››› or lead to serious injury

›

››

.The vehicle should not be lifted using lifting

p

latf

orms with lift pads containing fluid.

When raising a vehicle using a platform or

jack, a series of precautionary measures are

required. Do not raise the vehicle with a lift-

ing platform or jack unless you have received

training in how to do so and know how to do

so safely.

Notes on raising the vehicle with a jack

››› page 71. WARNING

The improper use of the lifting platform or

the jac k

when raising the vehicle may result

in accidents or serious injury.

● Before raising the vehicle, please observe

the manufact

urer's instructions for the plat-

form or jack, and the legal requirements,

where applicable.

● There should not be anyone inside the ve-

hicle when it

is being raised or once it is in

the air.

● Only use the jacking points indicated in the

figures

››› Fig. 158 and ››› Fig. 159 when rais-

ing the vehicle. If the vehicle is not lifted at

the indicated points, it may fall from the plat-

form while the engine or gearbox is being

dismounted, for example.

● The jacking points should be centrally

aligned and firmly

positioned on the platform

support plates. ●

Never s t

art the engine when the vehicle is

raised! The vehicle may fall from the platform

due to the engine vibrations.

● If it is necessary to work underneath the ve-

hicle whi

le it is raised, you should check that

the supporting stands have an adequate load

capacity.

● Never climb onto the lifting platform.

● Always make sure that the weight of the ve-

hicle doe

s not exceed the lifting platform

load capacity. CAUTION

● Never r ai

se the vehicle at the engine oil

sump, the gearbox or the rear or front axles.

● Always use an intermediate rubber support

to prev

ent damage to the vehicle underbody.

Check that the arms of the lifting platform are

able to move with obstruction.

● The arms should not come into contact with

the side runnin

g boards or other parts of the

vehicle. Caring for and cleaning the ve-

hic

le e

xterior

Introduction Regular maintenance and washing help to

m

aint

ain the

value of the vehicle. This may

166