jack Seat Mii 2017 Owner's manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2017, Model line: Mii, Model: Seat Mii 2017Pages: 232, PDF Size: 4.91 MB

Page 38 of 232

The essentials

● Sc r

ew the infl

ator tube ››› Fig. 48 3 into

the se al

ant

bottle. The bottle's seal will break

automatically.

● Remove the lid from the filling tube

›››

Fig. 48 3 and screw the open end of the

t ube int

o the ty

re valve.

● With the tyre sealant bottle upside down,

fill

the tyre with the contents of the sealant

bottle.

● Remove the bottle from the valve.

● Place the insert back into the tyre valve us-

ing the too

l ››› Fig. 48 1 .

Infl atin

g the ty

re

● Screw the compressor tyre inflator tube

›››

Fig. 48 5 into the tyre valve.

● Check that the air bleed screw is closed

› ›

›

Fig. 48 7 .

● Start the engine and leave it running.

● Insert the connector ››

›

Fig. 48 9 into the

v ehic

l

e's 12-volt socket ›››

page 120.

● Turn the air compressor on with the ON/OFF

switc

h ››› Fig. 48 8 .

● Keep the air compressor running until it

r e

ac

hes 2.0 to 2.5 bar

(29-36 psi/200-250 kPa). A maximum of 8

minutes.

● Disconnect the air compressor.

● If it does not reach the pressure indicated,

uns

crew the tyre inflator tube from the valve. ●

Move the

vehicle 10m so that the sealant is

distributed throughout the tyre.

● Screw the compressor tyre inflator into the

valve.

● R

epeat the inflation process.

● If the indicated pressure still cannot be

reac

hed, the tyre is too badly damaged. Stop

and request assistance from an authorised

technician.

● Disconnect the air compressor. Unscrew

the tyre infl

ator tube from the tyre valve.

● When the tyre pressure is between 2.5 and

2.0 bars, c

ontinue driving without exceeding

80 km/h (50 mph).

● Check the pressure again after 10 minutes

›››

page 74.

››› in TMS (Tyre Mobility System)* on

page 73

››› page 72 Changing a wheel

V ehic

l

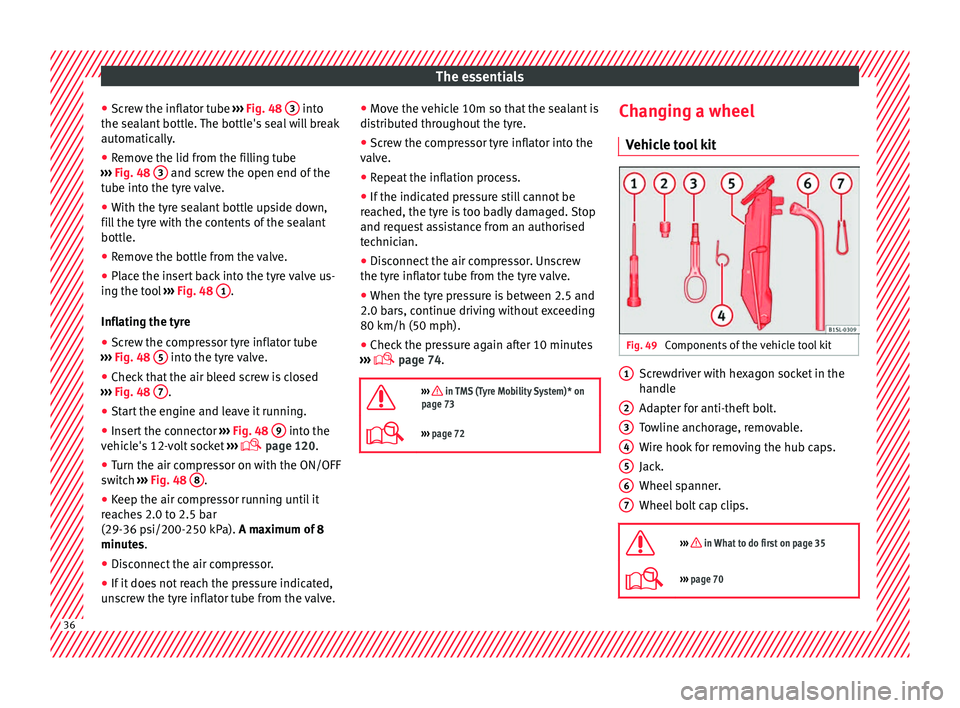

e tool kit Fig. 49

Components of the vehicle tool kit Screwdriver with hexagon socket in the

h

andl

e

Ad

apter for anti-theft bolt.

Towline anchorage, removable.

Wire hook for removing the hub caps.

Jack.

Wheel spanner.

Wheel bolt cap clips.

››› in What to do first on page 35

››› page 70 1

2

3

4

5

6

7

36

Page 40 of 232

The essentials

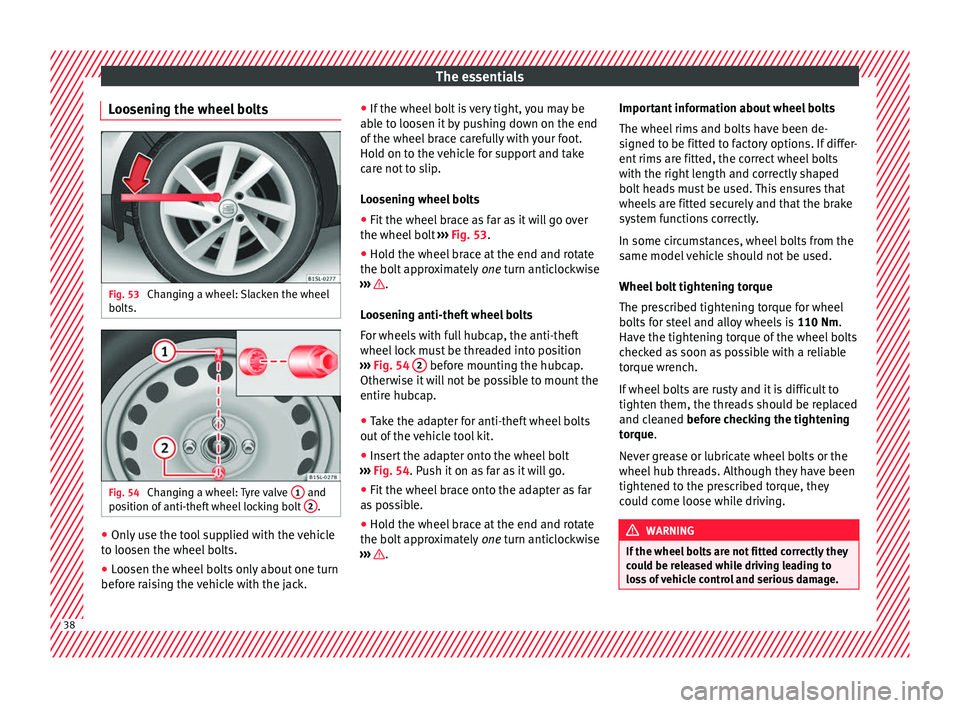

Loosening the wheel bolts Fig. 53

Changing a wheel: Slacken the wheel

bo lts. Fig. 54

Changing a wheel: Tyre valve 1 and

po s

ition of

anti-theft wheel locking bolt 2 .

●

Only use the tool supplied with the vehicle

t o loo

sen the wheel

bolts.

● Loosen the wheel bolts only about one turn

before r

aising the vehicle with the jack. ●

If the wheel bo

lt is very tight, you may be

able to loosen it by pushing down on the end

of the wheel brace carefully with your foot.

Hold on to the vehicle for support and take

care not to slip.

Loosening wheel bolts

● Fit the wheel brace as far as it will go over

the wheel bolt

››› Fig. 53.

● Hold the wheel brace at the end and rotate

the bolt ap

proximately one turn anticlockwise

››› .

L oo

senin

g anti-theft wheel bolts

For wheels with full hubcap, the anti-theft

wheel lock must be threaded into position

››› Fig. 54 2 before mounting the hubcap.

Other w

i

se it will not be possible to mount the

entire hubcap.

● Take the adapter for anti-theft wheel bolts

out of the

vehicle tool kit.

● Insert the adapter onto the wheel bolt

›››

Fig. 54. Push it on as far as it will go.

● Fit the wheel brace onto the adapter as far

as po

ssible.

● Hold the wheel brace at the end and rotate

the bolt ap

proximately one turn anticlockwise

››› .Important information about wheel bolts

The wheel

rims and bo

lts have been de-

signed to be fitted to factory options. If differ-

ent rims are fitted, the correct wheel bolts

with the right length and correctly shaped

bolt heads must be used. This ensures that

wheels are fitted securely and that the brake

system functions correctly.

In some circumstances, wheel bolts from the

same model vehicle should not be used.

Wheel bolt tightening torque

The prescribed tightening torque for wheel

bolts for steel and alloy wheels is 110 Nm.

Have the tightening torque of the wheel bolts

checked as soon as possible with a reliable

torque wrench.

If wheel bolts are rusty and it is difficult to

tighten them, the threads should be replaced

and cleaned before checking the tightening

torque.

Never grease or lubricate wheel bolts or the

wheel hub threads. Although they have been

tightened to the prescribed torque, they

could come loose while driving. WARNING

If the wheel bolts are not fitted correctly they

cou l

d be released while driving leading to

loss of vehicle control and serious damage. 38

Page 41 of 232

The essentials

●

Only u

se wheel bolts which correspond to

the wheel rims in question.

● Never use different wheel bolts.

● The bolts and threads should be clean, free

of oil

and grease and easy to thread.

● To loosen and tighten the wheel bolts, al-

way

s use the wheel brace supplied with the

vehicle.

● Loosen the wheel bolts only about one turn

before r

aising the vehicle with the jack.

● Never grease or lubricate wheel bolts or the

wheel hub thre

ads. Although they have been

tightened to the prescribed torque, they

could come loose while driving.

● Never loosen the bolted joints of wheel

rims with bo

lted ring trims.

● If the wheel bolts are not tightened to the

correct

torque, they may come loose while

driving, and the bolts and rims may come

out. If the tightening torque is too high, the

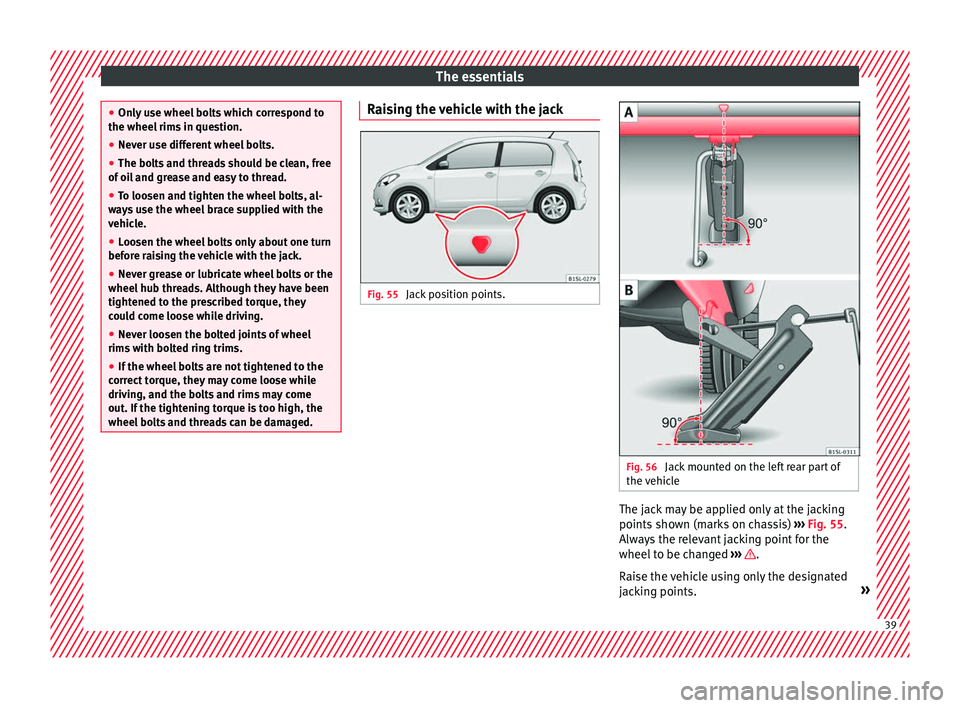

wheel bolts and threads can be damaged. Raising the vehicle with the jack

Fig. 55

Jack position points. Fig. 56

Jack mounted on the left rear part of

the v

ehic

le The jack may be applied only at the jacking

points

sho

wn (m

arks on chassis) ››› Fig. 55.

Always the relevant jacking point for the

wheel to be changed ››› .

R ai

se the

vehicle using only the designated

jacking points. » 39

Page 42 of 232

The essentials

WARNING

If the vehicle is not correctly raised, it could

fa l

l off the jack causing serious injury. Please

observe the following rules to minimise the

risk of injury:

● You should only use a jack approved by

SEAT f

or your vehicle. Other jacks, even those

approved for other SEAT models, might slip

out of place.

● The ground should be firm and flat. If the

ground i

s sloped or soft then the vehicle

could slip and fall off the jack. If necessary,

support the jack on a wide solid base.

● If the ground is slippery, such as tiles,

plac

e a non-slip surface (a floor mat, for in-

stance) beneath the jack to avoid slipping.

● Only fit the jack at the prescribed jacking

points. The c

law of the jack should grip the

reinforcement nerve on the underbody

››› Fig. 56.

● You should never place a body limb such as

an arm or leg u

nder a raised vehicle that is

solely supported by the jack.

● If you have to work underneath the vehicle,

you mus

t use suitable stands additionally to

support the vehicle, there is a risk of acci-

dent!.

● Never raise the vehicle if it is tilting to one

side or the engine i

s running.

● Never start the engine when the vehicle is

raised.

The vehicle may come loose from the

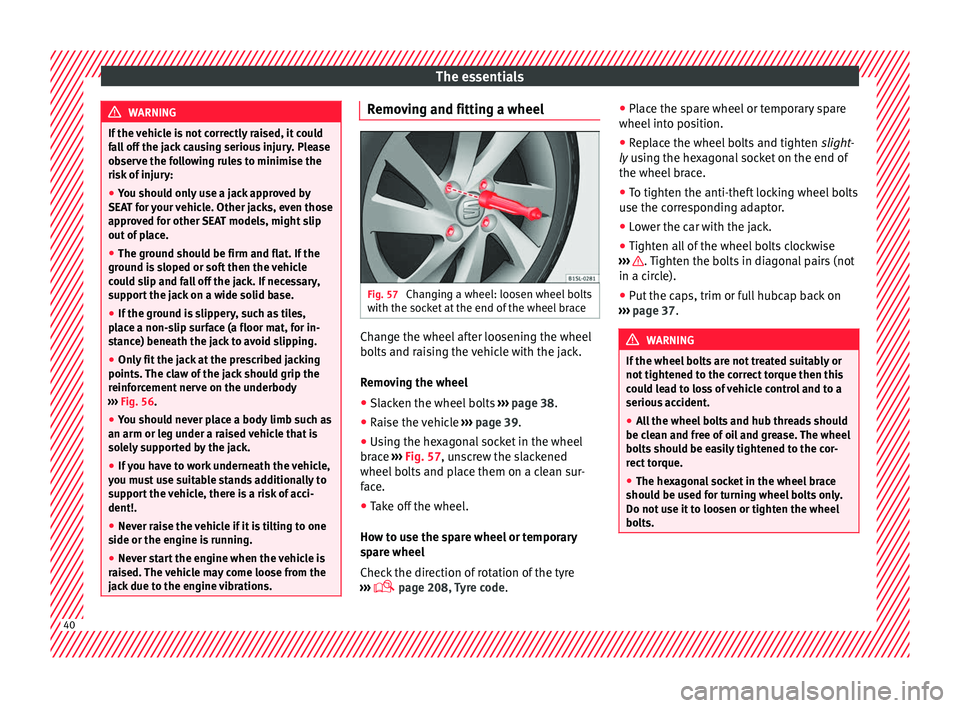

jack due to the engine vibrations. Removing and fitting a wheel

Fig. 57

Changing a wheel: loosen wheel bolts

w ith the soc

k

et at the end of the wheel brace Change the wheel after loosening the wheel

bo

lts

and r

aising the vehicle with the jack.

Removing the wheel

● Slacken the wheel bolts ›››

page 38.

● Raise the vehicle ›››

page 39.

● Using the hexagonal socket in the wheel

brace ›

›› Fig. 57, unscrew the slackened

wheel bolts and place them on a clean sur-

face.

● Take off the wheel.

How to u

se the spare wheel or temporary

spare wheel

Check the direction of rotation of the tyre

››› page 208, Tyre code. ●

Place the s

pare wheel or temporary spare

wheel into position.

● Replace the wheel bolts and tighten slight

-

ly using the hexagonal socket on the end of

the wheel brace.

● To tighten the anti-theft locking wheel bolts

use the corr

esponding adaptor.

● Lower the car with the jack.

● Tighten all of the wheel bolts clockwise

›››

. Tighten the bolts in diagonal pairs (not

in a c ir

c

le).

● Put the caps, trim or full hubcap back on

›››

page 37. WARNING

If the wheel bolts are not treated suitably or

not tight ened t

o the correct torque then this

could lead to loss of vehicle control and to a

serious accident.

● All the wheel bolts and hub threads should

be cle

an and free of oil and grease. The wheel

bolts should be easily tightened to the cor-

rect torque.

● The hexagonal socket in the wheel brace

should be u

sed for turning wheel bolts only.

Do not use it to loosen or tighten the wheel

bolts. 40

Page 73 of 232

Self-help

Location Fig. 77

In the luggage compartment: Raised

c arpet

. The vehicle tool kit, spare wheel, temporary

s

p

ar

e wheel and the tyre mobility set are

stored in the luggage compartment under the

carpeted floor panel ›››

Fig. 77.

● If necessary, remove the boot variable floor

›››

page 123.

● Raise the carpet at the recess (arrow)

›››

Fig. 77. Note

After use, return the jack to its initial position

us in

g the handle in order to securely store it

in the vehicle. Accessing the vehicle tool kit and tyre

mo

b

i

lity system in vehicles fitted with

the SEAT SOUND 7 speaker system

(with subwoofer)* ●

Open the boot hatch and lift the shelf.

● If necessary, remove the boot variable floor

›› ›

page 125.

● Lift up the carpet from the recess and re-

move it

from the luggage compartment.

● Disconnect the subwoofer’s speaker cable.

● Completely remove the hand-controlled

wheel fr om the c

entre of the subwoofer

speaker by turning it anti-clockwise.

● Take out the subwoofer, which is on top of

the tool

s and tyre mobility system.

● When finished, place the tools and system

back

in the same way and place as before to

ensure the speaker sits properly in its hous-

ing.

● Place the subwoofer in the direction of the

arrow and w

ith the word “FRONT” facing for-

ward.

● Reconnect the speaker cable and firmly ro-

tate the sec

uring wheel clockwise so that the

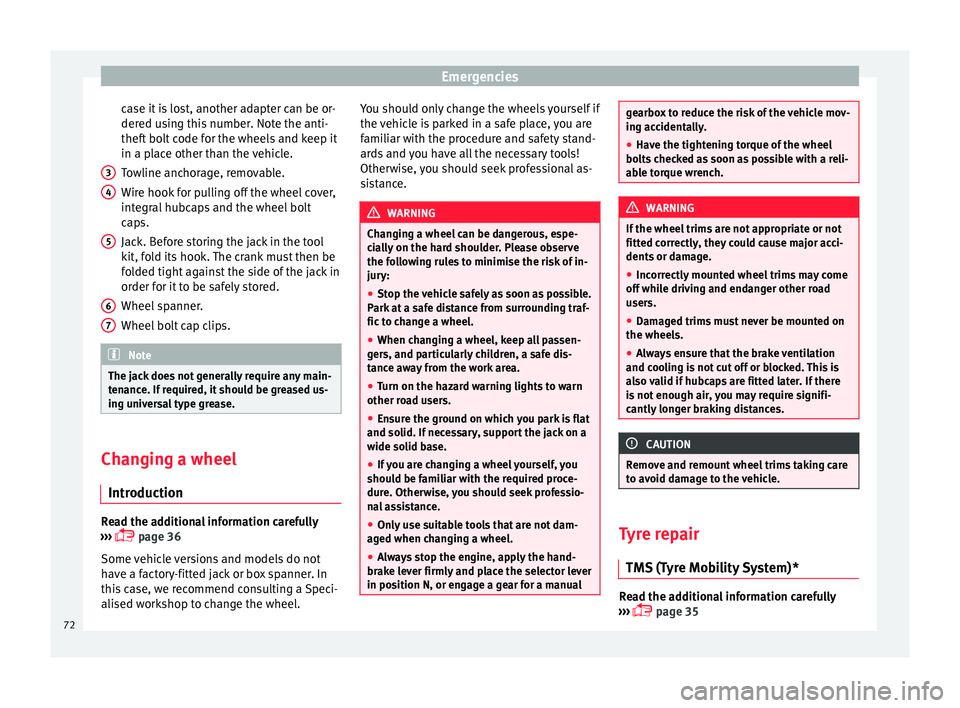

subwoofer is firmly in place. Components

Fig. 78

Components of the vehicle tool kit The vehicle tool kit depends on the vehicle

equipment

.

The f

ollowing is a description for

a vehicle with all options.

The individual elements of the vehicle tool

kit ››› Fig. 78

Screwdriver with hexagon socket in the

handle for screwing and unscrewing the

wheel bolts. The screwdriver bit is inter-

changeable. The screwdriver may be

found underneath the wheel spanner.

Adapter for anti-theft bolt. SEAT recom-

mend you carry the wheel bolt adapter in

the vehicle tool kit at all times. The code

number of the anti-theft wheel bolt is

stamped on the front of the adapter. In »

1 2

71

Technical data

Advice

Operation

Emergencies

Safety

Page 74 of 232

Emergencies

case it is lost, another adapter can be or-

der ed u

s

ing this number. Note the anti-

theft bolt code for the wheels and keep it

in a place other than the vehicle.

Towline anchorage, removable.

Wire hook for pulling off the wheel cover,

integral hubcaps and the wheel bolt

caps.

Jack. Before storing the jack in the tool

kit, fold its hook. The crank must then be

folded tight against the side of the jack in

order for it to be safely stored.

Wheel spanner.

Wheel bolt cap clips. Note

The jack does not generally require any main-

ten anc

e. If required, it should be greased us-

ing universal type grease. Changing a wheel

Intr oduction Read the additional information carefully

› ›

›

page 36

Some vehicle versions and models do not

have a factory-fitted jack or box spanner. In

this case, we recommend consulting a Speci-

alised workshop to change the wheel. 3 4

5

6

7 You should only change the wheels yourself if

the

v

ehic

le is parked in a safe place, you are

familiar with the procedure and safety stand-

ards and you have all the necessary tools!

Otherwise, you should seek professional as-

sistance. WARNING

Changing a wheel can be dangerous, espe-

ci a

lly on the hard shoulder. Please observe

the following rules to minimise the risk of in-

jury:

● Stop the vehicle safely as soon as possible.

Park at

a safe distance from surrounding traf-

fic to change a wheel.

● When changing a wheel, keep all passen-

gers, and p

articularly children, a safe dis-

tance away from the work area.

● Turn on the hazard warning lights to warn

other roa

d users.

● Ensure the ground on which you park is flat

and solid. If nec

essary, support the jack on a

wide solid base.

● If you are changing a wheel yourself, you

should be f

amiliar with the required proce-

dure. Otherwise, you should seek professio-

nal assistance.

● Only use suitable tools that are not dam-

aged when ch

anging a wheel.

● Always stop the engine, apply the hand-

brake l

ever firmly and place the selector lever

in position N, or engage a gear for a manual gearbox to reduce the risk of the vehicle mov-

ing ac

c

identally.

● Have the tightening torque of the wheel

bolts

checked as soon as possible with a reli-

able torque wrench. WARNING

If the wheel trims are not appropriate or not

fitt ed c orr

ectly, they could cause major acci-

dents or damage.

● Incorrectly mounted wheel trims may come

off whil

e driving and endanger other road

users.

● Damaged trims must never be mounted on

the wheels.

● Alw

ays ensure that the brake ventilation

and coolin

g is not cut off or blocked. This is

also valid if hubcaps are fitted later. If there

is not enough air, you may require signifi-

cantly longer braking distances. CAUTION

Remove and remount wheel trims taking care

to av oid d

amage to the vehicle. Tyre repair

TM S (T

yre Mobility System)* Read the additional information carefully

› ›

›

page 35

72

Page 75 of 232

Self-help

The Anti-puncture kit* (Tyre Mobility System)

w i

l

l reliably seal punctures caused by the

penetration of a foreign body of up to about

4 mm in diameter. Do not remove foreign ob-

jects, e.g. screws or nails, from the tyre.

After inserting the sealant residue in the tyre,

you must again check the tyre pressure about

10 minutes after starting the engine.

You should only use the tyre mobility set if

the vehicle is parked in a safe place, you are

familiar with the procedure and you have the

necessary tyre mobility set! Otherwise, you

should seek professional assistance.

Do not use the tyre sealant in the following

cases:

● If the wheel rim has been damaged.

● In outside temperatures below -20°C (-4°F).

● In the event of cuts or perforations in the

tyre gr

eater than 4 mm.

● If you have been driving with very low pres-

sure or a c

ompletely flat tyre.

● If the sealant bottle has passed its use by

date. WARNING

Using the tyre mobility system can be dan-

ger ou

s, especially when filling the tyre at the

roadside. Please observe the following rules

to minimise the risk of injury: ●

Stop the v

ehicle safely as soon as possible.

Park it at a safe distance from surrounding

traffic to fill the tyre.

● Ensure the ground on which you park is flat

and solid.

● Al

l passengers and particularly children

must

keep a safe distance from the work area.

● Turn on the hazard warning lights to warn

other roa

d users.

● Use the tyre mobility system only if you are

famili

ar with the necessary procedures. Oth-

erwise, you should seek professional assis-

tance.

● The tyre mobility set is intended for tempo-

rary

emergency use only until you can reach

the nearest specialised workshop.

● Replace the repaired tyre with the tyre mo-

bility

set as soon as possible.

● The sealant is a health hazard and must be

cle

aned immediately if it comes into contact

with the skin.

● Always keep the tyre mobility set out of the

reac

h of small children.

● Never use an equivalent jack, even if it has

been appro

ved for your vehicle.

● Always stop the engine, apply the hand-

brake l

ever firmly and engage gear if using a

manual gearbox, in order to reduce the risk of

vehicle involuntary movement. WARNING

A tyre filled with sealant does not have the

same per f

ormance properties as a conven-

tional tyre.

● Never drive faster than 80 km/h (50 mph).

● Avoid heavy acceleration, hard braking and

fas

t cornering.

● Drive for only 10 minutes at a maximum

speed of 80

km/h (50 mph) and then check

the tyre. For the sake of the environment

Dispose of used or expired sealant observing

any l

egal requirements. Note

● A new bottle of se

alant can be purchased at

SEAT dealerships.

● Take into account the separate instruction

manual

of the tyre mobility set* manufactur-

er. 73

Technical data

Advice

Operation

Emergencies

Safety

Page 171 of 232

Care and maintenance

●

Whil e driv

ing, the mobile telephone, other

equipment including telephone accessories

such as telephone supports, notepads and

navigators must be correctly secured, away

from the airbags deployment zones, or stored

in a safe place. WARNING

When using a mobile telephone or two-way

r a dio w

ithout connecting an external aerial,

the maximum permitted levels of electromag-

netic radiation in the vehicle may be excee-

ded, thus putting the driver and the rest of

the vehicle occupants in danger. This is also

the case if the aerial has not been correctly

installed.

● A minimum of 20 centimetres should be

kept betw

een mobile phone aerials and artifi-

cial pacemakers, as mobile telephones may

affect the working of pacemakers.

● Do not keep mobile phones in breast pock-

ets dir

ectly above pacemakers.

● Immediately switch off the mobile tele-

phone if y

ou suspect any interference with

pacemakers or other types of medical equip-

ment. Support points for raising the vehicle

Fig. 159

Front jacking points for raising vehi-

c l

e w

ith lifting platform or jack Fig. 160

Rear jacking points for raising vehi-

c l

e w

ith lifting platform or jack Always use the jacking points indicated in

the figur

e

s

››› Fig. 159 and ››› Fig. 160 when

raising the vehicle. If the vehicle is not lifted

at these points, it could be seriously dam-

aged ››› or lead to serious injury

›

››

.The vehicle should not be lifted using lifting

p

latf

orms with lift pads containing fluid.

When raising a vehicle using a platform or

jack, a series of precautionary measures are

required. Do not raise the vehicle with a lift-

ing platform or jack unless you have received

training in how to do so and know how to do

so safely.

Notes on raising the vehicle with a jack

››› page 72. WARNING

The improper use of the lifting platform or

the jac k

when raising the vehicle may result

in accidents or serious injury.

● Before raising the vehicle, please observe

the manufact

urer's instructions for the plat-

form or jack, and the legal requirements,

where applicable.

● There should not be anyone inside the ve-

hicle when it

is being raised or once it is in

the air.

● Only use the jacking points indicated in the

figures

››› Fig. 159 and ››› Fig. 160 when rais-

ing the vehicle. If the vehicle is not lifted at

the indicated points, it may fall from the plat-

form while the engine or gearbox is being

dismounted, for example.

● The jacking points should be centrally

aligned and firmly

positioned on the platform

support plates. » 169

Technical data

Advice

Operation

Emergencies

Safety

Page 189 of 232

Checking and refilling levels

●

Noise s

heard when refuelling are normal

and do not indicate the presence of a fault in

the system.

● The vehicle natural gas system is prepared

both for ref

uelling with a small compressor

(slow refuel) and a large compressor (fast re-

fuel) in natural gas service stations. Bonnet

Work in

g in the engine compartment Read the additional information carefully

› ›

›

page 10

Before working in the engine compartment,

make sure that the vehicle is parked on hori-

zontal and firm ground.

The engine compartment of the vehicle is a

hazardous area. Never work on the engine or

in the engine compartment if you are not fa-

miliar with the operations to be carried out,

the applicable safety standards and especial-

ly if you do not have the necessary instru-

ments, liquids and tools ››› ! If required,

h av

e an

y work carried out by a specialised

workshop. Negligent work can cause serious

injury. WARNING

If the vehicle moves unexpectedly, this could

cau se seriou

s injury. ●

Never w ork

under the vehicle if it has not

been immobilized. If you must work under-

neath the vehicle with the wheels in contact

with the ground then it should be parked on

flat ground, the wheels should be prevented

from moving and the key should be removed

from the ignition.

● If you have to work underneath the vehicle,

you mus

t use suitable stands additionally to

support the vehicle, there is a risk of acci-

dent!. The jack is not intended for this kind of

work and its failure could lead to severe inju-

ries.

● Disconnect the Start-Stop system. WARNING

The engine compartment is a dangerous area

cap ab

le of causing serious injury.

● For all type of work, always take the utmost

precaution

s, work carefully and note the gen-

eral safety standards in force. Never take per-

sonal risks.

● Never work on the engine or in the engine

compar

tment if you are not familiar with the

necessary operations. If you are not sure

about procedures then visit a specialised

workshop to carry out the necessary work.

Working incorrectly can cause serious inju-

ries.

● Never open the bonnet if you see steam or

cool

ant escaping from the engine compart-

ment. This may cause serious burns. Always

wait until you cannot see or hear the sound of steam or coolant coming from the engine

comp

ar

tment.

● Always allow the engine to cool down be-

fore openin

g the bonnet.

● Contact with hot elements of the engine

and the exhau

st system can cause burns.

● Once the engine has cooled, follow the in-

structions

below before opening the bonnet:

– Engage the handbrake and place the gear

selector lever in N or the gear stick in

neutral.

– Remove the key from the ignition.

– Keep children away from the engine com-

partment and never leave them unsuper-

vised.

● When the engine is warm or hot, the cool-

ing sys

tem is pressurised. Do not unscrew

the cap on the expansion tank when the en-

gine is hot. Otherwise, coolant may spray out

under pressure causing burns and serious in-

jury.

– After cooling, carefully and slowly un-

screw the cap anticlockwise, gently

pressing down on it.

– Always protect your face, hands and arms

from hot coolant and steam using a large,

thick cloth.

● When refilling liquids, avoid spilling them

on part

s of the engine and the exhaust sys-

tem. Spilled liquids could cause a fire. » 187

Technical data

Advice

Operation

Emergencies

Safety

Page 226 of 232

Index

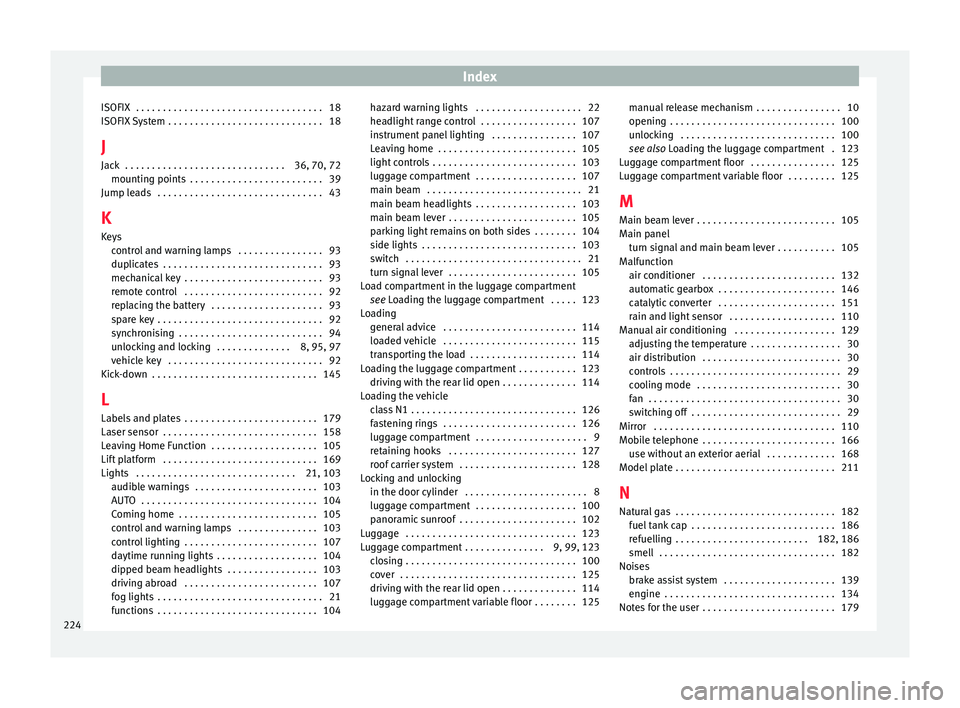

ISOFIX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

ISOFIX

S

ystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

J Jack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36, 70, 72 mounting points . . . . . . . . . . . . . . . . . . . . . . . . . 39

Jump leads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

K

Keys control and warning lamps . . . . . . . . . . . . . . . . 93

duplicates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

mechanical key . . . . . . . . . . . . . . . . . . . . . . . . . . 93

remote control . . . . . . . . . . . . . . . . . . . . . . . . . . 92

replacing the battery . . . . . . . . . . . . . . . . . . . . . 93

spare key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

synchronising . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

unlocking and locking . . . . . . . . . . . . . . 8, 95, 97

vehicle key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Kick-down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

L

Labels and plates . . . . . . . . . . . . . . . . . . . . . . . . . 179

Laser sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Leaving Home Function . . . . . . . . . . . . . . . . . . . . 105

Lift platform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21, 103 audible warnings . . . . . . . . . . . . . . . . . . . . . . . 103

AUTO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Coming home . . . . . . . . . . . . . . . . . . . . . . . . . . 105

control and warning lamps . . . . . . . . . . . . . . . 103

control lighting . . . . . . . . . . . . . . . . . . . . . . . . . 107

daytime running lights . . . . . . . . . . . . . . . . . . . 104

dipped beam headlights . . . . . . . . . . . . . . . . . 103

driving abroad . . . . . . . . . . . . . . . . . . . . . . . . . 107

fog lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104 hazard warning lights . . . . . . . . . . . . . . . . . . . . 22

headlight

range control . . . . . . . . . . . . . . . . . . 107

instrument panel lighting . . . . . . . . . . . . . . . . 107

Leaving home . . . . . . . . . . . . . . . . . . . . . . . . . . 105

light controls . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

luggage compartment . . . . . . . . . . . . . . . . . . . 107

main beam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

main beam headlights . . . . . . . . . . . . . . . . . . . 103

main beam lever . . . . . . . . . . . . . . . . . . . . . . . . 105

parking light remains on both sides . . . . . . . . 104

side lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

turn signal lever . . . . . . . . . . . . . . . . . . . . . . . . 105

Load compartment in the luggage compartment see Loading the luggage compartment . . . . . 123

Loading general advice . . . . . . . . . . . . . . . . . . . . . . . . . 114

loaded vehicle . . . . . . . . . . . . . . . . . . . . . . . . . 115

transporting the load . . . . . . . . . . . . . . . . . . . . 114

Loading the luggage compartment . . . . . . . . . . . 123 driving with the rear lid open . . . . . . . . . . . . . . 114

Loading the vehicle class N1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

fastening rings . . . . . . . . . . . . . . . . . . . . . . . . . 126

luggage compartment . . . . . . . . . . . . . . . . . . . . . 9

retaining hooks . . . . . . . . . . . . . . . . . . . . . . . . 127

roof carrier system . . . . . . . . . . . . . . . . . . . . . . 128

Locking and unlocking in the door cylinder . . . . . . . . . . . . . . . . . . . . . . . 8

luggage compartment . . . . . . . . . . . . . . . . . . . 100

panoramic sunroof . . . . . . . . . . . . . . . . . . . . . . 102

Luggage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Luggage compartment . . . . . . . . . . . . . . . 9, 99, 123 closing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

driving with the rear lid open . . . . . . . . . . . . . . 114

luggage compartment variable floor . . . . . . . . 125 manual release mechanism . . . . . . . . . . . . . . . . 10

opening . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

100

unlocking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

see also Loading the luggage compartment . 123

Luggage compartment floor . . . . . . . . . . . . . . . . 125

Luggage compartment variable floor . . . . . . . . . 125

M Main beam lever . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Main panel turn signal and main beam lever . . . . . . . . . . . 105

Malfunction air conditioner . . . . . . . . . . . . . . . . . . . . . . . . . 132

automatic gearbox . . . . . . . . . . . . . . . . . . . . . . 146

catalytic converter . . . . . . . . . . . . . . . . . . . . . . 151

rain and light sensor . . . . . . . . . . . . . . . . . . . . 110

Manual air conditioning . . . . . . . . . . . . . . . . . . . 129 adjusting the temperature . . . . . . . . . . . . . . . . . 30

air distribution . . . . . . . . . . . . . . . . . . . . . . . . . . 30

controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

cooling mode . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

switching off . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Mirror . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Mobile telephone . . . . . . . . . . . . . . . . . . . . . . . . . 166 use without an exterior aerial . . . . . . . . . . . . . 168

Model plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

N

Natural gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182 fuel tank cap . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

refuelling . . . . . . . . . . . . . . . . . . . . . . . . . 182, 186

smell . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Noises brake assist system . . . . . . . . . . . . . . . . . . . . . 139

engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Notes for the user . . . . . . . . . . . . . . . . . . . . . . . . . 179

224