spare wheel Seat Toledo 2013 Owner's manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2013, Model line: Toledo, Model: Seat Toledo 2013Pages: 258, PDF Size: 3.94 MB

Page 6 of 258

Care of the vehicle and cleaning . . . . . . . . . . . . 172

Care of the vehicle . . . . . . . . . . . . . . . . . . . . . . . . 172

Checking and refilling levels . . . . . . . . . . . . . . . 179

Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Engine compartment . . . . . . . . . . . . . . . . . . . . . . 182

Engine oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Brake fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Windscreen washer . . . . . . . . . . . . . . . . . . . . . . . . 190

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

Wheels and tyres . . . . . . . . . . . . . . . . . . . . . . . . . . 196

Wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

Accessories, modifications and spare parts . 204

General notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

Modifications and effects of the airbag system . 205

Self-help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

First-aid kit and warning triangle* . . . . . . . . . . . . 206

Fire extinguisher* . . . . . . . . . . . . . . . . . . . . . . . . . 206

Vehicle tool kit* . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Changing a wheel . . . . . . . . . . . . . . . . . . . . . . . . . 207

Tyre repair kit* . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

Jump-starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

Towing the vehicle . . . . . . . . . . . . . . . . . . . . . . . . 216

Fuses and bulbs . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

Changing bulbs . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

Changing front fog light bulbs . . . . . . . . . . . . . . . 226

Changing bulbs for rear lights (in side panel) . . 227

Changing rear lights (in rear lid) . . . . . . . . . . . . . 230

Changing bulb for the number plate light . . . . . . 232

Technical specifications . . . . . . . . . . . . 233

Description of the data . . . . . . . . . . . . . . . . . . . . 233

Important information . . . . . . . . . . . . . . . . . . . . . 233

Information on fuel consumption . . . . . . . . . . . . 235 Towing a trailer . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

Wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

Checking fluid levels . . . . . . . . . . . . . . . . . . . . . . . 238

Petrol engine 1.2 55 kW (75 PS) . . . . . . . . . . . . . 239

Petrol engine 1.2 TSI 63 kW (85 PS) . . . . . . . . . . 240

Petrol engine 1.2 TSI 77 kW (105 PS) . . . . . . . . . 241

Petrol engine 1.6 77 kW (105 PS) . . . . . . . . . . . . 242

Petrol engine 1.4 90 kW (122 PS) Automatic . . . 243

Diesel Engine 1.6 CR 66 kW (90 PS) . . . . . . . . . . 244

Diesel Engine 1.6 CR 77 kW (105 PS) . . . . . . . . . 245

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

4Table of Contents

Page 145 of 258

143

Driving

● Vehicle modifications (e.g. to the engine, brakes, frame or a combina-

tion of wheels and tyres) could impair the brake assist systems

⇒ page 204, Accessories, modifications and spare parts.

● In the event of a fault in the ABS system, the ESC, ASR and EDL are

switched off automatically. A fault in the ABS is indicated by the

⇒ page 73 warning lamp.

Brakes

Wear

The rate of wear of the brake pads depends on the driving style and on the

way in which the vehicle is used. The brake pads will wear more quickly if

you use your vehicle frequently in urban traffic and short trips or drive in a

sporty style. Under these demanding conditions, visit your specialised serv-

ice, even before the scheduled service date, so that the thickness of the

brake pads can be measured.

Wet roads or road salt

If brakes are wet or frozen, or if you are driving on roads which have been

gritted with salt, braking power may set in later than normal. Dry the brakes

as soon as possible by braking repeatedly.

Corrosion

Long periods of inactivity and little use can lead to rust on the brake discs

and dirt on the brake pads. Where the brake system is subjected to light

stress or in the case of corrosion, clean the brake discs by braking fully sev-

eral times at a high speed.

Brake system fault

If you notice that the braking distance suddenly increases and the brake

pedal can be pressed down more fully, there may be a fault in the brake sys-

tem. Visit a specialised service immediately and adjust your driving style to

the extent of the damage and to limit the effect of the brakes. Low brake fluid level

Insufficient brake fluid could cause faults in the brake system. The brake flu-

id level is controlled electronically

⇒ page 70, Brake system .

Brake servo

The brake servo supplements the pressure you exert on the brake pedal.

The brake servo only works when the engine is running.

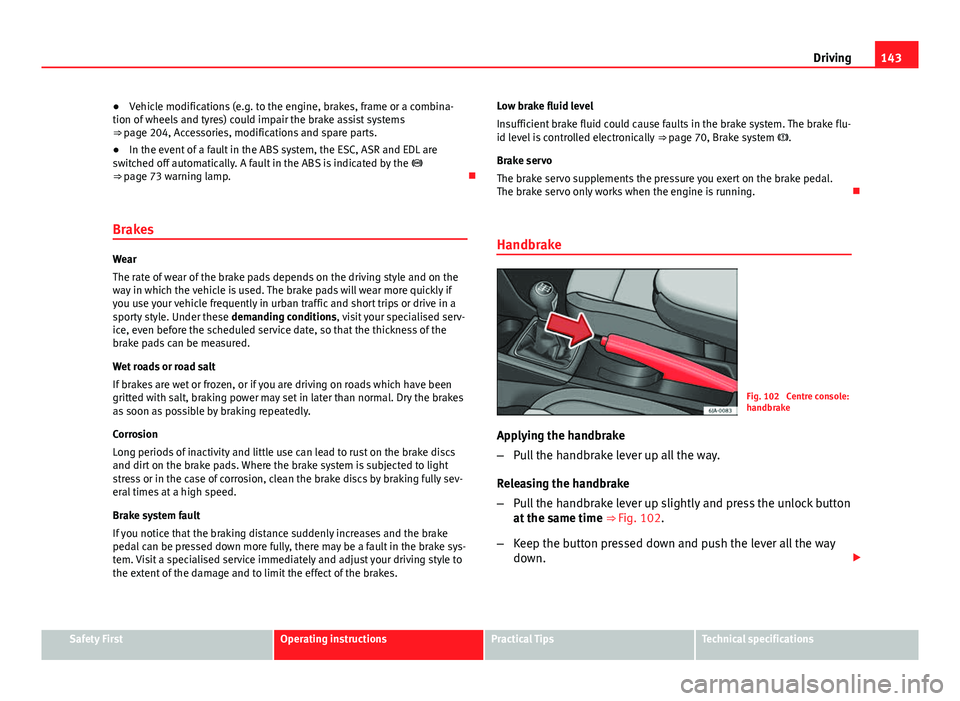

Handbrake

Fig. 102 Centre console:

handbrake

Applying the handbrake

– Pull the handbrake lever up all the way.

Releasing the handbrake

– Pull the handbrake lever up slightly and press the unlock button

at the same time ⇒ Fig. 102.

– Keep the button pressed down and push the lever all the way

down.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 163 of 258

161

Driving and the environment

Environmental friendliness

Environmental protection is a top priority in the design, choice of materials

and manufacture of your new SEAT.

Constructive measures to encourage recycling

● Joints and connections designed for easy dismantling

● Modular construction to facilitate dismantling

● Increased use of single-grade materials.

● Plastic parts and elastomers are marked in accordance with ISO 1043,

ISO 11469 and ISO 1629.

Choice of materials

● Use of recycled materials.

● Use of compatible plastics in the same part if its components are not

easily separated.

● Use of recycled materials and/or materials originating from renewable

sources.

● Reduction of volatile components, including odour, in plastic materials.

● Use of CFC-free coolants.

Ban on heavy metals, with the exceptions dictated by law (Annex II of ELV

Directive 2000/53/EC): cadmium, lead, mercury, hexavalent chromium.

Manufacturing methods

● Reduction of the quantity of thinner in the protective wax for cavities.

● Use of plastic film as protection during vehicle transport.

● Use of solvent-free adhesives.

● Use of CFC-free coolants in cooling systems.

● Recycling and energy recovery from residues (RDF).

● Improvement in the quality of waste water. ●

Use of systems for the recovery of residual heat (thermal recovery, en-

thalpy wheels, etc.).

● The use of water-soluble paints

Driving abroad General notes

It is possible that in some countries the SEAT dealer network is limited or

inexistent. Therefore it is difficult to acquire certain spare parts and the

workers at the specialised workshops can only carry out limited repair

works. SEAT will inform you about the technical requirements of your vehi-

cle, necessary maintenance work and possibilities for repair.

Unleaded petrol

Refuel only using unleaded petrol ⇒ page 157, Catalytic converter in petrol

engine vehicles. Automobile associations will provide information regarding

the network of petrol stations offering unleaded petrol.

Headlights

Your dipped beam headlights are adjusted in an asymmetrical formation.

The side of the road on which you are driving is illuminated more brightly.

If you are driving in a foreign country where traffic drives on the opposite

side of the road this will dazzle the oncoming traffic. In order to avoid daz-

zling oncoming traffic, it is essential to have the headlights adjusted at an

authorised SEAT dealer.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 166 of 258

164Driving the vehicle with a trailer

Driving the vehicle with a trailer

Driving the vehicle with a trailer

Technical requirements

If your vehicle has a factory-fitted towing bracket or is equipped with a se-

lection of SEAT Original Accessories, it meets all the relevant technical and

legal requirements.

In vehicles with a towing bracket it is possible to remove the ball joint, situ-

ated (together with the special assembly instructions) in the housing for the

spare wheel in the vehicle luggage compartment ⇒ page 207, Vehicle tool

kit*.

Your vehicle is fitted with a 13-pole power socket for the electrical connec-

tion between the trailer and the vehicle. If the trailer you are going to use

has a 7-pin connector, the corresponding adaptor, acquired from the SEAT

Original Accessories Catalogue, can be used.

If a towing bracket is to be retro-fitted to the car, it must be done according

to the instructions of the towing bracket manufacturer.

Note

Any queries that may arise can be directed to an authorised SEAT dealer.

Trailer weight

Trailer weight

The combined vehicle and trailer must be balanced. To do so use the maxi-

mum permitted towing bracket load. An insufficient weight exerted by the trailer drawbar on the ball joint of the towing bracket will have a negative

impact upon the response of the vehicle-trailer assembly on the road.

Weight distribution

Distribute loads in the trailer so that heavy objects are as near to the axle as

possible. Ensure that the objects do not move.

If the towing vehicle is empty and the trailer loaded then the load distribu-

tion is incorrect. However, if these conditions cannot be avoided, drive very

slowly.

Tyre pressure values

Correct the tyre pressure in your vehicle to “total load” ⇒

page 197, Tyre

useful life.

Trailer weight

Never exceed the authorised trailer weight under any circumstances

⇒ page 233, Description of the data.

The trailer weights listed are only applicable for altitudes up to 1000 m

above sea level. Due to a lower air density the engine power decreases de-

pending on the increase in altitude, this also causes the climbing ability to

decrease, which requires a reduction of the weight of the vehicle with a

trailer by 10 % for every 1000 m increase in altitude. The weight of the as-

sembly is calculated by adding the vehicle weight (loaded) to the trailer

weight (loaded). Always drive with special care when towing a trailer.

The towed load and support load information that is displayed on the tow-

ing bracket manufacturers label are only values for the verification of the

device. The correct figures for your specific vehicle, which are usually lower

than these figures, are given in the documentation of your vehicle.

Page 169 of 258

167

Driving the vehicle with a trailer

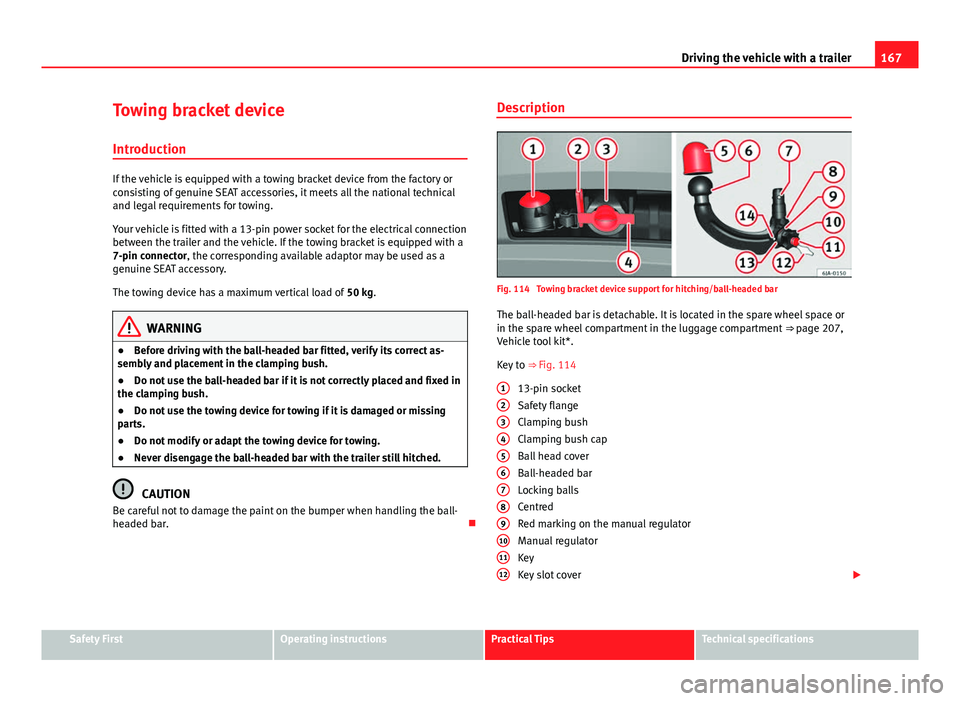

Towing bracket device Introduction

If the vehicle is equipped with a towing bracket device from the factory or

consisting of genuine SEAT accessories, it meets all the national technical

and legal requirements for towing.

Your vehicle is fitted with a 13-pin power socket for the electrical connection

between the trailer and the vehicle. If the towing bracket is equipped with a

7-pin connector, the corresponding available adaptor may be used as a

genuine SEAT accessory.

The towing device has a maximum vertical load of 50 kg.

WARNING

● Before driving with the ball-headed bar fitted, verify its correct as-

sembly and placement in the clamping bush.

● Do not use the ball-headed bar if it is not correctly placed and fixed in

the clamping bush.

● Do not use the towing device for towing if it is damaged or missing

parts.

● Do not modify or adapt the towing device for towing.

● Never disengage the ball-headed bar with the trailer still hitched.

CAUTION

Be careful not to damage the paint on the bumper when handling the ball-

headed bar. Description

Fig. 114 Towing bracket device support for hitching/ball-headed bar

The ball-headed bar is detachable. It is located in the spare wheel space or

in the spare wheel compartment in the luggage compartment ⇒ page 207,

Vehicle tool kit*.

Key to ⇒ Fig. 114

13-pin socket

Safety flange

Clamping bush

Clamping bush cap

Ball head cover

Ball-headed bar

Locking balls

Centred

Red marking on the manual regulator

Manual regulator

Key

Key slot cover

1

23456789101112

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 198 of 258

196Wheels and tyres

Wheels and tyres

Wheels

Introduction

WARNING

● During the first 500 km (300 miles), new tyres do not give maximum

grip, therefore you should drive carefully. Risk of accident!

● Never drive with damaged tyres. Risk of accident!

● Only use wheels and tyres that been authorised by SEAT or your vehi-

cle model. Failure to do so could impair road safety. Risk of accident!

● Never exceed the maximum speed permitted for your tyres. Risk of ac-

cident due to tyre damage and loss of vehicle control.

● Under-inflated tyres are submitted to greater rolling resistance. This

means that they can overheat at high speeds. This can cause tread sepa-

ration and even tyre blow-out.

● For driving safety, tyres should be replaced at least in pairs according

to the axle and not individually. The tyres with the deepest tread should

always be used on the front wheels.

● Never fit used tyres of an unknown age or prior use.

● Tyres must be immediately changed at the very latest when they have

worn down to the tread wear indicators.

● Worn tyres reduce the necessary grip at high speeds on damp surfa-

ces. This could lead to “aquaplaning” (uncontrolled vehicle movement –

“skidding” on damp surfaces).

● Damaged wheels and tyres must be replaced immediately.

WARNING (Continued)

● Do not use summer or winter tyres that are more than 6 or 4 years old

respectively.

● Wheel bolts should be clean and screw easily. However, they must

never be treated with grease or oil.

● If the tightening torque of the wheel bolts is too low, they could loos-

en while the vehicle is moving. Risk of accident! If the tightening torque

of the wheel bolts is too high, the bolts and threads could be damaged,

leading to the permanent deforming of the rim support surfaces.

● Incorrectly handled wheel bolts could lead to a wheel coming loose

while the vehicle is moving. Risk of accident!

● The national regulations on the use of snow tyres and chains should

be observed.

CAUTION

● Where a spare wheel that is not compatible with the wheels fitted is

used, follow the instructions ⇒ page 199.

● The prescribed tightening torque for wheel bolts on steel and alloy

wheels is 120 Nm.

● Protect your tyres from coming into contact with oil, grease and fuel.

● Replace any lost valve caps immediately.

For the sake of the environment

Under-inflated tyres increases fuel consumption.

Page 199 of 258

197

Wheels and tyres

Note

● We recommend having all work on tyres and wheels carried out by an

authorised SEAT dealer.

● We recommend using wheels, tyres, hub caps and snow chains from the

SEAT Original Accessories programme.

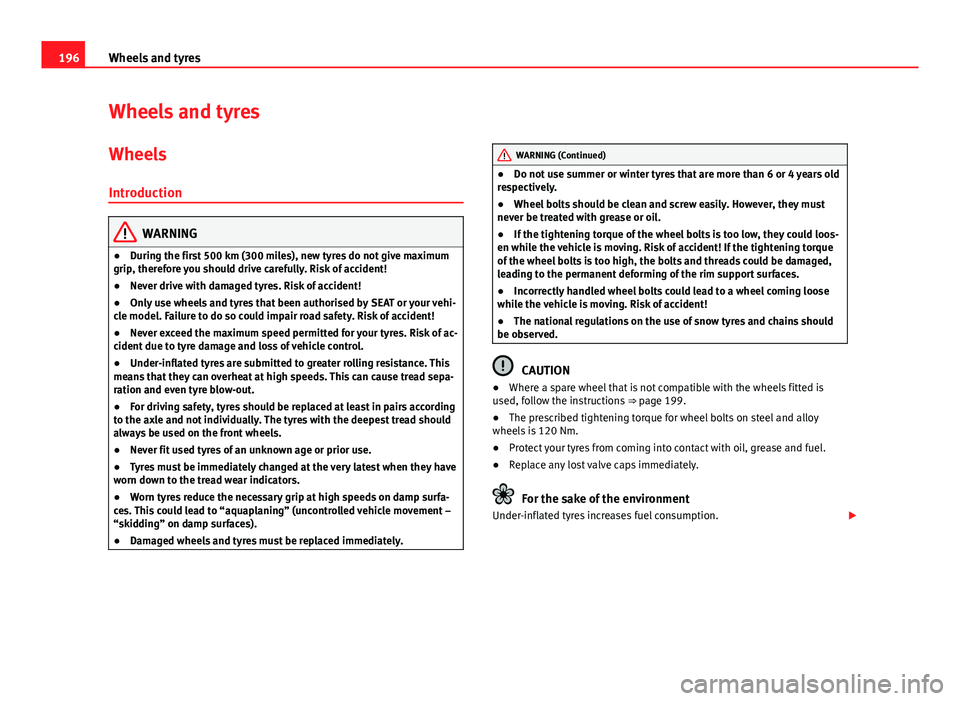

Tyre useful life

Fig. 131 Side view of

tyres with tread wear in-

dicators

Tread wear indicator

The base of the side of the original tyres on your vehicle show 1.6 mm high

tread wear indicators ⇒ Fig. 131. The position of these indicators is given

on the tyre sidewalls by the letters “TWI”, triangular symbols or other sym-

bols. The useful life of the tyres depends primarily on the following factors:

Tyre pressure values

Under-inflation or over-inflation will considerably reduce the useful life of

the tyres and impair the vehicle's handling. Therefore, check the tyre pres-

sure, including the spare wheel, at least once a month and before any long

journey.

Inflation pressures for

summer tyres are listed on a sticker inside the fuel

tank flap. The pressures for winter tyres are 0.2 bar (2.9 psi / 20 kPa) above

the summer values.

Always check the pressure when the tyre is cold. Do not reduce over-pres-

sure in warm tyres. The tyre pressures must be altered to suit notable

changes in the load being carried.

Driving style

Fast cornering, heavy acceleration and hard braking all increase tyre wear.

Wheel balancing

The wheels on new vehicles are balanced. Various factors encountered

when driving can cause them to become unbalanced, which results in vibra-

tion of the steering wheel.

The wheel must be rebalanced if a new tyre is fitted or if a tyre is repaired.

Incorrect wheel alignment

Incorrect front or rear wheel alignment causes excessive tyre wear, frequent-

ly on one side, and also impairs vehicle safety. If tyre wear is very irregular,

contact an Official Service.

Tyre damage

To avoid damage to tyres and wheels, only drive over kerbs or similar obsta-

cles slowly and at a right angle if possible.

Check tyres and wheels regularly for damage (punctures, cracks, blisters,

deformities, etc.). Remove any foreign objects embedded in outside of the

treads.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 201 of 258

199

Wheels and tyres

The manufacturing date is also indicated on the tyre sidewall (possibly only

on the inner side of the wheel). DOT … 27 12…

means, for example, that the tyre was produced in the 27th week of 2012.

Follow the instructions ⇒ page 199 if you only have a temporary spare

wheel.

Tyres with directional tread pattern

The direction of rotation is indicated by the arrows on the tyre sidewall. The

direction of rotation indicated must be respected. This guarantees optimum

grip and helps avoid excessive noise, wear and aquaplaning.

In the event of a flat tyre, a spare wheel with an undetermined tread pattern

or an opposite tread pattern must be used and you must drive carefully, as

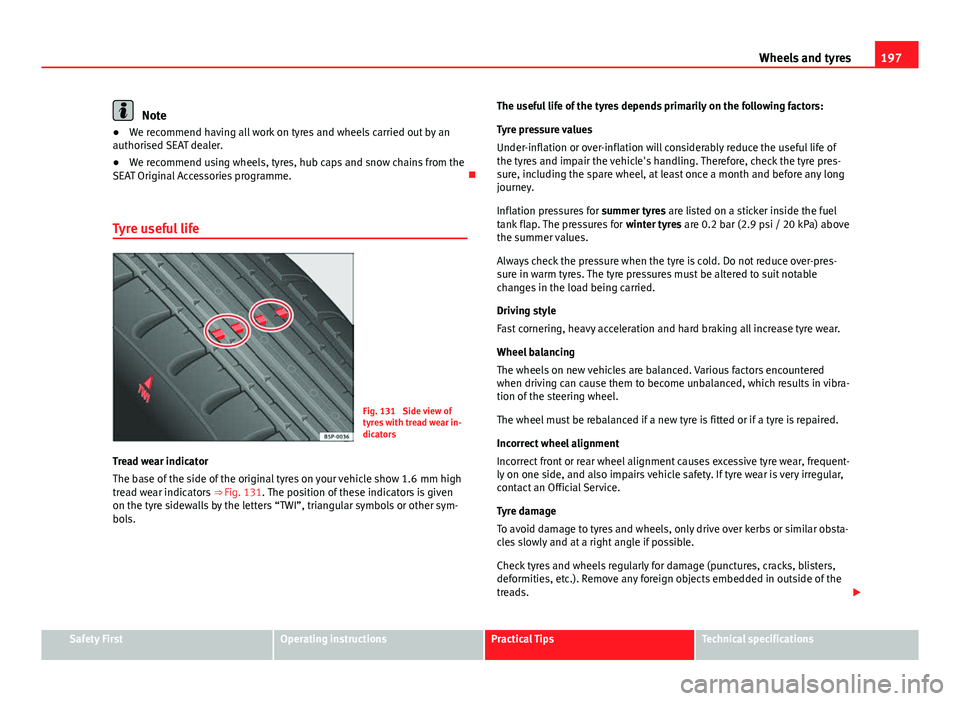

in these cases the tyres no longer offer maximum performance. Spare wheel*Fig. 133 Luggage com-

partment: spare wheel

The spare wheel is housed in a well under the floor panel in the luggage

compartment and is secured by a special bolt ⇒ Fig. 133.

Take out the tool box before removing the spare wheel.

The tyre pressure of the spare wheel must be checked (preferably whenever

the tyre pressure is checked – see sticker on fuel tank flap ⇒ page 197) to

ensure the spare wheel remains ready for use.

If the spare wheel is not the same size or design as the tyres that are moun-

ted on the car (for example if the car has winter tyres or tyres with direction

tread), only use the spare tyre for a short period of time in the event of

breakdown and drive with the corresponding care ⇒

.

It must be replaced as soon as possible for a wheel with a normal size and

finish.

Temporary spare wheel

If the vehicle is equipped with a temporary spare wheel, there will be a

warning sign on the rim of the wheel.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 202 of 258

200Wheels and tyres

Follow the instructions below when driving with this wheel fitted.

● After fitting the wheel, the warning sign must not be covered.

● Do not drive faster than 80 km/h (50 mph) with this spare wheel and

take great care during the trip. Avoid heavy acceleration, hard braking and

fast cornering.

● The tyre pressure is the same as that of the standard tyres.

● Only use this spare wheel to reach the nearest Official Service, as it is

not designed for permanent use.

WARNING

● Under no circumstances must damaged spare wheels be used.

● If the spare wheel is different in size or design to the tyres currently

fitted, never drive faster than 80 km/h (50 mph). Avoid heavy accelera-

tion, hard braking and fast cornering.

CAUTION

Follow the instructions given on the temporary spare wheel label.

Note

The tyre pressure of the spare wheel must always correspond to the highest

pressure prescribed for the model of vehicle in question.

Wheel trim

Removing

– Place the hook from the vehicle tool kit on the reinforced edge

of the wheel trim. –

Insert the box spanner through the hook, supporting it on the

tyre and remove the wheel trim.

Fitting

– First press the wheel trim onto the wheel at the cut out de-

signed for the valve. Then press the wheel trim on both sides in

the direction of the valve so that it fits correctly in place around

all the perimeter.

CAUTION

● Press down by hand, do not hit the wheel trim! Knocking it sharply, par-

ticularly at points where the wheel trim has not yet been inserted, could re-

sult in damage to the wheel trim guiding and centring elements.

● Before fitting the trim on a steel alloy wheel attached with an anti-theft

wheel bolt, make sure the bolt is in the hole in the valve area ⇒ page 211,

Anti-theft wheel bolts*.

● Where trim is fitted at a later date, ensure enough air inflow is guaran-

teed in order to cool the brake system.

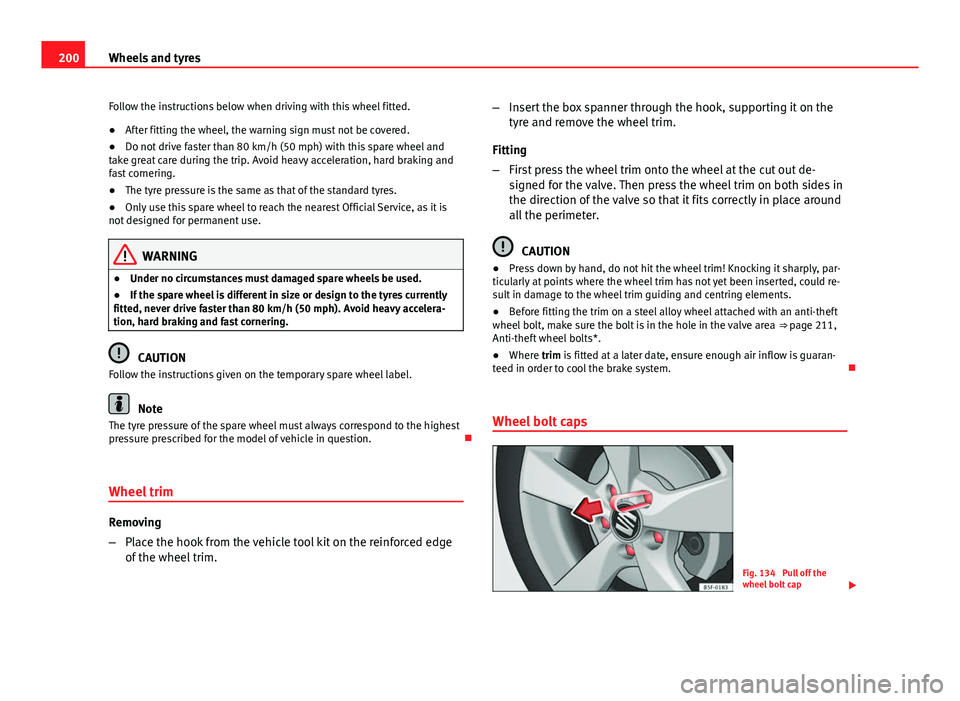

Wheel bolt caps

Fig. 134 Pull off the

wheel bolt cap

Page 203 of 258

201

Wheels and tyres

Removing

– Insert the plastic clip into the cap until the inner retaining

notches on the clips touch the collar of the cap and then re-

move ⇒ Fig. 134.

Fitting

– Insert the caps as far as they will go over the wheel bolts.

The wheel bolt caps are stored in a box on the spare wheel or in the spare

wheel well.

Tyre pressure *

Fig. 135 Tyre pressure

setting switch

The tyre pressure monitoring system uses ABS sensors to compare the revo-

lutions and the circumference of each wheel. Should the circumference of

any wheel change, the warning lamp in the general instrument panel

⇒ page 76 will light up and an audible warning will be heard.

Tyre circumference may change if:

● Tyre pressure is too low

● Tyre structure is damaged ●

Vehicle load not evenly distributed

● Wheels on one axle are subjected to greater load, (e.g. driving with trail-

er, uphill, downhill)

● Snow chains are fitted

● The temporary spare wheel is fitted

● One wheel on the axle has been changed

Basic system settings

Should the tyre pressure change or if one or more wheels are changed or

the position of the wheel on the vehicle is changed, e.g. changing round the

front and rear wheels, or where a warning lamp lights up when driving, the

system must be adjusted as follows:

● Inflate all tyres to the prescribed pressures ⇒ page 197.

● Switch the ignition on.

● Hold the

⇒ Fig. 135 button down for at least 2 seconds. The warn-

ing lamp will light up when the button is pressed. The system memory is

also deleted and a new calibration system will begin, which is indicated by

an audible warning before the warning lamp switches off .

● If the warning lamp remains lit and does not switch off, not even once

the basic setting process is complete, this indicates a fault in the system.

Contact an Official Service.

The warning lamp lights up

If the pressure on at least one tyre is significantly lower than the pressure

set by the driver, the warning lamp ⇒

will light up.

The warning lamp flashes

If the warning lamp flashes, there is a fault in the system. Contact a special-

ised service to have it fixed.

Safety FirstOperating instructionsPractical TipsTechnical specifications