engine SKODA 105S 1980 Workshop Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 1980, Model line: 105S, Model: SKODA 105S 1980Pages: 238, PDF Size: 47.09 MB

Page 10 of 238

The child'proof

lotch

of

the reor

door.s con

be

"ng"!J Uy

tipPing down

its

lever' The doors

;;; ;" open"d'froir outside

ofter

disengoging

iunfoctin'g1 the

lotch by pulling

the

Press'

button.

Fig.1.311 Inside

Door

Mechonisms

1 -

Hondle

2 -

Lock Press-button

3 -

Drop window cronk

4 -

Door pull

5 -

Ashtroy (depending

on

reor door

outfit) Fig.

1.312

Child'Proof Lotch

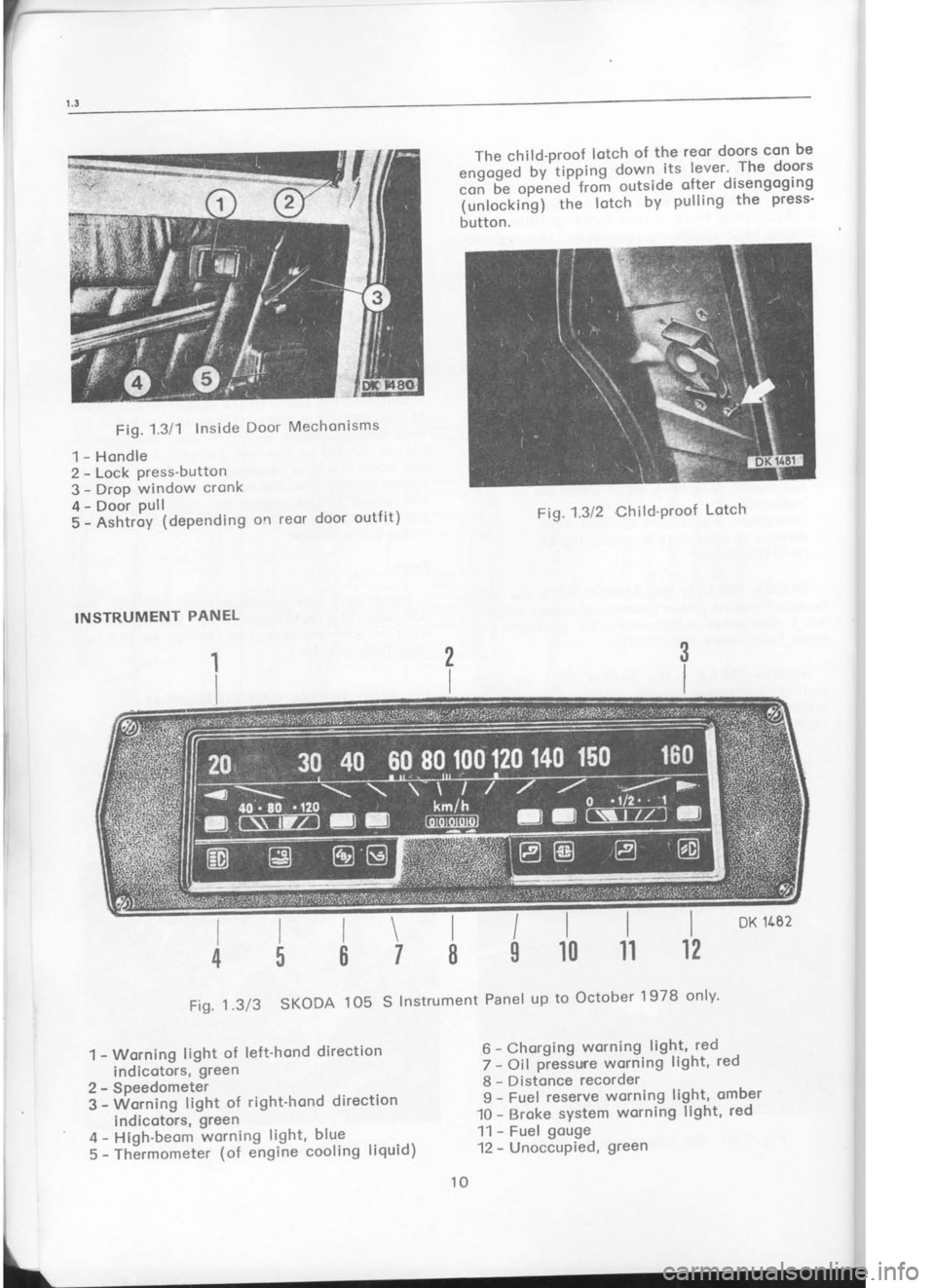

INSTRUMENT PANEL

t

a

(

Fis. 1 .3/3 SKODA 1O5

Slnstrument Panel

up

to October 1978

only'I

12

/l

910

1 -

Worning light

of

left-hond direction

indicotors, green

2 -

Speedometer

3 -

Worning light

of right'hond direction

indicotors, green

4 -

High-beom worning light,

blue

5 -

Th6rmometer (of

engine cooling liquid) 6

-

Chorging worning

light, red

7 -

Oil pressure

worning light,

reo

8 -

Distonce recorder

I -

Fuel reserve worning light,

omber

10 -

Broke sYstem

worning light,

red

11 -

Fuel gouge

12 -

UnoccuPied, green

Page 12 of 238

Worrring

lights:

5 -

left-hond direction indicotors, green

6 -

oil pressure,

red

7 -

right-hond direction indicotors, green

8 -

broke system, red

9 -

chorging, red

10 -

fuel reserve, omber

11 -

high beom, blue

The thermometer indicotes the temperoture

of the coolont with the ignition switched on.

The optimum operoting temperoture ronge is

from 75 to 105oC. In

SfOon 105 S, this

ronge

is identified by

the green

zone of the scole.

The fuel gouge

indicotes the level

of the fuel

with the ignition switched on. The scole is

provided with divisions 0 -

r/2

-

1, i. e., empty,

holf full,

ond full

tonk.

The driver is worned by the red worning light

when thene ore less thon 5litres of fuel in the

fuel tonk.

The tochometer indicotes the speed (revol-

utions) of the engine. The

speed should

never

rise to the red zone. When chonging the geors,

on increose of speed within the ronge

of the

yellow zone is permissible.

The porking

lights come on when the switch

is thrown to the first

right-hond position.

The

Fig. 1.3/6 Switches -

port I

1 -

Porking light switch ond feeder of heodlomp

dipswitch

2 -

Horn switch, direction indicotor switch,

ond dipswitch

3 -

Switch of ouxiliory (extro)

heodlomps

4 -

Door switch 12

-

unoccupied, green -

fog lomp worning light

included in speciol

extros

13 -

unoccupied, green -

low-beom worning light

included in speciol

extros

14 -

unoccupied, red

switch switches on the heodlomps, toil lights,

ond the licence plote

light.

The heodlights, i. e. driving (high

beom) ond

dipped (low

beom), ore switched on by throw-

ing the switch to the second

right-hond pos-

ition. The switch switches on oll porking

lights

ond the heodlights

in occordonce with the pos-

ition of the switch stem-type lever: centre

position -

dipped lights,

towords the instrument

ponel -

driving lights. When the

driving lights

ore on, the blue worning light glows.

The ouxiliory heodlomps

come on ofter pull.

ing the switch knob, but only while moin

heod-

lomps ore on.

heodlomp flasher storts floshing

when

the switch lever

toword the steering

ring.

horn is sounded by depressing

the lever

the steering wheel shoft.

Fig.1.317 Switches -

port ll ond oshtroy

1 -

Switchbox ond steering lock

2 -

Switch of windscreen wipers ond

wosher

3 -

Heoter switch

4 -

Switch for on odditionol device -

not

stondord fitted

5 -

Disobility worrning light

switch -

not on

SKoDA 105 s

6 -

Heoter control

7 -

Ashtroy

The

pulling

wheel

The

toword

i

I

L 12

Page 14 of 238

--

!

ti

f

I

n

i

Boot lid

up to 1978 -

To open it, press

down

the release on the

right-hand side

underthe facia

oanel. Then

lift

the lid on the right-hand side and

secure it

in its raised position with

the aid of

the

articulated strut. After

lowering the

lid, lock it by

pulling the release as

far as it will go.

'

Sinie 1978

open lid by pulling

handle and

lower as described above.

To

lock press lid above

catches. I

(in

egr

WO

r,nol

pul

T

rem

fore

B

Pus

the

lugs

forn

cusl

Fig.' OT

,4

Fig.1.3111 Controls

1 -

Geor lever

2 -

Hond broke

lever

3 -

Choke n

between Front

Seots

't488

Fig.1.3112 Switching Positions

of

Switchbox

c/w Steering Lock

0 -

All functions of

f, engine stopping

| -

lgnition on -

ignition system ond

oll ports

ol electricol equipment ore

supplied

with

curre nt

ll -

Engine storting -

before repeoting the

stort-

ing procedu,re,

return the key to the "0"

pos-

ition ond only then stort the

engine ogoin

STOP -

Position for

withdrowing the

ignition

key ond engoging the

steering lock (ofter

hoving withdrown the

ignition key,

turn the

steering wheel till

the lotch of the lock

c licks home

) .

lf the key connot be turned

when unlocking

the steering, relieve the stress

of the steering

geor by tuining the

steering wheel slightly-

LUGGAGE AND ENGINE

COMPARTMENTS

The moin luggoge comportment (boot)

is in

the forebody, the interior (inbuilt)

luggoge

comportment behind the

reor seot bockrests. Fig.

1.3/13 lloot Lid Releose

Engine bonnet -

To open it, pull

the lever in

the operture of the left-hond

reor door. To close

the bonnet, press

it down with the hond into

oosition.

For ony work in the engine comportment see

the notice in porogroph 1,

Chopter 2'1.

Fig. 13lM Reor Bonnet Releose Lever

SEATS, ADJUSTMENT AND CONVERSION

To moke the seot slide, unlock it by lifting

the lever ond tilt the bockrest by

rototing the

rosette. Set

Cor

by thr

only r

is pro

The

ofter

lifting

bock,

by its

positir

Ash

tion o

open i

its cos

hold i

inworc

first it

oshtro'

1.4 C,

Jqck

iock is

held in

14

Page 16 of 238

Lifting

the cor with o

Power iock -

When

r-rsing o service

Power iock, let the

cor rest on

the points

shown in Fi1.1.412.

To tow the cor, hook the towing rope on

to

the brocket under

the cor nose. Threod the pin

through the loop of the rope

ond the brocket

lugs ond secure the pin

with o cotter pin (both

thL pin

ond the cotter pin

ore included in the

cor occessories).

1.5 SPARE WHEEL

AND FUEL TANK

Spore wheel -

After having opened the

lug-

goge boot lid, pull the hondle of the spore

wheel corrier releose

rod.

The corrier is

re-

leosed ond swings

down (speciol equipment of

the cor includes

o sofety lotch behind the

bumper which hos to be pushecl

oside to

releose the corrier

) . After

hoving closed the corrier (by

lifting it),

push the releose lever under

the bumper to the

right os for os it will go.

Fuel tonk -

The filler neck with cop is in the

reor on the right-hond

side of the cor- lt con

be locked ond unlocked by meons of

the re'

spective key.

1.6 STARTING THE

ENGINE AND CHECKING

ITS CORRECT RUNNING

1. Moke sure thot the geor

lever is in its

neutrol position,

switch on the ignition (pos-

ition I on the switch box) ond wotch the

coming on of the oil pressure ond chorging

worning lights, i.

e. check the function of the

olternotor -

see the informotion in porogroph

4.

Prepore the engine

to its temperoture:

- Storting from cold in

the occelerotor pedol

- Storting from cold in

the occelerotor pedol

choke for

storting occording

winter -

do not touch

ond use the full choke

summer -

do not touch

ond use only holf of the

Fig. 1.5/1 Hondle ot

Rod (f ronr obove )Spcre

Wheel Lock

crnrl Safety Lotch -

Storting o wormed-up engine -

depress the

occelerotor pedol

slowly to tlre

toe-boord, do

not touch the choke

2. Depress the clutch pedol

(odvisoble

in

summer, necessory in

winter) ond stort

the

engine by turning the ignition key to position

ll.

Let go

of the key os soon os the engine fires

ond releose the occelerotor pedol

{if it hos

been

clepressed).

It the engine ,refuses

to fire, return the key

to the position "0"

ond rePeot the

storting

Pro-

cedure. lf the engine is wormed up, depress the

occelerotor pedol

to obout one third of its totol

trovel. lf the cold engine stolls even

ofter the

second ond third storting ottemPt, enrich the

storting mixture by quickly

depressing the

oc-

celerotor pedol

once or twice to holf of its

trovel during the next storting ottemPt.

Never let tlre storter motor run for more

thon

obout 5 seconds. Woit

some 5 seconds before

repeoting the storting.

Fuel is injected

by every quick

depression of

the occelerotor pedol

ond enriches the mixture

so thot it is difficult to ignite. lf the engine

is flooded, stort

it

with o fully depressed oc-

celerotor pedol.

3. Increose the engine speed corefully while

releosing the clutch pedol. lf the

engine shows

signs of stolling, depress

ogoin the clutch

pedol.

Relecse

L.ever

Fi.1.5t2 Fuel Tcrtrk Filler

Neck

16

Page 18 of 238

ii

i ENGINE

Model

- for Skodo 105 S ond 105

L

- for Skodo 12o L

- for Skodo 120 LS

Type

Number of cylinders

Cylinder orrongement

Cooling

Swept volume

- Skodo 105 S ond 105 L

- Skodo 12O L ond

120 LS

Bore

- Skodo 105 S ond 105 L

- Skodo 120 L

ond 120 LS

Stroke

Compression rotio

- Skodo 105 S, 105 L ond 120 L

- Skodo 120 LS

Engine power

output to CSN ond DIN

- Skodo 105 S ond 105 L

- Skodo 12O L

- Skodo 120 LS

Moximum torque

- Skodo 105 S ond 105 L

- Skodo 120 L

- Skodo 120 LS

Fuel -

recommended octone number

- Skodo 105 S,

- Skodo 120 Ls

Corburettor type

Fuel lift pump

type

CLUTCH

Type

Control

GEARBOX

Type Speeds

Geor rotios -

1st-speed geor

2nd-speed geor

3rd-speed geor

4th-speed geor

reverse geor Skodo 742.10 Engine No/l

Skodo

742.12 Engine No/2

Skodo 742.12x Engine

No/9

four-stroke, spork-ignltion,

corburettor engine with overheod volves

4 in line

pump-circuloted ontifreeze,

thermostotic temperoture control

1,046 c. c.

1,174 c.c.

68 mm

72 mm

72 mm

8.5:1

9.5:1

33.9 kW (46

h. p.)

ot 4,800 r.

P. m.

38.3 kW (52

h. p.)

ot 5,(X)0 r. p.

m.

42.7 kW (58

h. p.)

ot 5,2(X) r. p.

m.

74.5 Nm ot 3,000 r.p.m.

85.2 Nm ot 3,000 r.p.m.

90.2 Nm ot 3,250 r.p.m.

90 minimum 95 minimumduol, twostoge, downdrought

nrodel JIKOV 32 EDSR

diophrogm pump, model

JIKOV MF

dry, single-plote, with direct

disengogement

hydroulic

with helicol

spur geas

4 forword ond 1 reverse, synchrolock on the

1st-, 2nd-,

3rd-, ond 4th-speed geors

3.8

2.12 1.41

0.96 3.27

105 L ond

12O L

18

Page 20 of 238

Broke

fluid:

- clossificotion

- brond filled-in in the foctrY -

FUEL TANK

Locotion Fuel cleoning (filtrotion)

CHASSIS LUBRICATION

TyPe

ELECTRICAL EQUIPMENT

Eorthing

Roted voltoge

Service voltoge

lgnition

Storoge botterY .

Alternator PAL Magneteton

Voltoge regulotor

Distributor

lgnition coil

Storter motor

Sporking plugs -

see ChoPter 137

BODYWORK

Type Seoting copocity

Luggoge comportments, coPocitY

H e oter

FILLING CAPACITIES

Engine -

Skodo 105 S, 105 L

ond 120 L

Skodo 120 LS

Georbox ond

finol drive cose

Steering box

Broke system

ond clutch

Cooling system

Fuel tonk SAE J

1703C

SYNTOL HD

190

suspended under

floor boord of cor reor holf

stroiner in fuel tonk,

fuel filter, ond stroiner

in corburettor

self-lubricoting beori

ngs,

by greose nipples;

wheel

greose

negctive pole

12 volts

14 volts repocking

with greose

beorings pocked

with

bottery (coil)

type

type AKUMA 6N 37 -

12 volts, 37 ompere-hours

14V 35 amps 1976-79

1O5/12O

L

14V 42 amps 1979 on

1O5/12O

L

14V 42 amps 1976-79

120 LS

14V 55 amps 1979 on

120

LS

type PAL Mogneton, 14 volts

type PAL Mogneton

with centrifugol timing

device ond vocuum unit

type PAL Mogneton, 12

volts

type PAL Mogneton, 12

volts

0.66 kilowotts (0.9

h. p.)

oll-metol, closed, four'door,

chossisless body

5 occuponts

0.40 mi (0.28

rn: moin luggoge comPortment for

q lood of obout

0 kg, 0.12 mr interior luggoge

comportment for

o lood of obout 10 kg)

hot-woter heoter

with fon, fed with woter

from

the engine cooling sYstem

4 litres moximum -

2.5 litres minimum

of engine oil

4.6 litres moximum -

3 litres minimum

of engine oil

2.5 lities of geor

oil (2 litres when

chonging oil)

0.16 litres of gecrr oil (obout

0.25 litres when

topping up)

O.4A titres of broke f

luid (f

illing for tropicol

regions, etc. see ChoPter 16.2)

12.5 litres of

ontif'reeze

38 litres 1.8 Tt(

BC

1. Ap

von ized

out o sL

2.tti

Threo

ENGINE

Connecti

Nut of c

Nut of c

Nut of vr

Nut of fr

Nut of c

Nut of si Nut of c'

Cylinder Bolt of c

Flywheel

Bolt of cr

Oil sump

Oil sump

Droin plu

Bolt of ft

Bolt of oi

Socket ol

Oil pressr

Sporking

CLUTCH Connectir Generol

20 Bolt

foste

Page 24 of 238

metre), ond the

relotion of 1

kpm :9.806

Nm is'

opplicoble. When opplied to tightening

torques

of bolts ond nuts, use the relotion

10 Nm :

: 1 kpm.

d) The unit of power (output) tW'

(wott)

reploces the former "h.p."

(horsepower) ond

the relotion

of t h. p.:

735.499 W is opplicoble.

For procticol purposes,

o multiple of kW (kilo-

wott :

1,000 wotts) is used, i. e., t h. p. :

:0.736 kW.

e) The

unit of pressure "Po"

(poscol) or, in

proctice, MPo (megoposcol :

1,000,000 poscols)

or kPo (kiloposcol :

1,000 poscols)

reploces the

former "bor"

ond "kglcmz",

ond the following

relation is opplicoble: 1 MPo: 10 bors :1O.2

kg/cm2 (kp/cm2).

For current meosuring

of tyre

pressure etc., use the relotion: 100 kPo :

1 bor:

:1kglcm2 (kp/cm,) :1

otm.

1.10 GENERAL INSTRUCTIONS

With the exception of o few

speciol pro-

cedures or ossembly techniques

mentioned in

the respective section of

this monuol,

every

removol ond refitting (disossembly

ond re-

ossembly) should be governed

by the following

generol principles:

o) Use suitoble tools ond especiolly tubulor

box sponners which couse the leost domoge

to nuts ond bolt heods.

b) During disossembly note corefully how

the ports

hove been ossembled. This knowledge

is involuoble for correct reossembly.

c) Cleon ports

in trichloroethylene or tech-

nicol petrol.

They do not contoin substonces

(esoeciolly leod) which horm

the skin os motor

petrol does. Current bronds of seoling com-

pounds con be removed with denoturoted

ol-

cohol or scroped off. For o speciol

seoling

compound see the note ot the end of this

chopter.

Avoid contominotion of self-lubricoting

metol

beorings with ony degreosing

ogent os this

would unfovourobly offect their self-lubricoting

properties.

Cleon ports

of the broke ond clutch hydroulic

system with olcohor.

d) Lubricote

oll ports

moving on or in

eoch

other before their ossembly. Operoting lubri-

conts do not spreod eosily on dry surfoces,

the

ports ore not properly

lubricoted, ond friction

oreos ore opt to get

domoged. Coot the os-

sembled ports with the lubricont which is used

to lubricote them in operotion. When lubricoted

with oil, dip

the ports

in motor oil, the f luidity of which mokes

it

especiolly suitoble for

this

purpose. Use greoses

ond hydroulic f luid bronds

specified in the Toble

of Recommended Lubri-

conts.

e) Use new cotter pins

ond metol lock

woshers if you

ore not convinced of the perfect

condition of the old ones which could breok

ond leove the joints

unsecured. Moreover, there

is o risk

of the broken ports

domoging other

functionol ports.

f) Cleon new ontifriction beorings (boll,

rol-

ler, ond topered roller beorings) of preserving

greose using kerosene.

Preserving greose is not

suitoble for lubricotion ond it mixes bodly with

I ubriconts.

g) Some of the joints

hove to be tightened

with o moximum occurocy to the specified

tor-

ques listed in the previous

chopter.

h ) 'Ihe

permissible rototion unbolonce is spe-

cified for some of

the rototing ports,

usuolly in

gcm (gromcentimetres). A well boloqced port

con be stopped in

ony position

if it is

instolled

so thot no rototion resistonce

octs on it. With

the exception of dynomic boloncing, the ports

ore usuolly tested on on ouxiliory shoft ploced

on the

edges. The

unbolonced port

moves from

the deflected position

with its heoviest (i.

e.

unbolonced) port

downword. The

volue of un-

bolonce con be determined

when fostening

o weight corresponding to the permissible

un-

bolonce to the opposite side

of the unbolonced

port. lf the port

does not move when deflected

or if it moves with this weight downword; the

unbolonce is within the recommended limits.

The weight of the testing weight sholl be

de-

termined by dividing the volue of the permis-

sible unbolonce by the distonce of the weight

from the rototion

centre of the port.

i) Even slightly domoged seols ond pockings

must be reploced with new ones

Note: In the foctory,

the speciol seoling

compound

of the "Velvonton

C" brond is used for seoling

the engine reor

cover on the cylinder block, the

moting surfoces of the georbox housing holves,

ond the guide

of the clutch releose beoring.

This seoling compound is mode

on the bose

of o polyurethone

plostic ond it

corresponds to

"Hykemor", "Reineplost", "Curil

K" ond similor

compounds. lt con be removed from the ports

by scroping ond woshing with ocetone, butyl-

ocetone or chlorinoted solvents, for exomple

chloroform (trichloromethone)

ond corbon tetro-

ch loride.

24

Page 26 of 238

ENGIN

e

/\ e

.=

i

c)

-

'=

-

IJJ

3

.9

c

;

(n I

r

;

ir

33

46_

o

32. 5'

3t-

4/

ENGINE

Page 28 of 238

ENGINE

CYLINDER HEAD ASSEMBLY

Gr__53a- @ -54

a--&J

3oa

"3q;' 25

2t

66

/62

:> €}\

8- -60

)^\ 0-cl

I

38---\

64 ow,,, l\ '39

|

l2

Page 30 of 238

2.2-2.3

threods. Fill the etrgine with oil ond the cooling

systenr with on ontifreeze, ond

bleed them.

2.3 REASSEMBLING THE ENGINE

The reossembly procedure depends

on the

extent to which the engine hos been

dis-

rnontled. For better understonditrg, o

reossembly

of o conrpletely disnrontled

engine is described

in the following

porogrophs.

lnspection of

Cylinder Block

1. Clomp the thoroughly cleoned

cylinder

block into the MP 9-101 stond with the engine

corrier type MP 1-101 ond check it for complete-

ness -

see Chopter 2.6. Fit the

block with its

lugs on the engine corrier pins

ond use the side

bolt for ltolding it down.

DK 1188

Fig.2311- Cylinder Block Fostened on the

Assenrbly Stond by lVleons of the MP 1-10-l

Corrier

2. Rernove the pressure

relief volve, moke

sure thot the boll contoct {oces ore cleon,

ond

refit the cleoned volve. Forr

f itting o new volve

see Chopter 2.6.

3. Remove the cronkshoft beoring

covers ond

tlre i;ylinder block reor cover.

To Refit the Cronkshoft

4. Force the beoring shell lrolves with the

fingers into the cronkshoft beoring bores so thot

the shell lip snops home into the slot (cut-out)

in the block ond so thot the shells do not pro'

trude over the beoring surfoces for the beoring

covers, ond lubricote them with engine oil. Be

r;ure to fit shells motching the cronkshoft

i":urnols -

see Chopter 2.7.

5. Slip the oiled guide

ring on the cronkshcft

"vith oil grooves

pointing

toword the cronkshoft

'.veb ond {it the cronkshoft with the pressed-on

boll beoring (see

Chopter 2.7)

into the shell. 6.

Inscrt the

beoring shell

holf ir-rto

the cover

of the beoring No.-l

os described in

porogroph

4,

ond fit the cover with the

recess for the guide

ring turned outword. Proceeding from

the front

of lhe block, slip

on the next guide ring with

the oil grooves pointing

owoy from the block so

thot itJ

lip engoges ogoin into

the slot in the

cover. Coot the ring

with oil ond slip on the

thrust ring. Fit the MP -1'112

thrust collor on the

cronkshofi ond

tighten the

beoring slightly

using the belt

PrrlleY bolt.

7. Instoll the next

two beorirrg covers

corl'l'

plete with beoring shells

ond lightly

tighten l.he

cover nuts.

Press the cork

seol

into the

reo'r

cover moking

sure thot it

f its the groove

snugly

ond slightly bverlops the lower

seoting surfoce'

Before titting the cork seols,

compress them

for

o while in o vice to distort them. Insert the

distorted seols in the grooves

or gops between

the cover qnd

the cylinder block

where they

will expond onci provide

for perfect seoling.

lnsert tob woshers under

the nuts of the

beoring covers

ond while tightening the rruts

check their correct position so os

to enoble

o subsequent correct locking

of the nuts.

Fig.2.312 -

Meosuring Cronkshoft Ploy

1 -

Thrust collor, type

MP 1 112

2 -

Diol indicotor in o

speciolly mode yoke

8. Rotote the cronkshoft severol times ond

using o mollet top the covers ond both shoft

ends to ensure o correct bedding

of the covers

ond cronkshoft guide rings.

9. Tighten the belt pulley nut

to clomp the

thrust ring, ond

rotote ond force

off

the cronk-

shoft to

check its ploy. The

cronkshoft must

be

free to rotote but

without ony

noticeoble ploy.

lf there is o noticeoble ploy, recheck

its volue

ond odiust it by replocing the guide ring with

o new one. The

moximum ploy

should not ex-

ceed 0.10 mm, the recommended minimum ploy

being 0.04 mm. 10.

F

speciol

end onr Drive

suchr o

be turnr

cover. I

ever, tf

the cyl

speciol note in

11. Ti

the tigh

in the

covers. hoving

does no

must ro

Then lo,

woshers

ond nut

To Refil

12. R

greose i

it with i

o flywhr

engine,

with rec

under tt

Chopter

bending

shoft og

powl ins

For flyw

Fig.2.3l3

Using thr

Screw

holes, for

con be ur

further o1

the hondr

30