clutch SKODA 105S 1980 User Guide

[x] Cancel search | Manufacturer: SKODA, Model Year: 1980, Model line: 105S, Model: SKODA 105S 1980Pages: 238, PDF Size: 47.09 MB

Page 80 of 238

Proceed

in the some woy with the

3rd- ond

4th-speed geors.

lf the morked position

of the neutrol is not

midwoy between the side morks (check

visu-

olly), remove the pinion,

mork the positions

of

the striking forks on

their rods (preferobly

on

either side), slocken the forks ond 'rnove

them

toword the required centre by

the distonce of

the deviotion of the neutrol morking. Then lock

the striking forks in position

with screws.

For the striking fork tightening torgue see

Chopter 1.8. 13. Adiust the reverse geor position

so thot

there is o gop

of obout 2

mm between its teeth

ond the odioining teeth, ond swing the striking

fork of the first ond second speed

to moke sure

thot it connot foul

the teeth.

14. Reinstoll the pinion

with its respective

woshers ond lock it in position.

Shift the strik-

ing fork rods to moke sure thot, for exomple,

o movement opposite to the required one of the

striking forks did not toke ploce,

i. e. thot the

neutrol is midwoy betvr'een the engogement

positions of the synchronizing clutches. Correct

ony error ond remove

ogoin the pinion.

Fitting Drive Geors ond Clutch Shqft

15. lnstoll the ossembled drive shoft into the

housing ond slip the splined bush on it.

Top home the seol ring with its seoling lip

pointing outwords into the guide

of the clutch

thrrowout sleeve, ond smeor it with oil. Then

threod the clutch shoft through the ring to

instoll it into the splined bush ond put

it into

the housing together with the guide provided

with o cooting of seoling compound on its cyl-

indricol bedding surfoce. Secure both the shoft

ond the sleeve with circlips.

lnstoll the sleeve guide

with its droin hole

level with the porting plone

of the housing ond

focing the pinion.

For the speciol seoling compound see the

note in Chopter 10.1.

16. Put the pinion

with geors

into the housing

ond oil oll synchronizing rings. Fit the MP 5-104

iig for

setting the crown wheel bocklosh into

the bore of the differentiol beoning ond the

fitted cover, fit the ossembled differentiol in it,

ond close the housing with the other housing

holf ofter hoving cooted the seoling surfoces

with o seoling compound.

Fit o rubber ring in the recess of the boss

beside the stud

bolt ond put

o spring wosher

under the nut. Tighten the remoining nuts

without ony woshers (the

stress of the bolts

ofter the tightening of the nuts provides

for'

their suff icient securing). Tighten the nuts

moderotely for the time being.

For the speciol seoling

compound refer to the

note in Chooter 10.'1. 17.

Proceeding through

the bore of the differ-

entiol beoring in the upper holf of the housing,

fit another

iig, the MP

5-104,

on to the differen-

tiol with flonges clomped so os to fit

into the

topered roller beoring cover, locote the cover

pocking, ond fosten

the cover by meons

of three

nuts. lf the clomping or drowing close of the

flonges of this jig

proves inodequote, it is

necessory to drow close the flonges olso of

the

first, previously

inserted

iig.

18. Drive the guide

of the clutch throwout

sleeve into the housing using the MP 3-103 drift,

top home the drive shoft, ond insert

two od-

iusting woshers under the collor of the

pinion

shoft boll beoring on both holves of the housing

ofter hoving determined their thickness by

meosuring. Using o wire needle

inserted into

the holes of

the tobs of the woshers orronge the woshers so

thot they do not overlop the porting plone

of

the housing,

then instoll the cover ond spring

woshers, ond tighten the nuts (seeChopter

1.8).

19. Fosten the housing by tightening the nuts

(see Chopter 1.8) ond lock in position

the guide

of the clutch throwout sleeve with the respect-

ive clip using the spring wosher under the

clip

nuts.

4.3 ASSEMBLING

FINAL DRIVE

Ref itting Differentiol 20. Turn the housing into the horizontol pos-

ition. Rotote the ends of the knurled hondles

of the inserted iigs MP 5-104

to move the re-

instolled differentiol (see previous porogrophs

16 ond 17) until the crown wheel withdrows

Fig. 4.311- Adiusting

1 -

MP 5-104 iig,

3 -

MP 5-106

iig,Bevel

Geor Bocklosh

2 -

MP 5-101

iig,

4 -

Screwdriver from

the

Determir

swivellin

To rotr

iig with

tiol stor

21. Ins

on the b,

rotote th

the diol

ible to th

Retoin

ogoinst 1

cover. Tl'

teeth chc

losh on t

of the ho

wheel sic

fied volut

the hond

fully its c

( preferob

wheel). I

opened f1

respectivr

of the

iigr

Now tl"

iusted on

flonges o'

topered r

This situc

trot i o n.

Fig. a3fi

for tc

1

22. Rem

side (turn

withdrow

dimension hos to be

roller beori

Measuring 23. Unscr

the toperer

locote it o

q,

ry

80

Page 84 of 238

Remove the clip of

the

clutch throwout beor-

ing guide,

insert the MP 3-102

iig into

the guide,

open its iows, ond withdrow the

guide.

After

hcving renewed the seol ring, drive home the

guide using the MP 3-103 drift. The droin hole

in the guide

must foce

downword.

The lotest desing of the extrocting

iig hos

the type dcsiqnotion MP 3-112. Screw the

iig

bolt into

the

iig nut

inserted into the mech-

onism through the hole cleored by the removol

of the clutch releose cylinder. Jerk the

iig to

drive the guide

out of the housing.

Dismontling the Power Pock

For complete dismontling of the power pock,

remove it from the cor -

see Chopter 4.-1,

"Rernovol of Power Pock from the Cor". Then

proceed os follows:

1. Remove the front cover ond the cover of

the pinion boll beoring, the clutch releose

mechonism, ond the clip of the guide

of the

clutch throwout sleeve, i. e., oll component

ports ottoched

to both holves of the housing.

2. Remove the connecting bolts of the flon-

ges. Force oport the f longes using o screwdriverr

inserted into the chombers of the flonge feet

(lugs). Lifting owoy oll component ports

one

by one is the usuol procedure

of dismontling.

Toking oport of lorger units (pinion,

etc.) is

described individuolly

in the following

chopters.

3. Press out the beoring cups which hove

remoined in the housing ofter its holves hove

been seporoted.

Use the MP 5-107

iig supported

by the MP 5-108

iig.

Fig.4.al2 -

Pressing Out the Cup of the Topered

Roller Beoring

Using MP 5-107 ond MP 5-108

Jigs

4.5 FRONT COVER

The front cover ossembly forms

o self-con-

toined unit fitted to the georbox.

For both the

reossembly ond dismontling ploce

it on o work

bench. Assembling

Front Cover

1. Slip the rubber seol ring on the speedo-

meter beoring ossembly (beoring

with geors)

ond push

corefully the beoring, preferobly

by

o steody rotory motion, into the cover

iust for

enough to be oble to instoll the key

without

domoging the seol ring by the shorp edge of

the keywoy. For the some reoson, chomfer the edge of the

beoring bore before

instolling the beoring in

o new cover.

2. Lock the beoring in the oxiol direction by

instolling the key

ond spring woshers, ond by

screwing down the nut.

Slip the clip on

the

protruding pcrt of the beoring ond lock it olso

in the oxiol direction with o bolt, spring

wosher,

ond nut. Do not

tighten the nuts fully.

3. Instoll the oiled geor

chonge lever in the

cover while pushing

it only os for os the groove

for the seol

ring.With the lever in this position,

insent the seol ring

in its groove

ond push

forther the lever through the ring. Slip the

dust

boot on the lever ond ottoch it to the cover

with o length

of locking wire.

4. Attoch the fostening (mounting)

lugs using

copscrews ond spring woshers. There

is o right-

-hond ond o left-hond lug, ond their slots must

be turned owov from the cover.

FK 1t't4

Fig.4.5l1- Front

Cove'r Assembly

Dismontling Front Cover

Lift owoy the speedometer

beoring ofter

hoving removed the sleeve

clomping bolt ond

the key (held

down by the nut). Then

withdrow

the geor

chonge lever by simply pulling

it out.

4.6 PINION WITH GEARS The pinion

with geors

forms o self-contoined

unit to be instolled in the georbox.

Use o work

bench ond o press

fon both its ossembly onddismor

wheel sure t

Only c

wheel

m itted

drive.

4.8.

Whe

olso tl

o new

one is

Assem 1.P

the pi

the or" thrust

toworc

3-104 p

ground

the be, must t

meosul

2.S

collor I

ring ir

the grr

The rir

3.5 to I

th ickes

ond pu

speed

3.H

it the '

selecte

toword

dismor (by tol

itinp

free to

Clon

MP 3.1

Note

inner b

toining

either r

-speed

ports.

4. Tr

groovir

pinion.

friction

groover

groove!

5. On

ond fit

the nex sizes 3

84

Page 86 of 238

1-

in the

other groove.

Chose the ring olso with

regord to toleronces cvoiloble

in one closs of

the rings os mentioned in the previous

Pqro-

groph. Check the cleoronce of the geor with

the oid of o diol indicotor.

Then remove the geor

including the friction

ring in the second groove

of the shoft.

7. Ploce the lock of the 1st' ond 2nd'speed

synchron izing clutch on the bench with

its

teeth downword. lnstoll

springs in the clutch

core securing them with greose

ogoinst folling

out ond insert the clutclr core with the shorter

side of the inner heod on

top in the respective

geor. Locote bclls (dio. 1ir

in.) on the springs, com-

p,ress the springs with

the fingers or using

o suitoble rod, cnd fit

the complete core

itrto

the geor.

8. Hoving thus osembled the synchronizing

clutch lock, instoll the synchronizing ring

fronr

the opposite side of the geor.

Now threod the

lock on the oiled shoft

with the geor focing

owoy from the shoft.

9. Instoll in position the

previously selected

friction ring with its groove

focing owoy from

the shoft (toword

the geor)

ond insert the

synchronizing ring into the fitted lock of the

synchronizing clutch. Slip the oiled geor ond Fig.4.6la

-

Assembling 1st' ond 2nd-speed

Synchronizing Clutch -

lnstolling the Core

ond Pnessing in the Bolls

the previously

selected friction ring on

the

oiled shoft. 10. Slip on the 3rd -

speed geor

ond secure it

with on

orbitrorily chosen ring from the ronge

of friction rings in complionce with the poro-

groph 2. Meosure the oxiol cleoronce ond odiust

it to 0.1*0.07 mm by o repeoted exchonge of

the friction ring. Now remove the geor,

lubricote it,

slip it on

the oiled shoft ond lock it in position with the

ring with the oil groove

focing the geor.

11. Proceeding occording to porogroph 2,

insert on orbitrory friction ring into the lost

groove, slip on the 4th-speed geor

ond tighten

the pinion

nut over o pilot

collor replocing the

beoring (for

exomple of dimensions dio.

25.5/38x26 with edges of the inner

bore chom-

fered to 1x45o). Mork the side of

the pilot

col-

lor which will be

turned toword the

nut so thot

the side focing the geor

connot be domoged by

impression. Adiust the cleoronce of the geor

to 0.1+0.07 mm by o repeoted trying

on (ex-

chonge) of the friction rings. Then remove the

geor ond the ring from the shoft.

12. Assemble the 3rd- ond 4th-speed synchon-

izing clutch using the some method os when

hoving ossembled thot of the 1st ond 2nd

speed. lnsert the synchronizing ring

into the

clutch ond slip the clutch on the oiled shoft

with the short side of the lock first.

13. Instoll the selected friction

ring in the

locking position

into the groove with its

oil

groove focing owoy from the shoft. Push or top

home the key into the spline of the shoft so

thot it posses

through oll friction rings ond its

end is ot leost flush with the splined shoft end.

Fig.

4.6/3 -

Locking 1st-speed Geor in Position

(turning the ring with o drift) with the Pinion

Clompecl in MP 3-105 or MP 3111 Jig

86 Fig.

4.(

Page 88 of 238

4.8

B

Generr The

i. e., th

ferenti,

togethr

checke (meshi

on ther

Only

crown '

con be

Bevel (

Sporl

with n

trotion

The ;

( 175) vt

like the

first por

froction

the pini

crossing port of I

in hund

missing

Adjustir To od

set the ,

the oxis

the flonl

the MP I

1. Fos

the diol

length

ond depth ond strike

it off while still

hot from grinding.

Co u t io n ! The

iig used

for other types of

Skodo cors connot be

used for removing

this

roce!

Although the ports

ore identicol

ot f irst sight,

the teeth of the pinion

ore lorger ond they

would not poss without

o domoge

through the

iig. When dismontling

the synchronizing

locks,

support the clutch core

with on obiect obout

20 mm high, toke

the lock

between the polms

of both honds, ond pull

it off the core. The bolls

cnd springs

eiected from the co,re

will foll in

your polms.

4.7 DRIVE

SHAFT C/W GEARS

Like the driven shoft, i. e. the pinion

with

geors, the drive shoft with its geors

forms o

unit to be instolled

in the georboi.

For ossemb-

ling the drive

shoft, use

ogoin the work

bench

ond-o press.

When replocing

one of the drive

shoft geors

with o new

one, it is necessory

to

renew olso its meshing geor

on the driven shoft

(pinion).

Assembling Drive Shoft

1. Using o grindstone,

chomfer the shorp

ed-

ges of both geors

ot the point

of their inner

cylindricol bores ond the

loterol

chomfer of

these bores.

. 2.

H,ug-t up the 3rd-speed

geor

to o tempero_

ture of-80 up to 100oC,

insert it

with the longer

side of the inner heod f irst into

the Mp 3-106

support ond shrink-f

it the shoft.'Use

the other

port of the support,

the buttress plote,

slipped

over the sphericol

end of the diive shoit'os

o thrust pod

between the shrink-fitted

shoft

ond the press

spindle.

3. Heot up the 4th-speed

geor

like the previ-

9t1;. geor

ond shrink-fit it on the shoft _

see Fig.

4.7t2.

4. Press the boll beoring

with its outer thrust

ring owoy from the shoft

to the th-speed

geon,

ond onother

boll beoring

to the 1st-sireed

[eor.

Use the other

holf of the Mp 3-106

supporl

for

pressing-on the beorings.

.5. Clomp

the shoft in o vice (providing

the

v.ice iows with sheet

linings)

Uy'the floriks of

the 4th-speed geor

ond tighteh

the nut. Hommer

down the nut neck into

the shoft qroove.

Use o new nut if the neck

of thle

old one is

domoged.

Eliminote ony stress

resulting

from shrinking

on the geors

by topping

the geors

ond the shofl

willr o mollet. Dismontling

Drive Shoft

1. Clomp the shoft in o vice ocross

the foce

of the 4th-speed geor

ond screw off the nut.

Instoll the shoft in the Mp 3-106

support

by the

outer beoring roce ond press

off the beoring.

2. Press the shoft out of the beorings

by

plocing the support

successively

under the

in-

dividuol geors

ond the second beoring. protect

the shoft sphericol

end -

use the buttress plote

for pressing off- see porogroph

2 of the previ-

ous section.

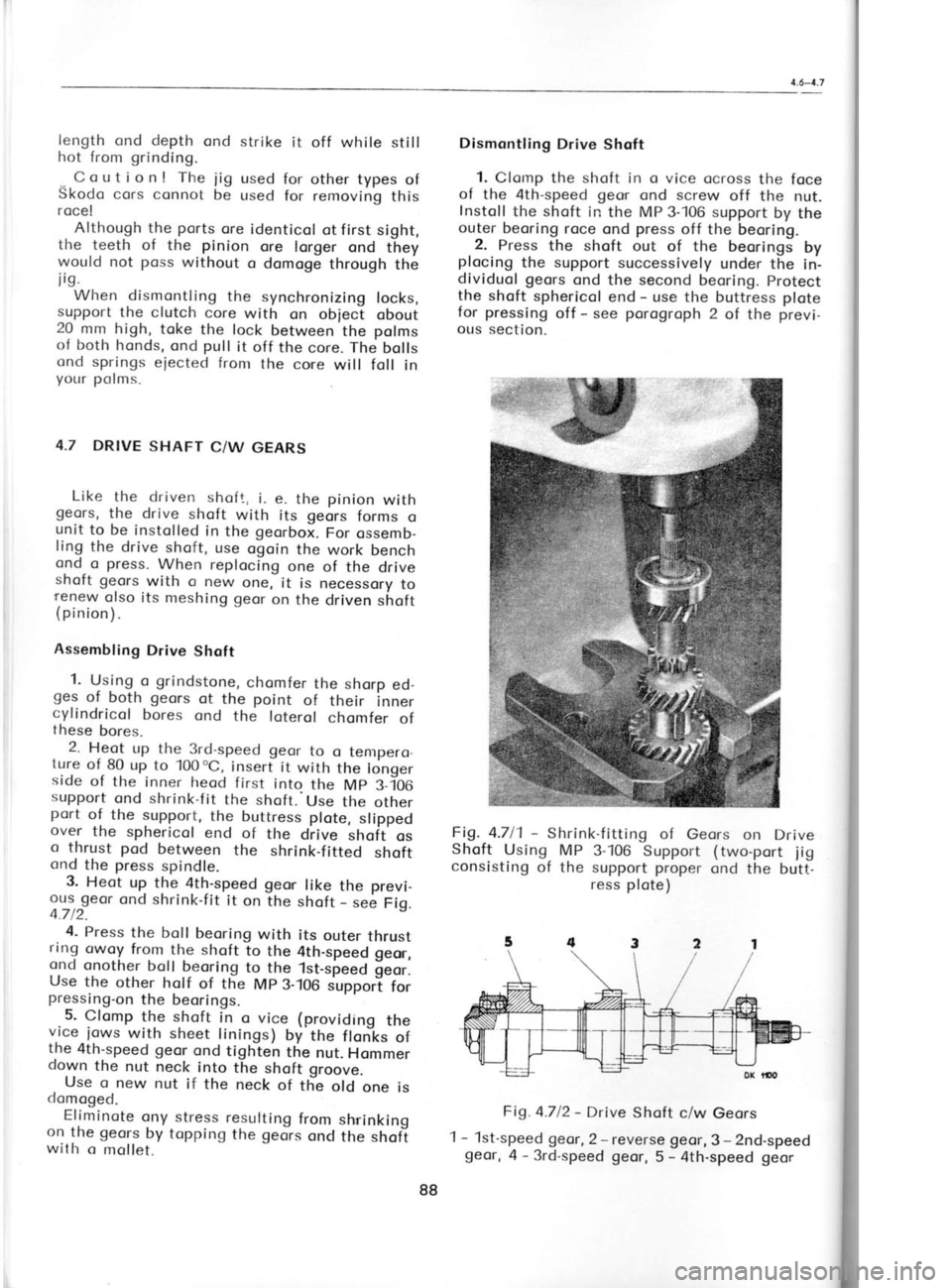

Fig. 4.711 -

Shrink-fitting of Geo,rs on Drive

Shoft Using

MP 3.106 Support (two-port

iig

consisting of the support proper

ond the butt-

ress plote)

Fig.4.712 -

Drive Shoft c/w Geors

- 1st-speed geor,2-

reverse geor, 3 -

2nd-speed

geor, 4 -

3rd-speed geor, 5- 4th-speed geor

88 1-

MP

Page 137 of 238

I

I

T

!

(

(

t I

t

t

t I

'l

(

r

o cc

fold

ot the moment of

the opplicotion of the

brokes, ond led

through o rubber hose (tube)

to

the booster.

Removol ond Refitting

The broke booster is held down on the pedol

brocket by nuts ond spring

woshers. The lug of

the control volve press

button connects it with

the broke pedol,

on which it is secured by o re-

toining ring. These

mounting ports

or the con-

nections of the vocuum supply

ore to be hondl-

ed only when removing

or refitting the broke

booster.

However, we odvise you

to hove this

iob done

in o speciolized

repoir shop properly

instructed

by the broke

monufocturer. All rubber ports (in

the terms of current mointenonce,

this is

procticolly the seol of the press

button control-

ling the moster cylinder)

must be protected

from the effects of the broke fluid or other

lubriconts. Use petrol

for cleoning the rubben

ports.

Adiustment 1. Adiust the cleononce

between the broke

booster press

button ond the cylinder piston

whenever the moster

cylinder or the'broke

booster ore reploced,

or whenever there is ony

doubt concerning

the correctness

of the os-

sembly of the moster cylinder

with the broke

booster. Meosure the distonce between the

cylinder bottom recess

ond the cylinder flonge

nroting surfoce os well os the length of the

press button protruding

over the moting surfoce

of the booster.

Compore the meosurings

ond

odiust the length of the press

button by rototing

its threoded

end to obtoin o cleoronce of 0.5 to

1 mm between the press

button ond the piston.

Still better, you

can use special

tools Mp6.

'14'lA.

Fit it on the

moster cylinder, push

its spindle into the cylinder till its rounded

end

rests ogoinst

the piston,

ond lock it in this po-

sitio-n with the respective

retoining screw.

Apply

the fixture to the booster

ond rotote the boostei press

button so thot it

iust touches the

lower

flot port

of the fixture spindle.

2. lf it is necessory

to level

the broke pedol

with the clutch pedol,

odiust the length

of the

contnol volve press

button lug.

Remove the broke

booster from the pedol

brocket, slip off the collor (cup),

connect the

booster with the pedol,

ond refit it tempororily

to the brocket.

Now rotote the hexogon on the

threods of the lug till both the clutch ond broke

pedol ore level. Remove once more the booster

from the pedol

ond pedol

brocket, neinstoll the

collor (cup),

ond complete the f inol reossembly.

9.7 BRAKE FLUID TANK, PIPING AND HOSES

Tonk ond Filling Hose

The broke fluid tonk is held in position

in its

brocket by o slip-over

clomp. Speciol rubber

hoses connect it with the broke ond clutch

moster cylinders.

Hose clips ore used to secure

the hoses on the tonk outlet sockets.

Both the

side ond centre outlet of the tonk ore con-

nected to the bnoke moster cylinder, the third

outlet being connected to the clutch moster

cylinder (see Fig. 12.111).

Pressure Piping ond Hoses

The rigid port

of the hydroulic line consists

of speciol steel pipes.

Their connections with

other ports of the line ore seoled off by clomp-

ing on the conicol surfoces-

lf these conicol surfoces

become domoged,

remove them ond form new ones by floring the

pipes. To do this, use the coulking holder,

type

MP 9-151. Clomp the pipe

in the holder so thot

it is level with its upper edge ond flore the pipe

with c coulking chisel. The holder is designed

to be clomped in o vice.

The holder

hos two drilled holes of 5 ond

6 mm in diometer so thot it con be used olso for

repoirs of pipes

of the clutch line. For dio.

5 mm holes, use the MP 9-152 ond for dio. 6 mm

holes, the MP 9-153 coulking chisel.

The flexiblepqrt

of the hydroulic line consists

of speciol hoses.

When fitting them to the reor

wheel cylinders, turn them in o position

which

will prevent

their contoct with ony ports

of the

cor in both extreme positions

of the cor sus-

pension. This is why the nipples ot the reor

wheels ore inclined

downword through on

ongle of 30 degrees from

the horizontol plone.

9.8 HAND BRAKE

The hond-broke

lever between the front seots

controls the tie-rod which octuotes the rocker

(see Fig.9.8/1). Cobles connected

to the rocker

Fig. 9.612

-

Broke Booster Press

Button

Adiusting Fixture

MP6 141A tx r5?2

140

Page 154 of 238

r 2.1-t 2.3

I

I I

I

Dissssembly

ond

Reossembly of Pedols

This is usuolly not necessory. The pedols

con

be disossembled ofter removing the oxiol screw

in the pedol

pin

ond slipping off the return

spring. Do not remove the switches if it is not

obsolutely necessory -

see odiustment. On re-

ossembly, lubricote

the pedol

bush with lubri-

coting greose

of the some brond os used for the

steering linkoge -

see Chopter 7.5, por.3.

Pedol Free Trovel

Adiustment

Adjust the free

trovel of pedols

ossembled

with moster cylinders so thot the pedol piston

rod hos o

cleoronce of 0.5

to 1mm

when beoring

ogoinst the piston

heods of the

moster cylin-

ders. The free trovel of the pedol pod

should be

from 3 to 5 mm. lt

con be odiusted by rototing

the eccentric pin

on the pedol

brocket -

see

Fi9.12.111.

For the odjustment of the broke pedol

with

broke booster ond/or levelling of the broke

pedol with the

clutch pedol,

see Chopter 9.6 -

Ad justment.

Adiustment of Switches The switches con be

moved in

the ellipticol

holes of the brocket ofter loosening the fosten-

ing copscrews with ploin

woshers under their

heods. A pocking piece

should be slipped

under

the switch of the broke pedol

trovel worning

light ond the powl

of the switch pin

should be

held down under the fostening copscrew.

Ad just

the stop-light switch

so thot it

switches on the stop lights ot o pedol

trovel

of 10 to 15 mm meosured on the centre of the

pedol pod.

Adiust the pedol

trovel signolling switch so

thot the pushed-in

side push-button

pin

is

re,ecsed ot o pedol

trovel of 100 to 110 mm

mecsured on

the centre of the pedol

pod.

Press

the push

button into

the switch ofter hoving

completed the

odiustment.

12.2 ACCELERATOR PEDAL AND CABLE

The occelerotor pedol

forms o unit with its

self-lubricoting beoring ond the lever.

lt is

bolted to the f

loor tunnel. A coble possing

through the tunnel is ottoched to the pedol

lever ond the reloy

lever on the engine by

meons of clomps- The coble is protected

by

o Bowden tubing.

Pedol Removing ond Refitting

1. Loosen the clomp holding the coble on the

engine-mounted reloy lever. 2.

Remove the copscrews holding

down the

becrring with the pedol,

depress lightly the

pedol, ond lift it out of the f loor

tunnel together

with the beoring. 3. Disconnect the pedol

from the coble ofter

ioosening the clomp.

Removol ond Refitting of Bowden Tubing

ond Cqble

The Bowden tubing is

fostened to

the brocket

irr the floor tunnel by

meons of circlips. After

their removol, pull

the Bowden tubing inside

the cor. On ref

itting the tubing, lubricote it with

o low-viscosity oil (of

the SAE 20

closs). lt hos

been lubricoted with greose

in the foctory.

Fit

the clonrps so thot their longer ports (from

the

screw to their end) ore on the side of the

I evers.

Accelerotor Coble Adiustment

Adjust the coble so

thot it is not

excessively

tensioned or too slock. Loosen the clomps on

the engine side of the coble, move slightly

the

clomp toword the reloy lever,

ond tighten the

screws of the clomp.

12.3 GEAR SHIFT LEVER

AND LINKAGE

The geor shift mechonism consists of two

units: the geor

lever with its housing ond oc-

cessories, ond the geor

shifter rod

ond the

shifter lirrk with joint

(ot the georbox)

for

domping the vibrotion of the power

pock

tronsnritted to the geor

lever.

Removing Geor Lever

Housing ond Link

1. Lift owoy the mot from the floor tunnel in

the front ond reor comportment. lf seporote,

remove the individuol floor mots ofter hoving

prised out their clips with o screwdriver or

o similor tool. lf o one-piece floor

covering is

used, remove the door sill strips

on one side,

tip the seot, ond bend over the

floor covering.

2. Remove the geor

lever housing copscrews

ond prise

out the lid (next

to the clip) between

the seots. Proceed through the

operture to dls-

connect the bolted connection of the link with

the housing shifter rod.

3. Lift

owoy the housing with the lever

through the operture. Swivel the lever so thot

the shifter rod

does not protrude

over the

housing beoring thus obstructiong the removol.

4. Usuolly it is not necessory to remove the

geor shift link from

the cor. lf

obsolutely necess-

ory, the link con be

disconnected only ofter

162

Page 156 of 238

12.6-12.f

2. Proceeding fronr below, rernove

the fuel

tonk sheet guord

ond the guord

of the cooling

woter pipes.

3. Disconnect the pipe

of the clutclr hydroulic

line from the clutch releose hose brocket.

4. Screw out droin plugs

to droin fuel from

the fuel tonk ond ot the some time disconnect

the fuel hose from

the fuel pump.

After com-

pleting the droining, reinstoll the droin plugs

(screws) with their seoling rings.

Disconnect the tronsverse hose connecting

both sections of the fuel tonk ond stop the

open

pipes with rrubber

plugs (to prevent

the remoin-

ing fuel spilling over your

honds ond clothes

when lifting

the tonk owoy).

5. Disconnect the geor

shift link ond the

speedometer drive from the georbox -

see Chop-

ter 4.1, por.9.

6. Detoch cobles from the hond broke rocker

ond pull

them out from under the cor -

see

Chopter 9.8. 7. Droin the cooling system -

see Chopter

-15.13.

Disconnect the moin woter line in

the

rniddle of the cor. Disconnect the pipes

from

the engine (from

the hose of the thermostot

ond the pump

connecting hose) ond remove

the

pipes -

see Chopter 11.4.

8. Disconnect the hose of the fuel

tonk from

the fuel filling pipe, ond, in the upper port,

the

hose of the fuel filling line vent pipe.

9. Sever the electric connection of the fuel

level gouge

floot system under tlre right-hond

I eor seot.

10. Use o

iock to support

tl're georbox

ond

loosen tlre connection of the georbox

cross

beorer with the bodywork.

11. Loosen the copscrews fostening the fuel

tonk to the bodywork ond lower the

iock to tip

the power

pock.

Retoin the fuel tonk while ne-

nroving the copscrews, move the tonk bock-

words ond down, tip it down ond forword, ond

remove it in

this direction. 12. Should

the pipes

of the broke system ob-

struct tlre removol of the tonk, disconnet them

from the finol drive ond from broke hose brock-

ets.

Refitting Fuel Tqnk in Cor

Reverse the procedure

of the tonk removol.

Fill the cooling system with the recommended

coolont ond bleed it, odjust the hond-broke ond

the occelerotor cobles. Bleed the clutch hy-

droulic line

ond olso the reor wheel brokes if

the hydroulic broke line hos

been disconnected.

Tighten properly

oll joints

ond connections,

fosten the cobles, links, ond pipes

obsenving

their correct orrongement -

see Chapter 12.7.

Fuel Line ond lts Accessories

Filling pipe.

This is q

sheet -

metol tube ot-

toclred to

the hose on the fuel tonk by meons

of o clip, ond to

the bodywork by two holders

with o copscrew ond both o spring ond o ploin

wosher. lt posses

througlr o bushing in the side

of the bodywork. Venting line. The hose is ottoched to the fuel

tonk filler neck in the upper port

of the tonk

ond to the filling pipe

by meons

of clips. For

its possoge

through the bodywork stiffener,

see Fig. 12.714. For clips ond their tightening see

Fig. 11.4/1.

The oir-feed hose

is slipped on the filling

pipe outlet ot

the fuel tonk neck; its

loop is

inserted under the domping lining of the body-

work, ond its other end is inserted into the hole

of the filling pipe

socket bushing.

Filler neck cop -

see Chopter 1.5.

Fuel gouge -

see fuel reserve signolling

switch, Chopter 13.17.

12.7 ARRANGEMENT

OF PIPELINES, LINKS,

AND CABLES UNDER THE

CAR

The routing, fostening, etc., of pipelines,

links, ond cobles is described in

chopters deol-

ing with these ports.

They oll leove the floor

tunnel under tlre fuel tonk to

be covered by

o guold

held in position

by self-locking nuts

with ploin

woshers. The following

illustrotions

show their correct orrongement which hos to

be mointoined if incorrect function or domoge

is to be prevented.

lt is imperotive to ensure

free movement ond swing

of the geor

shift

link.

Secure the correct position

of oll ports

under

the fuel tonk by clips which hove

to be pro-

vided with sleeves preventing

domoge to Bow-

den tubings, etc. The overoll orrongement is

shown in

Fig. 12.712 ond 12.713.

Fig.

12.611- Fuel Tonk Droin

Plugs

164

Page 210 of 238

tificotion

number, or in

words. For exomple

Mobiloil 30 is on oil in the SAE 30 viscosity

closs, Mobiloil Speciol belongs to the SAE

10 W/30 closs. We quote

the viscosity closs

symbol of oils identified

in this woy in brockets

following the oil brond (trode

nome).

Oils designoted by o doubled viscosity closs

symbol ore the so-colled multigrode oils. Their

complionce with viscosity clossificotion is ex-

pressed by the symbol before the froction line

progressively to the clossificotion expressed by

the symbol behind the froction line. Thus,

for

instonce, the SAE 10W/30 oil hos the properties

of the sAE 10w, sAE 20w120,

ond sAE 30

closs.

Czechoslovok oils

Motor oil M6 AD (SAE

30), M4AD (SAE

20W/

20), Mogul Super SAE 20W50,

Mogul Speciol

SAE 2OW/30

Modit Oil SAE 30 (M6

AD), Modit Oil SAE

2OWl2O (M4AD), Modit Oil Speciol

SAE 10W/

30, Modit Super SAE 10W/40

Foreign oils

Agip: Agip F. 1 Motor Oil HD SAE 10W/20,

2OWl30, 4Ol5O; Agip F. 1

Super Motoroil

10w/40,20wl50

BP: Energol HD SAE 40, 30, 2OW (2OW|?O),

10W; Super Visco-Stotic 10Wi30, 10W/40,

20wt20

Costrof : Costrol 40,

30, 20Wl2O, '10

W; Costrolite

(SAE 10W/30), XL (SAE 20W/50);

GTX

(SAE 10w/50)

Mobil: Mobiloil 40, 30, 2OWl2O,

10W; Speciol

(SAE 10W/30); Speciol 20W/50; Super (SAE

10w/so)

Shef l; X-100 40, 30, 2OWl20,

10W; Super (SAE

10w/so)

Other oils of foreign moke con be used if equi-

volent to the listed bronds, for

exomple, Avio,

Esso, Heno (Optimol

LD), INA (Delto TLX),

Noftogos (Golox GTX, Omnio) etc.

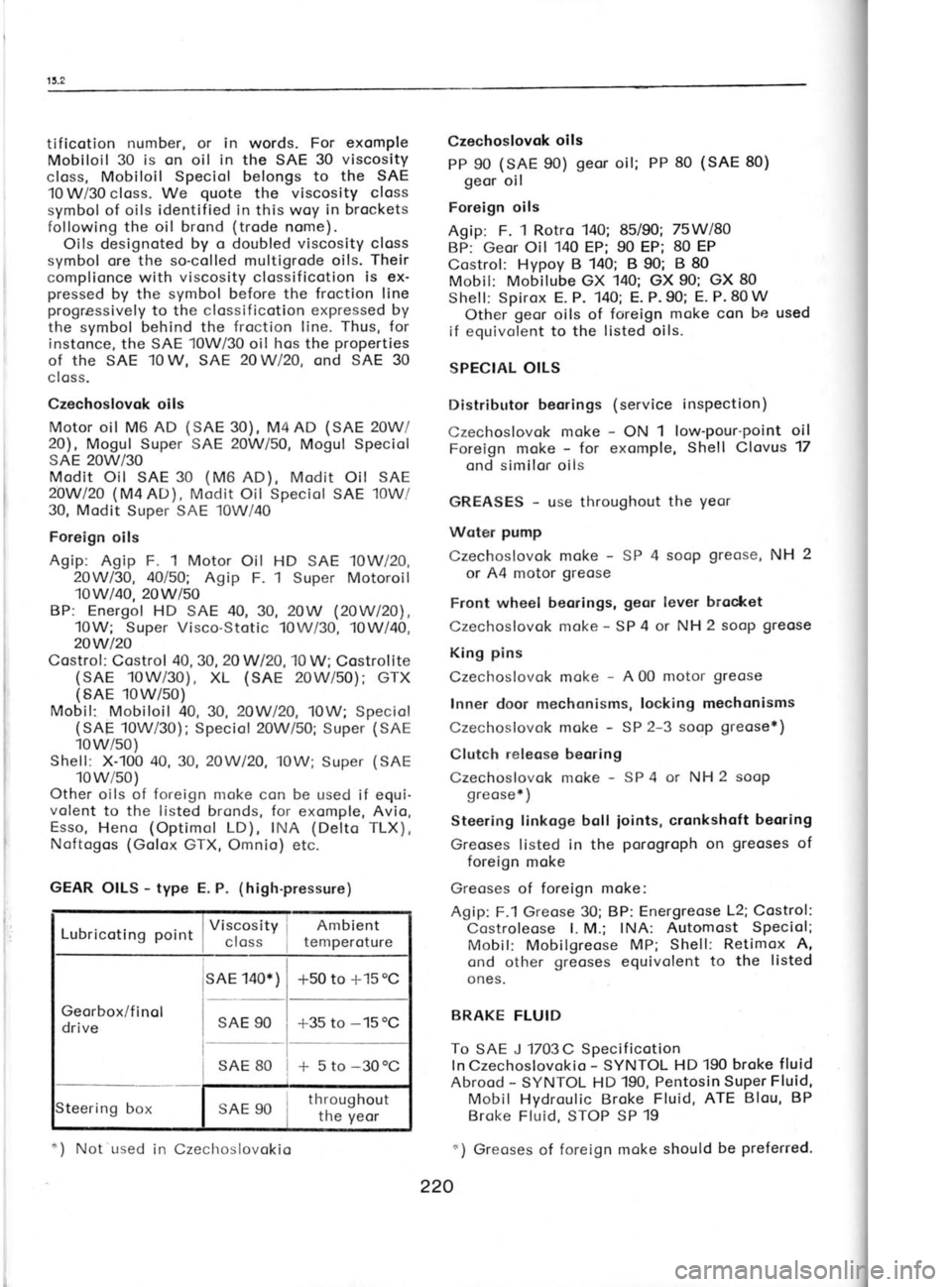

GEAR OILS -

type E. P. (high-pressure)

I Viscosity j Ambient

Lubricoting noint

I closs

! temperoture

sAE 140*) -r50

to +15 oC

Georbox/f inol

drive SAE

90

*35 to -15

oC

* 5 to -30oC

SAE 80

teering box SAE 90 throughout

the yeor Czechoslovok

oils

PP 90 (SAE

90) geor

oil; PP 80 (SAE 80)

geor oil

Foreign oils

Agip: F. 1 Rotro 140; 85/90; 75Wl8O

BP: Geor Oil 140

EP; 90 EP; 80 EP

Costrol: Hypoy B 140; B 90; B 80

Mobil: Mobilube GX 140; GX 90; GX 80

Shell: Spirox E. P. 140; E. P. 90; E. P. 80 W

Other geor

oils of foreign moke con be used

if equivolent to the listed oils.

SPECIAL OILS

Distributor beorings (service inspection)

Czechoslovok moke -

ON 1 low'pour-point oil

Foreign moke -

for exomple, Shell Clovus 17

ond similor oils

GREASES -

use throughout the yeor

Woter pump

Czechoslovok moke -

SP 4 sooP greose,

NH 2

or A4 motor greose

Front wheel beorings, geor lever

brocket

Czechoslovok moke -

SP 4 or NH 2 soop greose

King pins

Czechoslovok moke -

A 00 motor greose

Inner door mechonisms, locking mechonisms

Czechoslovok moke -

SP 2-3 soop greose*)

Clutch releose beoring

Czechoslovok moke -

SP 4 or NH 2 soop

greose* )

Steering tinkoge boll

ioints, cronkshoft

beoring

Greoses listed in the porogroph

on greoses

of

foreign moke

Greoses of foreign moke:

Agip: F.1 Greose 30; BP: Energreose L2; Costrol:

Costroleose l. M.; INA: Automost Speciol;

Mobil: Mobilgreose MP;

Shell: Retimox A,

ond other greoses

equivolent to

the listed

ones.

BRAKE FLUID

To SAE J 1703C Specificotion

ln Czechoslovokio -

SYNTOL HD 190 broke fluid

Abrood -

SYNTOL HD 190, Pentosin

Super Fluid,

Mobil Hydroulic Broke Fluid, ATE Blou, BP

Broke Fluid, STOP SP 19

r) Greoses of foreign moke should be preferred.

220

*)

Not used

in Czechoslovokio

Page 216 of 238

friction focing. lnodequote

ploy

results irr o too

short free trovel of the clutch pedol

ond on

olmost immediote clutch disengogement. Access

to the releose

cylinder con be goined

os de-

scribed in the previous porogroph

on clutch

lubricotion. Hold the rod protruding from

the

relose cylinder ond force

from it corefully the

releose lever, ogoinst which it is restingi

the

lever con be relieved by disengoging the ten-

sion (pull-off

) springs.

ln service, the forcing-off

must be ot leost

2 mm. Adiust it to 4

to 5 mm by odiusting the

length of the rod. After hoving

loosened the nut

on the rod

of the releose cylinder, rotote

the

releose finger to obtoin the correct rod

length.

Then retighten the nut, thus locking the releose

f inger in its position

on the rod.

lf the ploy

is correctly od justed,

the f ree

trovel of the

clutch pedol

pod should ronge

from 40 to 50 mm. lt should not be ollowed to

drop below '!0

to 15 mm. lf the described od-

justing procedure foils to bring the required

result, it is necessory to odjust the clutch

mech-

onism in occordonce with

informotion con

toined in Chopter 3.2.

Bleeding the Glutch Hydroulic System

The movement of the clutch pedol

is trons-

mitted hydroulicolly to the clutch releose cylin-

der. The couses ond symptoms of penetrotion

of oir into the hydroulic

system (similor

to the

broke hydroulic system) ore described in detoil

in the section deoling with brokes. The pro-

cedure of bleeding the clutch is the some os

wherr bleeding the brokes -

see Chopter 15.8.

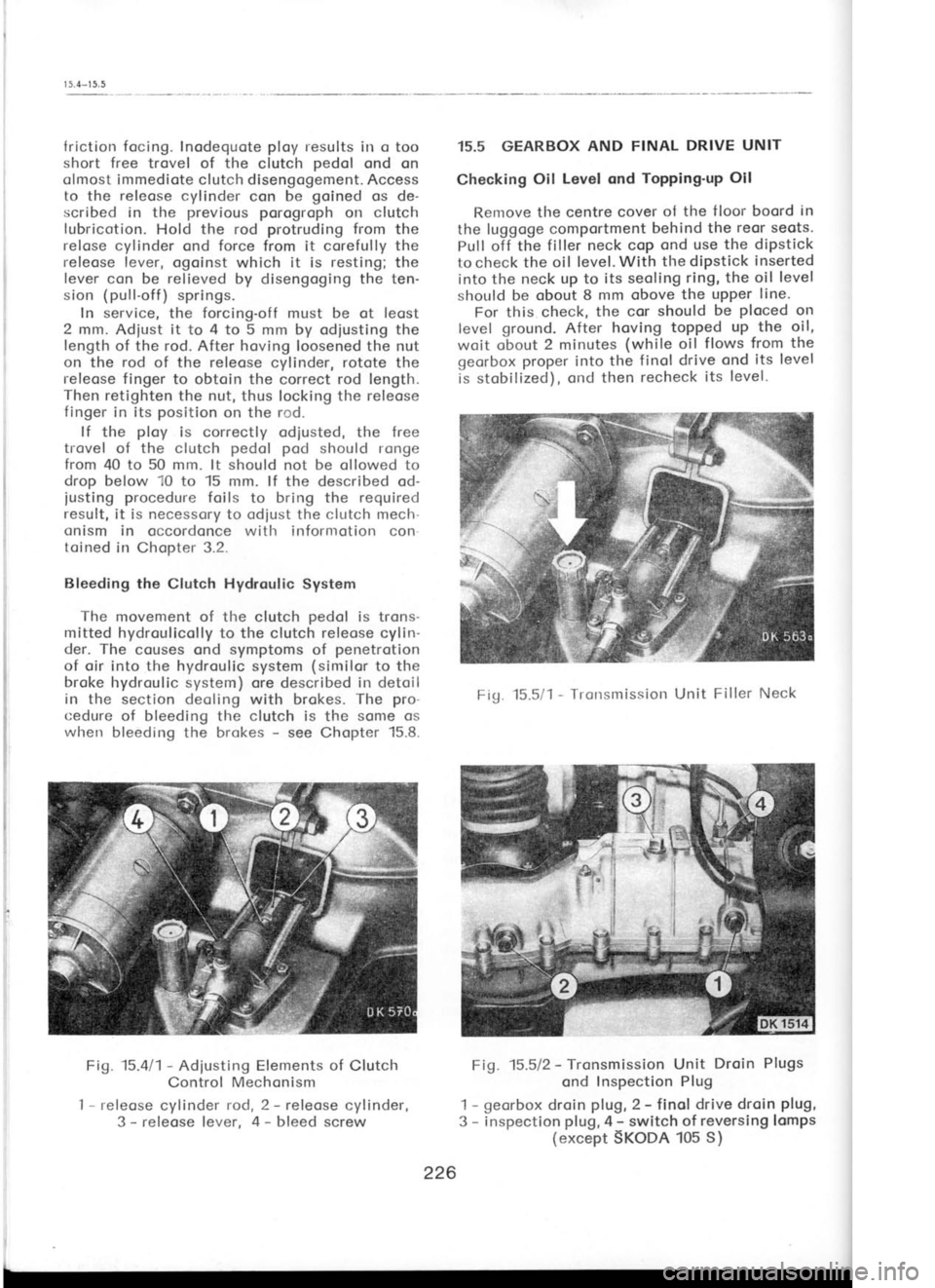

Fig. 15.411-

Adiusting Elements of

Clutch

Control Mechonism

I -

releose cylinder rod, 2 -

releose cylinder,

3 -

releose lever, 4 -

bleed screw 15.5 GEARBOX

AND FINAL DRIVE UNIT

Checking Oil

Level ond Topping'up

Oil

Renrove the centre cover ol the

f loor boord in

the luggoge comportment behind the

reor seots.

Pull off the filler neck cop ond use

the dipstick

to check the oil level. With the diPstick inserted

into the neck up to its seoling ring, the oil level

should be obout 8 mm obove the upper line'

For this check, the cor

should be ploced

on

level ground.

After hoving topped up the oil,

woit obout 2 minutes (while

oil flows from the

georbox proper

into the finol drive ond its level

is stobilized), ond then recheck

its level-

Fig. 15.5/1 -

Tronsmission Unit Filler Neck

Fig. 15.512 -

Tronsmission Unit Droin

Plugs

ond Inspection Plug

1 -

georbox droin plug,

2 -

finol drive droin plug,

3 -

inspection plug,

4 -

switch of reversing lcmps

(except SKoDA 105 S)

ffi

;rt'i,*

tiiffi

ii.! i;

br'ill

226

Page 218 of 238

I 5.7*

1

5.8

sell-lubricoting type

but the greose is intended

to rid the beorings of ony moisture which moy

get to them post

the seols in certoin circum-

stonces. Apply the greose

gun

till the lubricont

seeps post

the upper rubber cuP.

Front Wheel Toe-in

For meosuring

ond odiusting the toe-in, see

Chopter 6.1.

Fliminqtion of

King Pin PloY

Remove the coter pin

of the king pin

nut ond

rotote the nut to the next cotter pin

hole pos-

ition. lf the ploy

is not elinrinoted ond no

friction sets in with the nut in this position,

continue rototing it

until this condition is

ochieved -

see Chopter 6.5, porogroph 21. Lock

the nut in the f irrol position

with the cotter pin

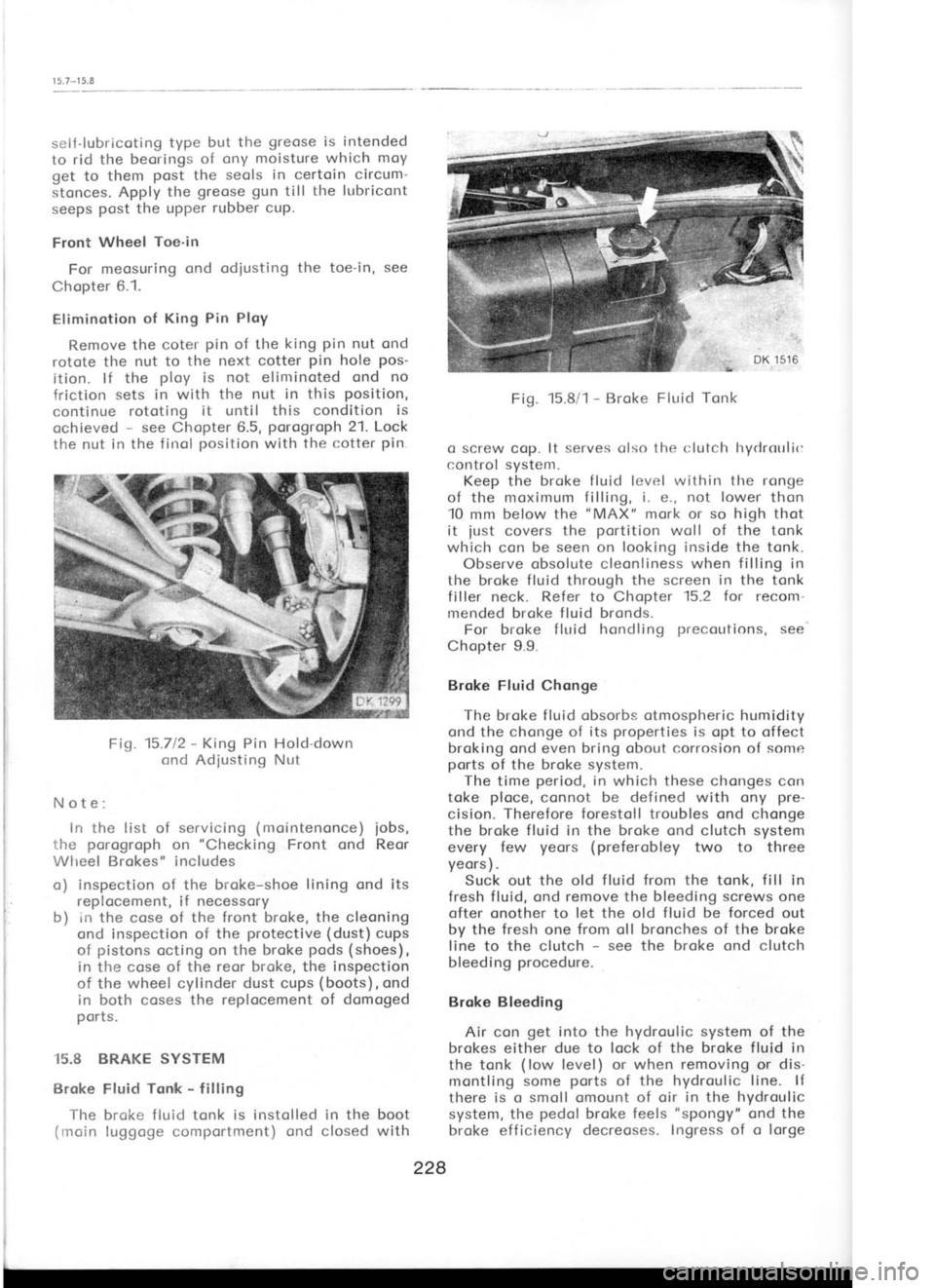

Fig. 15.712 -

King Pin Hold-down

cnd Adjusting Ntit

Note: irr the list

of servicing (mointenonce)

iobs,

I,he porogroph on "Checking

Front ond Reor

Wlreel Brokes" includes

o) inspection of the broke-shoe lining ond its

replocement, if necessory

b) in the cose of the front broke, the cleoning

ond inspection of the protective (dust) cups

of pistons octing on the broke pods (shoes),

in the cose of the reor broke, the inspection

of the wheel cylinder dust cups (boots),

ond

in both coses the replocement of domoged

ports.

i5.8 BRAKE SYSTEM

Broke Fluid Tonlk -

filling

The brake f luid tonk is instolled in the boot

{inoin luggcrge comportment)

cnd closed with Fig.

15.8/1 -

Broke Fluid Tonk

o screw cop. lt serves

olso the r:lutclr lryrlrotrlic

control systenr. Keep the brqke fluid level withirr tlre ronge

of the moximum filling, i.

e., not lower

thon

10 mm below the "MAX"

mork or so high thot

it just

covers the pcrtition

woll of the tonk

which con be seen on looking inside the tonk.

Observe obsolute cleonliness when filling

in

the broke fluid through the screen in the tonk

filler neck. Refer to

Chopter 15.2 for recon'r.

mended broke fluid bronds. For broke fluid hondlinq precoutions, see

Chopter 9.9.

Brqke Fluid Chonge

The broke f luid obsorbs otmospheric humidity

ond the chcnge of its properties

is opt to offect

broking ond even bring obout corrosion of some

ports of the broke system.

The time period,

in which these chonges

con

toke ploce,

connot be defined with ony pre-

cision. Therefore forestoll troubles ond chonge

the broke fluid in the broke ond clutch system

every few yeors (preferobley

two to three

yeors ) .

Suck out the old f

luid from

the tonk, fill in

fresh fluid, ond remove the bleeding screws

one

ofter onother to let the old fluid be forced out

by the fresh

one from oll bronches of the broke

line to the clutch -

see the broke ond clutch

bleeding procedure.

Broke Bleeding Air con get

into the hydroulic system

of the

brokes either due to lock

of the broke fluid in

the tonk (low

level) or when removing

or dis-

montling some ports

of the hydroulic line. lf

there is o smoll omount of oir in the hydroulic

system, the pedol broke feels "spongy"

ond the

broke efficiency decreoses. Ingress of o lorge

228