jacking points SKODA CITIGO 2015 1.G Owner's Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 2015, Model line: CITIGO, Model: SKODA CITIGO 2015 1.GPages: 160, PDF Size: 23.1 MB

Page 127 of 160

›Replace the wheel trim or the caps.

To be equipped for a possible wheel change, the adapter for the anti-theft

wheel bolts must always be kept in the vehicle. The adapter is stowed in the

tool kit.

The position of the anti-theft wheel bolt is marked on the back of the wheel

cover on every factory-fitted or ŠKODA Original Accessory hub cap.

When using an anti-theft wheel bolt, make sure that this has been fitted ac-

cording to the position marked on the back of the wheel cover position.

Note

■ Note the code number which is embossed both on the adapter and also on

the end of each anti-theft wheel bolt. This number can be used to purchase a

replacement adapter from ŠKODA Original Parts if necessary.■

The anti-theft wheel bolt set and adapter can be purchased from a ŠKODA

Partner.

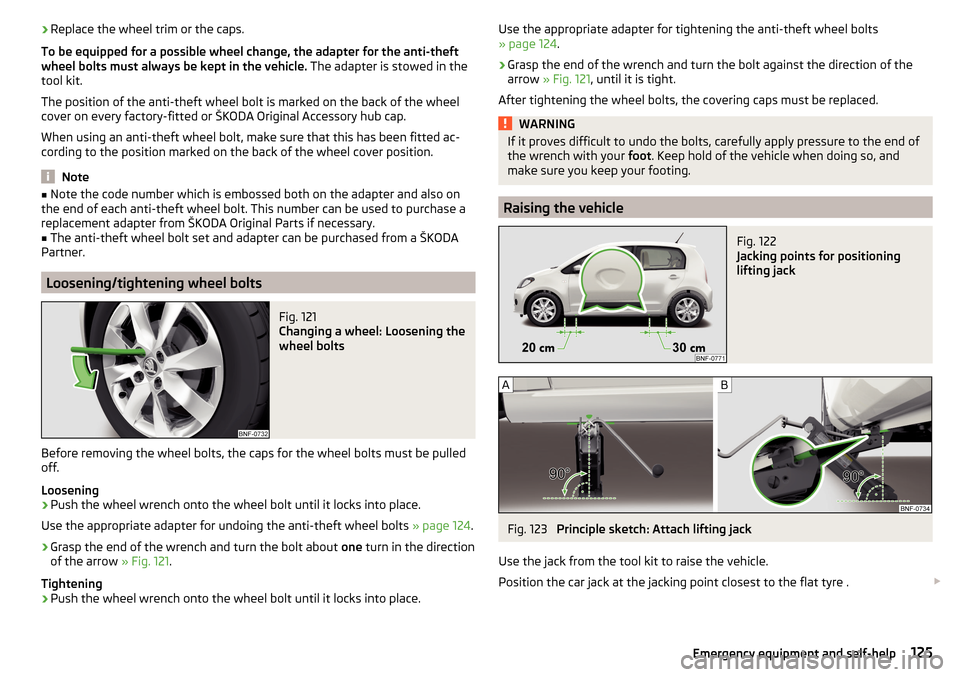

Loosening/tightening wheel bolts

Fig. 121

Changing a wheel: Loosening the

wheel bolts

Before removing the wheel bolts, the caps for the wheel bolts must be pulled

off.

Loosening

›

Push the wheel wrench onto the wheel bolt until it locks into place.

Use the appropriate adapter for undoing the anti-theft wheel bolts » page 124.

›

Grasp the end of the wrench and turn the bolt about one turn in the direction

of the arrow » Fig. 121.

Tightening

›

Push the wheel wrench onto the wheel bolt until it locks into place.

Use the appropriate adapter for tightening the anti-theft wheel bolts

» page 124 .›

Grasp the end of the wrench and turn the bolt against the direction of the

arrow » Fig. 121 , until it is tight.

After tightening the wheel bolts, the covering caps must be replaced.

WARNINGIf it proves difficult to undo the bolts, carefully apply pressure to the end of

the wrench with your foot. Keep hold of the vehicle when doing so, and

make sure you keep your footing.

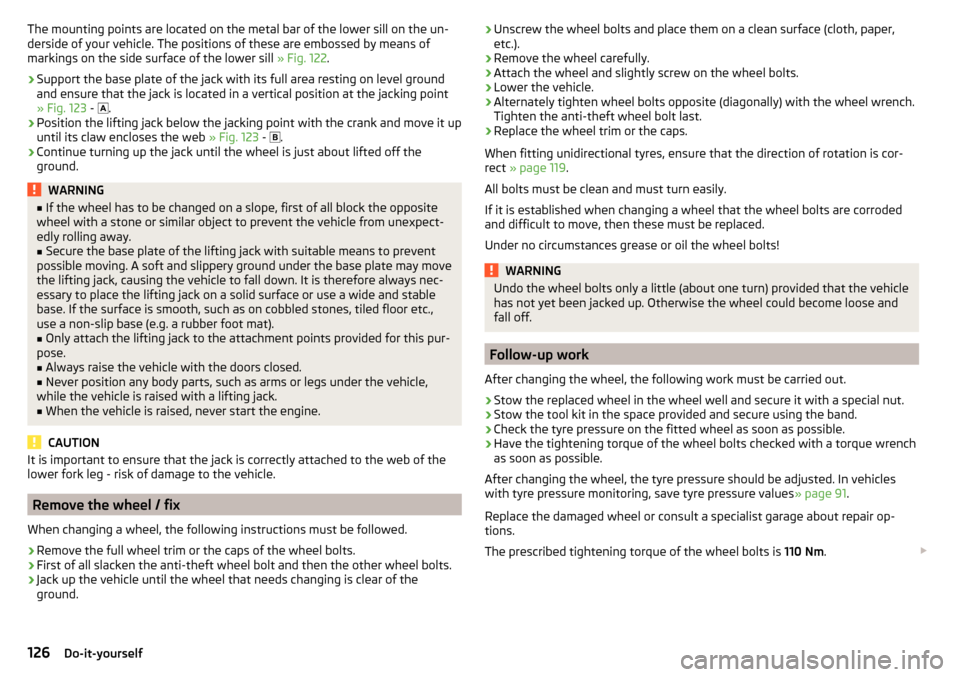

Raising the vehicle

Fig. 122

Jacking points for positioning

lifting jack

Fig. 123

Principle sketch: Attach lifting jack

Use the jack from the tool kit to raise the vehicle.

Position the car jack at the jacking point closest to the flat tyre .

125Emergency equipment and self-help

Page 128 of 160

The mounting points are located on the metal bar of the lower sill on the un-

derside of your vehicle. The positions of these are embossed by means of

markings on the side surface of the lower sill » Fig. 122.›

Support the base plate of the jack with its full area resting on level ground

and ensure that the jack is located in a vertical position at the jacking point

» Fig. 123 -

.

›

Position the lifting jack below the jacking point with the crank and move it up

until its claw encloses the web » Fig. 123 -

.

›

Continue turning up the jack until the wheel is just about lifted off the

ground.

WARNING■ If the wheel has to be changed on a slope, first of all block the opposite

wheel with a stone or similar object to prevent the vehicle from unexpect-

edly rolling away.■

Secure the base plate of the lifting jack with suitable means to prevent

possible moving. A soft and slippery ground under the base plate may move

the lifting jack, causing the vehicle to fall down. It is therefore always nec-

essary to place the lifting jack on a solid surface or use a wide and stable

base. If the surface is smooth, such as on cobbled stones, tiled floor etc.,

use a non-slip base (e.g. a rubber foot mat).

■

Only attach the lifting jack to the attachment points provided for this pur-

pose.

■

Always raise the vehicle with the doors closed.

■

Never position any body parts, such as arms or legs under the vehicle,

while the vehicle is raised with a lifting jack.

■

When the vehicle is raised, never start the engine.

CAUTION

It is important to ensure that the jack is correctly attached to the web of the

lower fork leg - risk of damage to the vehicle.

Remove the wheel / fix

When changing a wheel, the following instructions must be followed.

›

Remove the full wheel trim or the caps of the wheel bolts.

›

First of all slacken the anti-theft wheel bolt and then the other wheel bolts.

›

Jack up the vehicle until the wheel that needs changing is clear of the

ground.

› Unscrew the wheel bolts and place them on a clean surface (cloth, paper,

etc.).›

Remove the wheel carefully.

›

Attach the wheel and slightly screw on the wheel bolts.

›

Lower the vehicle.

›

Alternately tighten wheel bolts opposite (diagonally) with the wheel wrench.

Tighten the anti-theft wheel bolt last.

›

Replace the wheel trim or the caps.

When fitting unidirectional tyres, ensure that the direction of rotation is cor-

rect » page 119 .

All bolts must be clean and must turn easily.

If it is established when changing a wheel that the wheel bolts are corroded and difficult to move, then these must be replaced.

Under no circumstances grease or oil the wheel bolts!

WARNINGUndo the wheel bolts only a little (about one turn) provided that the vehicle

has not yet been jacked up. Otherwise the wheel could become loose and

fall off.

Follow-up work

After changing the wheel, the following work must be carried out.

›

Stow the replaced wheel in the wheel well and secure it with a special nut.

›

Stow the tool kit in the space provided and secure using the band.

›

Check the tyre pressure on the fitted wheel as soon as possible.

›

Have the tightening torque of the wheel bolts checked with a torque wrench

as soon as possible.

After changing the wheel, the tyre pressure should be adjusted. In vehicles

with tyre pressure monitoring, save tyre pressure values » page 91.

Replace the damaged wheel or consult a specialist garage about repair op-

tions.

The prescribed tightening torque of the wheel bolts is 110 Nm.

126Do-it-yourself