mirror SKODA 120 LSE 1980 Workshop Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 1980, Model line: 120 LSE, Model: SKODA 120 LSE 1980Pages: 238, PDF Size: 47.09 MB

Page 54 of 238

6.

Complete the pump

ossembly by fitting

the

Stouffer lubricotor filled with

the recommended

greose.

2.15 ROCKER SHAFT AND ROCKERS

Assembly (on

Skodo 105 engine)

1. Instoll the lock ring, ploin

wosher, ond

spring wosher on the ro6ker shoft

with both

ends plugged.

Smeor the shoft with oil, fit the

rocker (with

its orm with the thrust foce de-

flected toword the next ossembled ports),

the

shim, the rocker support, ond the other

orm

def lected toword the support, i. e. the complete

rocker unit of cylinder

No. 1.

2. Then slip the spring,

the rocker, the sup-

port, the shim,

ond the next rocker, i.e.

the

complete rocker unit of cylinder

No.2, on the

shoft.

3. Threod on the spring ond, using the mirror

orrongement of the ossembled

rocker units,

instoll the rocker

units of the remoining

two

cylinders. Use o lock ring supplemented

with

o ploin

ond o spring wosher

to lock the os-

sembled ports

in position.

The rocker support of the cylinder No.4 must

be provided

with on oil hole

to provide

for the

supply of oil to the rocker shoft.

4. Compress

the springs

by holding down the

rocker orms ond lubricote

oll loterol contoct

surfoces with oil.

Assembly (on Skodo 120 L

ond 120 LS engines)

The rocker shoft is provided

with two od-

ditionol rocker supports fitted from

the outside

of the rocker units (the

shoft is longer), re-

plocing woshers obutting

on the lock rings.

For

the rest, the ossembly is identiccl

with the pro-

cedure described in porogrophs

1 to 4 obove.

NJote: Rocker orms

on the Skodo 120 LS en-

gine ore shorter (18.5

mm) thon those on the

Skodo -120

L ond Skodo 105 engines,

in order

to obtoin o higher rotio.

Disossembly

Remove the lock ring from the shoft

end ond

strike off the

entire volve nocker geor

from

the

shoft.

2.16 CYLINDER HEAD, VALVES

AND

SPRINGS

The cylinder heod is o costing of speciol grey

cost iron. The volve seots ond guides

ore cost

ond mochined directlv in tlre heod. The volves ore of different

diometers, the intoke volves

being lorger. Outer (exhoust)

ports

ore single,

oll remoinlng ore doubled, i.e. bifurcoted

ond

bronching to two volves in odioining

cylinders.

The centre exhoust port

bronches to the cyl.

inders No.2 ond 3, the neighbouring

intoke port

to the cylinders No. 1 ond 2, ond No. 3 ond 4.

The cylinder heod con be hondled

in the cor os

o unit. Of the individuol

iobs, only

the reploce-

ment of volve springs,

cotters, ond cylinder

heod bolts con be corried out with the engine

in. position in the cor. For oll the remoining

iobs, the

cylinder heod hos to be removed

from

the cor.

To remove

the volve springs,

screw out

the

sporking plugs ond, using o tommy

bor with

o curved end (steel

bor of obout 5 mm dio-

meter), broce

the volve to prevent

it from

sliding down into the combustion

chomber.

To Remove

Cylinder Heod from Engine

1. Let

the engine cool down before removing

the cylinder heod to preclude

worping of its

beoring surfoce.

2. Droin

the coolont into o cleon vessel (see

Chopter 15.13), detoch oll ports

connecting the

cylinder heod to the vehicle,

ond remove

oll

ports which ore likely

to obstruct the removol.

3. Remove the oir cleoner,

lift owoy

the

cylinder heod cover, ond remove

the nuts ond

bolts holding down

the cylinder heod (on

en-

gines of Skodo 120 L

ond 120 LS cors, two

bolts olso hold down

the end rocker

shoft sup-

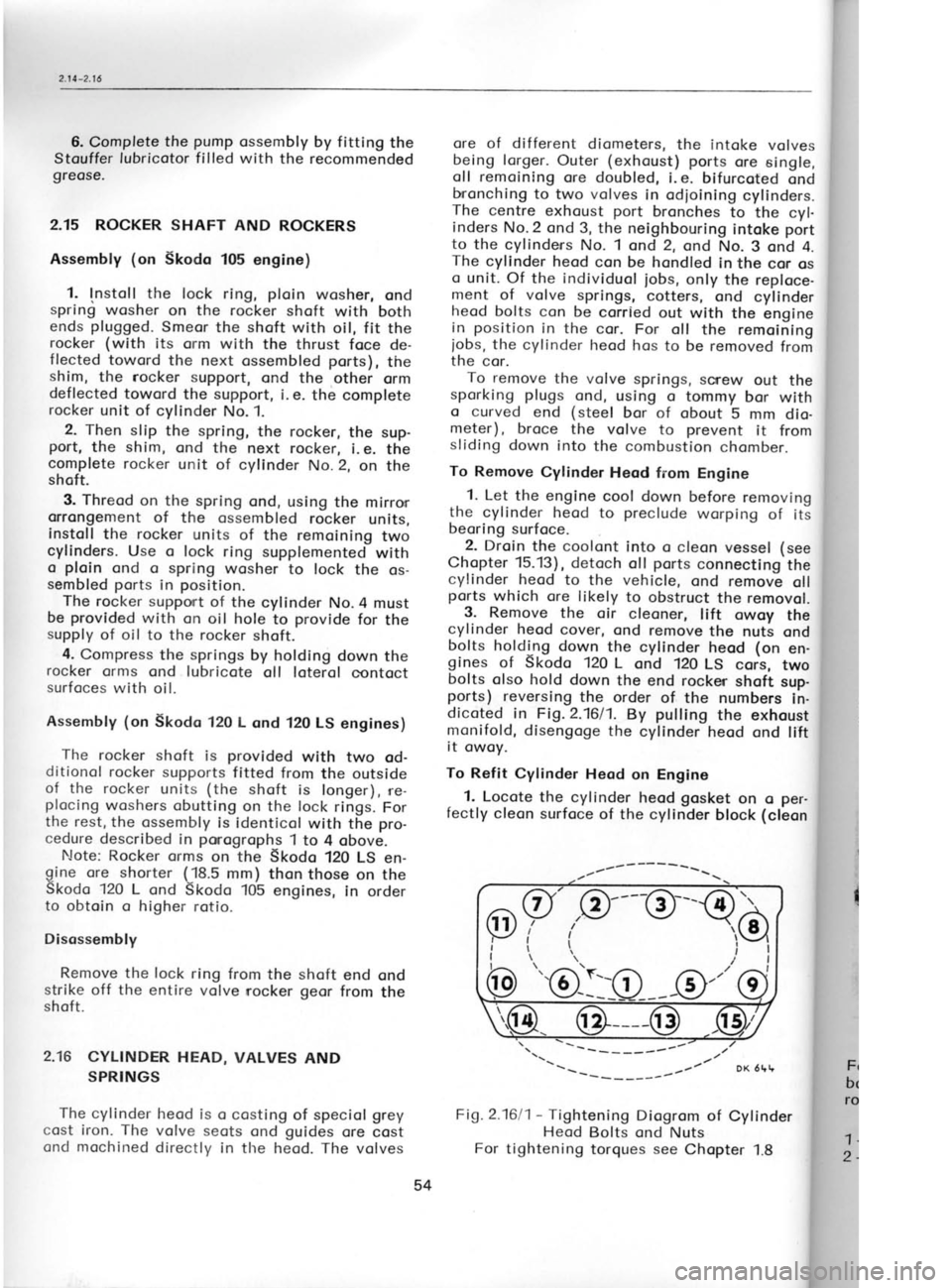

ports) reversing the order of the numbers

in-

dicoted in Fig. 2.1611.

By pulling

the exhoust

monifold, disengoge the

cylinder heod ond lift

it owoy.

To Refit Cylinder

Heod on Engine

. 1.

Locote the cylinder heod gosket

on o per-

fectly cleon surfoce of the cylinder

block (cleon

Fi1.2.1611- Tightening Diogrom of Cylinder

Heod Bolts ond Nuts

For tightening torques see Chopter

1.8 the

cylinc

the oilwo,

structed c

Releose

once odjur

heod. lf nr

the rocker

2. Swin<

down the

porogroph

opply the

liminory o

the sequ€

(Fig. 2.16/

shoft suppr

3. Adjus

ter 2.13,

re

cleoner, rer

tighten oll

Cylinder Hr

Disossem

heod on o r

o support i

it does

not

o iob from

t

An exomple

1. Remove

the cosing

control, end

geor ofter

supports.

Fig.2Je

For holding

c

bolt M 8 scrt

rocker-shoft st

1 -

MP 1-113

v,

2 -

MP 1-114

v

Itl

I

I

/\.

-

( 3 r--{ 4)

\-/

\II

l

/

,/

t___v'

?,3

"'@-:lO

54

Page 175 of 238

I

I

I

s

I

I

I

t

(

(

t

l

,

t

T c

R

L D

v Ir

1' 2

3

orotely

(

screen the other one) . With lef t

directionol heodlomps,

the borderline deviotes

towords the other

side.

lf the heodlomps ore neorer to the woll thon

the soid

5 metres, decreose the meosure indi-

coting the

deviotion of the light ond

dorkness

bordeiline from the

height of the heodlomps

obove the ground in the

direct proportion to

the

decreose of

tfre distonce, for

exomple when

plocing the cor 2.5 metres

from the woll, de-

creose the deviotion bY holf.

Light proiections "A"

ond "B"

correspond to

the spocing of heodlomPs on

the cor ond they

hove the following dimensions:

Heodlomps, dio. 160

mm 1,030

mm

Duol heodlomps, dio.

130 mm 1,114

mm

Auxiliory heodlomps, dio.

130 mm 790 mm

When odjusting the heodlomps, the cor must

be empty ond the

tyres must be correctly in-

floted. Hologen heodlomps should

not be left

switched on for too long o period os they build

up heot if not cooled by heod-on

oir blost when

driving. For lhe odiustment of

heodlomPs ore intended

screws in their fromes. The screws

ore occess'

ible ofter the removol of the side ports

of the

grille. Remove the copscrews of the corners

ond push

the grille

oside.

Heodlomp Assembly

o) The fundomentol fostening

Port of

circulor

heodlomps is the

so-colled support plote

(rec-

tongulor plote)

ottoched to the bodywork by

copscrews with lock woshers. The

heodlomp

housing is bolted to this suPPort plote by bolts

with nuts ond lock woshers. One of the bolts holds

down olso the

lug of the eorthing coble-

The inner frome,

forming the

odiusting element

of the heodlomp insert, is ottoched

to the

hous'

ing by two speciol odiusting screws

ond two

tension springs. The heodlomp insert

is ot'

toched to

the bezel by

three copscrews.

There is one left-hond ond

one right-hond

support plote.

Both should

be mounted with the

oriow ond the word "TOP"

upwords. With

the

exception of the ouxiliory heodlomps, the

heod'

lomp inserts ore different for

the left-hond ond

the right-hond troffic. The leods

enter the hous-

ing through o

rubber grommet.

When r-eplocing the insert, remove

the bezel

copscrews. After

hoving fitted o new insert, it

is necessory to reodiust the

heodlomps.

Front Direction Indicotors

The right-hond ond

left-hond direction indi-

cotors ore undisossembloble units

(the

lomp

fostening sockets (locks) ore

mounted in the

direction towords the cor longitudinol centre

line). They ore fostened to their brockets in the

bumper with o nut ond o ploin ond

o lock

wosher.

Toil Lomp Cluster

The lomp cluster is on undisossembloble unit

fostened to

the bodywork by

nuts with ploin

woshers ond the

respective bolts.

Scrope off

the enomel ot the

top bolt used for holding

down the eorthing coble.

For the sequence

of the individuol lomps ond

their bulbs see Fig. 13.111 ond the respective

porogroph on bulbs.

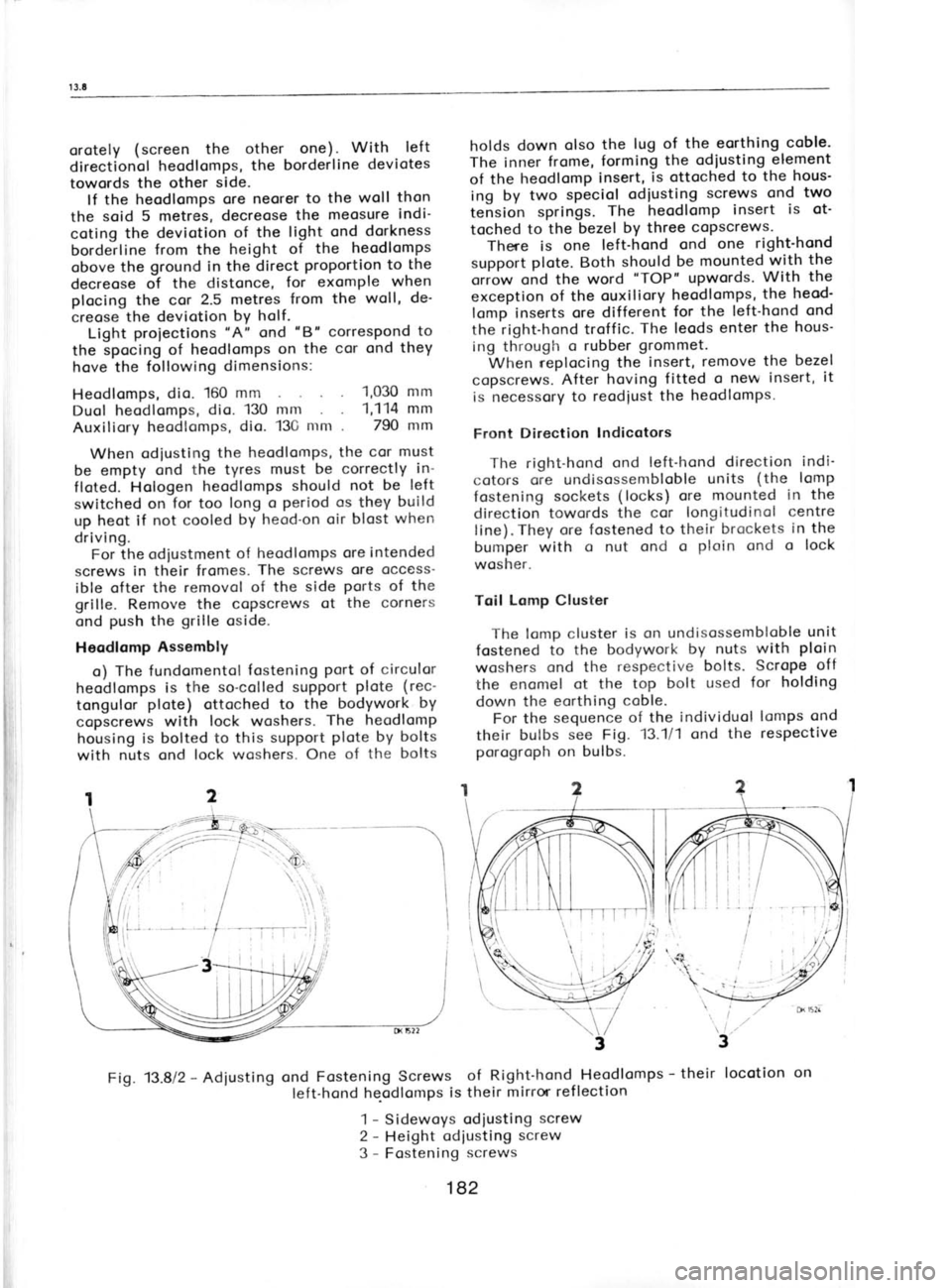

Fig. 13.812 -

Adiusting ond

Fastening Screws of Right-hond Heodlomps -

their locotion

on

left-hond he-odlomps is their

mirror ref lection

1 -

Sidewoys odiusting screw

2 -

Height odiusting screw

3 -

Fostening screws

182