check engine SKODA CITIGO 2016 1.G User Guide

[x] Cancel search | Manufacturer: SKODA, Model Year: 2016, Model line: CITIGO, Model: SKODA CITIGO 2016 1.GPages: 172, PDF Size: 24.59 MB

Page 114 of 172

WARNING (Continued)â Do not manipulate individual parts of the airbag system, as this might re-

sult in the airbag being deployed.â

If the airbag has been deployed, the airbag system must be replaced.

WARNINGThe airbag system operates using pressure sensors located in the front

doors. For this reason, no adjustments may be carried out to the doors or

door panels (e.g. installation of additional loudspeakers). Resulting damage

can impair the functioning of the airbag system - risk of accidents and fatal

injuries! The following guidelines must therefore be observed.â

Any work on the front doors and their door panels must be carried out by

a specialist garage.

â

Never drive the vehicle with the inner door panels removed or with open-

ings in the panelling.

Trailer operation

Read and observe

on page 110 first.

The vehicle is not approved for towing a trailer. The vehicle is not factory-

equipped with a towing device and it cannot be retrofitted with a towing de-

vice.

WARNINGNever attach a towing device to the vehicle.

Acceptance and recycling of used vehicles

Read and observe

on page 110 first.

All new Å KODA vehicles are 95% recyclable.

ï¤ï¤Service intervals

ï¤ Introduction

This chapter contains information on the following subjects:

Overview of service intervals

113

Fixed service intervals QI1 - QI4

113

Digital Service Plan

113

The service interval display in the display of the instrument cluster will remind

you to carry out every service stipulated by the manufacturer at the right time

in order to prevent you from forgetting any » page 42.

The completion of services can be verified through the printed verification

from the digital service schedule and the respective receipts.

The specified service intervals are tailored to normal operating conditions.

In the case of aggravated operating conditions, it will be necessary to have

some service work carried out before the date of the next regular service or

between the specified service intervals. This applies mainly to the cleaning or

the replacement of the air filter insert in regions with heavy dust pollution as

well as checking and replacing the toothed belt, but also to vehicles with die-

sel particle filters, which can put greater strain on the engine oil.

The following is taken to mean aggravated operating conditions: ⶠFrequent short trips.

ⶠLonger periods of engine idling (e.g. taxis).

ⶠOperation in areas with heavy dust pollution.

ⶠPredominantly stop-and-go traffic as is e.g. often the case in city driving.

ⶠOperation predominantly during winter.

You will be told at the specialist garage whether the operating conditions of

your vehicle may make it necessary for service work to be carried out between

the normal service intervals.

Different service charges may apply according to the particular scope of work

required, the vehicle type and specification, and your vehicleâs condition.

Note

â The customer is responsible for covering the cost of all services including

changing or replenishing the oil, even during the warranty period, unless sta-

ted otherwise in the Å KODA AUTO warranty terms or other agreements.â

You will be informed about the service checks and actions at each service by

the specialist garage.

112General Maintenance

Page 121 of 172

CAUTIONPetrol additives (additives)â Unleaded petrol complying with the EN 228 standard1)

meets all the condi-

tions for problem-free engine operation. We therefore do not recommend mix-

ing fuel additives into the petrol - risk of engine damage or damage to the ex-

haust system.â

The following additives may not be used - risk of engine damage or damage

to the exhaust system! â Additives with metal components (metallic additives), in particular with

manganese and iron content.

â Fuels with metallic content (e.g. LRP - lead replacement petrol).

Note

â Unleaded petrol that has a higher octane number than that required by the

engine can be used without limitations.â

On vehicles using the prescribed unleaded petrol of min. 95 RON, the use of

petrol with a higher octane number than 95 RON can lead to an increase in

power and reduction in fuel consumption.

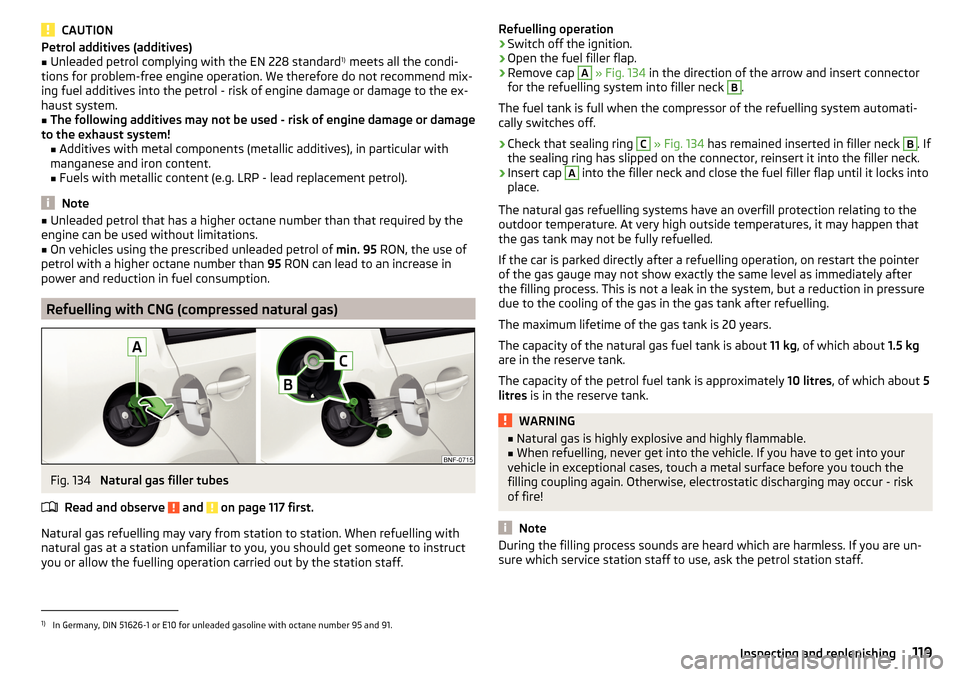

Refuelling with CNG (compressed natural gas)

Fig. 134

Natural gas filler tubes

Read and observe

and on page 117 first.

Natural gas refuelling may vary from station to station. When refuelling with natural gas at a station unfamiliar to you, you should get someone to instruct

you or allow the fuelling operation carried out by the station staff.

ï¤Refuelling operationâºSwitch off the ignition.âº

Open the fuel filler flap.

âº

Remove cap

A

» Fig. 134 in the direction of the arrow and insert connector

for the refuelling system into filler neck

B

.

The fuel tank is full when the compressor of the refuelling system automati-

cally switches off.

âº

Check that sealing ring

C

» Fig. 134 has remained inserted in filler neck

B

. If

the sealing ring has slipped on the connector, reinsert it into the filler neck.

âº

Insert cap

A

into the filler neck and close the fuel filler flap until it locks into

place.

The natural gas refuelling systems have an overfill protection relating to the

outdoor temperature. At very high outside temperatures, it may happen that

the gas tank may not be fully refuelled.

If the car is parked directly after a refuelling operation, on restart the pointer

of the gas gauge may not show exactly the same level as immediately after

the filling process. This is not a leak in the system, but a reduction in pressure

due to the cooling of the gas in the gas tank after refuelling.

The maximum lifetime of the gas tank is 20 years.

The capacity of the natural gas fuel tank is about 11 kg, of which about 1.5 kg

are in the reserve tank.

The capacity of the petrol fuel tank is approximately 10 litres, of which about 5

litres is in the reserve tank.

WARNINGâ

Natural gas is highly explosive and highly flammable.â When refuelling, never get into the vehicle. If you have to get into your

vehicle in exceptional cases, touch a metal surface before you touch the

filling coupling again. Otherwise, electrostatic discharging may occur - risk

of fire!

Note

During the filling process sounds are heard which are harmless. If you are un-

sure which service station staff to use, ask the petrol station staff.1)

In Germany, DIN 51626-1 or E10 for unleaded gasoline with octane number 95 and 91.

119Inspecting and replenishing

Page 122 of 172

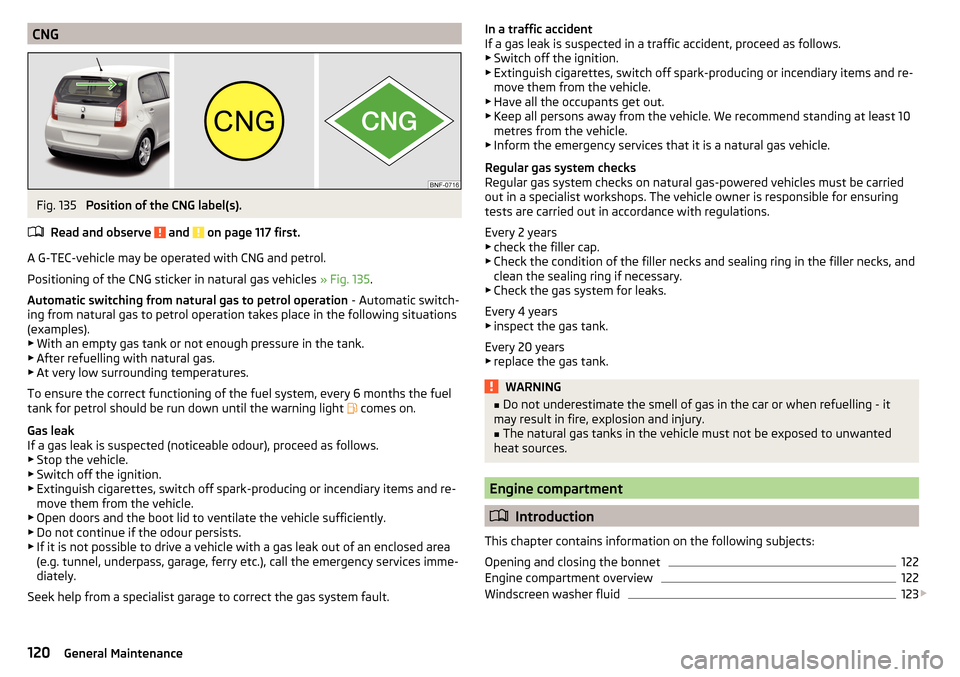

CNGFig. 135

Position of the CNG label(s).

Read and observe

and on page 117 first.

A G-TEC-vehicle may be operated with CNG and petrol.

Positioning of the CNG sticker in natural gas vehicles » Fig. 135.

Automatic switching from natural gas to petrol operation - Automatic switch-

ing from natural gas to petrol operation takes place in the following situations

(examples). ⶠWith an empty gas tank or not enough pressure in the tank.

ⶠAfter refuelling with natural gas.

ⶠAt very low surrounding temperatures.

To ensure the correct functioning of the fuel system, every 6 months the fuel tank for petrol should be run down until the warning light ï comes on.

Gas leak

If a gas leak is suspected (noticeable odour), proceed as follows. ⶠStop the vehicle.

ⶠSwitch off the ignition.

ⶠExtinguish cigarettes, switch off spark-producing or incendiary items and re-

move them from the vehicle.

ⶠOpen doors and the boot lid to ventilate the vehicle sufficiently.

ⶠDo not continue if the odour persists.

ⶠIf it is not possible to drive a vehicle with a gas leak out of an enclosed area

(e.g. tunnel, underpass, garage, ferry etc.), call the emergency services imme-

diately.

Seek help from a specialist garage to correct the gas system fault.

ï¤In a traffic accident

If a gas leak is suspected in a traffic accident, proceed as follows.

ⶠSwitch off the ignition.

ⶠExtinguish cigarettes, switch off spark-producing or incendiary items and re-

move them from the vehicle.

ⶠHave all the occupants get out.

ⶠKeep all persons away from the vehicle. We recommend standing at least 10

metres from the vehicle.

ⶠInform the emergency services that it is a natural gas vehicle.

Regular gas system checks

Regular gas system checks on natural gas-powered vehicles must be carried

out in a specialist workshops. The vehicle owner is responsible for ensuring

tests are carried out in accordance with regulations.

Every 2 years ⶠcheck the filler cap.

ⶠCheck the condition of the filler necks and sealing ring in the filler necks, and

clean the sealing ring if necessary.

ⶠCheck the gas system for leaks.

Every 4 years ⶠinspect the gas tank.

Every 20 years

ⶠreplace the gas tank.WARNINGâ Do not underestimate the smell of gas in the car or when refuelling - it

may result in fire, explosion and injury.â

The natural gas tanks in the vehicle must not be exposed to unwanted

heat sources.

Engine compartment

ï¤ Introduction

This chapter contains information on the following subjects:

Opening and closing the bonnet

122

Engine compartment overview

122

Windscreen washer fluid

123

ï£

120General Maintenance

Page 125 of 172

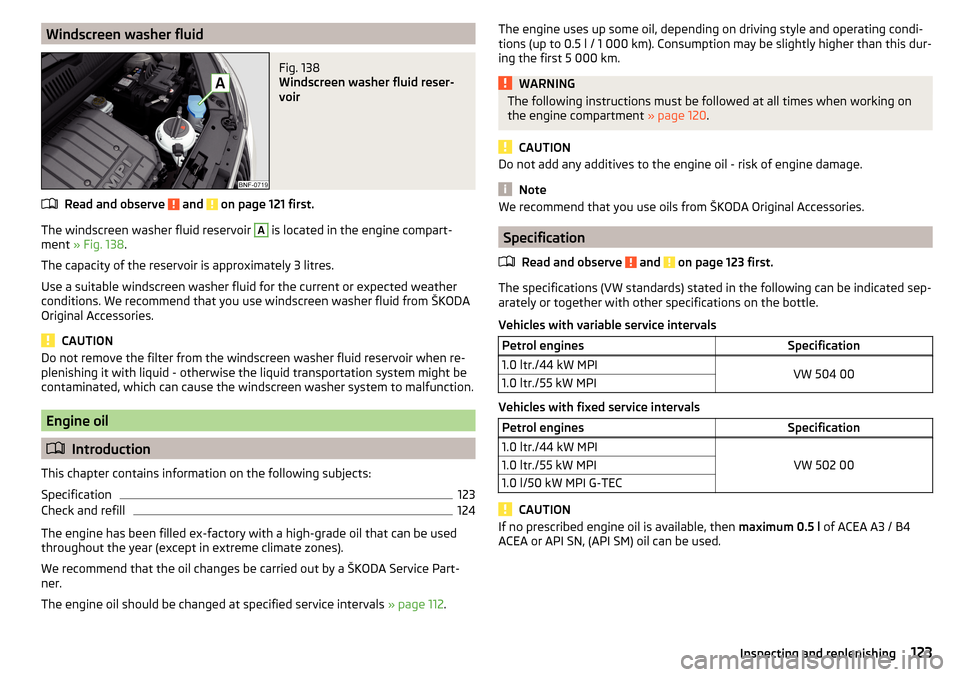

Windscreen washer fluidFig. 138

Windscreen washer fluid reser-

voir

Read and observe and on page 121 first.

The windscreen washer fluid reservoir

A

is located in the engine compart-

ment » Fig. 138 .

The capacity of the reservoir is approximately 3 litres.

Use a suitable windscreen washer fluid for the current or expected weather

conditions. We recommend that you use windscreen washer fluid from Å KODA

Original Accessories.

CAUTION

Do not remove the filter from the windscreen washer fluid reservoir when re-

plenishing it with liquid - otherwise the liquid transportation system might be

contaminated, which can cause the windscreen washer system to malfunction.

Engine oil

ï¤ Introduction

This chapter contains information on the following subjects:

Specification

123

Check and refill

124

The engine has been filled ex-factory with a high-grade oil that can be used

throughout the year (except in extreme climate zones).

We recommend that the oil changes be carried out by a Å KODA Service Part-

ner.

The engine oil should be changed at specified service intervals » page 112.

ï¤The engine uses up some oil, depending on driving style and operating condi-

tions (up to 0.5 l / 1 000 km). Consumption may be slightly higher than this dur-

ing the first 5 000 km.WARNINGThe following instructions must be followed at all times when working on

the engine compartment » page 120.

CAUTION

Do not add any additives to the engine oil - risk of engine damage.

Note

We recommend that you use oils from Å KODA Original Accessories.

Specification

Read and observe

and on page 123 first.

The specifications (VW standards) stated in the following can be indicated sep-arately or together with other specifications on the bottle.

Vehicles with variable service intervals

Petrol enginesSpecification1.0 ltr./44 kW MPIVW 504 001.0 ltr./55 kW MPI

Vehicles with fixed service intervals

Petrol enginesSpecification1.0 ltr./44 kW MPI

VW 502 00

1.0 ltr./55 kW MPI1.0 l/50 kW MPI G-TEC

CAUTION

If no prescribed engine oil is available, then maximum 0.5 l of ACEA A3 / B4

ACEA or API SN, (API SM) oil can be used.ï¤123Inspecting and replenishing

Page 126 of 172

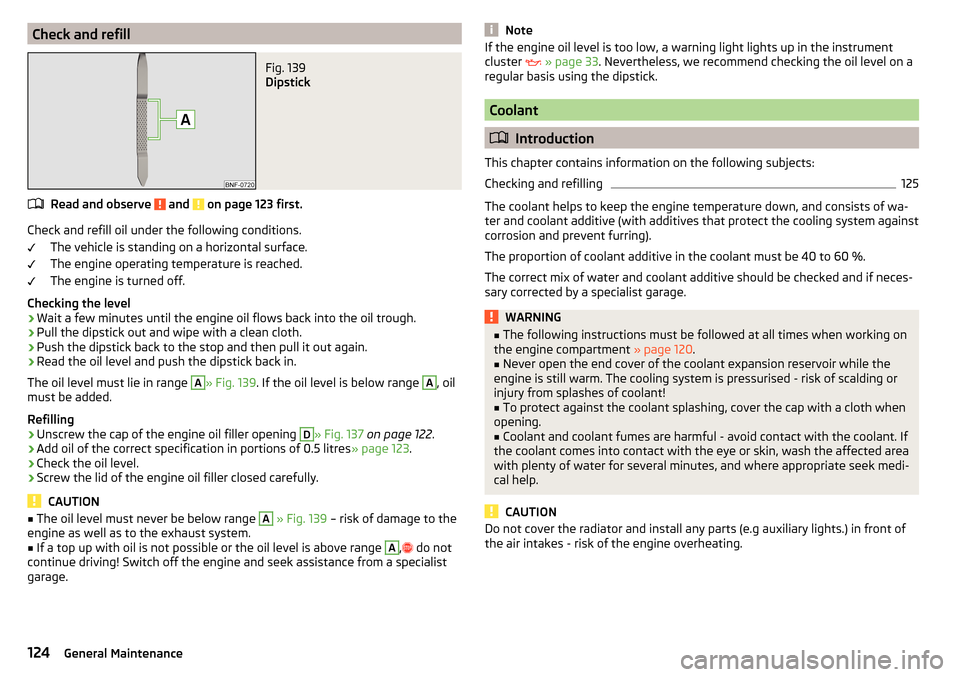

Check and refillFig. 139

Dipstick

Read and observe and on page 123 first.

Check and refill oil under the following conditions.The vehicle is standing on a horizontal surface.

The engine operating temperature is reached.

The engine is turned off.

Checking the level

âº

Wait a few minutes until the engine oil flows back into the oil trough.

âº

Pull the dipstick out and wipe with a clean cloth.

âº

Push the dipstick back to the stop and then pull it out again.

âº

Read the oil level and push the dipstick back in.

The oil level must lie in range

A

» Fig. 139 . If the oil level is below range

A

, oil

must be added.

Refilling

âº

Unscrew the cap of the engine oil filler opening

D

» Fig. 137 on page 122 .

âº

Add oil of the correct specification in portions of 0.5 litres

» page 123.

âº

Check the oil level.

âº

Screw the lid of the engine oil filler closed carefully.

CAUTION

â

The oil level must never be below range A » Fig. 139 â risk of damage to the

engine as well as to the exhaust system.â

If a top up with oil is not possible or the oil level is above range

A

, ï²

do not

continue driving! Switch off the engine and seek assistance from a specialist

garage.

ï¤ï¥ï¥ï¥NoteIf the engine oil level is too low, a warning light lights up in the instrument

cluster ï¥ Â» page 33 . Nevertheless, we recommend checking the oil level on a

regular basis using the dipstick.

Coolant

ï¤ Introduction

This chapter contains information on the following subjects:

Checking and refilling

125

The coolant helps to keep the engine temperature down, and consists of wa-

ter and coolant additive (with additives that protect the cooling system against

corrosion and prevent furring).

The proportion of coolant additive in the coolant must be 40 to 60 %.

The correct mix of water and coolant additive should be checked and if neces-

sary corrected by a specialist garage.

WARNINGâ The following instructions must be followed at all times when working on

the engine compartment » page 120.â

Never open the end cover of the coolant expansion reservoir while the

engine is still warm. The cooling system is pressurised - risk of scalding or

injury from splashes of coolant!

â

To protect against the coolant splashing, cover the cap with a cloth when

opening.

â

Coolant and coolant fumes are harmful - avoid contact with the coolant. If

the coolant comes into contact with the eye or skin, wash the affected area

with plenty of water for several minutes, and where appropriate seek medi-

cal help.

CAUTION

Do not cover the radiator and install any parts (e.g auxiliary lights.) in front of

the air intakes - risk of the engine overheating.124General Maintenance

Page 127 of 172

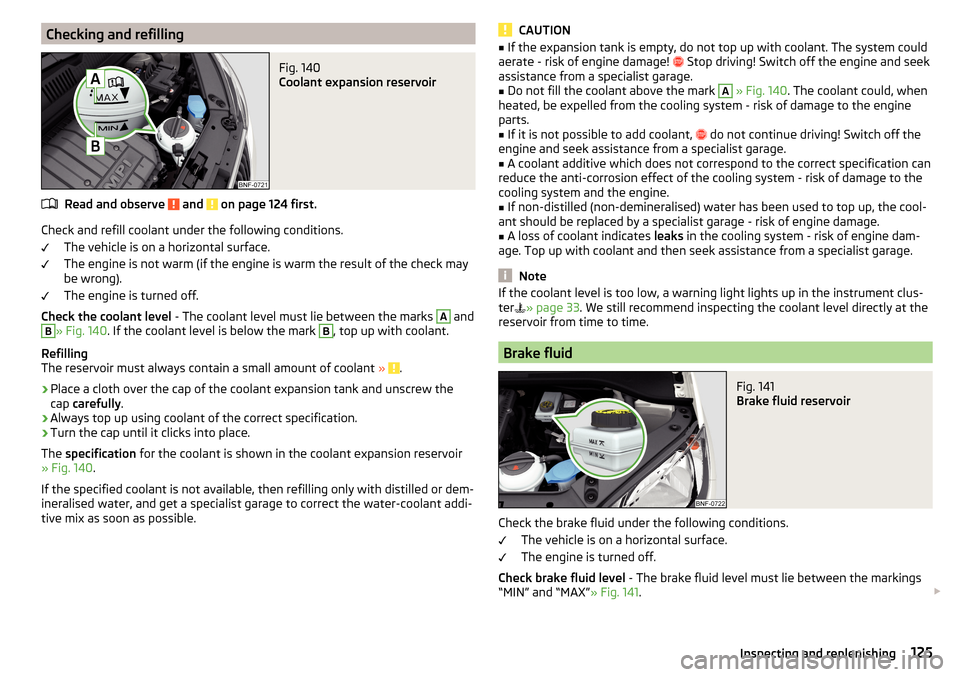

Checking and refillingFig. 140

Coolant expansion reservoir

Read and observe and on page 124 first.

Check and refill coolant under the following conditions.The vehicle is on a horizontal surface.

The engine is not warm (if the engine is warm the result of the check may

be wrong).

The engine is turned off.

Check the coolant level - The coolant level must lie between the marks

A

and

B

» Fig. 140. If the coolant level is below the mark

B

, top up with coolant.

Refilling

The reservoir must always contain a small amount of coolant »

.

âº

Place a cloth over the cap of the coolant expansion tank and unscrew the

cap carefully .

âº

Always top up using coolant of the correct specification.

âº

Turn the cap until it clicks into place.

The specification for the coolant is shown in the coolant expansion reservoir

» Fig. 140 .

If the specified coolant is not available, then refilling only with distilled or dem-

ineralised water, and get a specialist garage to correct the water-coolant addi-

tive mix as soon as possible.

ï¤ï¥ï¥ï¥CAUTIONâ If the expansion tank is empty, do not top up with coolant. The system could

aerate - risk of engine damage! ï² Stop driving! Switch off the engine and seek

assistance from a specialist garage.â

Do not fill the coolant above the mark

A

» Fig. 140 . The coolant could, when

heated, be expelled from the cooling system - risk of damage to the engine

parts.

â

If it is not possible to add coolant, ï²

do not continue driving! Switch off the

engine and seek assistance from a specialist garage.

â

A coolant additive which does not correspond to the correct specification can

reduce the anti-corrosion effect of the cooling system - risk of damage to the

cooling system and the engine.

â

If non-distilled (non-demineralised) water has been used to top up, the cool-

ant should be replaced by a specialist garage - risk of engine damage.

â

A loss of coolant indicates leaks in the cooling system - risk of engine dam-

age. Top up with coolant and then seek assistance from a specialist garage.

Note

If the coolant level is too low, a warning light lights up in the instrument clus-

ter ï¯Â» page 33 . We still recommend inspecting the coolant level directly at the

reservoir from time to time.

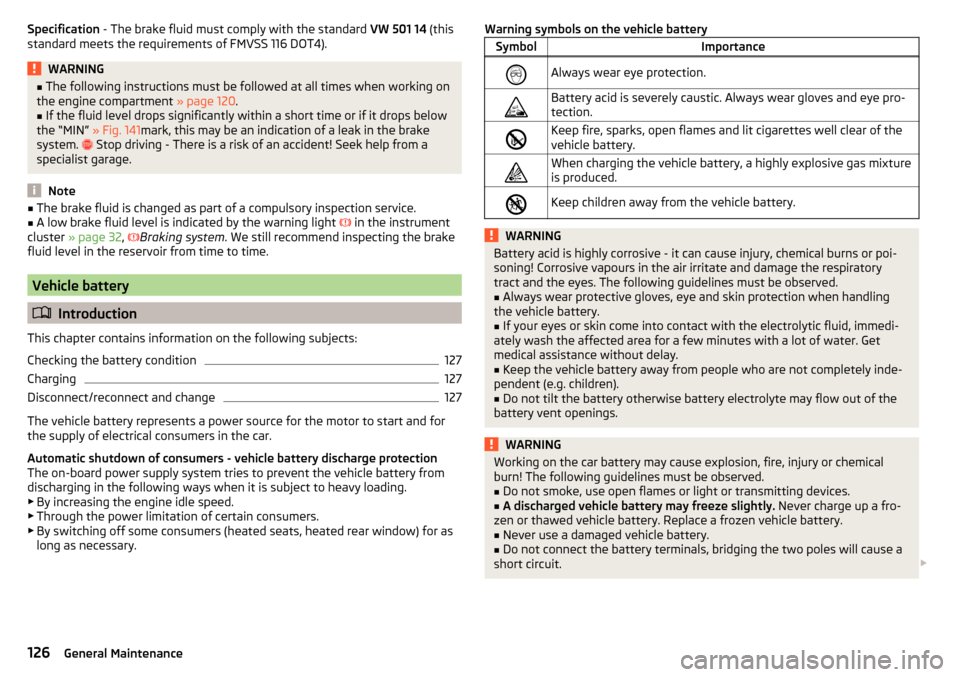

Brake fluid

Fig. 141

Brake fluid reservoir

Check the brake fluid under the following conditions.

The vehicle is on a horizontal surface.

The engine is turned off.

Check brake fluid level - The brake fluid level must lie between the markings

âMINâ and âMAXâ » Fig. 141. ï£

ï¥ï¥125Inspecting and replenishing

Page 128 of 172

Specification - The brake fluid must comply with the standard VW 501 14 (this

standard meets the requirements of FMVSS 116 DOT4).WARNINGâ The following instructions must be followed at all times when working on

the engine compartment » page 120.â

If the fluid level drops significantly within a short time or if it drops below

the âMINâ » Fig. 141mark, this may be an indication of a leak in the brake

system. ï²

Stop driving - There is a risk of an accident! Seek help from a

specialist garage.

Note

â The brake fluid is changed as part of a compulsory inspection service.â A low brake fluid level is indicated by the warning light ï¨ in the instrument

cluster » page 32 , ï¨

Braking system . We still recommend inspecting the brake

fluid level in the reservoir from time to time.

Vehicle battery

ï¤ Introduction

This chapter contains information on the following subjects:

Checking the battery condition

127

Charging

127

Disconnect/reconnect and change

127

The vehicle battery represents a power source for the motor to start and for

the supply of electrical consumers in the car.

Automatic shutdown of consumers - vehicle battery discharge protection

The on-board power supply system tries to prevent the vehicle battery from

discharging in the following ways when it is subject to heavy loading. ⶠBy increasing the engine idle speed.

ⶠThrough the power limitation of certain consumers.

ⶠBy switching off some consumers (heated seats, heated rear window) for as

long as necessary.

Warning symbols on the vehicle batterySymbolImportanceïAlways wear eye protection.ïBattery acid is severely caustic. Always wear gloves and eye pro-

tection.ïKeep fire, sparks, open flames and lit cigarettes well clear of the

vehicle battery.ïWhen charging the vehicle battery, a highly explosive gas mixture

is produced.ïKeep children away from the vehicle battery.WARNINGBattery acid is highly corrosive - it can cause injury, chemical burns or poi-

soning! Corrosive vapours in the air irritate and damage the respiratory

tract and the eyes. The following guidelines must be observed.â

Always wear protective gloves, eye and skin protection when handling

the vehicle battery.

â

If your eyes or skin come into contact with the electrolytic fluid, immedi-

ately wash the affected area for a few minutes with a lot of water. Get

medical assistance without delay.

â

Keep the vehicle battery away from people who are not completely inde-

pendent (e.g. children).

â

Do not tilt the battery otherwise battery electrolyte may flow out of the

battery vent openings.

WARNINGWorking on the car battery may cause explosion, fire, injury or chemical

burn! The following guidelines must be observed.â

Do not smoke, use open flames or light or transmitting devices.

â

A discharged vehicle battery may freeze slightly. Never charge up a fro-

zen or thawed vehicle battery. Replace a frozen vehicle battery.

â

Never use a damaged vehicle battery.

â

Do not connect the battery terminals, bridging the two poles will cause a

short circuit. ï£

126General Maintenance

Page 129 of 172

CAUTIONEnsure that battery acid does not come into contact with the bodywork â risk

of damage to the paintwork.

Note

â We recommend having all work on the vehicle battery carried out by a spe-

cialist garage.â

You should replace batteries older than 5 years.

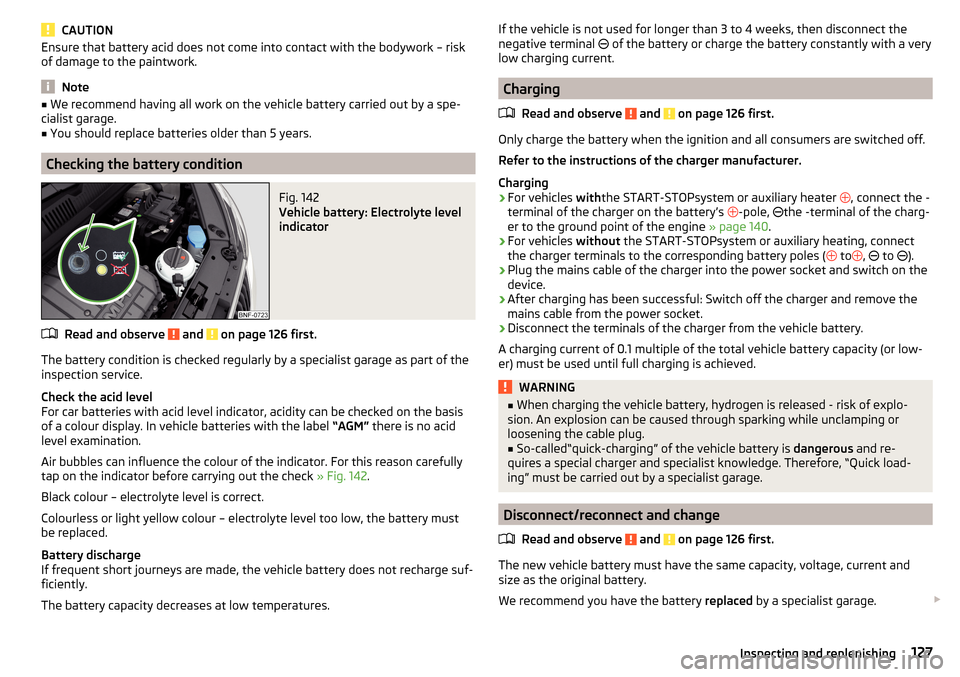

Checking the battery condition

Fig. 142

Vehicle battery: Electrolyte level

indicator

Read and observe and on page 126 first.

The battery condition is checked regularly by a specialist garage as part of the inspection service.

Check the acid level

For car batteries with acid level indicator, acidity can be checked on the basis

of a colour display. In vehicle batteries with the label âAGMâ there is no acid

level examination.

Air bubbles can influence the colour of the indicator. For this reason carefully

tap on the indicator before carrying out the check » Fig. 142.

Black colour â electrolyte level is correct.

Colourless or light yellow colour â electrolyte level too low, the battery must

be replaced.

Battery discharge

If frequent short journeys are made, the vehicle battery does not recharge suf-

ficiently.

The battery capacity decreases at low temperatures.

ï¤If the vehicle is not used for longer than 3 to 4 weeks, then disconnect the

negative terminal ï of the battery or charge the battery constantly with a very

low charging current.

Charging

Read and observe

and on page 126 first.

Only charge the battery when the ignition and all consumers are switched off.Refer to the instructions of the charger manufacturer.

Charging

âº

For vehicles withthe START-STOPsystem or auxiliary heater

ï, connect the -

terminal of the charger on the batteryâs ï-pole,

ïthe -terminal of the charg-

er to the ground point of the engine » page 140.

âº

For vehicles

without the START-STOPsystem or auxiliary heating, connect

the charger terminals to the corresponding battery poles ( ï to

ï,

ï to

ï).

âº

Plug the mains cable of the charger into the power socket and switch on the

device.

âº

After charging has been successful: Switch off the charger and remove the

mains cable from the power socket.

âº

Disconnect the terminals of the charger from the vehicle battery.

A charging current of 0.1 multiple of the total vehicle battery capacity (or low-

er) must be used until full charging is achieved.

WARNINGâ When charging the vehicle battery, hydrogen is released - risk of explo-

sion. An explosion can be caused through sparking while unclamping or

loosening the cable plug.â

So-calledâquick-chargingâ of the vehicle battery is dangerous and re-

quires a special charger and specialist knowledge. Therefore, âQuick load-

ingâ must be carried out by a specialist garage.

Disconnect/reconnect and change

Read and observe

and on page 126 first.

The new vehicle battery must have the same capacity, voltage, current and

size as the original battery.

We recommend you have the battery replaced by a specialist garage. ï£

ï¤ï¤127Inspecting and replenishing

Page 136 of 172

Wheel wrench

Extraction pliers for the wheel bolt caps

Breakdown kitWARNINGâ The factory-supplied lifting jack is only intended for your model of vehicle.

Under no circumstances attempt to lift other vehicles or loads with it â

there is a risk of injury.â

Always stow the tool safely in the box and make sure that it is attached

with the belt to the spare wheel - otherwise it could cause injury to the oc-

cupants if breaking suddenly or colliding with another vehicle.

CAUTION

Screw the jack back to its starting position prior to putting it back in its box -

risk of damage to the box.

Note

The declaration of conformity is included with the jack or the log folder.

Changing a wheel

Preliminary work

For safety's sake, the following instructions must be observed before

changing a wheel on the road.

âº

As far as possible park the vehicle as far as possible away from the traffic

flow - choose a place with a flat and firm surface.

âº

Switch off the engine.

âº

For vehicles with manual transmission select 1st gear .

âº

For vehicles with

automated transmission shift the lever to position D or R.

âº

Firmly apply the handbrake.

âº

Switch on the hazard warning lights and set up the warning triangle at the

prescribed distance.

âº

Have all the occupants get out . The passengers should not stand on the

road while the wheel is being changed (they should remain behind a crash

barrier, for instance).

Changing a wheel

âº

Take out the emergency or spare wheel » page 135.

âº

Remove the full wheel trim » page 135 or caps » page 135 .

678âºLoosen the wheel bolts

» page 136 » .âºJack up the vehicle until the wheel that needs changing, is clear of the

ground » page 136 .âº

Unscrew the wheel bolts and place them on a clean surface (cloth, paper,

etc.).

âº

Remove the wheel carefully.

âº

Attach the spare wheel and slightly screw on the wheel bolts.

âº

Lower the vehicle.

âº

Tighten the wheel bolts opposite each other using the wheel wrench (âpull- ing crosswaysâ) » page 136.

âº

Replace the wheel trim » page 135 and caps » page 135 .

When fitting unidirectional tyres, ensure that the direction of rotation is cor-

rect » page 129 .

All bolts must be clean and must turn easily. If screws are corroded and diffi-

cult to move, these must be replaced.

WARNINGâ Undo the wheel bolts just a little (about one turn), provided the vehicle

has not yet been jacked up. Otherwise the wheel could come loose and fall

off â risk of injury.â

Under no circumstances must the bolts be greased or oiled - cause an ac-

cident.

Subsequent steps

After changing the wheel, the following work must be carried out.

âº

Stow the replaced wheel in the well under the floor covering of the luggage

compartment and secure it with a nut.

âº

Stow the tool kit in the space provided and secure using the band.

âº

Check tyre pressure on the mounted wheel and adjust if necessary and, with

vehicles with tyre pressure monitoring, save the tyre pressure values in the

system » page 109 .

âº

Have the tightening torque of the wheel bolts checked as soon as possible.

The prescribed tightening torque is 110 Nm.

Replace the damaged wheel or consult a specialist garage about repair op-

tions. ï£

134Do-it-yourself

Page 141 of 172

âºFor vehicles with

automated manual transmission leave the selector lever in

position N.âº

Check that the screw for the tire pressure reduction

6

is closed.

âº

Start the engine.

âº

Plug the connector

4

into 12 volt socket » page 63, 12-volt socket .

âº

Switch on the air compressor with the ON and OFF switch

9

.

âº

Once tyre inflation pressure of 2.0-2.5 bar has been reached, turn off the air

compressor. Maximum run time of 6 minutes » .

âº

If you cannot reach an air pressure of 2.0 - 2.5 bar, unscrew the tyre inflation

hose

8

from the tyre valve.

âº

Drive the vehicle 10 metres forwards or backwards to allow the sealing agent

to âdistributeâ in the tyre.

âº

Firmly screw the tyre inflation hose

8

back onto the tyre valve and repeat

the inflation process.

âº

Stick the sticker

1

» Fig. 154 on page 138 on the dash panel in the driver's

field of view.

At a tyre inflation pressure of 2.0 â 2.5 bar, the journey can be continued at a maximum speed of 80 km/h or 50 mph.

WARNINGâ If the tire does not inflate at least. 2.0 bar, the damage is too great. The

sealing agent cannot be used to seal the tyre. ï² Stop driving! Seek help

from a specialist garage.â

The tyre inflation hose and air compressor may get hot as the tyre is be-

ing inflated â risk of burning.

CAUTION

Switch off the air compressor if it has been running for as much as 6 minutes â

risk of damage to the compressor! Allow the air compressor to cool a few mi-

nutes before switching it on again.

Information on driving with repaired tyres

Read and observe

on page 137 first.

The inflation pressure of the repaired tyre must be checked after driving for 10minutes.

If the tyre pressure is 1.3 bar or less

âº

The tyre cannot be properly sealed with the breakdown kit. ï²

Do not contin-

ue to drive! Seek help from a specialist garage.

ï¤If the tyre pressure is 1.3 bar or moreâºSet the tyre pressure back to the correct value » page 129.âº

Continue driving carefully to the nearest specialist garage at a maximum

speed of 80 km/h (50 mph).

WARNINGA tyre filled with sealant has the same driving characteristics as a standard

tyre. The following guidelines must therefore be observed.â

Do not drive faster than 80 km/h (50 mph).

â

Avoid accelerating at full throttle, sharp braking and fast cornering.

Jump-starting

ï¤ Introduction

This chapter contains information on the following subjects:

Jump-starting using the battery from another vehicle

140WARNINGâ The following instructions must be followed at all times when working on

the engine compartment » page 120.â

When handling the vehicle battery, the following warnings must be ob-

served » page 126 .

â

A discharged vehicle battery may already freeze at temperatures just be-

low 0 °C. If the battery is frozen, do not carry out a jump start with the bat-

tery of another vehicle â risk of explosion and injury!

â

Never jump-start vehicle batteries with an electrolyte level that is too low

â risk of explosion and caustic burns.

139Emergency equipment and self-help