light SKODA 105S 1980 User Guide

[x] Cancel search | Manufacturer: SKODA, Model Year: 1980, Model line: 105S, Model: SKODA 105S 1980Pages: 238, PDF Size: 47.09 MB

Page 78 of 238

r

t

i

5. Prc

scri bed

rods onc

4th spee

fork rod,

irr the b

6. lnsl

guide bu

cover inr heods. S

tob wos

edges of

F it thr

stri ki ng

weoker s

ing forks 7. Tigl

the forks fork rod

the strik

function

Reverse-:

Fig

-1 - Rever

2-1st-o

3-3rd- o

4 -

Rever

8. Inst

press-f ittr

verse-spe

inside th

through t

Turn tl'

end foces

lock it in

hole. Tigl

Pinion Ar

9. Instc

ing ond,

r

_-_-- -

. i\:r,,,

\. 43

Fig. A.1l'l -

Power Pock

1 -

engine with mounting, 2 -

georbox/f inol

drive with

mounting, 3 -

reor oxle (holf-oxles),

4 -

rodius orms

retighten it using the recommended torque

(Chopter 1.8) ond screw down the clinch nut.

lf necessory, top up engine oil, f ill the cooling

system witlr on qntifreeze,

bleed the broke sys-

tem, ond

odiust the hond broke.

For the fosten-

ing of broke hoses (routing)

see Chopter 9.7.

4.2 ASSEMBLING

GEARBOX

Generolly, the reossembly

p'rocedure

depends

on the extent, to wlrich the unit hos been token

oport. For betterunderstonding,

we sholl des-

cribe the procedure

ond peculieorities

of reos-

sembly of o completely

disossembled unit.

Gear Chonge Mechonism

. 1.

Clomp the right-hond holf of the housing

(when viewed from the flonge securing

it to

the engine) in the MP 9-101 stond

com-

plemented with the MP 3-101 georbox

rock, ond

check the housing for completeness.

2. Instoll

circlips on the striking fork rods

of

the reverse

ond 1st ond 2nd speed. The ring

with the lower

nose is to be fitted

on the 1st--

ond 2nd-speed rods.

3. lnsert the reverse speed

striking fork rod

into the housing

so thot the inserted

end pro-

trudes slightly from its guide,

slip on it the

striking fork with the longer

side of its heod

first,- ond push

the striking fork rod through

the fork

ond the end of the guide

os for os=it

will go. 4. Fit tlre

MP 3-109 jig

into the free holes for

striking fork rods (both pins

of the

iig), ond

proceeding through the hole in its side ond

using o stick or o length of wire, push

the lock

pin into the housing

os for os it will go.

Proceed

in the some monner for

inserting the next pin

(use one pirr

of the

iig). Shift

it

iust so thot

the centre lrole remoins free for inserting

the

striking rod.

Puslr the lock pin

into the end

guide of the strikirrg

fork rods olso os for os it

will go. The

iig is not required

for

the instol-

lqtion of this pin.

Fig.4.2l1- Clomping Georbox Housing in Stond

Using MP 3-101 Rock

Fig.4.212 -

Locking Striking Fork Rods in

Position bv Meons of Lock

Pins ond Bolls

78 Fig.4.2l3

-

Instolling Lock Pins Using

MP 3-109 Jig

Page 90 of 238

^l;

eil

ell

€; \l-

I

4.9-4.

r

O

Fig. I

((

,'.ffi

l|i

3. To evoluote

the doto

obtoined from

the diol

indicotor reoding ond the

doto of the geor

set,

odopt the following procedure:

The setting distonce of the gouge -

60.00 mm

- is morked on the gouge

orm; the reoding

of

the diol indicotor

hos shown

o deviotion

of e. g.

plus 66 divisions, i. e. 0.66 millimetres (plus

meons thot the tip

of the gouge is pushed

in-

word from the set zero position

ond the in-

dicotor reoding is higher;

o reverse deviotion -

minus reoding -

connot procticolly

occur). By

subtrocting this deviotion from the meosure on

the gouge, the octuol distonce between the

pinion ground foce ond the geor

cross oxis will

be obtoined,

i. e. 60.00 mm minus 0.66 mm :

59.34 mm.

The meosure on the crown

wheel indicoting

the ossembly

distonce of the pinion

is, foi

exomple, 59.60. Accordingly,

the pinion

must be

moved slightly

out of the housing

0.26 mm, i.

e.,

by the difference

of the two

meosurings (59.60

minus 59.34:0.26 mm).

4. Prepore

odiusting

sirims 0.30 mm thick to

be inserted

under the flonge

of the pinion

beor-

ing on further

ossembly of the housing.

Shims 0.14, O.2, 0.3, ond 0.5 mm thick ore

ovoiloble. lf the required

occurote outword shift-

ing of the pinion

connot be ochieved

with shims

of ony of the specif

ied thickness, combine them

to obtoin

the next higher

volue.

Note: The thickness of shims required

for the od-

iustment of the

pinion

con be olso

colculoted

in the following

woy:

o) Set the diol indicotor

of the Mp 5-103 gouge

os in porogroph

1of the preceding

texi i.6.,

with the gouge

odiusted on the meosuring

contoct, the reoding

of the diol indicoto-r

will be 1.00 mm.

b) .Swing the

tip of the diol

indicotor

ogoinst

the pinion ground foce ond push

the

iinion

by meons

of the Mp 5-102

beorinq

retoiner

into the housing

till the diol

indicitor reods

1.00 mm. pointer

ofter pushing

the pinion

into the

housing is the meosure (thickness)

of the

shims.

4.9 DIFFERENTIAL

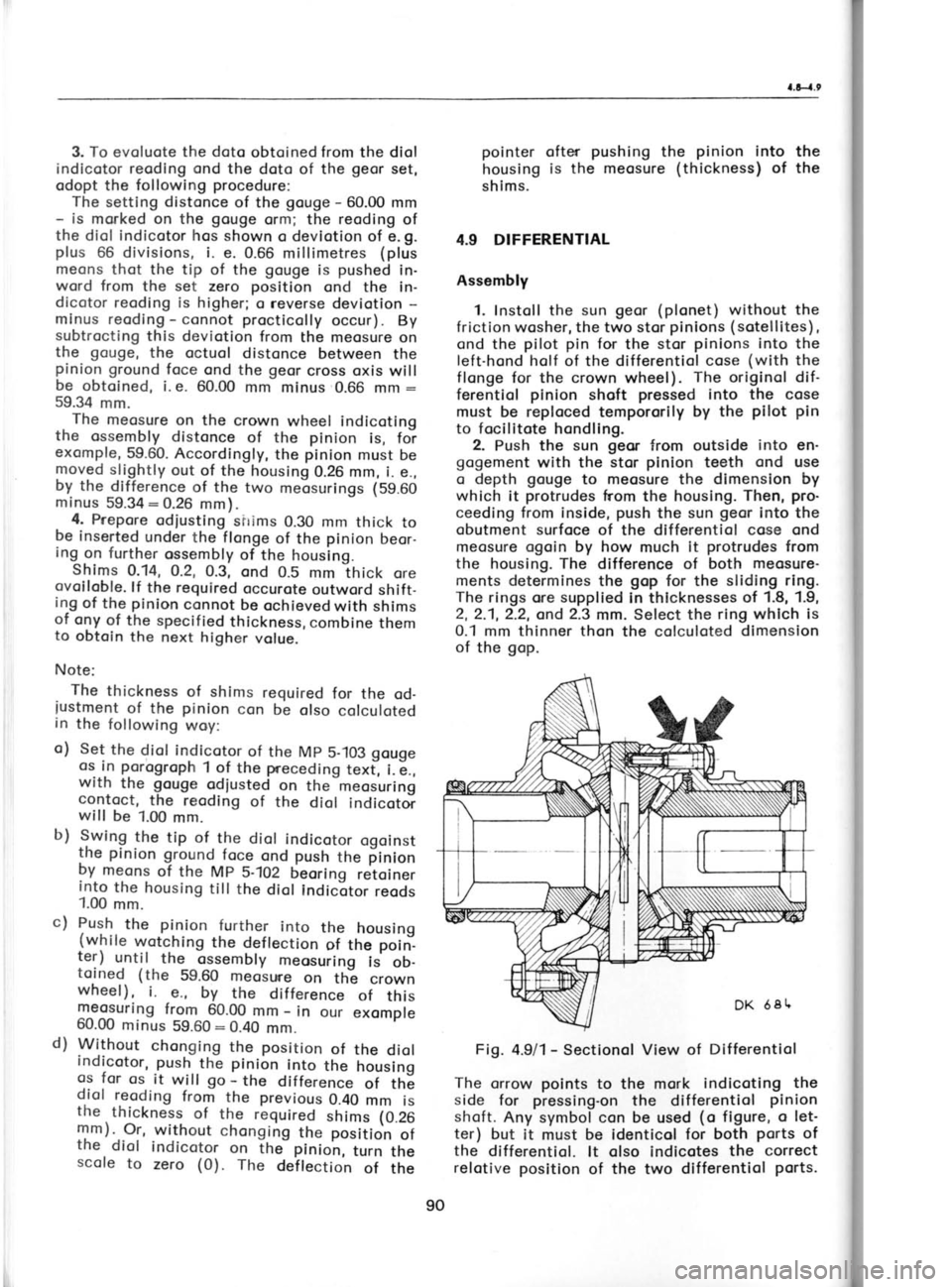

Assembly 1. Instoll the sun geor (plonet)

without the

friction wosher, the two stor pinions

(sotellites),

ond the pilot pin

for the stor pinions

into the

left-hond holf of the differentiol cose (with

the

flonge for the crown wheel). The originol

dif-

ferentiol pinion

shoft pressed into the cose

must be reploced tempororily by the pilot

pin

to focilitote hondling. 2. Push the sun geor

from outside into

en-

gogement with the stor pinion

teeth ond

use

o depth gouge

to meosure the dimension by

which it protrudes

from the housing. Then, pro-

ceeding from inside, push

the sun geor

into the

obutment surfoce of the differentiol cose ond

meosure ogoin

by how

much lt protrudes

from

the housing. The difference of both meosure-

ments determines the gop

for the sliding ring.

The rings ore supplied

in thlcknesses of 1.8,

1.9,

2, 2.1,2.2, ond 2.3

mm. Select the ring whlch is

0.1 mm thinner thon

the colculoted dimension

of the gop.

Fig. 4.9/1- Sectionol View of Differentiol

The orrow points to the mork indicoting the

side for pressing-on

the differentiol pinion

shoft. Any symbol con be used (o

figure, o let-

ter) but it must be identicol for both ports

of

the differentiol. lt olso indicotes the

correct

relotive position of the two differentiol ports.

c)

d) Push,

the pin-ion further into the housing

{while w.otching

the deflection

of the poin-.

ter) until the ossembly

meosuring

is ob-

toined (the 59.60 meosure

on th; crown

wheel) , i.

e., by the dif ference

of this

meosuring from 60.00

mm -

in our exomple

60.00 minus 59.60:0.40

mm.

Without chonging the position

of the

diol

Indicotor, push

the pinion into the housing

gs for os

it

will go -

the difference

of th6

d.iol reoding

from the previous

0.40 mm is

the thickness

of the required

shims (0.26

mm). Or, without chonging

the position

of

the diol indicotor on tfrJ pinion,

trin tf,e

scole to zero (0).

The

deilection

of the

90 Fig-

Page 95 of 238

5.

rl in

t-o o

el

st

th

w

ce

re

q

tr

t

Fig.

5.1i3 -

Forcing Slroft out of Beoring Using

MP 5-113 Jigs ond Jirrs os per

Fig. 5."1/1

The oxle shoft moy Inove out of the holf-oxle

only to such on extent thot the reor edge of the

beoring thrust ring is flush

with the holf-oxle

socket. Otherrwise it is opt to

foll out of the

epicyclic geor

ond its refitting would require

the removol

of the holf-oxle from

the georbox

housing. 4. To fit o new boll beoring proceed

occording

to Chopte'r 5.2.

Pull out ogoin

the shoft slightly

until the thrust ring con be seen, fit the beoring

I I

I of the

broke mechonism

odhering to the in-

structions of the obove-mentioned chopter,

lo'

cote the beoring

shim 0.3 mm thick, ond com'

plete the ossembly.

Note: The 3 mm shim should

be used only

when replocing the wheel hub or when elimirr-

oting on oscertoined shoft ploy,

thot is

to soy

if the shoft moves oxiolly ond

knocks. However,

it is recommended never

to use more shims

thon three.

5. A domoged seoling

ring con be removed

with o hook or o needle, ond o new one driven

or pressed-on.

The lotter olternotive should be

preferred with regord to the visuol checking of

the pressing-on operotion. The

tightening fin

ond spring of the pocking

hove to be

tunned in-

side the holf-oxle.

When driving home the seol

ring, slip the

MP 5-114 pilot toper (see

Fig.5.213) on the

shoft,

smeor it with oil, ond move the seoling

ring

olong it to drive it finolly into the holf-oxle

using tlre MP 5-116 drift os shown in Fig-

5-212.

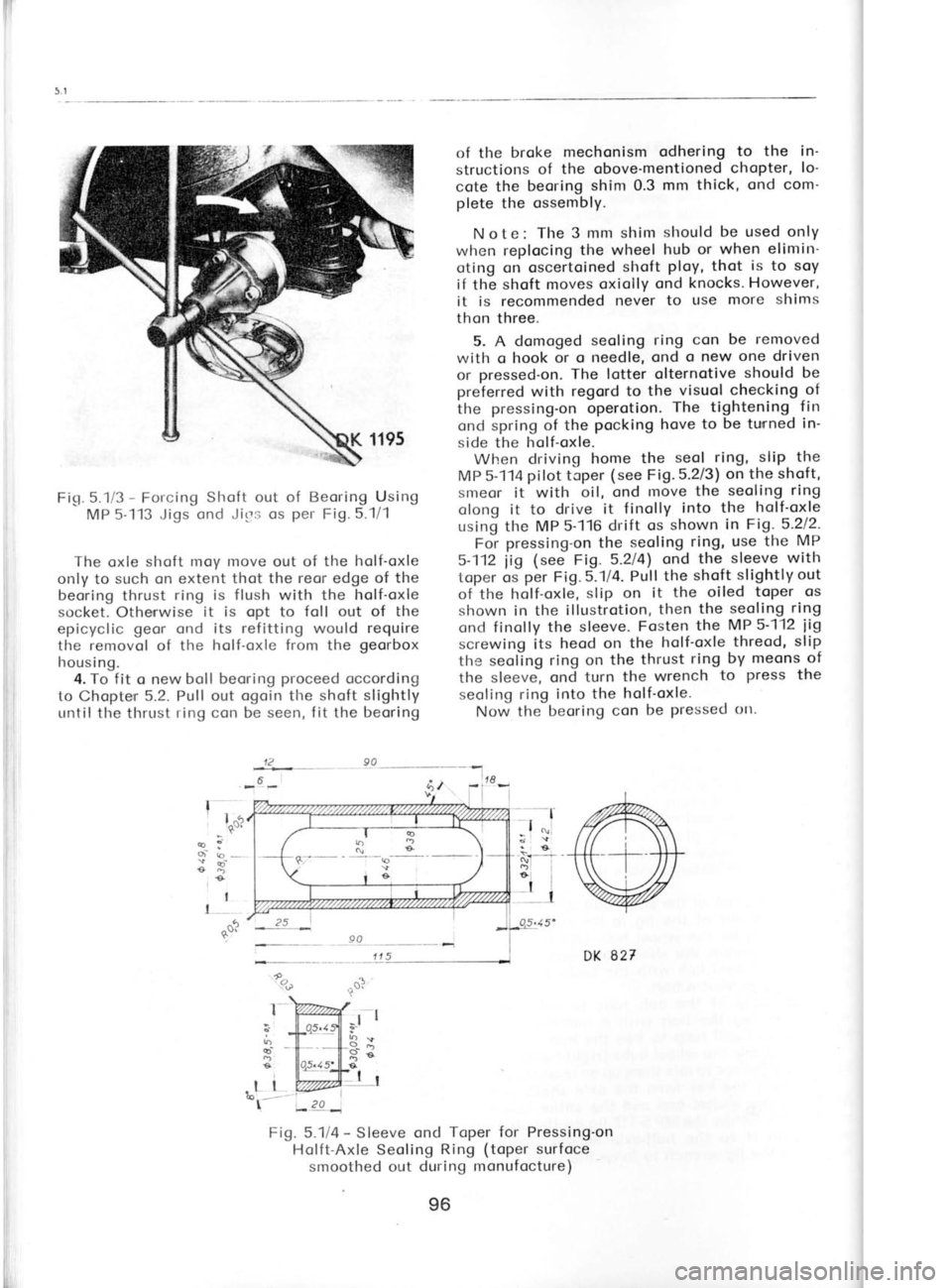

For pressing-on

the seoling ring, use the MP

5-112 iig (see

Fig. 5.214)

ond the, sleeve

with

toper os per

Fig.5.-1l4. Pull the shoft

slightly out

of'the holf-oxle, slip

on it the oiled toper os

shown in the illustrotion, then the

seoling ring

ond finolly the sleeve. Fosten the MP 5-112

iig

screwing its heod on

the holf-oxle threod, slip-

the seoling ring on

the thrust ring

by meons of

the sleeve, ond turn the wrench to

press

the

seoling ring into the holf-oxle.

Now the beoring con

be pressed ott.

l^5

oi ro --

€D

.90 DK 827

4 '%

I i5

t"'

I

-l

b

F)

g

d

e \

r

e

.l I

€['----

Fig. 5.1i4 -

Sleeve ond Toper for Pressing'on

Holft-Axle Seoling Ring (toper

surfoce

smoothed out during monufocture)

12

90

6"44 t;)

20 96

Page 97 of 238

5.:

pr

stl

bc

5-t

bo

thr

u*,

on

dit

on arI

ioi

sPl

SW

I

gor

:

wo

bol

cyl

del

\

mo

th€ hot

WO

F

clo

POS +:

nec

wol

reo

toe

wit

T

o)

b)

Alil 1.

con

sloc

seo'

int

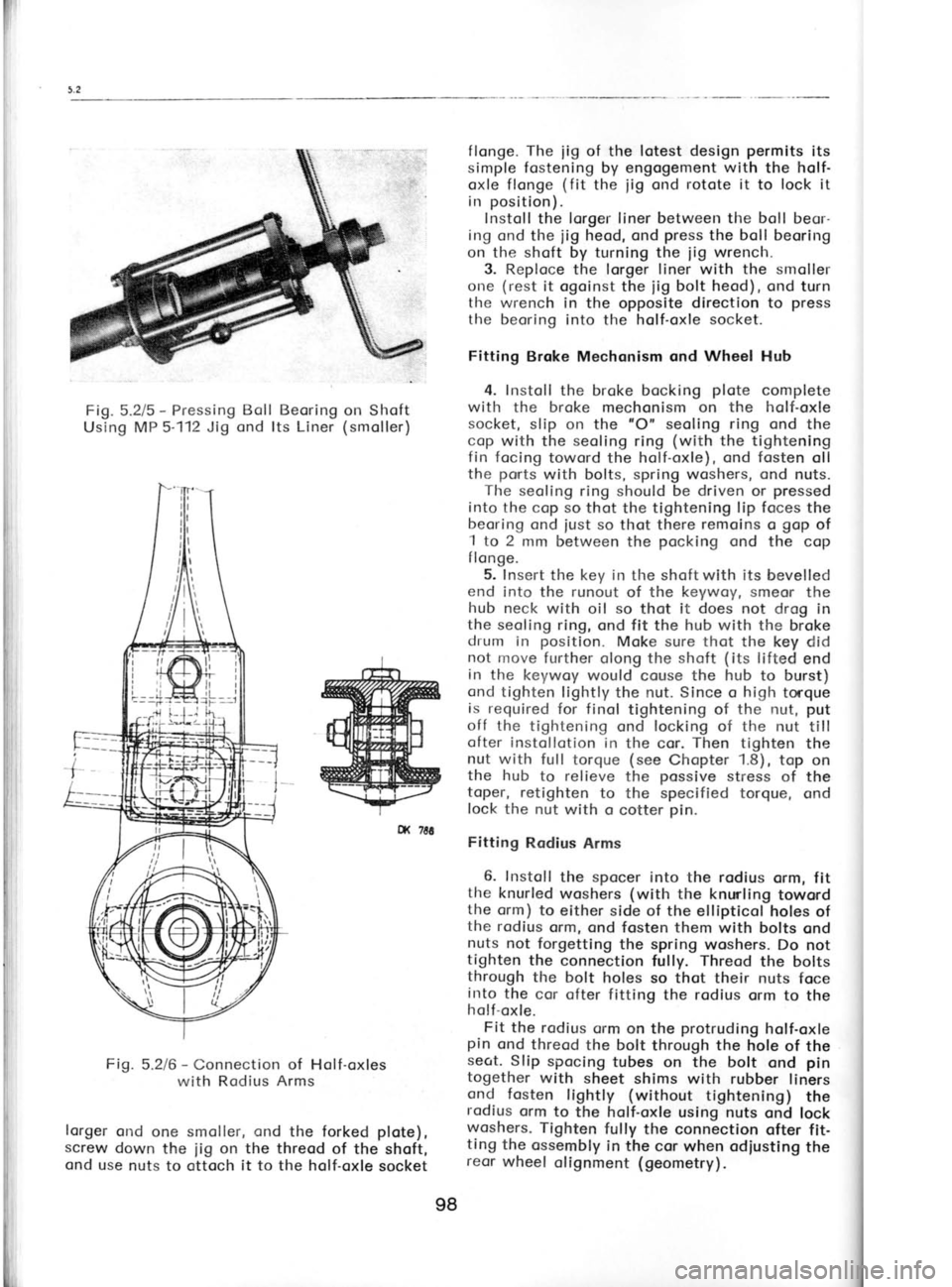

Fig.5.2l5

-

Pressing Boll Beoring

on Shoft

Using MP 5-112 Jig ond

lts Liner (smoller)

Fig.5.216 -

Connection of

Holf-oxles

with Rodius Arms

lorger ond one smoller, ond the forked plote),

screw down the

iig on the threod

of the shoft,

ond use

nuts to ottoch it

to the holf-oxle socketf

longe. The

iig of

the lotest design permits

its

simple fostening by engogement with

the holf-

oxle flonge (fit

the

iig ond

rotote

it to lock it

in position).

Instoll the lorger liner between the boll

beor-

irrg ond the

iig heod, ond

press

the boll

beorirrg

on the shoft by turning the iig wrench.

3. Reploce the lorger liner with the smoller

one (rest it ogoinst the

iig bolt heod), ond turn

the wrench in the opposite direction to press

the beoring into the holf-oxle socket.

Fitting Broke Mechonism ond Wheel Hub

4. Instoll the broke bocking plote

complete

with the broke

mechonism on the holf-oxle

socket, slip on the "O"

seoling ring ond the

cop with the seoling ring (with

the tightening

f in focing toword the holf-oxle), ond fosten

oll

the porrts

with bolts, spring woshers, ond

nuts.

The seoling ring should be driven or pressed

into the cop so thot the tightening lip foces the

beoring ond

iust so thot there

remoins

o gop

of

1 to 2 mm between the pocking

ond the cop

f longe.

5. lnsert the key in

the shoftwith its bevelled

end into the runout of the keywoy, smeor

the

hub neck with oil so

thot it does not

drog in

the seoling ring, ond fit the hub with the broke

drum in position.

Moke sure thot the key did

not move further olong the shoft (its

lifted end

in the keywoy would couse the hub to burst)

ond tighten

lightly the nut. Since o high

torque

is required

for finol tightening of the nut, put

off the tightening ond locking of the nut till

ofter instollotion in the cor. Then

tighten the

nut with full torque (see

Chopter 1.8),

top on

the hub to relieve

the possive

stress of the

toper, retighten to the specified torque, ond

lock the nut with o cotter pin.

Fitting Rodius Arms

6. Instoll

the spocer into the rodius

orm, fit

the knurled

woshers (with

the knurling toword

the orm)

to either side of the ellipticol holes of

the rodius

orm, ond fosten them with bolts ond

nuts not

forgetting the spring woshers. Do not

tighten the connection fully. Threod

the bolts

through the bolt holes so thot their nuts foce

into the cor ofter fitting the rodius orm to the

holf-oxle.

Fit the rodius

arm on the protruding

holf-oxle

pin ond threod

the bolt through the hole

of the

secrt. Slip

spocing tubes on the bolt ond pin

together with sheet shims with rubber liners

ond fosten

lightly (without tightening)

the

rodius orm to the holf-oxle using nuts

ond lock

woshers. Tighten

fully the connection

ofter fit-

ting the ossembly

in the cor when odiusting

the

reor wheel

olignment (geometry).

il

i

ii

I

I

I

I

lr

il

H, DK

?EI

98

Page 105 of 238

wi

prl

tht

rer

oul MT

ott

rec

.a

Fig

Dis S

boll

6-1C

rubl

ovo

exomple

50,000 km ond

more, check the wheel

comber ond prepore

suitoble woshers for its

correction. 2. Jock up the cor ond support the body on

both sides to relieve the front wheels, ond

remove the wheels. 3. Proceeding from

inside the luggoge boot,

remove covers protecting

the threods of the

shock-obsorber piston

rods ond screw off the

nuts. Retoin the piston

rod by holding its flot-

tened end.

b) Operotions inside the cor

4. Remove the steering wheel, the steering

column cowling, ond detoch the steering

shoft

from the body -

see Chopter 7.8.

c) Operotions from under the cor

5. Remove the bolt of the connection of the

steering shoftwith the steering box ond releose

the shoft sleeve from the connection by pull-

ing the steering geor

inside the cor.

6. Slocken the nuts of the bottom wishbone

pins fostening the front oxle to the brocket on

the body until the woshers of the brockets ore

releosed. 7. Detoch the onti-roll bor brockets from

the

body ond disconnect the rubber broke hoses

from the front broke systems.

Before discon-

necting the hose, cleon thoroughly the hose

connector ond its surroundings to prevent

foreign motter from getting

into the broke

system. For the some reoson,

wrop the

hose

ends in o cleon rog. Toke

the some precoutions

with the disconnected broke piping.

8. Ploce o roll-o-cor

iock under the oxle ond

remove the bolts (two

on either side

of the tele-

scopic shock obsorber) fostening the oxle to

the body from obove. 9. Compress the telescopic shock obsorbers,

lower the

iock, ond

move it with the oxle from

under the cor.

6.3 REFITTING FRONT AXLE IN

CAR

1. To reinstoll the oxle in

the cor, reverse the

procedure of its removol, i.

e., begin with the

porogroph 9 ond proceed

to the porogroph

1.

Coot the rubber

cup with greose

ot the point

of its contoct with the steering shoft.

2. While reconnecting the broke hoses, ob-

serve the utmost cleonliness ond bleed the front

wheel brokes if no other ports

of the broke

system hos been dismontled. (lf

such o dis-

montling hos token ploce,

bleed the brokes of

oll wheels ofter hoving fully reclosed

the broke

circuit). 3. Turn the wheels in the stroight oheod di-

rection before connecting the steering shoft

with the steering box. Fit the steering wheel tentotively

ond odiust the direction indicotor

switch -

see Chopter 13.17.

4. Using the steering wheel, tunn the wheels

into full lock positions

to moke sure thot the

lock ongle is correctly limited by the king pin

socket stops -

see Chopter 6.5, porogroph

36.

5. Adiust the toe-in -

see Chopter 6.1.

6.4 DISMANTLING

FRONT AXLE

No speciol instructions ore required for

dis-

montling mony of the subossemblies. Accord-

ingly, only the bosic dismontling procedure

will be

deolth with ond porticulors

will be men-

tioned only os fon

os they ore necessory for the

sequence of operotions ond the use of iigs.

Ports which con be dismontled witlrout re-

moving them from the cor ore the wheel hubs

and beorings, the broke mechonisms, steering

orms, shock obsorbers, ond the

onti-roll bor.

lf ony odditionol ports

hove to be dismontled,

remove the oxle from the cor ond dismontle it

on the stond.

Dismontling Wheel Hubs

ond Beorings

1. Dismontle the broke mechonism os per

Chopter 9.1 ond remove

the wheel hub

cop

using the MP 6-124 drog. When using the MP

6-136 pull-off

cortridge, the hub cop hos to be

prised off with o

tyre lever or o similor tool.

Now remove the costelloted nutwith its wosher

ond pull

out the hub,

ossisting the removol

with

light blows of o mollet, if necessory.

2. Toke out the inner port

of the outer beor-

ing, then the seoling ring, ond, f

inolly, the inner

port of the reor beoring (cone

with topered

rollers). Prise out the seoling ring using o

scrrewdriver. Proceed corefully olong the ring

circumference to ovoid distorting the ring which

Fig. 6.4/1 -

Removing Hub Cop Using

MP 6-124 Drog

106

Page 107 of 238

Fig.

Hol

over t

remo!

6.5 F

The

which

provid

$H

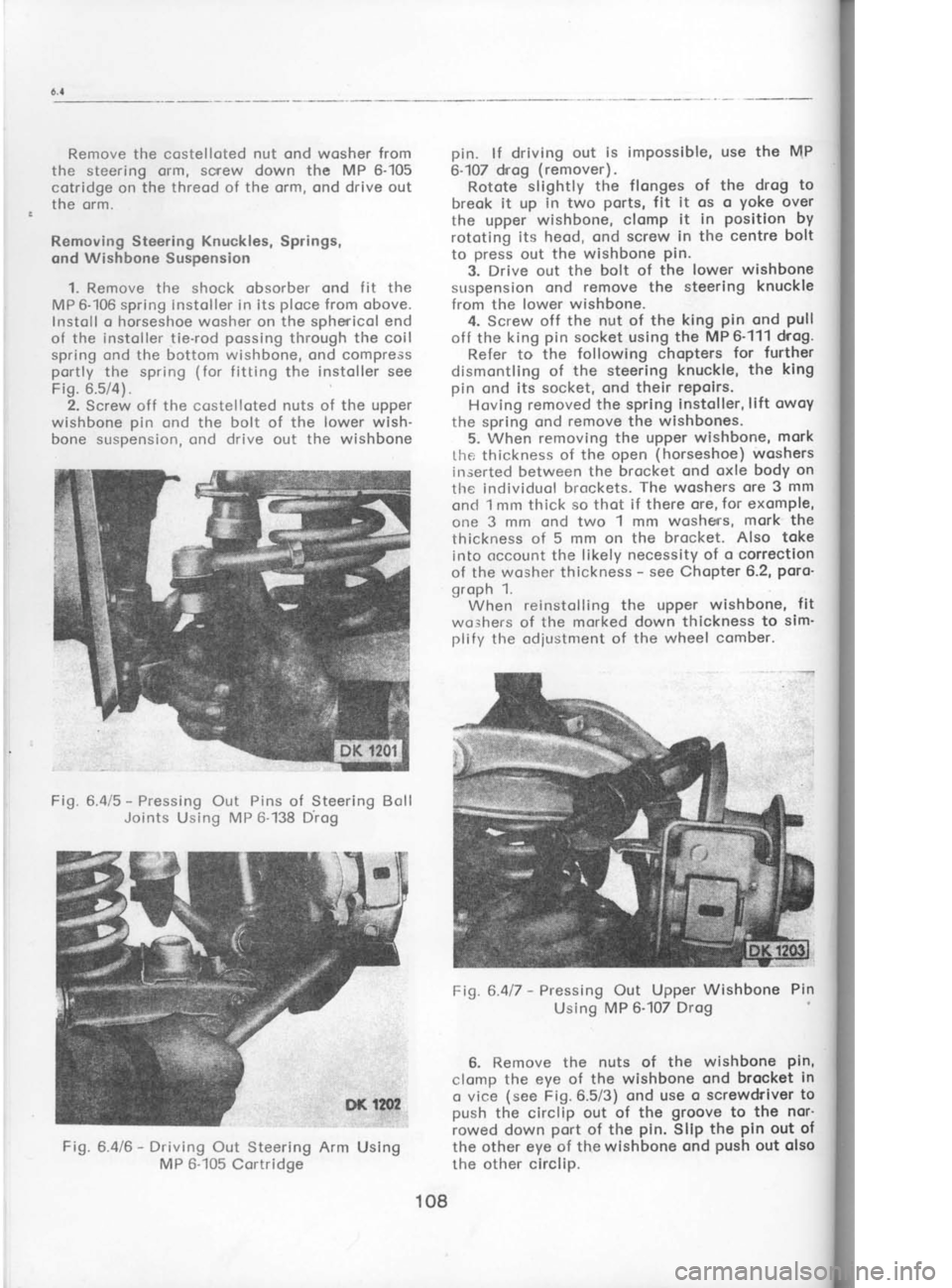

Remove the csstelloted

nut ond wosher from

the steering orm, screw down the MP 6-105

cotridge on the threod of the orm, ond drive out

the orm.

Removing Steering Knuckles,

Springs,

ond Wishbone

Suspension

1. Remove tlre shock obsorber ond fit the

MP 6-106 spring

instoller in its ploce from obove.

lnstoll o horseshoe wosher on the sphericol end

of the instoller tie-rod possing

tlrrough the

coil

spring ond the bottom wishbone, ond compress

portly the spring (for

fitting the instoller see

Fig. 6.5/4).

2. Screw off the

costellqted nuts of the upper

wishbone pin

ond the bolt of the lower wish-

bone suspension, ond drive out the wishbone

Fig. 6.415 -

Pressing Out Pins of Steering Bcrll

Joints Using MP 6-138

Drog

Fig.6.416 -

Driving Out Steering Arm Using

MP 6-105 Cortridge pin.

lf driving out is impossible, use the MP

6-107 drrog (remover).

Rotote slightly the

flonges of the drog to

breok it up in two ports,

fit it os o yoke

over

the upper wishbone,

clomp it in position

by

rototing its heod, ond screw in the centre bolt

to press

out the wishbone pin.

3. Drive out the bolt of the lower wishbone

suspension ond remove the steering knuckle

from the lower wishbone.

4. Screw off the nut of

the king pin

ond pull

off the king pin

socket using the MP 6'111 drog.

Refer to the following chopters for

further

dismontling of the steering knuckle, the king

pin ond its socket, ond their repoirs.

Hoving removed the spring instoller,lift owoy

the spring ond remove

the wishbones.

5. When removing the upper wishbone, mork

the thickness of the open (horseshoe) woshers

irrserted between the brocket ond oxle body on

tlre individuol brockets. The

woshers ore 3

mm

onct 1 mm thick so thot if there ore, for exomple,

one 3 mm ond two 1

mm woshe'rs, mork the

thickness of 5 mm on the brocket. Also toke

into occount the likely necessity of o correction

of the wosher thickness -

see Chopter 6.2, poro-

groph 1. When reinstolling the upPer wishbone, fit

wo;hers of the morked down thickness to sim'

plify the cdjustnrent of the wheel comber.

Fig.6.4l7 -

Pressing Out Upper Wishbone Pin

Using MP 6-'107 Drog

6. Remove the nuts of the wishbone pin,

clomp the eye of the wishbone ond brocket in

o vice (see

Fig.6.5/3) ond use o screwdriver to

push the circlip out of the groove

to the nor'

rowed down port

of the pin.

Sllp the pin out of

the other eye of the wishbone ond push

out olso

the other circlip.

108

Page 111 of 238

1

\

I

(

r

t

(

s I

I

(

S

lf

m

gr

lir

O1

sy

ro

po

th

th

th, tir

on

m€

tht

of

onl

I

by tr

Cl

A

6-

tl-

th

th

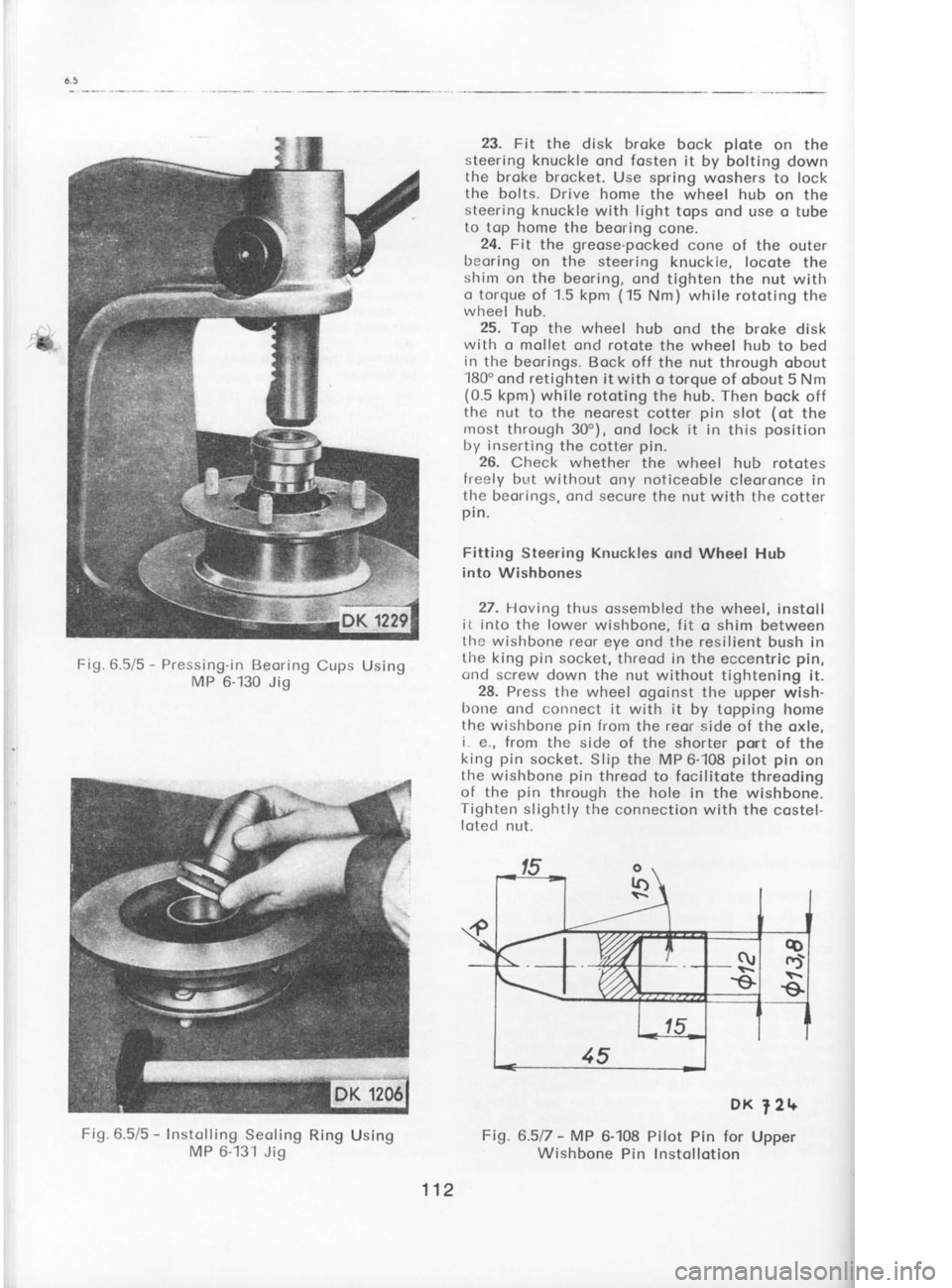

Fig.6.5/5

-

Pressing-in Beoring Cups Using

MP 6-130 Jig

Fig.6.5/5 -

Instolling Seoling Ring

Using

MP 6-131 Jig 23-

Fit the disk broke bock plote

on the

steering knuckle ond fosten it by bolting down

the broke brocket. Use spring woshers to lock

the bolts. Drive home the wheel hub

on the

steering knuckle with light tops ond use o tube

to top home the beoring cone.

24. Fit the greose-pocked

cone of the outer

beoring on the steering knuckie, locote

the

shim on the beoring, ond tighten the nut with

o torque of 1.5 kpnr (15

Nm) while rototing the

wheel hub.

25. Top

the wheel hub ond the broke disk

with o mollet ond rotote

the wheel hub to bed

in the beorings. Bock off the nut

through obout

-180o

ond retighten it with o torque of obout 5 Nm

(0.5 kpm) while rototing the hub. Then bock off

the nut to the neorest cotter pin

slot (ot

the

most through 30"), ond lock it in this position

by inserting the cotter pin.

26. Check whether the wheel hub rototes

freely br-rt without ony noticeoble

cleoronce in

the beorings, ond secure the nut with the cotter

pin.

Fittirrg Steering Knuckles ond Wheel Hub

into Wishbones

27. Hoving thus ossembled the wheel, instoll

ii into the lower

wishbone, fit

o shim between

tl-re wishbone reor eye ond the resilient bush in

the king pin socket,

threod in the eccentric pin,

cind screw down the nut without tightening it.

28. Press

the wheel ogoinst tlre

upper wish-

borre ond connect it with it

by topping home

the wishbone pin

from the reor side

of the

oxle,

i. e., from the side of the shorter port

of the

king pin

socket. Slip the MP 6-108 pilot

pin

on

the wishbone pin

threod to focilitote threoding

of the pin

through the hole in the wishbone.

Tighten slightly the connection with the costel-

loted nut.

DK ? 2r+

Fig. 6.517 -

MP 6--108 Pilot Pin for

Upper

Wishbone Pin lnstollotion

112

Page 121 of 238

(

t

t

s r

1

S

t S

n

o

fl

p

t\

e

g

tl

St

T

o

e

ir

h,

el

r€

re

5. Ploce

the steering

box with its bottom

boll

beoring resting on the MP 7-102 jig

ond press

the steering screw

with both beorings into the

iig. Extroct the

bottom beoring using

the MP

6-111 king pin

socket remover

ond push

the

steening screw with the top beoring oert of the

steering box. Support the beoring by the Mp

7-102 iig crnd

press

it out.

7.3 REASSEMBLING STEERING BOX

1. Press the dust cup with its seoling

ring

into the steering

box with the pressed-in

bush

ofter hoving thorouchly

cleorred the box. Now

pf oce the box on the MP 7-102

iig oncl

press-in

the bottom boll beorinct

using tlrei pressing

mandrel MP 7-103.

2. Fit the lower beoring

cop seoled

off with

o poper

gcsket

ond seoling compound, slip

lpring woshers

on to the bolts,

ond tighten the

bolts with o torque os per

Chopter t.6. f it the

wosher on the steering screw

with its deflec-

tion focing

the screw threod ond press

the

top beoring on the screw

using the Mp Z-103

pressing mondrel.

3. Then ploce

ogoin the steering box on the

MP7-102 iig ond

press

into it ond into the bot-

tom beoring the steering

screw with the pnessed-

-on top boll beoring,

using ogoin

the Mp7-103

pressing mondrel. For further ossembly, use the

vice ond the dummy brocket.

Fig. 7.311 -

Pressing-in Bottom

Beoring

on MP 7-102

Jig (support

plote)

Using

MP 7-103 Piressinq

Mondrel 4.

Meosure the height of the beoring pro-

truding from the steering box ond odiust it by

fitting shims interspoced with poper goskets

cooted with o seoling

compound.

Fosten down

the cop by tightening the bolts. Check the

steering screw for free rototion

ond the obsence

of ploy.

The beoring should be without o cleor-

once or there hos

to be o prestress

of up to

0.07 mm.

5. Remove the bolts of the cop, slip the rub-

ber seoling ring dipped in oil on to the shoft,

ond fit the dust cup on the cop. lnstoll spring

woshers on the bolts. Should the cup be over-

stroined due to the toleronce

of the recess for

the seoling ring or the ring itself

, instoll

o poper

gosket under it os under tlre ccrp.

6. Locote the steering nut on the screw fol-

lowecl by the rocker shoft with pin, spring,

spring pin, ond the licl gosket

cooted with

o seoling compound, ond fit the lid with bush

in position to close the steering

box. Instoll

spring woshers under the bolts orrd tighten the

bolts with o torque os per

Chopter 1.8. Screw

the set screw into the lid ond rnove

the steer-

ing geor

so thot the drop orrn is swivelled

through obout one holf of its trovel from the one

or the other extreme lock position.

Witlr the

drop ornr in this position,

screw down the set

screw os for os it will go

ond then bock it off

through obout 95 to '120'.

This will provide

for

on odequote cleoronce of the steering geor.

[.ock the set screw in position

with the re-

spective nut.

7. Drive the key on to the rocker shoft cone,

fit the drop orm ond hold it down lightly with

the nut. Clomp the drop orm in o vice, tighten

fully the nut (for

the tightening torque see

Chopter 1.8), ond secure tlre nut with o cotter

pi n.

8. Clomp ogoin the steering box by meons of

the dummy brocket ond moke sure

thot the dnop

orm con swivel from one extreme lock position

to the other. A certoin

resistonce should olwoys

be present,

but if the resistonce is too greot,

decreose it by o slight slockening of the set

screw in the lid. The

rototing resistonce of the

shaft should not exceed 20 Nm (O.2

kpm). Refer to

page 117/118 for testing

procedure.

9. Set the ossembled steering box in its fit-

ting position

(inclined

by obout 40o) ond pour

in oil through the hole in the bbx lid (cover)

till the oil level reoches the bottom edge of the

filling hole. Then

screw down the topered plug.

7.4 RELAY (TDLER)

LEVER

For its instollotion (ond

removing in reverse

order) ond ony pertinent porticulors

see the

Chopter 6.5, porogrophs

2 ond 3.

122

Page 123 of 238

7

.7-1.8

(

t

t

t

; (

(

b

tl

ir

tl

p il

o

tl

p

odiust,

if necessory, the driving dog of the di-

rection indicotor switch -

see Chopter 13.17.

Refit the steering wheel so thot its spokes

ore horizontol, lock it in position

with the nut

(for tightening torque, see

Chopter 1.8), ond

bolt down the spoke shroud.

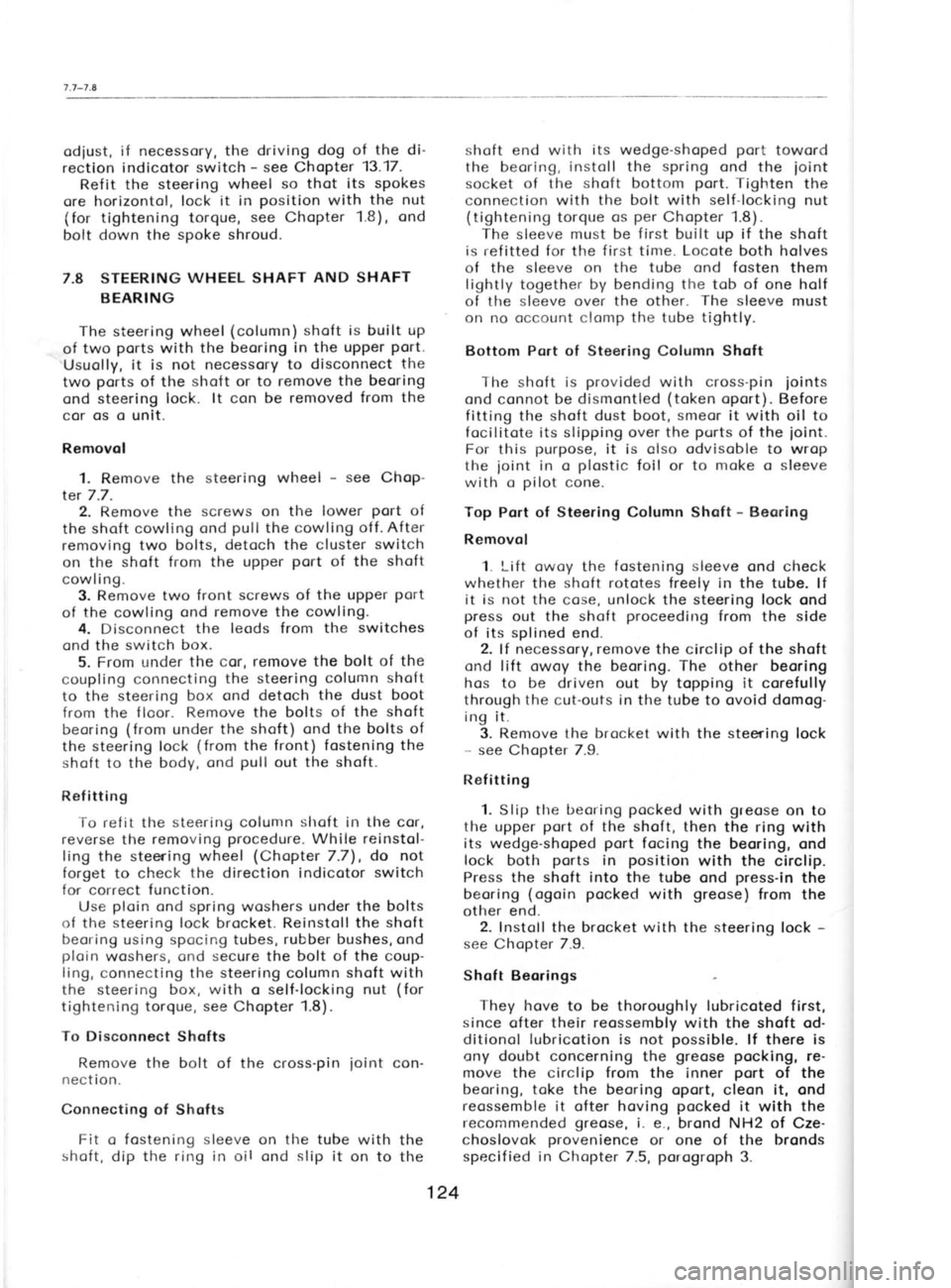

7.8 STEERING WHEEL SHAFT AND SHAFT

BEARING

The steering wheel (column) shoft is built

up

of two ports

with the beoring in the uPPer port.

Usuolly, it is not necessory to disconnect the

two ports

of the shoft or to remove the beoring

ond steering lock. lt

con be removed from the

cor os o unit.

Removol 1. Remove the steering wheel -

see Chop-

ter 7.7. 2. Remove the screws on the lower port

of

the shoft cowling ond pull

the cowling off.After

removing two bolts, detoch the cluster switch

on the shoft from the upper port

of the shoft

cowling. 3. Remove two front screws of the upper

Port

of the cowling ond remove the cowling.

4. Disconnect the leods

from the switches

ond the switch box.

5. From under the cor, remove the bolt of the

coupling connecting the steering

column shoft

to the steering box ond detoch the dust boot

from the floor. Remove the

bolts of the shoft

beoring (from

under the shoft)

ond the bolts of

the steering lock (from

the front) fostening the

shoft to the body, ond pull

out the shoft.

Ref itting To ref it the steering column shoft

in the cor,

reverse the removing procedure. While reinstol-

ling the steering wheel (Chopter

7.7), do not

forget to check the direction indicotor switch

for correct function.

Use ploin

ond spring woshers under the bolts

of the steering lock

brocket. Reinstoll the shoft

beoring using spocing tubes, rubber bushes, ond

ploin woshers, ond secure the bolt of

the coup-

ling, connecting the steering

column shoft with

the steering box, with

o self-locking nut (for

tightening torque, see

Chopter 1.8).

To Disconnect Shofts

Remove the bolt

of the cross-pin

ioint con-

nection.

Connecting of Shofts

Fit o fostening sleeve on the tube

with the

shoft, dip the ring in oil ond slip

it on to the shoft end with

its wedge-shoped port

toword

the beoring, instoll the spring

ond the

ioint

socket of

the shoft bottom port.

Tighten

the

connection with the bolt with self-locking

nut

(tightening torque os per

Chopter 1.8).

The sleeve must be f irst built up if

the shoft

is refitted for the first time. Locote

both holves

of the sleeve on the tube ond fosten

them

lightly together by bending the tob of one holf

of ttre sleeve over the

other. The

sleeve must

on no occount clomp the tube tightly.

Bottom Port of Steering

Column Shoft

The shoft is provided

with cross-pin

ioints

ond connot be dismontled (token

oport). Before

fitting the shoft dust boot, smeor

it with

oil to

focilitote its slipping over the pcrrts

of the joint.

For this purpose,

it is clso odvisoble to wrop

the joint

in o plostic

foil or to moke o sleeve

with o pilot

cone.

Top Port of Steering Column

Shoft -

Beoring

Removol 1. l-ift owoy the fostening sleeve

ond check

whether the shoft rototes

freely in the tube. lf

it is not the cose, unlock the steering lock ond

press out the shoft proceedirrg

from the side

of its splined

end.

2. lf necessory, remove

the circlip of the shoft

ond lift owoy the beoring. The other beoring

hos to be driven out by topping it corefully

through the cut-outs in

the tube to ovoid domog-

ing it. 3. Remove the brocket with the steering

lock

- see Chopter 7.9.

Ref itting

1. Slip tlre beoring pocked

with greose

on to

the upper port

of the shoft, then the ring with

its wedge-shoped port

focing the beoring, ond

lock both ports

in position

with the circlip.

Press the shoft into the tube ond press-in

the

beoring (ogoin pocked

with greose)

from the

other end.

2. lnstoll the brocket with the steering lock -

see Chopter 7.9.

Shoft Beorings They hove to be thoroughly lubricoted

first,

since ofter their reossembly with the shoft od-

ditionol lubricotion is not possible.

lf there is

ony doubt concerning the greose

pocking,

re-

move the circlip f

rom the inner port

of the

beoring, toke the beoring oport, cleon it, ond

reossemble it ofter hoving pocked

it with the

recommended greose,

i. e., brond NH2 of Cze-

choslovok provenience

or one of the bronds

specif ied in Chopter 7.5, porogroph

3.

124

Page 141 of 238

r 0.3-t0,5

Ihe permissible

out-of-bolonce must not ex-

ceed 50 grommes

on the rim rodius. Every new

tyre is provided

with o coloured dot on its side,

indicoting its lightest point.

Fit the tyre olwoys

with this dot focing

the tube volve.

ln this

position, the volve octs os on odditionol weight

compensoting the wheel overoll unbolonce to

o consideroble extent.

lf dynomic boloncing of the wheel is not

possible, bolonce the wheel stoticolly with the

greotest possible qssuroc|.

Boloncing weights

of 30, 50, 75,

ond 100 grommes

ore ovoiloble.

10.4 TUBED TYRES

For mounting,

dismounting,

ond repoirs of

conventionol tyres with inner tubes (for

por-

ticulors, see the preceding

Chopters), the usuol

procedures ore opplicoble. The permissible run-

out (untrue

running)

of the rim is the some os

for tubeless tyres (Chopter

10.5).

10.5 TUBELESS TYRES

The oir-tight seoling of these tyres requires

more core ond o different hondling thon thot of

the tyres with inner

tubes.

Preporotlon of Rirrr

13elore mounting the tyre, inspect the rim for

ony technicol defects. The points

to be checked

ore the rim shoulder ond the moting foce for

the tyre beods,

in oddition to the overoll con-

dition of the rim. lf ony defects ore found, the

rim must be reconditioned.

A sotisfoctory rim

nrust comply with the following conditions:

o) The

rim shoulder ond the tyre volve hole

must not be distorted;

there must be no

shcrp edges or protrusions

likely to domoge

the tyre beod. Minor unevennesses

con be

hornmered flot ond smoothed

with o file.

The moximum eccentric running

of the rim

side must not exceed 1.5 mm.

b) The moting surfoces

must be obsolutely

cleon (free

from stuck-on rubber, rust,

etc.).

Cleon them with emery poper

or o wire brush

ond coot them with point.

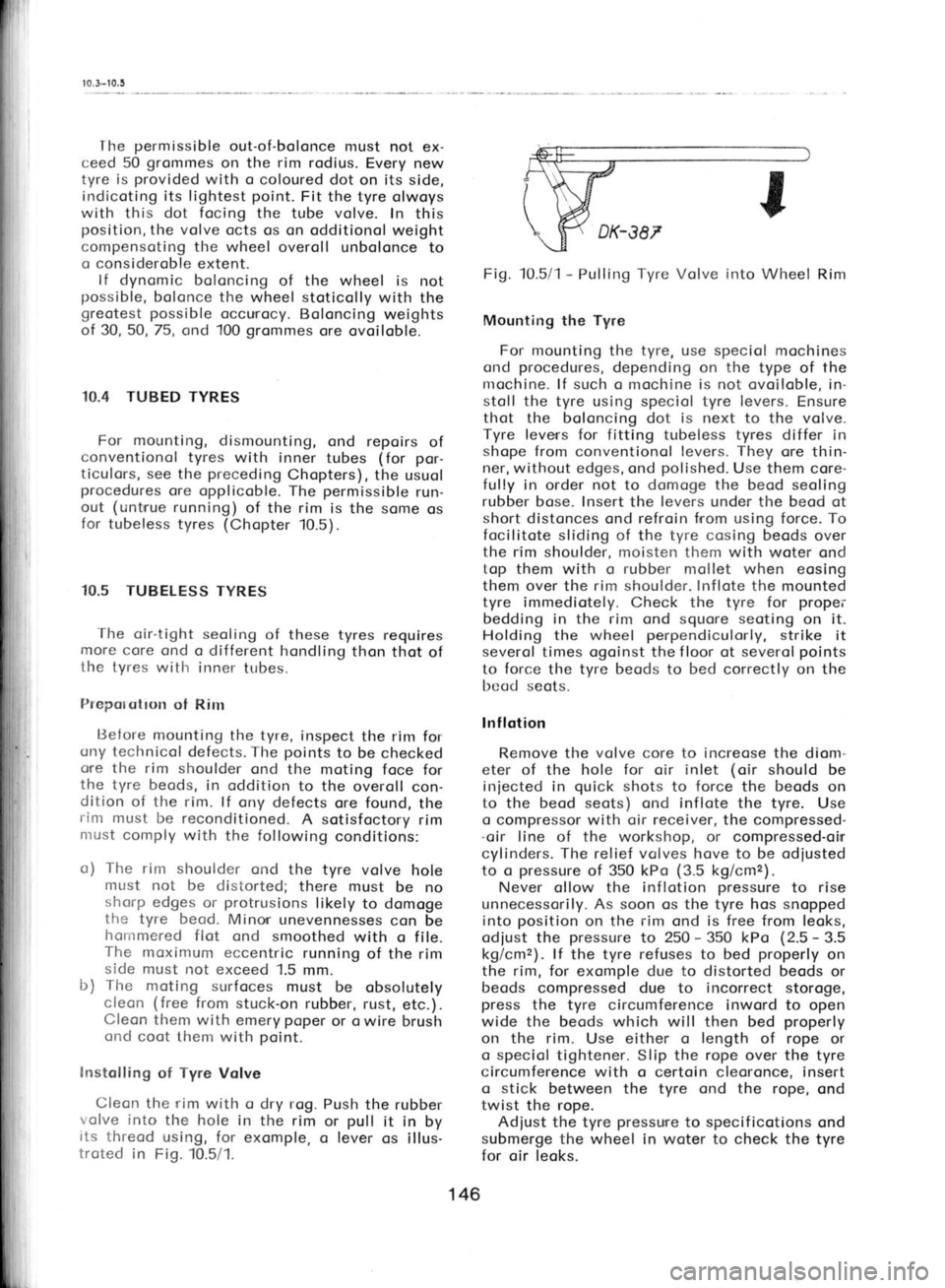

lnstolling of Tyre

Volve

Cleon the rim with o dry rog. Push

the rubber

volve into

the hole in the rim

or pull

it in

by

its threod using, for exomple,

o lever

os illus-

troted in Fig. 10.5/1. Fig. 10.5/1

-

Pulling Tyre Volve

irrto Wheel Rim

Mounting the Tyre

For mounting the tyre, use speciol mochines

ond procedures,

depending on the type of the

nrochine. lf such o mochine is not ovoiloble, in-

stoll the tyre using speciol tyre levers.

Ensure

thot the boloncing dot is next to the volve.

Tyre leverrs for fitting tubeless tyres

differ in

shope from conventionol levers. They

ore thin-

ner, without edges, ond polished.

Use them core-

fully in order not to domoge the

beod seoling

rubber bose. Insert the levers

under the beod

ot

short distonces ond refroin from using force. To

focilitote sliding of the tyre cosing beods over

the rim shoulder, moisten them with woter ond

top them with o rubber

mollet when eosing

them over the rim shoulder. Inflote

the mounted

tyre immediotely. Check the tyre for propei'

bedding in the rim ond

squore seoting

on it.

Holding the wheel perpendiculorly,

strike it

severol times ogoinst the f loor ot severol points

to force the tyre beods

to bed

correctly on the

bcad seots.

lnf lotion

Remove the volve

core to increose

the diom-

eter of the hole for oir inlet (oir

should be

iniected in quick

shots to force

the beods

on

to the beod seots) ond inflote the tyre. Use

o compressor with oir receiver, the

compressed-

.oir line of the

workshop, or

compressed-oirr

cylinders. The relief volves hove to be odiusted

to o pressure

of 350 kPo (3.5

kg/cmz).

Never ollow the inflotion pressure

to rise

unnecessorily. As soon os the tyre hos snopped

into position

on the rim

ond is free from leoks,

odiust the pressure

to 250 -

350 kPo (2.5 -

3.5

kg/cmz). lf the tyre refuses to

bed properly

on

the rim,

for exomple due to distorted beods or

beods compressed due to incorrect storoge,

press the tyre circumference inword to open

wide the beods which will then bed properly

on the rim. Use either o length of

rope or

o speciol tightener. Slip the rope over the

tyre

circumference with o certoin cleoronce, insert

o stick

between the tyre ond the rope, ond

twist the rope.

Adiust the tyre pressure

to specif

icotions ond

submerge the wheel in woter to check the

tyre

for oir leoks.

146