engine SKODA 120L 1980 Owner's Guide

[x] Cancel search | Manufacturer: SKODA, Model Year: 1980, Model line: 120L, Model: SKODA 120L 1980Pages: 238, PDF Size: 47.09 MB

Page 154 of 238

r 2.1-t 2.3

I

I I

I

Dissssembly

ond

Reossembly of Pedols

This is usuolly not necessory. The pedols

con

be disossembled ofter removing the oxiol screw

in the pedol

pin

ond slipping off the return

spring. Do not remove the switches if it is not

obsolutely necessory -

see odiustment. On re-

ossembly, lubricote

the pedol

bush with lubri-

coting greose

of the some brond os used for the

steering linkoge -

see Chopter 7.5, por.3.

Pedol Free Trovel

Adiustment

Adjust the free

trovel of pedols

ossembled

with moster cylinders so thot the pedol piston

rod hos o

cleoronce of 0.5

to 1mm

when beoring

ogoinst the piston

heods of the

moster cylin-

ders. The free trovel of the pedol pod

should be

from 3 to 5 mm. lt

con be odiusted by rototing

the eccentric pin

on the pedol

brocket -

see

Fi9.12.111.

For the odjustment of the broke pedol

with

broke booster ond/or levelling of the broke

pedol with the

clutch pedol,

see Chopter 9.6 -

Ad justment.

Adiustment of Switches The switches con be

moved in

the ellipticol

holes of the brocket ofter loosening the fosten-

ing copscrews with ploin

woshers under their

heods. A pocking piece

should be slipped

under

the switch of the broke pedol

trovel worning

light ond the powl

of the switch pin

should be

held down under the fostening copscrew.

Ad just

the stop-light switch

so thot it

switches on the stop lights ot o pedol

trovel

of 10 to 15 mm meosured on the centre of the

pedol pod.

Adiust the pedol

trovel signolling switch so

thot the pushed-in

side push-button

pin

is

re,ecsed ot o pedol

trovel of 100 to 110 mm

mecsured on

the centre of the pedol

pod.

Press

the push

button into

the switch ofter hoving

completed the

odiustment.

12.2 ACCELERATOR PEDAL AND CABLE

The occelerotor pedol

forms o unit with its

self-lubricoting beoring ond the lever.

lt is

bolted to the f

loor tunnel. A coble possing

through the tunnel is ottoched to the pedol

lever ond the reloy

lever on the engine by

meons of clomps- The coble is protected

by

o Bowden tubing.

Pedol Removing ond Refitting

1. Loosen the clomp holding the coble on the

engine-mounted reloy lever. 2.

Remove the copscrews holding

down the

becrring with the pedol,

depress lightly the

pedol, ond lift it out of the f loor

tunnel together

with the beoring. 3. Disconnect the pedol

from the coble ofter

ioosening the clomp.

Removol ond Refitting of Bowden Tubing

ond Cqble

The Bowden tubing is

fostened to

the brocket

irr the floor tunnel by

meons of circlips. After

their removol, pull

the Bowden tubing inside

the cor. On ref

itting the tubing, lubricote it with

o low-viscosity oil (of

the SAE 20

closs). lt hos

been lubricoted with greose

in the foctory.

Fit

the clonrps so thot their longer ports (from

the

screw to their end) ore on the side of the

I evers.

Accelerotor Coble Adiustment

Adjust the coble so

thot it is not

excessively

tensioned or too slock. Loosen the clomps on

the engine side of the coble, move slightly

the

clomp toword the reloy lever,

ond tighten the

screws of the clomp.

12.3 GEAR SHIFT LEVER

AND LINKAGE

The geor shift mechonism consists of two

units: the geor

lever with its housing ond oc-

cessories, ond the geor

shifter rod

ond the

shifter lirrk with joint

(ot the georbox)

for

domping the vibrotion of the power

pock

tronsnritted to the geor

lever.

Removing Geor Lever

Housing ond Link

1. Lift owoy the mot from the floor tunnel in

the front ond reor comportment. lf seporote,

remove the individuol floor mots ofter hoving

prised out their clips with o screwdriver or

o similor tool. lf o one-piece floor

covering is

used, remove the door sill strips

on one side,

tip the seot, ond bend over the

floor covering.

2. Remove the geor

lever housing copscrews

ond prise

out the lid (next

to the clip) between

the seots. Proceed through the

operture to dls-

connect the bolted connection of the link with

the housing shifter rod.

3. Lift

owoy the housing with the lever

through the operture. Swivel the lever so thot

the shifter rod

does not protrude

over the

housing beoring thus obstructiong the removol.

4. Usuolly it is not necessory to remove the

geor shift link from

the cor. lf

obsolutely necess-

ory, the link con be

disconnected only ofter

162

Page 156 of 238

12.6-12.f

2. Proceeding fronr below, rernove

the fuel

tonk sheet guord

ond the guord

of the cooling

woter pipes.

3. Disconnect the pipe

of the clutclr hydroulic

line from the clutch releose hose brocket.

4. Screw out droin plugs

to droin fuel from

the fuel tonk ond ot the some time disconnect

the fuel hose from

the fuel pump.

After com-

pleting the droining, reinstoll the droin plugs

(screws) with their seoling rings.

Disconnect the tronsverse hose connecting

both sections of the fuel tonk ond stop the

open

pipes with rrubber

plugs (to prevent

the remoin-

ing fuel spilling over your

honds ond clothes

when lifting

the tonk owoy).

5. Disconnect the geor

shift link ond the

speedometer drive from the georbox -

see Chop-

ter 4.1, por.9.

6. Detoch cobles from the hond broke rocker

ond pull

them out from under the cor -

see

Chopter 9.8. 7. Droin the cooling system -

see Chopter

-15.13.

Disconnect the moin woter line in

the

rniddle of the cor. Disconnect the pipes

from

the engine (from

the hose of the thermostot

ond the pump

connecting hose) ond remove

the

pipes -

see Chopter 11.4.

8. Disconnect the hose of the fuel

tonk from

the fuel filling pipe, ond, in the upper port,

the

hose of the fuel filling line vent pipe.

9. Sever the electric connection of the fuel

level gouge

floot system under tlre right-hond

I eor seot.

10. Use o

iock to support

tl're georbox

ond

loosen tlre connection of the georbox

cross

beorer with the bodywork.

11. Loosen the copscrews fostening the fuel

tonk to the bodywork ond lower the

iock to tip

the power

pock.

Retoin the fuel tonk while ne-

nroving the copscrews, move the tonk bock-

words ond down, tip it down ond forword, ond

remove it in

this direction. 12. Should

the pipes

of the broke system ob-

struct tlre removol of the tonk, disconnet them

from the finol drive ond from broke hose brock-

ets.

Refitting Fuel Tqnk in Cor

Reverse the procedure

of the tonk removol.

Fill the cooling system with the recommended

coolont ond bleed it, odjust the hond-broke ond

the occelerotor cobles. Bleed the clutch hy-

droulic line

ond olso the reor wheel brokes if

the hydroulic broke line hos

been disconnected.

Tighten properly

oll joints

ond connections,

fosten the cobles, links, ond pipes

obsenving

their correct orrongement -

see Chapter 12.7.

Fuel Line ond lts Accessories

Filling pipe.

This is q

sheet -

metol tube ot-

toclred to

the hose on the fuel tonk by meons

of o clip, ond to

the bodywork by two holders

with o copscrew ond both o spring ond o ploin

wosher. lt posses

througlr o bushing in the side

of the bodywork. Venting line. The hose is ottoched to the fuel

tonk filler neck in the upper port

of the tonk

ond to the filling pipe

by meons

of clips. For

its possoge

through the bodywork stiffener,

see Fig. 12.714. For clips ond their tightening see

Fig. 11.4/1.

The oir-feed hose

is slipped on the filling

pipe outlet ot

the fuel tonk neck; its

loop is

inserted under the domping lining of the body-

work, ond its other end is inserted into the hole

of the filling pipe

socket bushing.

Filler neck cop -

see Chopter 1.5.

Fuel gouge -

see fuel reserve signolling

switch, Chopter 13.17.

12.7 ARRANGEMENT

OF PIPELINES, LINKS,

AND CABLES UNDER THE

CAR

The routing, fostening, etc., of pipelines,

links, ond cobles is described in

chopters deol-

ing with these ports.

They oll leove the floor

tunnel under tlre fuel tonk to

be covered by

o guold

held in position

by self-locking nuts

with ploin

woshers. The following

illustrotions

show their correct orrongement which hos to

be mointoined if incorrect function or domoge

is to be prevented.

lt is imperotive to ensure

free movement ond swing

of the geor

shift

link.

Secure the correct position

of oll ports

under

the fuel tonk by clips which hove

to be pro-

vided with sleeves preventing

domoge to Bow-

den tubings, etc. The overoll orrongement is

shown in

Fig. 12.712 ond 12.713.

Fig.

12.611- Fuel Tonk Droin

Plugs

164

Page 158 of 238

nolly

emerges into spoce under the floor toword

the georbox.

lt is ottoched to the speedometer

by meons of o union nut ond to the georbox

by

o sleeve ond o screw.

It is lubricoted

with oil from the georbox

which creeps olong it due to copillory elev-

otion" Lubricote it with engine oil of o lower

viscosity dripped into its sheoth only if the

lubricotion by creeping is inodequote. When refitting

it in position, put

it into the

cor from the front, connect its

both ends, ond

then orronge it so thot it does not form ony

shorp bends ond is

not too tout. The speedo-

meter con be disconnected ofter removing

the

instrument ponel,

ond removed by pulling

it in

forword direction.

For the speedometer drive shoft possoge

under the ffoor refer to Chopter 12.7.

166

Page 165 of 238

'i

iiiI 14. Fuse box

Centrol connection of conductors -

do not

seporote them from the bunch!

15. Direction indicotor switches, dip switch,

and horn switch

eight-pole terminol

boord

six-pole terminol boord

16. Porking light switch ond high beom feeder four-pole terminol boord

17. Switch box femole connectors 5.5 with symbols "15",

"30", ond '50"

to be

connected to symbols

"15u, "30', ond '50"

on the switch box

18. Instrument ponel

ten-pole terminol boord

six-pole terminol boord

eorthing coble with lug

'19. Heoter switch

four-pole terminol boord

20. Switch of disobility lights

six-pole terminol boord

21. Door switch, right-hond

green -

femole connector 5.5

22. Dome light,

right-hond

green -

femole connector 5.5

red -

femole connector 5.5

23. Stop switches

forked (yellow) -

femole connectors 5.5 .

red -

femole connector 5.5

white -

femole connector 5.5upper ond lower

switch

upper switch lower switch

24.Fuel gouge block -

femole connector 5.5

yellow -

femole connector 5.5

blue -

femole connector 5.5

to be connected to the respective pins

(blodes) of the some colour of the fuel gouge

25. Storter motor, reversing

lomp switch

conductors with lugs stater motor moin

terminol boord

storter motor

control switch

green -

femole connectors 5.5 heodlomp switch

26. Oil pressure

gouge,

thermometer, corburettor

iet seporotor

green -

femole connector 5.5 yellow

-

femole connector 5.5

green - telethermometer

primory element

femole connector 7.

corburettor

iet seporotor

27. lgnition coil, voltoge regulotor, olternotor,

tochometer

conductor with femole connector ond

bronching lug

femole connector-regulotor terminol 15/54

lug -

ignition coil terminol 15

blue -

femole connector 5.5,

symbol "R"

. regulotor terminol "R"

yellow -

femole connector 5.5,

symbol "M"

regulotor terminol "M"

blue -

connector "R"

. olternotor terminol "R"

yellow -

connector "M".

olternotor terminol "M"

lug terminol "+B"

conductor with

lug ignition coilterminol "1"

(tochometer operotion

)

28. Toil lomp cluster, right.hond

yellow -

femole connector 5.5 toil light

block -

femole connector 5.5 direction indicotors

red -

femole connector 5.5 stop light

green -

femole connector 5.5 reversing lomp

29. Licence plote light

conductors with femole connectors 5.5

30. Toil lomp cluster, left.hond

se point

28.

b) Connection

of free conductors

1. Storoge bottery

bottery coble positive

(*)

terminol -

storter motor

bottery eorthing strip negotive (-)

terminal -

bodywork (eorthing conductor)

2. Engine engine eorthing strip (fostening

lug) -

engine cross beorer (eorthing conductor)

3. Distributor speciol coble from distributor to

ignition

coil; end with interference suppressing

terminol to distributor

coble from distributor to ignition coil

terminol "1"

cylindricol

(pin)

connector

pressure gouge172

Page 169 of 238

L

i g)

Excitotion of the olternotor by o current

supply outside the cor is not permitted.

Agoin the semiconductors would suffer.

h) A blown chorging worning lomp must be

reploced immediotely with o new

one. Other-

wise correct excitotion of the olternotor is

not ensured. Use o new lomp of

the some

roting (or input), i.

e., 1.5

to 2 W.

i) Be sure thot there is

o perfect

electricol

connection on the connecting terminols ond

thot the olternotor

ond regulotor

ore properly

eorthed.

i) The

olternotor is oeroted, open. Therefore

toke core when woshing the cor thot woter

or cleoning ogents do not get

into it through

the venting holes.

Removing the Alternqtor

1. Disconnect the bottery.

2. Disconnect the olternotor leods. lt will be

helpful to remember the colour of one conductor

ond its connection for reinstollotion.

3. Remove oll ports

holding the olternotor on

the engine, ond lift owoy the olternotor.

Reinstolling the Alternotor

1. Cleon oll mounting surfoces.

For the olter-

notor mounting, see Chopter 2.3, por.42.

2. With the bottery

disconnected, insert the

conductors into the respective

connectors "M,,

ond "R"

(the conductors beor the some sym-

bols), ond fosten the remoining leod with o nut.

3. Reconnect the botterv. Alternotor

Disossembly -

Repoirs

1. Screw off the belt pulley

nut ond remove

the belt pulley

ond fon.

2. Lift the brushes with o hook proceeding

through the holes in the

commutotor end

shield

ond hold them in the lifted position

by wires

inserted into the shield through dio. 3 mm holes

under the terminols uM'

ond "Ru.

3. Mork the mutuol (relotive) position

of the

commutotor ond drive end shields ond seporote

the qlternotor

ofter hoving removed its clomping

bolts. The drive end shield remoins connected

with the stotor.

This disossembly will give

occess to the

brushes ond some

of the diodes. All other

iobs,

with the exception of the renewol of the beor-

ing, should be done by experts in speciolized

repcir shops -

see the note supplementing the

following porogrophs.

Alternotor Reossembly

1. Insert the circlip into the becring bore

in

the commutotor end shield.

2. Fit the drive end shield with beoring on

the rotor shoft.

3. Assemble the stotor with the rotor ond the

commutotor end shield. 4" Tighten the olternoior with clomping bolts

ond check the rotor for free rototion while

tightening the bolts.

5. Slip the spocer on to tlre shoft,

top the

key in position,

fit the fon ond belt pulley,

ond

tighten the entire ossembly using the nut with

spring wosher.

6. Pull out wires from the commutotor end

shield which hove been used to hold

brushes

in their lifted position.

Replocement of Beorings

The used beorings ore fullyclosed ond seoled,

ond they hove been filled in the foctory

with

lubricont to lost through their entire service life.

1. Pull the beoring off the rotor

using o suit-

oble puller.

When ref itting the beoring, press

it

on to beor on the shoft

collor-

2. Before removing the drive end shield

beor-

ing, f irst drill off the heods

of the flonge rivets

ond then drive the beoring out from

the outer

side of the drive end shield using o suitoble

mondrel (drift).

On reossembly,

close the beoring with the

flonge ond rivet the flonge to the shield.

Replocement of Diodes

The use of the removoble

diode block with

the individuol

corriers of the so-colled positive,

negotive, ond ouxiliory diodes, focilitotes con-

siderobly the replccement of ony defective

176

Fig.133la

-

Alternotor -

Sectionol View

Page 171 of 238

junction

with the olternoto,r occording to

Chop-

ier 13.3 ond mointoining

o constont voltoge of

tlre power

supply set within the

entire ronge

of

service speeds.

Tlre voltoge regulotor

is instolled orr the body

cross beorer, to

the right of the engine ond

beside the ignition coil.

To focilitote hondling

of its leods' especiolly

the occess to their

connections, it

is recom-

rrrended to remove the regulotor fostening

screws. For disconnecting procedures,

see

Chopter 13.3 "Alternotor

lnstollotion ond Gen-

erol lnstructions".

DK 1565

Fig.13.411- Internol

Wiring Diogrom of

Alternotol with

Voltoge Regulotor ond

Outer

Connections

Altenrotor: B, R, M -

olternotor outlets

f -

olternotor phose

windings

m -

olternotor field winding

D1,2,3, 4, 5, 6 -

moin diodes

D7, 8,9 -

olternotor ouxiliory diodes

D10 -

olternotor choking diode

Voltoge regulotor:

R, M, 15/54 -

regulotor outlets

reg -

regulotor tension winding

Rk -

boloncing resistor

Ro -

protective resistor

Rr -

odiustoble resistor

Kr -

regulotor contocts

Outer connections: K -

worning lomp (1.5

W)

S -

switch (switch

box)

B -

bottery

Checking Voltoge Regulotor

on Cor

The regulotor operotion con be offected by

loosened connections ond on imperfect eorth- ing.

lf the wsrning lomp does not go

o.ut when

driving, i. e., if it glows

ot increosed engine

speed brightly or dimly,

or if it does not stort

glowing ofter stopping

the engine ond

o new

iurning of the ignition key in

the switch box,

the voitoge regulotor

is probobly

foulty. Another

symptom of o regulotor

foilure is

o poor

chorg-

irrg of tlre bottery or its

overchorging.. lf there

is nothing wrong with the regulotor, check the

reguloted voltoge over the regulotor which

slrould reod 13.2 volts ot the

minimum ond 14.8

volts ot the moximunr. This check

in the

cor

is only tentotive ond only

o check on

the test

bench'con be considered os definite ond

bind'

i ng.

Electricol Adiustment

The voltoge regulotot- should be tested

ond

odjusted only on o test bench

in o connection

slrown in Fig. 13.412.

At o lood of some

2

onrperes, the checked

voltoge should correspond to

volues specified

in the column "Checking".

lf the checked volt-

oge is within the specified ronge, do

not odiust

the regulotor. Othenwise odiust it to the volues

specified in the column "Adiustment".

lf woter

evoporotes obnormolly from the bottery, odiust

the voltoge regulotor to the bosic volues of

"Adiustment" utilizing the lower section of

the

toleronce zone.

Fig.13.al2 -

Wiring Diogrom of

Regulotor Tested

ond Adiusted on

o

G -

olternotor

REG -

voltoge regulotor

A -

ommeter

V -

voltmeter

S -

switch

R -

lood resistor

B -

bottery DK

1566

Voltoge Test Bench

178

Page 173 of 238

I

I

t

b

c ll

e

c

tl

d n

tN'

>

\'

J I

(Il

qt3

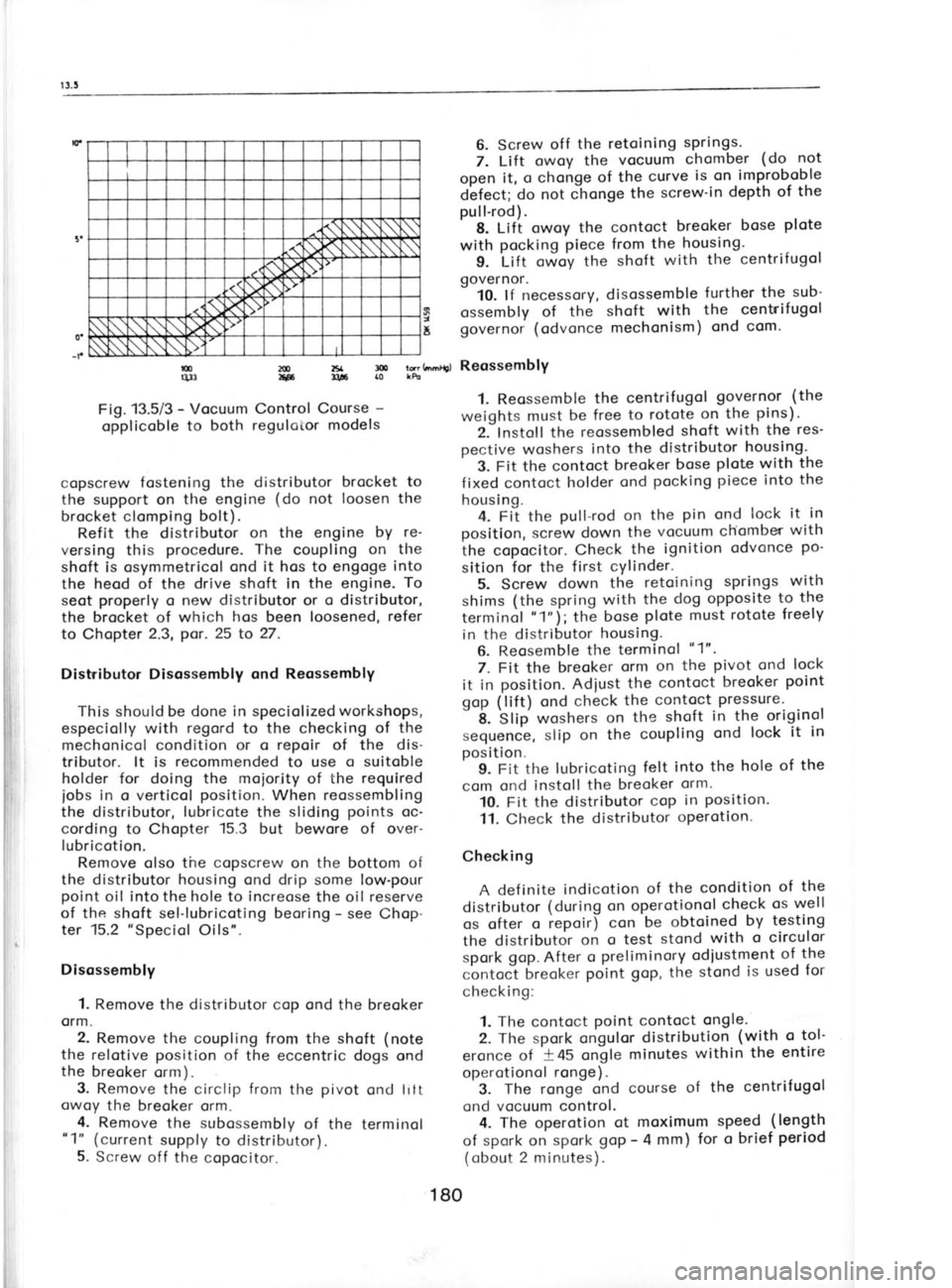

Fig. 13.5i3 -

Vocuum Control Course -

opplicoble to both

regulotor models

copscrew fostening the distributor brocket to

the support on the engine (do

not loosen the

brocket clomping bolt).

Refit the distributor on the engine by

re-

versing this procedure. The

coupling on

tlre

shoft is osymmetricol ond it hos to engoge into

the heod of the drive shoft in the engine. To

seot properly

o new distributor

or o distributor,

the brocket of which hos

been loosened, refer

to Chopter 2.3, por.25

to 27.

Distributor Disossembly ond Reossembly

This should be done in speciolizedworkshops,

especiolly with regord

to the checking of the

mechonicol condition or o repoir

of the dis-

tributor. lt is recommended

to use o suitoble

holder for doing the moiority of the required

iobs in

o verticol position.

When reossembling

the distributor, lubricote

the sliding points

oc-

cording to Chopter 15.3

but bewore of over-

lubricotion.

Remove olso the copscrew

on the bottom of

the distributor housing ond drip some low-pour

point oil into the hole to increose the oil reserve

of the shoft

sel-lubricoting beoring -

see Chop-

ter 15.2 "Speciol

Oils".

Disossembly 1. Remove the distributor cop ond the breoker

orm.

2. Remove the coupling from the shoft (note

the relotive position

of the eccentric dogs ond

the breoker

orm).

3. Remove

the circlip from

the pivot

ond litt

owoy the breoker orm.

4. Remove

the subossembly

of the terminol

"1" (current supply to distributor).

5. Screw off the copocitor. 6. Screw

off

the retoining springs.

7. Lilt owoy the vocuum chomber (do

19t

open it, o chonge of the curve is on.improboble

d'efect; do not chonge the screw-in depth

of the

pull-rod).

' 8. Lift owoy the contoct breoker

bose plote

with pocking piece from

the housing.

g. Litt owoy the shoft with the

centrifugol

governor. -

10. lf necessory, disossemble further

the sub'

ossembly of the shoft with the centrif

ugol

governor (odvonce mechonism) ond

com.

l?;h.',0, ReossemblY

1. Reossemble the centrifugol governor

(the

weights must be free

to rotote on the pins).

2. lnstoll the reossembled shoft

with the res'

pective woshers into

the distributor housing.

3. Fit the contoct breoker bose plote

with the

f ixed contoct holder ond pocking

piece into the

housing. 4. Fit the pull-rod on

the pin

ond lock it in

position, screw down the vocuum chiomber with

the copocitor. Check the

ignition odvonce po-

sition for the first cYlinder.

5. Screw down

the retoining springs

with

shims (the

spring with

the dog opposite to

the

terminol "1"i;

the bose plote must

rotote freely

in the distributor housing.

6. Reosemble the terminol "1".

7. Fit the breoker orm

on

the pivot

ond lock

it in position. Adiust the contoct breoker point

gop (lift) ond check the

contoct

Pressure'

"

if. 'Stip

woshers on

the shoft in

the originol

sequence, slip on the coupling ond

lock

it in

position^ 9. Fit the lubricoting felt

into the hole of

the

com ond instoll the breoker orm.

10. Fit the distributor cop

in position.

11. Check the distributor operotion.

Checking A def inite indicotion of the condition of

the

distributor (during on operotionol check

os

well

os ofter o

repoir) con be obtoined by testing

the distributor on

o test stond with

o circulor

spork gop.

After o preliminory

odiustment of

the

contoc-t breoker point gop,

the stond is

used for

check i ng:

1. The contoct point

contoct ongle.

2. The spork ongulor distribution (with o

tol-

eronce of -+45

ongle minutes within

the entire

operotionol ronge).

3. The rongJ ond course of the

centrifugol

ond vocuum control. 4. The

operotion ot

moximum speed (length

of spork on spork goP -

4 mm) for o

brief period

(obout 2 minutes).

180

t

5

2tD zsa !l!

F llti

rc

Page 179 of 238

(

1

z

Strike the

slip-over ring off the circlip

(towords the motor windlng). Open the circlip

ond pull

it off the shoft together with the re-

leosed ports.

8. lf necessory, re-turn the commutotor ond

scrope or mill out the insulotion between the

lominotions. "Mikonit"

should be 0.4 to 0.8 mm

below the octive surfoce.

Note: The

switch connot be further token

opat. lf

defective, lt hcs to be reploced with

o new one. When cleoning ports

of the storter

motor, do not dip the ormoture or the pinion

with the idler into petrol

or onother degreosing

ogent.The some opplles to the end shieldswith

beorings. By dipping them in o degreosing

ogent, the beorings become procticolly

worth-

less"

Storter Motor Reossembly 1. Lubricote the hellx of the ormoture shoft

with greose -

see Chopter 15.2 'Lubriconts

of

foreing mokeu ond fit the pinion

with the idler

ond the slip-over ring in posltion.

Fit the

circlip

into the groove

in the shoft, ond drive the slip-

on ring over it. The pinion

with the idler must

move freely olong the shoft.

2. Slip the respective

woshers on the shoft in

their originol sequence (corrier

ring, distonce

ring, fibre ring, distonce ring) ond insert the

ormoture with the engoging lever

into the drive

end shield. 3. Suspend the switch

ormoture into the

pre-engoging lever ond bolt down the switch

lightly. Fit the lever pin

into the drive

end

shield ond lock it in position

with the retoiner.

4. Tighten the copscrews of the switch

ond

fit the stotor on the drive

end shield.

5. Instoll the respective

woshers into

the

commutotor end shield in

their originol se-

quence (the dished wosher with its centre

focing the shield, then the ploin

wosher, the

toothed wosher, ond the drive wosher).

6. Fit the commutotor end shield with lifted

brushes on the shoft (in

the position

occording

to the recess

for the excitotion outlet ond the

notch) ond screw in the clomping bolts.

7. Instoll the brush interconnecting strip ond

bolt it down together with the field winding

outlets to the positive

brush holders, lower the

brushes. 8. Fit the Insuloting strip in position

ond bolt

down the cover. 9. Test the storter mottr.

Diognosing Storter Motor Defects in Cor

o) lf the storter motor refuses

to operote, look

first for on interrupted connection between

the bottery ond

the storter

motor, the engine

eorthing ond the storter

motor, or the engine

eorthing ond the bottery. lf these connec-

tions ore in order (current

flows to the ter' DK

1575

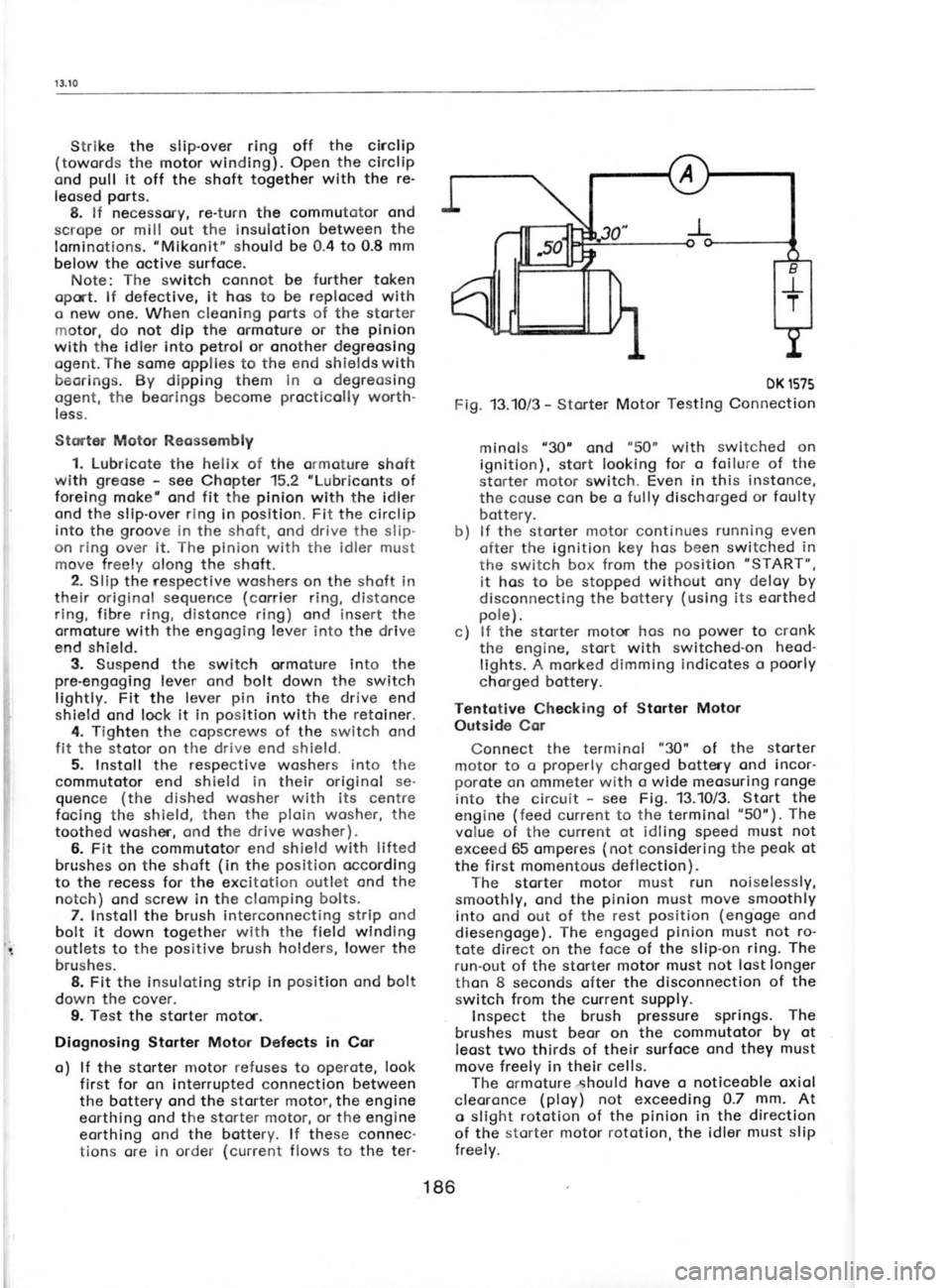

Fig. 13.10/3 -

Storter Motor Testlng Connection

minols u30"

ond "50"

with switched on

ignition), stort looking for o foilure of the

storter motor switch. Even in this instonce,

the couse con be o fully dischorged or foulty

bottery.

b) lf the storter motor

continues running

even

ofter the ignition key hos been switched in

the switch box from the position "START",

it hos to be stopped without ony deloy by

disconnecting the bottery (using

its eorthed

pole).

c) lf the storter motor hos no power

to cronk

the engine, stort with switched-on heod-

lights. A

morked dimming indicotes c poorly

chorged bottery.

Tentotive Checking of

Storter Motor

Outside Cor

Connect the terminol "30'of

the storter

motor to o properly

chorged bottery ond incor'

porote on ommeter with o wide

meosuring ronge

into the circuit -

see Fig. 13.10/3.

Stort the

engine (feed

current to the terminol "50").

The

volue of the current ot idling speed must

not

exceed 65 omperes (not

considering the peok

ot

the first momentous deflection).

The storter motor must run noiselessly,

smoothly, ond the pinion

must move smoothly

into ond out of the rest position

(engoge

ond

diesengoge). The engoged pinion

must not ro-

tote direct on the foce of the slip-on ring. The

run-out of the storter motor must not lost longer

thon 8 seconds ofter the disconnection of the

switch from the current supply.

Inspect the brush pressure

springs. The

brushes must

beor on the commutotor by ot

leost two thirds of their surfoce ond they must

move freely in their cells.

The ormoture should hove o noticeoble oxiol

cleoronce (ploy)

not exceeding 0.7 mm.

At

o slight rototion of the pinion

in the direction

of the storter motor rototion,

the idlor must

slip

freely.

186

Page 193 of 238

1 t.1

-1

4.3

surfoces ore

sproyed with o

Protective com'

pound. The floor boords including the floor of

the boot ore covered with textile corpets while

rubber mots ore used in Skodo 105 S.

The in-

terior luggoge comportment is

lined with insu-

loting felt

sheet.

fne body finish consists of severol loyers of

speciol onti-corrosive cootings, o primer

coot,

ond o synthetic boking enomel top

coot in

colours complying with

o speciol specificotion.

14.1 BUMPERS

To Remove Front BumPer

Disconnect the

leods of the horn ond front

direction indicotors. Remove bolts connecting

the side sections of

the bumper with the wings

ond bolts of the bumper brockets, connecting

them to the wheel splosh guords. Now

the

entire bumper is free ond it con be removed.

Te Remove Reor BumPer

Proceed in the some woy with the exception

thot there ore no leods to be disconnected.

To Remove Overriders

Screw off the nut M 10 ond lift owoy the

overri der.

14.2 WTNGS

To Remove Front Wing

First remove the front bumper (see

Chop-

ter 14.1), the front door (see

Chopter 14.5), ond,

in the cose of the left-hond wing, the boot lid

Fig. 14.211- Removing Front Wing -

orrows

indicote fostening points (see

Chopter 14.3). lf the door sill is covered

with o trim moulding, loosen this moulding

portiolly. Now remove the bolts fostening the wing to

the bodywork under the sill (from

underneoth),

on the side edge of the body post,

in the chon'

nel next to the boot, ond in the forebody under

the heodlomp.

To Reinstqll Front Wing

lf the seol strip in the front

Port of the wing

is domoged, reploce it with o new one, ond

stick it on if it hos got

unstuck. Pock olwoys

o new seoling strip between the wing edge ond

the body fromework. Then instoll

the wing in

position ond locote it by tightening slightly the

connecting (fostening) bolts.

Do not tighten

the bolts firmly before hoving fitted properly

the wing.

14.3 BONNET AND BOOT LID

Removing Boot Lid

Remove the nut ond bolt of the strut ond

the screws fostening the

hinges, ond lift owoy

the complete lid.

Removing Engine Bonnet

Slip the bonnet strut out of

its guide,

screw

off the nuts of the hinge fostening bolts, ond

lift owoy the bonnet.

Reinstollotion ond Adiustment of Boot Lid

ond Engine Bonnet

Instoll the lid (or

bonnet) over

the luggoge

(or engine) comportment ond

tighten lightly

the bolts ond/or the nuts of the hinge bolts.

Moke the lid (or

bonnet) fit perfectly

with the

edges of the bodywork by shifting the hinges

in their respective holes

os necessory, ond

tighten fost the bolts ond/or nuts of the hinges-

Assemble the strut of the boot lid.

Boot Lid Releose Rod ond Engine Bonnet

Releose Coble

The releose rod of the boot lid (Fig.

1.3113)

is connected with the reloy link by meons of

o pin

ond forms on ossembly unit with the lid

locks. The

hondle of the releose rod con be

removed ofter pushing

out the pin.

The entire

ossembly con be lifted owoy ofter removing the

lid locks.

Reverse this procedure

to reinstoll the os'

sembly. Tighten the bolts of the locks lightly

ond fit the lid properly

in positlon.

Now odiust

202 c

o

o

o ir

e

tt d

Page 203 of 238

l4.l

l-14.12

has two anchoring points.

The seat belts have

anchoring bolts

on the size 7/16-20 UNF-2A'

In f ront, the anchoring threads

are easily

accessible being provided

on the door posts

(remove only one of the pair

of pins

covering the

thread), on sills

below the posts,

and on

the sides

of the'floor tunnel

behind the front seats'

Anchoring points

for rear seat belts are shown

in the illustation. For the seat

belt of the person

sitting in the

middle, the threads are under the

seat cushions and rather removed from each other

(A3). For the seat belts of persons

occupying the

butside places

the threads are also under the

cushions, nearer to the centre (A2),

in the body

sides close to the cusions (82),

and in window

pillars (C2). These latter threads can be found by

touch in the point

of intersection of the plane

passing about 165 mm

above the

rear window

parcel tray and in parallel

with the door frame at a

distance of about 85 mm. To gain

access to

them,

it is necessary to cut through the trimming.

We must stress that for the fitting of points A2

and A3, the bolts should not protrude

beyond the Fig.M.11l2

-

Lower Anchoring Points

14-12 FACIA

l-he focio cctl be rentoved otter unsct-ewlllg

the nuts of its peripherol bolts ond

ofter lifting

owoy the instrument ponel -

see Chopter '13'15'

It is olso necessory to

remove the steering

wheel with the shroud of

the steering wheel

shoft (see

Chopters 7.7

ond

7.8), ond the heoter

control ponel

(see ChoPter 11.0).

The bolts holding down the focio

ore occess-

ible ofter removin! the

instrument ponel

ond

the heoter control ponel, ond

ofter swinging. out

the glove

box. To swing

out the glove

box,

open its lid ond loosen tlre screws of its

stops'

Fig. 14.1111 -

Upper Anchoring Point

captive not more

than 1lz mm or there is every

likelihood of damaging the

fuel tank.

The depth of the nut from the mounting face

is

15 mm.

Child seat fixing

Follow the seat belt manufacturers instructions

as to the spacing of the belt straps.

The straps can be mounted to the rear parcel

shelf if the mounting holes are drilled 30 mm from

the front engine bulkhead. The

sound deadening

trim in the engine compartment

will need to be

lowered to fit the spreading plate

and nut.

Be careful when drilling the shelf, not to

scratch the rear screen. Fig.

14.1211 -

Focio Mounting Points

14.13 WATER LEAKS

To determine the

source of

a water leak

proceed in a progressive

manner.

1. Determine area

water finally rests'

2. lf possible follow

water trace to

source'

3. lf hot, remove carpets and clutter'

4. Dry car inside

and out'

5. Us'e a sprinkler rather

than

a hose jet'

6. Start on the

underside of

the vehicle and

work up. Do not

do any adjustments or

sealing until after the

first test.

7. When"you have

finished adjustments and

sealing RE

TEST.

212