change wheel Seat Toledo 2013 Owner's Guide

[x] Cancel search | Manufacturer: SEAT, Model Year: 2013, Model line: Toledo, Model: Seat Toledo 2013Pages: 258, PDF Size: 3.94 MB

Page 212 of 258

210Self-help

–Grip the box spanner as close to the end as possible and tight-

en the bolt firmly by turning clockwise.

WARNING

The wheel bolts should only be loosened slightly (about one turn) before

raising the vehicle with the jack. Risk of accident!

Note

If the wheel bolt is very tight, it may be possible to loosen it by pushing

down the end of the box spanner carefully with your foot. Hold on to the ve-

hicle for support and take care not to slip.

Raising the vehicle

Fig. 139 Changing a

wheel: Jacking points

Fig. 140 Fitting the jack

To place the jack, locate the jacking point under the door sill clos-

est to the wheel to be changed ⇒ Fig. 139. The jacking point is di-

rectly underneath the stamp on the door sill.

– Turn the crank handle on the jack to wind it up under the jack-

ing point until its claw is directly below the jacking point of the

door sill.

– Adjust the jack so that its claw surrounds the jacking point on

the door sill ⇒ Fig. 140 - B underneath the stamp on the door

sill.

– Make sure that the base of the jack is entirely supported on a

flat surface and that it is vertical ⇒ Fig. 140 to the point where

the claw surrounds the jacking point on the door sill.

– Continue to wind up the jack using the crank handle until the

defective wheel is clear off the ground.

Page 215 of 258

213

Self-help

Before using the tyre repair kit

The following jobs must be performed before using the tyre repair

kit:

– If you have a flat tyre, stop the vehicle well away from moving

traffic. Stop on flat, solid ground.

– All vehicle occupants should leave the vehicle. Vehicle occu-

pants should waiting in a safe place, e.g. behind the roadside

crash barrier) while the wheel is being changed.

– Switch off the ignition and engage neutral or move the selector

lever on the automatic gearbox to position P.

– Apply the handbrake firmly.

– Check whether the tyre can be repaired using the tyre repair kit

⇒ page 211.

– If towing a trailer, unhitch it.

– Take the tyre repair kit out of the luggage compartment.

– Fix the sticker 2

⇒ Fig. 142 ⇒

page 212 onto the dash panel

where the driver will see it.

– Do not remove the foreign body, e.g. bolts or nails, from the

tyre.

– Unscrew the tyre valve cap.

– Using the valve extractor 1

, unscrew the valve insert and place

it onto a clean surface (cloth, paper, etc.) Filling and inflating the tyre

Filling the tyre

–

Shake the tyre sealant can 10

⇒ Fig. 142 ⇒ page 212 thorough-

ly several times.

– Attach the flexible filling hose 3

onto the can 10. The foil seal-

ing the can will be automatically pierced.

– Remove the cap from the flexible filling hose 3

and insert the

open end as far as it will go into the tyre valve.

– Hold the can 10

upside down and fill the complete contents of

the can into the tyre.

– Remove the empty can from the tyre.

– Screw the valve insert back into the tyre valve using the valve

extractor 1

.

Inflating the tyre

– Screw the tyre filling hose 5

⇒ Fig. 142 ⇒ page 212 firmly onto

the tyre valve.

– Make sure that the bleed screw 7

is closed.

– Start the vehicle engine and leave it running.

– Plug the connector 9

into the 12-volt power socket.

– Turn the air compressor on with the switch 8

.

– Leave the air compressor running until the tyre pressure has

reached 2.0-2.5 bar (29-36 psi / 200-250 kPa). Max. operating

time for the compressor is 8 minutes ⇒

!

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 222 of 258

220Fuses and bulbs

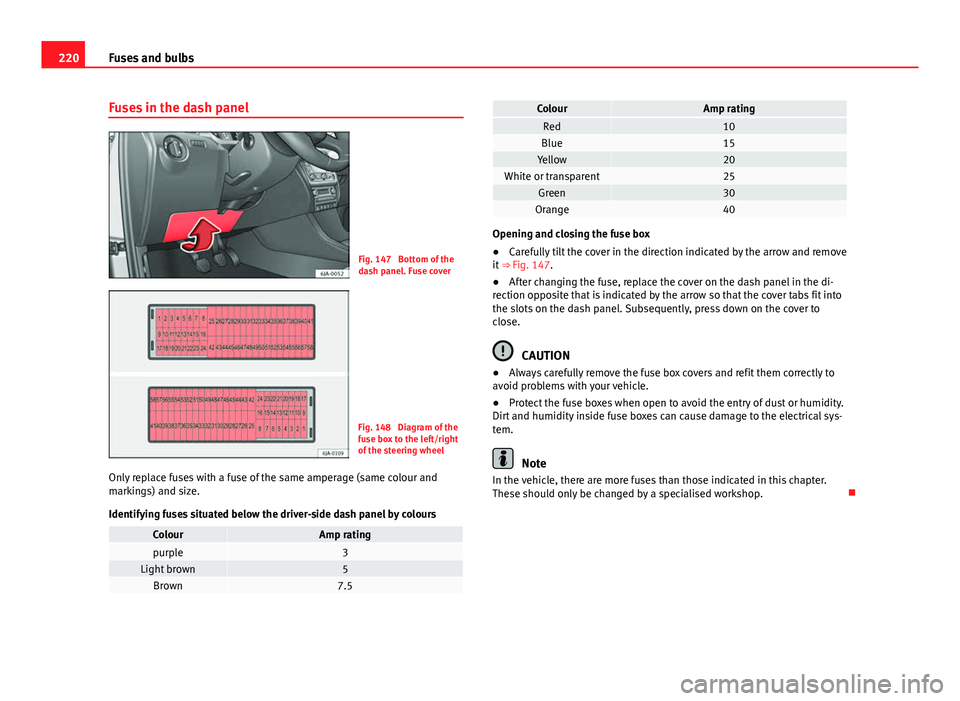

Fuses in the dash panel

Fig. 147 Bottom of the

dash panel. Fuse cover

Fig. 148 Diagram of the

fuse box to the left/right

of the steering wheel

Only replace fuses with a fuse of the same amperage (same colour and

markings) and size.

Identifying fuses situated below the driver-side dash panel by colours

ColourAmp ratingpurple3Light brown5Brown7.5

ColourAmp ratingRed10Blue15Yellow20White or transparent25Green30Orange40

Opening and closing the fuse box

● Carefully tilt the cover in the direction indicated by the arrow and remove

it ⇒ Fig. 147.

● After changing the fuse, replace the cover on the dash panel in the di-

rection opposite that is indicated by the arrow so that the cover tabs fit into

the slots on the dash panel. Subsequently, press down on the cover to

close.

CAUTION

● Always carefully remove the fuse box covers and refit them correctly to

avoid problems with your vehicle.

● Protect the fuse boxes when open to avoid the entry of dust or humidity.

Dirt and humidity inside fuse boxes can cause damage to the electrical sys-

tem.

Note

In the vehicle, there are more fuses than those indicated in this chapter.

These should only be changed by a specialised workshop.

Page 224 of 258

222Fuses and bulbs

Changing bulbs

Introduction

Changing bulbs requires a certain degree of practical skill. If in doubt, we

recommend you have defective bulbs changed by a specialised service or,

in case of an emergency, seek professional assistance.

● Switch off the ignition and all of the lights before changing a bulb.

● Do not touch the glass part of the bulb with your bare hands. The finger-

prints left on the glass will vaporise as a result of the heat generated by the

bulb, causing a reduction in bulb life and condensation on the mirror sur-

face, thus reducing effectiveness.

● A bulb must only be replaced by one of the same type. The type is indi-

cated on the bulb, either on the glass part or on the base.

● There is a storage area for the bulb box in the spare wheel well or below

the carpet in the luggage compartment.

The light source used for each function is listed below:

Double headlights

H7 Long Life

H7

W5W Long Life PY21W NA P21W Super Long Life

Dipped beam:

Main beam:

Side lights:

Turn signals:

Daytime driving lights:

WARNING

● Take particular care when working on components in the engine com-

partment if the engine is warm. Risk of burns.

● Bulbs are highly sensitive to pressure. The glass can break when you

touch the bulb, causing injury.

● The high voltage element of gas discharge bulbs* (xenon light) must

be handled correctly. Otherwise, there is a risk of death.

● When changing bulbs, please take care not to injure yourself on sharp

parts in the headlight housing.

CAUTION

● Remove the ignition key before working on the electric system. Other-

wise, a short circuit could occur.

● Switch off the lights and the parking light before changing a bulb.

For the sake of the environment

Please ask your specialist retailer how to dispose of used bulbs in the prop-

er manner.

Note

● Depending on weather conditions (cold or wet), the front lights, the fog

lights, the rear lights and the turn signals may be temporarily misted. This

has no influence on the useful life of the lighting system. By switching on

the lights, the area through which the beam of light is projected will quickly

be demisted. However, the edges may continue to be misted.

● Please check at regular intervals that all lighting (especially the exterior

lighting) on your vehicle is functioning properly. This is not only in the inter-

est of your own safety, but also in that of all other road users.

Page 238 of 258

236Description of the data

Weights

Kerb weight refers to the basic model with a fuel tank filled to 90% capacity

and without optional extras. The figure quoted includes 75 kg to allow for

the weight of the driver.

For special versions and optional equipment fittings or for the addition of

accessories, the weight of the vehicle will increase ⇒

.

WARNING

● Please note that the centre of gravity may shift when transporting

heavy objects; this may affect vehicle handling and lead to an accident.

Always adjust your speed and driving style to suit road conditions and re-

quirements.

● Never exceed the gross axle weight rating or the gross vehicle weight

rating. If the allowed axle load or the allowed total weight is exceeded,

the driving characteristics of the vehicle may change, leading to acci-

dents, injuries and damage to the vehicle.

Towing a trailer Trailer weights

Trailer weight

The trailer weights and drawbar loads approved are selected in intensive tri-

als according to precisely defined criteria. The approved trailer weights are

valid for vehicles in the UE for maximum speeds of 80 km/h (50 mph) (in

certain circumstances up to 100 km/h (62 mph)). The figures may be differ-

ent in other countries. All data in the official vehicle documentation takes

precedence over these data at all times ⇒

.Drawbar loads

The maximum permitted drawbar load on the ball joint of the towing bracket

must not exceed

75 kg.

In the interest of road safety, we recommend that you always tow approach-

ing the maximum drawbar load. The response of the trailer on the road will

be poor if the drawbar load is too small.

If the maximum permissible drawbar load cannot be met (e.g. with small,

empty and light-weight single axle trailers or tandem axle trailers with a

wheelbase of less than 1 metre), a minimum of 4% of the actual trailer

weight is legally required for the drawbar load.

WARNING

● For safety reasons, you should not drive at speeds above 80 km/h (50

mph) when towing a trailer. This also applies to countries where higher

speeds are permitted.

● Never exceed the maximum trailer weights or the drawbar load. If the

permissible axle load or the permissible total weight is exceeded, the

driving characteristics of the vehicle may change, leading to accidents,

injuries and damage to the vehicle.

Wheels

Tyre pressure, snow chains, wheel bolts

Tyre pressures

The sticker with the tyre pressure values can be found on the inside of the

fuel tank flap. The tyre pressure values given there are for cold tyres. Do not

reduce the slightly raised pressures of warm tyres ⇒

.

Page 239 of 258

237

Description of the data

Snow chains

Snow chains may be fitted only to the front wheels.

Consult the section “wheels” of this manual.

Wheel bolts

After the wheels have been changed, the tightening torque of the wheel

bolts should be checked as soon as possible with a torque wrench ⇒

.

The tightening torque for steel and alloy wheels is 120 Nm.

WARNING

● Check the tyre pressure at least once per month. Checking the tyre

pressure is very important. If the tyre pressure is too high or too low,

there is an increased danger of accidents, particularly at high speeds.

● If the tightening torque of the wheel bolts is too low, they could loos-

en while the vehicle is in motion. Risk of accident! If the tightening tor-

que is too high, the wheel bolts and threads can be damaged.

Note

We recommend that you ask your Technical Service for information about

appropriate wheel, tyre and snow chain size.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 248 of 258

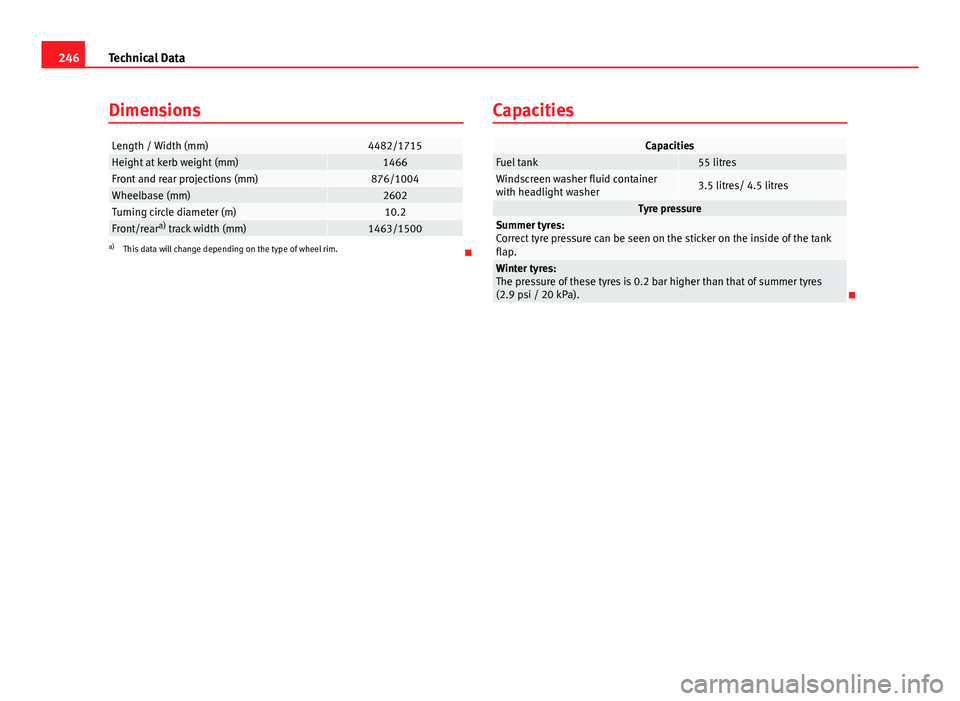

246Technical Data

Dimensions

Length / Width (mm)4482/1715Height at kerb weight (mm)1466Front and rear projections (mm)876/1004Wheelbase (mm)2602Turning circle diameter (m)10.2Front/reara)

track width (mm)1463/1500a) This data will change depending on the type of wheel rim.

Capacities

CapacitiesFuel tank 55 litresWindscreen washer fluid container

with headlight washer 3.5 litres/ 4.5 litres

Tyre pressureSummer tyres:

Correct tyre pressure can be seen on the sticker on the inside of the tank

flap.

Winter tyres:

The pressure of these tyres is 0.2 bar higher than that of summer tyres

(2.9 psi / 20 kPa).