change wheel Seat Toledo 2013 User Guide

[x] Cancel search | Manufacturer: SEAT, Model Year: 2013, Model line: Toledo, Model: Seat Toledo 2013Pages: 258, PDF Size: 3.94 MB

Page 148 of 258

146Driving

Engage reverse gear only when the vehicle is stopped. On engaging reverse

gear while the engine is running, first wait a moment with the clutch pedal

pressed down fully to limit gear shift noise.

The reverse lights switch on when the reverse gear is selected and the igni-

tion is on.

WARNING

Never engage reverse gear when moving forwards. Risk of accident!

Note

Do not rest your hand on the gear lever while driving. The pressure of your

hand could lead to premature wear of the gear system.

Automatic gearbox Introduction

WARNING

● Never press the accelerator when selecting the operating mode of the

automatic gearbox when the vehicle is stationary. Risk of accident!

● Never move the selector lever to positions R or P when driving. Risk of

accident!

● If the vehicle is to be stopped with a gear selected and the engine

idling (e.g. waiting or moving slowly at traffic lights), press down on the

brake pedal because the transmission is not entirely interrupted when

the engine is idling and the vehicle will tend to start moving.

WARNING (Continued)

● Apply the handbrake firmly and put the selector lever in position P

before opening the bonnet and working on the vehicle with the engine

running. Risk of accident! Strictly follow the safety instructions

⇒ page 182, Engine compartment.

● When stopping on a slope (hill), try not to stop the vehicle from mov-

ing by pressing the “accelerator” with a gear selected. This could over-

heat the clutch. If the clutch risks being burnt due to this force, it would

switch off and the vehicle could move backwards. Risk of accident!

● If you have to stop on a hill, press down on the brake pedal to stop

the vehicle from moving.

● The drive wheels could lose traction on a slippery road surface when

the kick-down function is activated. Risk of sliding!

CAUTION

● In DSG automatic gearboxes, the double clutch is protected from over-

loads. If the hill hold control is used, the clutches are subjected to greater

force if the vehicle is at a standstill on a slope or suddenly accelerating on a

slope.

● Should the clutches overheat, the symbol is shown on the informative

display with a warning message Gear overheated. Stop! Instruction Manual!

An audible warning is also heard. Stop the vehicle in this case, stop the en-

gine and wait until the symbol has switched off. Danger of damage to the

gearbox! You can continue driving once the symbol is switched off.

Basic information

The gearbox changes up and down automatically. The gearbox can be set to

Tiptronic mode. The gears can be changed manually in this mode

⇒ page 148.

Page 157 of 258

155

Driving

● Engine at operating temperature

● Vehicle's battery sufficiently charged

● Vehicle not on a very steep slope

● Engine speed below 1200 rpm

● Vehicle's battery temperature is neither too high nor too low

● Sufficient brake system pressure

● Difference between outside temperature and set interior temperature

not too great

● Vehicle speed since last time the engine started was above 3 km/h (2

mph)

● Particulate filter ⇒ page 74 not being cleaned

● Front wheels not overly turned (steering wheel turned less than three

quarters of a turn)

Conditions for engine start up (Start phase)

● Clutch pedal pressed

● Max./min. temperature set

● Windscreen defrost function switched on

● High blower speed

● START-STOP button pressed

Conditions for automatic engine start up without driver involvement

● Vehicle moving at a speed of over 3 km/h (2 mph)

● Difference between outside temperature and interior temperature is too

great

● Vehicle's battery insufficiently charged

● Insufficient brake system pressure

If the driver seat belt is unfastened for more than 30 seconds in Stop phase,

the engine must be started using the ignition key. Please observe the mes-

sages on the general instrument panel display. Warnings on the instrument panel display (valid for vehicles not fitted with

an informative display)

FAULT: START-STOPFault in the START-STOP systemSTART-STOP IMPOSSIBLEEngine cannot be automatically shut

down

START-STOP ACTIVEAutomatic engine shut down (Stop

phase)

SWITCH OFF IGNITIONSwitch the ignition offSTART MANUALLYStart the engine manually

WARNING

● If the engine is switched off, neither the brake servo or the power

steering will work.

● Do not move the vehicle when the engine is switched off.

CAUTION

Switch off the START-STOP system ⇒ page 162 before driving through a

pool of water on the road.

Note

● The battery temperature may reflect the changes in outside temperature

after several hours. If the vehicle has been stopped outside at temperatures

below zero or in direct sunlight, for example, the battery temperature may

take several hours to reach the values required for the correct operating of

the START-STOP system.

● If the Climatronic system is operating automatically, this could impair

automatic engine shut down in certain conditions.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 167 of 258

165

Driving the vehicle with a trailer

WARNING

● Exceeding the maximum established load per axle and the maximum

towing bracket load in addition to the maximum permitted load or the

load of the vehicle + trailer assembly can cause accidents and serious in-

juries.

● A sliding load could considerably affect the stability and safety of the

vehicle + trailer assembly, resulting in accidents and serious injuries.

Towing a trailer

Exterior mirrors

Check whether you can see enough of the road behind the trailer with the

standard rear vision mirrors. If this is not the case, you should have addi-

tional exterior mirrors fitted. Observe the relevant statutory requirements of

the country you are in.

Headlights

Before starting a journey, also check the headlight beam settings with the

trailer hitched up. Adjust the headlight range settings if necessary

⇒ page 99, Range control of main lights .

Driving speed

For your own safety do not drive faster than the maximum permitted speed

indicated on the trailer.

At all times, immediately reduce speed if you detect the slightest swaying

movement of the trailer. Never try to “return the trailer to a straight posi-

tion” by accelerating.

Brakes

Brake in due course! If the trailer has an overrun brake, apply the brakes

gently at first and then, firmly. This will prevent the jerking that can be caused by locking of trailer wheels. Change to a lower gear in good time be-

fore descending a slope in order to take advantage of the engine brake.

The trailer is incorporated into the vehicle anti-theft alarm system.

●

When the vehicle has a factory-fitted anti-theft alarm and a towing

bracket

● When the trailer is electrically connected to the vehicle via the towing

bracket socket

● When the vehicle electrical device and the towing bracket are operation-

al

● When the vehicle is locked and the vehicle anti-theft alarm device is ac-

tivated

Once the electrical connection is interrupted with the vehicle trailer locked,

the alarm sounds.

Always switch off the vehicle anti-theft alarm device before connecting or

disconnecting a trailer. The vehicle anti-theft alarm device could cause the

alarm to sound ⇒ page 91, Anti-theft alarm system*.

Engine overheating

In the event that the coolant temperature gauge needle moves to the right

section of the scale or to the red area, immediately reduce speed. If the con-

trol lamp flashes on the general instrument panel, stop the vehicle and

switch off the engine. Wait several minutes and check the coolant level in

the tank ⇒ page 188.

Please observe the following indications ⇒ page 72, Coolant level and tem-

perature .

The coolant temperature can be reduced by switching on the heating.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 180 of 258

178Care of the vehicle and cleaning

CAUTION

● Avoid exposing leather to direct sunlight for long periods so that it does

not lose its colour. If the car is left for a prolonged period outdoors, cover

the leather so that it does not lose its colour.

● Sharp-edged objects on clothing, such as zips, rivets or belts can leave

permanent scratches and rough marks on the surface of the leather.

● Use of the mechanical steering wheel lock can damage the leather sur-

face of the steering wheel.

Note

● Use a suitable impregnating cream with ultra-violet protection at regular

intervals and after cleaning. The cream will nourish and moisturise the

leather, keep it supple and able to breathe. In addition, it will also help to

protect the surface of the leather.

● Clean the leather every 2 to 3 months and remove fresh dirt as necessa-

ry.

● Preserve the colour of the leather. A special coloured cream for leather

will renew the colour of more heavily worn areas as required.

● Leather is a natural material with specific properties. During vehicle use,

parts of the leather covers may change in appearance, such as folds or wrin-

kles, as a result of their use.

Seat belts

Keep the seat belts clean!

Wash soiled seat belts with mild, soapy water, removing any heavier dirt

with a soft brush.

Check the condition of all seat belts at regular intervals.

Very soiled belts may not retract properly.

WARNING

● The seat belts should never be removed from the vehicle for cleaning.

● Never clean using chemical products, as chemical detergents destroy

the fabric. Ensure that the seat belts do not come into contact with corro-

sive fluids such as acids, etc.

● If you find any damage to the belt webbing, belt fittings, the belt re-

tractor or the buckle, the belt in question must be replaced by an Official

Service.

● Make sure that the inertia reel seat belts are completely dry before

allowing them to retract.

Page 198 of 258

196Wheels and tyres

Wheels and tyres

Wheels

Introduction

WARNING

● During the first 500 km (300 miles), new tyres do not give maximum

grip, therefore you should drive carefully. Risk of accident!

● Never drive with damaged tyres. Risk of accident!

● Only use wheels and tyres that been authorised by SEAT or your vehi-

cle model. Failure to do so could impair road safety. Risk of accident!

● Never exceed the maximum speed permitted for your tyres. Risk of ac-

cident due to tyre damage and loss of vehicle control.

● Under-inflated tyres are submitted to greater rolling resistance. This

means that they can overheat at high speeds. This can cause tread sepa-

ration and even tyre blow-out.

● For driving safety, tyres should be replaced at least in pairs according

to the axle and not individually. The tyres with the deepest tread should

always be used on the front wheels.

● Never fit used tyres of an unknown age or prior use.

● Tyres must be immediately changed at the very latest when they have

worn down to the tread wear indicators.

● Worn tyres reduce the necessary grip at high speeds on damp surfa-

ces. This could lead to “aquaplaning” (uncontrolled vehicle movement –

“skidding” on damp surfaces).

● Damaged wheels and tyres must be replaced immediately.

WARNING (Continued)

● Do not use summer or winter tyres that are more than 6 or 4 years old

respectively.

● Wheel bolts should be clean and screw easily. However, they must

never be treated with grease or oil.

● If the tightening torque of the wheel bolts is too low, they could loos-

en while the vehicle is moving. Risk of accident! If the tightening torque

of the wheel bolts is too high, the bolts and threads could be damaged,

leading to the permanent deforming of the rim support surfaces.

● Incorrectly handled wheel bolts could lead to a wheel coming loose

while the vehicle is moving. Risk of accident!

● The national regulations on the use of snow tyres and chains should

be observed.

CAUTION

● Where a spare wheel that is not compatible with the wheels fitted is

used, follow the instructions ⇒ page 199.

● The prescribed tightening torque for wheel bolts on steel and alloy

wheels is 120 Nm.

● Protect your tyres from coming into contact with oil, grease and fuel.

● Replace any lost valve caps immediately.

For the sake of the environment

Under-inflated tyres increases fuel consumption.

Page 199 of 258

197

Wheels and tyres

Note

● We recommend having all work on tyres and wheels carried out by an

authorised SEAT dealer.

● We recommend using wheels, tyres, hub caps and snow chains from the

SEAT Original Accessories programme.

Tyre useful life

Fig. 131 Side view of

tyres with tread wear in-

dicators

Tread wear indicator

The base of the side of the original tyres on your vehicle show 1.6 mm high

tread wear indicators ⇒ Fig. 131. The position of these indicators is given

on the tyre sidewalls by the letters “TWI”, triangular symbols or other sym-

bols. The useful life of the tyres depends primarily on the following factors:

Tyre pressure values

Under-inflation or over-inflation will considerably reduce the useful life of

the tyres and impair the vehicle's handling. Therefore, check the tyre pres-

sure, including the spare wheel, at least once a month and before any long

journey.

Inflation pressures for

summer tyres are listed on a sticker inside the fuel

tank flap. The pressures for winter tyres are 0.2 bar (2.9 psi / 20 kPa) above

the summer values.

Always check the pressure when the tyre is cold. Do not reduce over-pres-

sure in warm tyres. The tyre pressures must be altered to suit notable

changes in the load being carried.

Driving style

Fast cornering, heavy acceleration and hard braking all increase tyre wear.

Wheel balancing

The wheels on new vehicles are balanced. Various factors encountered

when driving can cause them to become unbalanced, which results in vibra-

tion of the steering wheel.

The wheel must be rebalanced if a new tyre is fitted or if a tyre is repaired.

Incorrect wheel alignment

Incorrect front or rear wheel alignment causes excessive tyre wear, frequent-

ly on one side, and also impairs vehicle safety. If tyre wear is very irregular,

contact an Official Service.

Tyre damage

To avoid damage to tyres and wheels, only drive over kerbs or similar obsta-

cles slowly and at a right angle if possible.

Check tyres and wheels regularly for damage (punctures, cracks, blisters,

deformities, etc.). Remove any foreign objects embedded in outside of the

treads.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 200 of 258

198Wheels and tyres

Unusual vibration or the car pulling to one side may indicate that one of the

tyres is damaged. Reduce speed immediately and stop if you suspect that

damage may have occurred! Check the tyres for damage (blisters, cracks,

etc.). If no external damage is visible, drive slowly and carefully to the near-

est Official Service and have the vehicle inspected.

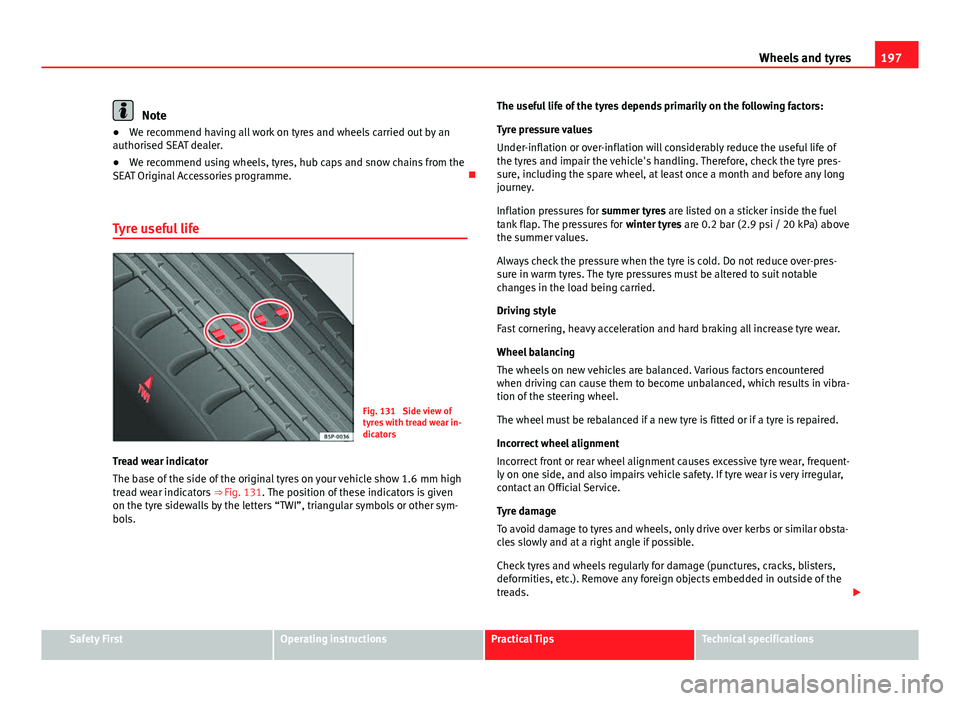

Handling wheels and tyres

Fig. 132 Changing

wheels around

Changing wheels around

If the wear is visibly greater on the front tyres, they should be exchanged for

the rear tyres as shown in the diagram ⇒ Fig. 132. All the tyres will then last

for about the same time.

To ensure that the wear is equal on all tyres and maintain their optimum

useful life, they should be changed around every 10 000 km (6000 miles).

Storing tyres

When you remove the tyres, mark them in order to maintain the same direc-

tion of rotation when they are installed again.

When removed, the wheels and/or tyres should be stored in a cool, dry and

preferably dark location. Store tyres in a vertical position if they are not fit-

ted on wheel rims. Replacing tyres and wheels

All four wheels must be fitted only with tyres of the same type, size and the

same tread pattern.

The correct tyre/wheel combinations specified for your vehicle are listed in

its registration documentation.

Understanding the tyre designations makes it easier to choose the correct

tyres. The tyre designation is marked on the sidewall. For example.

195/55 R 15 85 H

This contains the following information:

195Tyre width in mm55Height/width ratio in %RTyre construction – Radial15Rim diameter in inches85Load rating codeHSpeed rating code letter

The tyres are subject to the following maximum speed limits:

Speed rating code letterMaximum speed limitQ160 km/h (99 mph)R170 km/h (106 mph)S180 km/h (112 mph)T190 km/h (118 mph)U200 km/h (124 mph)H210 km/h (130 mph)V240 km/h (149 mph)W270 km/h (168 mph)

Page 203 of 258

201

Wheels and tyres

Removing

– Insert the plastic clip into the cap until the inner retaining

notches on the clips touch the collar of the cap and then re-

move ⇒ Fig. 134.

Fitting

– Insert the caps as far as they will go over the wheel bolts.

The wheel bolt caps are stored in a box on the spare wheel or in the spare

wheel well.

Tyre pressure *

Fig. 135 Tyre pressure

setting switch

The tyre pressure monitoring system uses ABS sensors to compare the revo-

lutions and the circumference of each wheel. Should the circumference of

any wheel change, the warning lamp in the general instrument panel

⇒ page 76 will light up and an audible warning will be heard.

Tyre circumference may change if:

● Tyre pressure is too low

● Tyre structure is damaged ●

Vehicle load not evenly distributed

● Wheels on one axle are subjected to greater load, (e.g. driving with trail-

er, uphill, downhill)

● Snow chains are fitted

● The temporary spare wheel is fitted

● One wheel on the axle has been changed

Basic system settings

Should the tyre pressure change or if one or more wheels are changed or

the position of the wheel on the vehicle is changed, e.g. changing round the

front and rear wheels, or where a warning lamp lights up when driving, the

system must be adjusted as follows:

● Inflate all tyres to the prescribed pressures ⇒ page 197.

● Switch the ignition on.

● Hold the

⇒ Fig. 135 button down for at least 2 seconds. The warn-

ing lamp will light up when the button is pressed. The system memory is

also deleted and a new calibration system will begin, which is indicated by

an audible warning before the warning lamp switches off .

● If the warning lamp remains lit and does not switch off, not even once

the basic setting process is complete, this indicates a fault in the system.

Contact an Official Service.

The warning lamp lights up

If the pressure on at least one tyre is significantly lower than the pressure

set by the driver, the warning lamp ⇒

will light up.

The warning lamp flashes

If the warning lamp flashes, there is a fault in the system. Contact a special-

ised service to have it fixed.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 209 of 258

207

Self-help

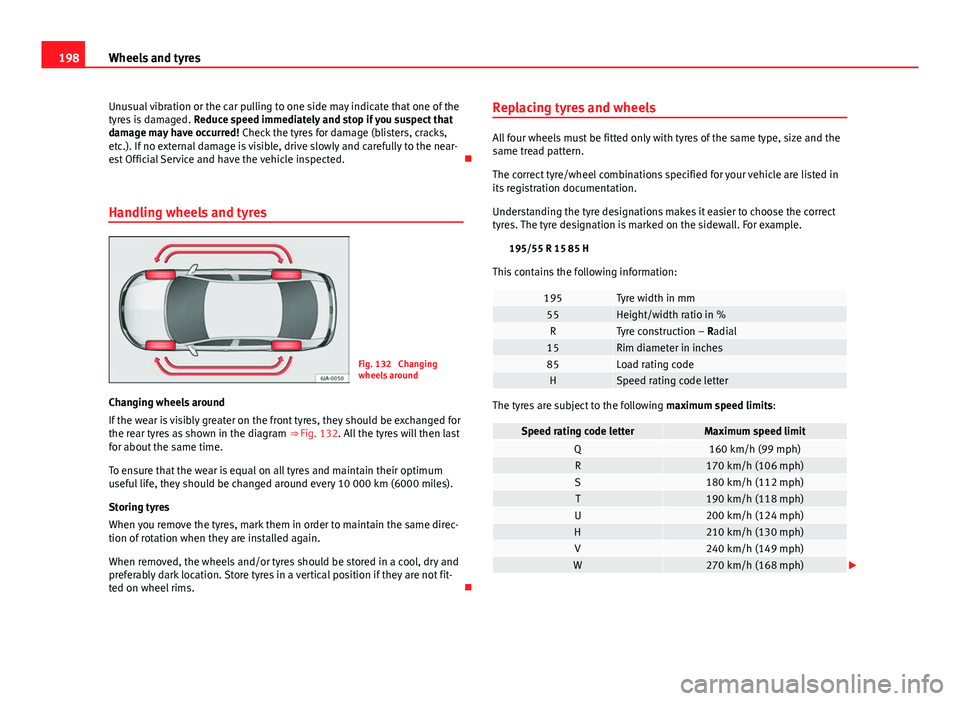

Vehicle tool kit*

Fig. 137 Vehicle tool kit

The vehicle tool kit and the jack are stored in a box on the spare wheel or in

the spare wheel well. There is also enough space for the towing bracket ball

coupling. The box is strapped to the spare wheel with tape.

The vehicle tool kit includes the following parts (depending on equipment): Screwdriver

Adapter for anti-theft wheel bolts

Towline anchorage

Wire hook for removing hub caps

Jack

Box spanner for wheel bolts

Clip for wheel bolt cover

Spare set of bulbs

Before stowing the jack again, screw down the arm as far as it will go. 1

2345678

WARNING

● The factory-supplied jack is only designed for changing wheels on

this model of vehicle. On no account attempt to use it for lighting heavier

vehicles or other loads. Risk of injury!

● Make sure that the vehicle tools are stored properly in the luggage

compartment.

Note

Make sure the box always remains strapped to the spare wheel with tape.

Changing a wheel Introduction

WARNING

● If you have a puncture in moving traffic, switch on the hazard warning

lights and place the warning triangle at the obligatory distance. Observe

the applicable local legal regulations. This is for your own safety and that

of other road users.

● If you have a flat tyre, stop the vehicle well away from moving traffic.

Choose a location that is as level and solid as possible.

● If you have to change the tyre on a gradient, block the wheel opposite

the wheel being changed by placing a stone or similar object under it to

prevent the vehicle from rolling away unexpectedly.

● If the vehicle has been fitted with tyres or alloys that are different to

those fitted in manufacture, the instructions ⇒ page 198, Replacing tyres

and wheels must be followed.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 210 of 258

208Self-help

WARNING (Continued)

● Always raise the vehicle with the doors closed.

● Never place parts of your body, e.g. arms and legs, underneath the

vehicle when supported only by the jack.

● Secure the base of the jack with suitable supports so that it cannot

slip. The jack could slide if the ground below it is soft and slippery and

the vehicle could slip off it. Therefore, place the jack on a firm surface or

use a large, stable base. On a slippery surface, e.g. tiles, use a non-slip

base such as a rubber mat.

● Never start the engine when the vehicle is raised. Risk of injury.

● The jack should only be used in the correct jacking points.

CAUTION

● The prescribed tightening torque for wheel bolts on steel and alloy

wheels is 120 Nm.

● If the anti-theft wheel bolt is overly tightened, this could damage the

bolt and the adapter

Note

● The set of anti-theft wheel bolts or the adapter are available from au-

thorised SEAT dealers.

● Please observe the relevant local legal regulations when changing the

wheel.

Preparation work

Some preparation is required before changing a wheel:

– If you have a flat tyre, stop the vehicle as far away as possible

from moving traffic. The surface must be horizontal.–

All vehicle occupants should leave the vehicle . Vehicle occu-

pants should waiting in a safe place, e.g. behind the roadside

crash barrier) while the wheel is being changed.

– Switch off the ignition and engage neutral or move the selector

lever on the automatic gearbox to position P.

– Apply the handbrake firmly.

– If towing a trailer, unhitch it.

– Take the vehicle tool kit ⇒ page 207 and the spare wheel

⇒ page 207 out of the luggage compartment.

Changing a wheel

If possible, change the wheel on a level surface.

– Pull off the hub cap ⇒ page 200 or the wheel bolt covers

⇒ page 200.

– First loosen the anti-theft wheel bolts and then the other wheel

bolts ⇒ page 209.

– Raise the vehicle until the wheel to be changed is no longer

touching the ground ⇒ page 210.

– Remove the wheel bolts and place them on a clean surface

(cloth, paper, etc.).

– Take off the wheel.

– Lift the spare wheel into position and tighten the wheel bolts

lightly.